Are you ready to stand out in your next interview? Understanding and preparing for Pump and Valve Troubleshooting interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Pump and Valve Troubleshooting Interview

Q 1. Explain the different types of pumps and their applications.

Pumps are categorized based on various factors, including the type of energy used to move the fluid and the fluid’s properties. Here are some key types:

- Centrifugal Pumps: These are the most common type, using a rotating impeller to increase fluid velocity. Applications include water supply, irrigation, and industrial processes. Think of a garden hose sprinkler – that’s a simple centrifugal pump in action.

- Positive Displacement Pumps: These pumps trap a fixed volume of fluid and move it through the system. They are excellent for high-pressure, low-flow applications and are used in areas like chemical processing and oil refining. Imagine a syringe – it’s a type of positive displacement pump.

- Rotary Pumps: These pumps use rotating elements to move the fluid. Types include gear pumps, lobe pumps, and vane pumps. Applications range from lubricating systems in machinery to transferring viscous fluids like paints and oils. Think of a car’s oil pump.

- Reciprocating Pumps: These pumps use a piston or diaphragm to create pressure and move the fluid. They are typically used for high-pressure applications where a pulsating flow is acceptable, like in water well systems or industrial hydraulics.

The choice of pump depends heavily on the fluid being pumped (viscosity, abrasiveness), the required flow rate and pressure, and the overall application requirements. For instance, a viscous fluid like honey would require a positive displacement pump, while a large-scale water supply system benefits from a high-flow centrifugal pump.

Q 2. Describe the various types of valves and their functions.

Valves control fluid flow within a system. There’s a wide variety, classified based on their function and operating mechanism:

- Gate Valves: Primarily used for on/off service, offering minimal resistance to flow when fully open. Think of a simple on/off switch for a water pipe.

- Globe Valves: Regulate flow by changing the opening of a disc within the valve body. They offer precise control but can have more pressure drop than gate valves. These are often used for throttling applications.

- Ball Valves: A rotating ball controls the flow. Quick and easy on/off operation and compact design make these popular for many industrial and domestic applications.

- Butterfly Valves: A rotating disc controls flow; simple and compact, used for both on/off and throttling operations.

- Check Valves: Allow flow in only one direction, preventing backflow. Essential for safety and preventing damage to pumps.

- Control Valves: Used for automated flow regulation, often incorporating pneumatic or electric actuators. These are commonly used in process control systems.

Selecting the appropriate valve depends on factors like flow rate, pressure, fluid properties, required control precision, and the overall system design. For example, a high-pressure system might need a gate valve for on/off control, while a precise chemical process would rely on control valves for finely tuned regulation.

Q 3. How do you troubleshoot a pump that is not delivering sufficient flow?

Troubleshooting low flow from a pump is a systematic process. I would follow these steps:

- Check for Suction-Side Problems: Insufficient flow often stems from issues on the suction side. Verify sufficient NPSH (Net Positive Suction Head) – the pump needs enough pressure to prevent cavitation. Check for leaks, clogged strainers, or air in the suction line. A partially closed valve on the suction line is a common culprit.

- Inspect the Pump Itself: Look for mechanical issues: wear in the pump bearings, impeller damage (e.g., erosion or fouling), or a leaking seal. Listen for unusual noises which may indicate problems with the mechanical components.

- Discharge-Side Assessment: Check for blockages or restrictions in the discharge pipe, including closed or partially closed valves. High-pressure drop in the discharge can severely restrict the flow.

- Verify System Integrity: Check the overall system layout; ensure there are no significant elevation changes or pipe restrictions that might limit the flow rate. Excessive friction loss due to long pipe runs or bends can also reduce flow.

- Motor Check: Ensure the pump motor is functioning correctly; verify that it is operating at its rated speed. A weak motor won’t be able to pump as expected.

Often, the problem is something as simple as a partially closed valve or a clogged strainer, easily remedied. However, more complex mechanical issues may require repair or replacement of the pump components.

Q 4. What are the common causes of valve leakage?

Valve leakage can be caused by several factors:

- Wear and Tear: Over time, valve seats and seals can wear out due to continuous operation and exposure to the fluid. This is especially true for valves handling abrasive or corrosive fluids.

- Corrosion: Corrosion, particularly in valves exposed to aggressive chemicals, can damage sealing surfaces and cause leakage.

- Erosion: High-velocity fluid flow can erode valve components over time, leading to leakage.

- Improper Installation: Incorrect installation of a valve, leading to misalignment or improper sealing, can cause leakage. This includes inadequate tightening of bolts and nuts during installation.

- Damage: Physical damage to the valve body or internal components (such as accidental impacts) can cause leakage.

- Foreign Material: Small particles entering the valve can damage sealing surfaces or prevent proper closure, leading to leakage.

- Improper Valve Selection: Selecting the wrong valve for the specific application or operating conditions can cause premature wear or failure and eventual leakage.

Addressing valve leakage involves identifying the root cause, which might necessitate visual inspection, pressure testing, or specialized analysis depending on the circumstances. Repair may involve replacing seals, repairing or replacing damaged components, or even replacing the valve entirely.

Q 5. Explain the process of diagnosing a malfunctioning pump using vibration analysis.

Vibration analysis is a powerful diagnostic tool for malfunctioning pumps. It involves measuring the vibration levels and frequencies generated by the pump during operation. This data can be correlated with potential faults to identify the problem.

The process typically involves the following steps:

- Data Acquisition: Using specialized sensors (accelerometers), vibration data is collected at various points on the pump (bearing housings, pump casing). Data is acquired over a specific time period, often under various operating conditions.

- Spectral Analysis: The acquired vibration data is processed using Fast Fourier Transform (FFT) to determine the frequency components of the vibration signal. Specific frequencies can be indicative of certain problems (e.g., imbalance, misalignment, bearing faults).

- Fault Diagnosis: By analyzing the frequency spectrum (frequency vs. amplitude), experienced engineers can correlate specific frequencies and amplitude patterns with common pump faults. For example, high amplitude at specific rotational frequencies might indicate rotor imbalance, while higher-frequency peaks might point to bearing damage.

- Trend Analysis: Tracking vibration levels over time provides critical insights into the progression of a fault and can help predict potential failures. This proactive approach aids in scheduling maintenance before catastrophic failure occurs.

For example, a significant increase in vibration at a specific frequency close to the pump’s running speed could suggest rotor imbalance, necessitating balancing. High-frequency vibrations might point towards bearing wear, requiring replacement before it leads to catastrophic failure.

Q 6. How do you identify the root cause of recurring pump failures?

Identifying the root cause of recurring pump failures requires a thorough investigation that goes beyond simply repairing the immediate problem. It’s a systematic approach:

- Comprehensive Data Collection: Gather data on all past failures, including when the failures occurred, the nature of the failures, any preceding events, repair actions taken, and pump operating conditions.

- Failure Mode and Effects Analysis (FMEA): Conduct an FMEA to systematically identify potential failure modes, their causes, and their effects on the system. This helps anticipate potential problems and mitigate risks.

- Root Cause Analysis (RCA): Employ a structured RCA technique (e.g., 5 Whys, Fishbone diagram) to drill down to the underlying causes of repeated failures. Don’t just fix the symptoms; discover the root problems.

- Operational Review: Analyze the pump’s operating conditions, including the fluid being pumped, flow rates, pressures, and any unusual operating scenarios. Are the pumps being used outside their design parameters?

- Maintenance Review: Examine the pump’s maintenance history, including the frequency and quality of maintenance performed. Are routine maintenance tasks (e.g., lubrication, inspections) being carried out effectively?

- Material Selection: If corrosion or erosion is implicated, reviewing the materials used in the pump and piping system might be necessary to choose more suitable materials for the application.

By systematically addressing these points, you can transition from reactive (fixing failures after they occur) to proactive maintenance, minimizing downtime and extending the lifespan of your pumps.

Q 7. Describe your experience with different pump maintenance procedures.

My experience encompasses a wide range of pump maintenance procedures, including:

- Routine Inspections: Regular visual inspections of pumps, checking for leaks, wear, corrosion, and proper alignment. This often includes checking couplings and belts.

- Lubrication: Proper lubrication of bearings and other moving parts, using specified lubricants and following manufacturer’s recommendations. This crucial step helps extend the life of bearings and prevent premature failure.

- Seal Replacement: Replacing worn or damaged seals to prevent leakage. This involves careful disassembly and reassembly of the pump components, ensuring proper sealing is achieved.

- Bearing Replacement: Replacing worn bearings, which are often a major source of pump failures. This procedure requires careful attention to alignment and proper bearing seating.

- Impeller Inspection and Repair: Inspecting for wear, erosion, or corrosion. Repair might involve cleaning, balancing, or, if necessary, replacement.

- Vibration Analysis and Balancing: Periodically conducting vibration analysis to identify imbalances or other mechanical issues. Balancing of the pump rotor is key in preventing excessive vibrations and premature component failure.

- Preventive Maintenance Schedules: Developing and implementing scheduled maintenance programs, including lubrication, inspection, and component replacement, to prevent failures and optimize pump performance. This is a cornerstone of effective pump maintenance.

In several instances, I’ve led the implementation of predictive maintenance using vibration analysis and other condition monitoring techniques, which has drastically reduced unexpected downtime and saved substantial operational costs. I also have experience working with various pump types, ensuring procedures are tailored to the specific pump design and operating conditions.

Q 8. What are the safety precautions you take when working with pumps and valves?

Safety is paramount when working with pumps and valves, especially given the potential for high pressure, hazardous fluids, and moving parts. My approach follows a strict protocol. Before beginning any work, I always ensure the system is properly isolated and depressurized. This involves closing relevant valves and confirming zero pressure using pressure gauges. Lockout/Tagout procedures are meticulously followed, preventing accidental activation. I use appropriate Personal Protective Equipment (PPE) including safety glasses, gloves, and possibly a face shield, depending on the fluid handled. I thoroughly inspect the equipment for any visible damage or leaks before starting any maintenance or repair. When working on systems containing hazardous materials, respiratory protection and specialized suits might be needed. Finally, I always follow company safety regulations and procedures, and work with a partner if dealing with high-risk situations.

Q 9. How do you interpret pressure gauges and flow meters?

Pressure gauges directly indicate the pressure within a system, usually in units like PSI (pounds per square inch) or bar. Understanding pressure is key: high pressure might indicate blockage or system overload, while low pressure might suggest leaks or pump failure. I always note the units and check for gauge calibration. Flow meters, on the other hand, measure the volumetric flow rate of the fluid, commonly in gallons per minute (GPM) or liters per second (L/s). A low flow rate could indicate valve malfunction, pump issues, or pipe blockage. An unusually high flow rate may indicate a system leak or failure. I compare readings from pressure and flow meters to diagnose system performance and potential issues. For example, if pressure is high but flow is low, a blockage is likely. If both are low, a pump problem is suspect.

Q 10. Explain the concept of Net Positive Suction Head (NPSH).

Net Positive Suction Head (NPSH) is a crucial concept representing the available energy to prevent cavitation in a pump. Cavitation occurs when the liquid pressure drops below its vapor pressure, causing vapor bubbles to form and collapse, damaging pump components. NPSH is expressed as the difference between the absolute pressure at the pump suction and the vapor pressure of the liquid at the pump’s operating temperature. NPSHavailable is the pressure available from the system to overcome vapor pressure, while NPSHrequired is the minimum pressure the pump needs to avoid cavitation. A safe system ensures NPSHavailable is always significantly higher than NPSHrequired. Think of it like this: NPSH is the safety margin to prevent vapor bubbles from forming and damaging the pump. Insufficient NPSH can lead to noisy operation, reduced efficiency, and ultimately, pump failure.

Q 11. How do you perform a pressure test on a valve?

A pressure test on a valve verifies its integrity and leak tightness. First, the valve is isolated from the system by closing upstream and downstream valves. Then, the valve is closed and the section of pipe containing the valve is filled with a test fluid (usually water or air), depending on the system’s design and pressure rating. A pressure gauge is connected to monitor the pressure within the isolated section. The system is slowly pressurized to a specific test pressure, usually higher than the operating pressure, but within the valve’s allowable test pressure. The pressure is maintained for a predetermined time (e.g., 30 minutes), and any pressure drop is observed. A significant drop might indicate a leak within the valve or pipe. If no leak is detected, the pressure is slowly released, completing the test. The test results are documented, providing evidence of valve functionality and safety.

Q 12. What are the different types of valve actuators and their applications?

Valve actuators are devices that provide the force to open or close valves. Several types exist:

- Pneumatic Actuators: Use compressed air to generate the force, often preferred in hazardous areas due to the non-sparking nature of air. They’re commonly used for large valves and in applications requiring high speed and force.

- Hydraulic Actuators: Use pressurized hydraulic fluid for high force applications, often in large-diameter or high-pressure systems. They’re reliable and offer precise control.

- Electric Actuators: Utilize electric motors to provide the driving force. These are versatile, offering precise control and easy integration with automated systems. They’re ideal for smaller valves and applications requiring precise positioning.

- Manual Actuators: Are hand-operated, usually a simple handwheel or lever, suitable for smaller valves that don’t require automation.

Q 13. How do you troubleshoot a control valve that is not responding correctly?

Troubleshooting a non-responsive control valve involves a systematic approach. First, verify the valve’s power source (pneumatic, hydraulic, or electric) is working correctly. Then, inspect the actuator for any visible damage or obstructions. If pneumatic, check air pressure and lines for leaks. For hydraulic, examine the hydraulic fluid level and pressure. For electric actuators, check for power supply and motor operation. Next, examine the valve stem for binding or free movement. Inspect the valve itself for any internal obstructions or damage. If everything looks fine, check the control signal (e.g., 4-20 mA signal for electric actuators). If the signal isn’t correct, you might have an issue with the controller or the wiring. Use system documentation or process diagrams to aid diagnosis. A systematic check-list ensures efficient fault-finding.

Q 14. Explain the importance of regular pump and valve inspections.

Regular pump and valve inspections are crucial for safety, efficiency, and preventing costly breakdowns. Inspections involve visually checking for leaks, corrosion, wear, and damage. Lubrication points are checked and lubricated if needed. Moving parts are assessed for smooth operation. Pressure and flow readings are compared to baseline values to detect performance degradation. The frequency of inspection depends on several factors, including the criticality of the equipment and the operating conditions. Regular maintenance, based on these inspections, extends equipment life, optimizes operation, and minimizes downtime. Consider regular maintenance as preventative medicine for your system. It’s far cheaper to prevent a failure than to fix it. Imagine a heart needing regular check-ups, pumps and valves are similar in terms of needing continuous oversight.

Q 15. Describe your experience with pump and valve lubrication techniques.

Pump and valve lubrication is critical for preventing wear, friction, and ultimately, failure. The techniques employed depend heavily on the specific equipment. For example, gear pumps often utilize a splash lubrication system where the gear teeth themselves churn the lubricant, while centrifugal pumps might have separate lubrication systems for bearings and seals. Valve lubrication, on the other hand, primarily focuses on stem packing.

- Bearing Lubrication: This often involves using specialized greases chosen for their temperature and pressure resistance, as well as their compatibility with the bearing material. Regular greasing, following manufacturer recommendations, is key. Over-lubrication can be as detrimental as under-lubrication, leading to leakage or seal damage.

- Seal Lubrication: Many pumps utilize mechanical seals that require a specific lubricant – often a specialized fluid compatible with the pumped media to prevent contamination and ensure proper sealing. Insufficient lubrication here can lead to rapid seal wear and leakage.

- Valve Stem Packing: Lubricating valve stem packing helps prevent leakage and wear. This is typically done by injecting a suitable lubricant (often graphite-based) into the packing gland. The process requires careful control to avoid over-lubrication, which can lead to excessive pressure and damage. Regular inspection and adjustment of packing gland pressure are crucial.

In my experience, proper lubrication scheduling and record-keeping are essential for preventative maintenance. I’ve seen countless instances where neglecting routine lubrication has led to costly repairs and downtime. Developing a proactive lubrication program, based on manufacturer recommendations and historical data, is paramount for maintaining equipment reliability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle emergency situations related to pump or valve failures?

Emergency situations involving pump or valve failures require quick thinking and decisive action. My approach involves a structured process:

- Safety First: Isolate the affected equipment immediately to prevent further damage or injury. This may involve shutting down the system or isolating valves upstream and downstream.

- Assess the Situation: Quickly determine the nature and severity of the failure. Is it a complete failure, or is there a partial malfunction? What are the potential consequences of the failure (e.g., loss of pressure, product spillage)?

- Implement Immediate Corrective Actions: This might involve activating backup systems, implementing bypass lines, or deploying temporary repairs. The goal is to minimize downtime and prevent further escalation.

- Initiate Troubleshooting: Begin a systematic investigation to identify the root cause of the failure. This might involve visual inspection, data analysis (pressure, flow, vibration data), and component testing.

- Implement Permanent Repair: Once the root cause is identified, implement a permanent solution, which may involve repairs, replacements, or upgrades.

- Documentation: Thoroughly document the entire incident, including the cause, corrective actions, and lessons learned. This information is crucial for preventing future similar occurrences.

For instance, I once handled an emergency involving a critical centrifugal pump failure in a chemical processing plant. By quickly isolating the pump and activating the standby pump, we prevented a costly production shutdown. Through systematic troubleshooting, we found a worn-out bearing to be the root cause. This experience reinforced the importance of proactive maintenance and spare parts management.

Q 17. What is cavitation, and how do you prevent it?

Cavitation is the formation and collapse of vapor bubbles in a liquid due to rapid pressure changes. Think of it like tiny, explosive implosions within the pump. This phenomenon is extremely damaging, leading to erosion, vibration, and ultimately, pump failure. The collapse of these bubbles generates shock waves that can erode internal pump components, particularly the impeller and casing.

Preventing cavitation involves several strategies:

- Ensure Sufficient Net Positive Suction Head (NPSH): NPSH is the difference between the absolute pressure at the pump suction and the vapor pressure of the liquid. Insufficient NPSH leads to cavitation. This can be addressed by increasing suction pressure, reducing pump speed, or lowering the liquid temperature.

- Proper Pump Selection: Choosing a pump with a sufficiently high NPSH requirement for the application is crucial.

- Optimize Piping Design: Avoid excessive pipe bends, valves, or constrictions in the suction line, as these can restrict flow and reduce NPSH. Ensure the suction pipe diameter is appropriately sized.

- Regular Maintenance: Inspect the pump regularly for signs of erosion or damage, which can indicate cavitation. Also, keep the pump clean to reduce potential restrictions.

In practice, I often use specialized software to model the hydraulic system and predict NPSH values, ensuring the pump is operating within its safe range. Failure to address cavitation can lead to significant downtime and costly repairs; therefore, prevention is always the preferred approach.

Q 18. Explain the difference between positive displacement and centrifugal pumps.

Positive displacement and centrifugal pumps are fundamentally different in how they move liquids:

- Centrifugal Pumps: These pumps use a rotating impeller to increase the velocity of the liquid, converting kinetic energy into pressure. Think of a spinning fan; it creates a low-pressure zone at the center and pushes the fluid outwards. They are generally suitable for low-viscosity fluids and high-flow applications. They can handle higher flow rates with less pressure but struggle with very viscous fluids.

- Positive Displacement Pumps: These pumps trap a fixed volume of liquid and then force it through the discharge. Imagine squeezing a toothpaste tube; you are displacing a fixed volume of paste. They provide a constant flow rate regardless of pressure changes, making them suitable for high-viscosity fluids and applications requiring precise flow control. They excel at high pressures but typically have lower flow rates compared to centrifugal pumps.

The choice between these pump types depends entirely on the application. A water supply system might use a centrifugal pump due to its high-flow capabilities, whereas a lubricating oil system might use a positive displacement pump to ensure precise delivery at a high pressure. The viscosity of the fluid is a key deciding factor.

Q 19. Describe your experience with different types of valve packing and sealing.

Valve packing and sealing materials are chosen based on the fluid’s characteristics (temperature, pressure, corrosiveness), the valve’s operating conditions, and the required seal life. Common types include:

- Braided Packing: This is a common type made from various materials such as PTFE, graphite, or asbestos (though asbestos is now largely phased out). It’s relatively inexpensive and easy to install, but it requires regular adjustment and replacement.

- PTFE (Teflon) Packing: This packing is chemically inert, resistant to a wide range of fluids, and has excellent sealing properties. It’s often preferred for corrosive or high-temperature applications.

- Graphite Packing: Graphite packing is self-lubricating and resistant to high temperatures, making it suitable for demanding applications. However, it can be abrasive.

- Mechanical Seals: Unlike packing, mechanical seals utilize a combination of stationary and rotating components to create a leak-free seal. They are typically more expensive than packing but offer superior sealing performance and longer life, especially in high-pressure or high-temperature applications.

My experience includes working with all these types of packing and seals. The selection process involves considering factors like leakage rate, temperature limits, chemical compatibility, and maintenance requirements. In high-pressure applications where zero leakage is critical, mechanical seals are usually the preferred option despite the higher initial cost. For less demanding applications, braided packing can be a cost-effective solution.

Q 20. How do you select the appropriate pump for a specific application?

Selecting the right pump for a specific application requires careful consideration of several factors:

- Fluid Properties: Viscosity, temperature, corrosiveness, and abrasiveness of the fluid are crucial. High-viscosity fluids require positive displacement pumps, while low-viscosity fluids are suitable for centrifugal pumps.

- Flow Rate: The required volume of fluid to be pumped per unit time. Centrifugal pumps are often preferred for high flow rates.

- Head (Pressure): The total pressure required to move the fluid from the suction to the discharge point. Positive displacement pumps can handle higher pressures.

- Operating Conditions: Ambient temperature, pressure fluctuations, and potential for cavitation need to be considered.

- Budget: Initial cost, operating costs (energy consumption, maintenance), and lifecycle costs should all be taken into account.

- Maintenance Requirements: Ease of access for maintenance, spare parts availability, and maintenance schedules are important considerations.

I typically use pump selection software and manufacturer’s data to determine the appropriate pump. For example, when selecting a pump for a high-viscosity, high-pressure application, a positive displacement pump such as a gear pump or a diaphragm pump might be more suitable than a centrifugal pump. The selection is always a balance of performance requirements, cost considerations, and operational reliability.

Q 21. What are the common causes of pump vibrations?

Pump vibrations can stem from various sources, often indicating an underlying problem that needs addressing. Common causes include:

- Mechanical Imbalance: An unbalanced impeller or rotor will cause significant vibration. This can be due to manufacturing defects, wear, or damage to the impeller.

- Misalignment: Misalignment between the pump shaft and the driver (motor or engine) creates excessive vibration and can lead to premature bearing failure.

- Bearing Wear or Damage: Worn or damaged bearings are a frequent source of vibration. This can be caused by insufficient lubrication, contamination, or excessive load.

- Cavitation: The collapse of vapor bubbles within the pump generates shock waves that cause intense vibration.

- Fluid Turbulence: Excessive turbulence in the suction or discharge lines can generate vibration. This is often caused by improperly sized piping or flow restrictions.

- Resonance: The pump’s natural frequency might coincide with an excitation frequency, leading to amplified vibration.

- Loose Components: Loose bolts, couplings, or other components can cause vibration.

Diagnosing the cause of pump vibration typically involves visual inspection, vibration analysis using specialized instruments (accelerometers), and analysis of operational data (flow rate, pressure, temperature). Ignoring pump vibration can result in catastrophic failure. Therefore, prompt investigation and appropriate corrective measures are essential for maintaining equipment reliability and preventing costly repairs and downtime.

Q 22. How do you troubleshoot a pump that is overheating?

A pump overheating is a serious issue that can lead to equipment failure. The first step is to understand why it’s overheating. This usually boils down to insufficient cooling, excessive friction, or a problem with the fluid being pumped.

- Insufficient Cooling: Check the cooling system – is there enough airflow around the pump? Is the cooling jacket (if present) functioning correctly? Are there blockages preventing proper heat dissipation? A clogged cooling jacket, for instance, would severely restrict heat transfer.

- Excessive Friction: High friction within the pump itself generates heat. This could be due to wear and tear on bearings, seals, or impellers. Listen carefully for unusual noises – grinding or squealing indicates friction. Also, check for misalignment of the pump shaft.

- Fluid Problems: The fluid being pumped might be too viscous, causing increased friction and heat buildup. Conversely, cavitation (formation of vapor bubbles) can also cause significant overheating. Check the fluid’s viscosity and ensure the pump’s operating pressure is within its designed range to avoid cavitation.

Troubleshooting steps include checking all these areas systematically. You would use temperature sensors to monitor pump casing temperature and bearing temperatures. Infrared thermography can quickly pinpoint hot spots. If a problem is identified, address it promptly. Replacing worn bearings, flushing the cooling jacket, or adjusting the pump’s operating parameters are all possible solutions.

Q 23. Explain the concept of pump curves and their significance.

Pump curves are graphical representations of a pump’s performance characteristics. They show the relationship between flow rate (typically in gallons per minute or cubic meters per hour), head (the vertical distance the pump can lift the fluid), and power required. Think of it like a car’s performance chart – showing speed versus fuel consumption.

These curves are crucial because they:

- Determine the best operating point: The pump curve intersects the system curve (representing the resistance of the piping system) at the best efficiency point (BEP). Operating at the BEP ensures optimal efficiency and minimizes energy consumption.

- Identify potential problems: Deviations from the expected pump curve can indicate issues such as impeller wear, blockage in the piping system, or issues with the motor.

- Help in pump selection: Before installing a pump, you use pump curves to ensure the pump is correctly sized for the application and meets the required flow rate and head.

For example, if you see that the actual flow rate is significantly lower than what the pump curve predicts at a given head, it suggests a problem such as a partially closed valve or a clogged pipe. Similarly, a higher-than-expected power consumption might point to increased friction due to wear or misalignment.

Q 24. How do you identify and address issues related to valve noise and chatter?

Valve noise and chatter are indicative of problems in the valve itself or in the piping system. Chatter is a rapid opening and closing of the valve, resulting in a distinctive clicking or hammering sound. Noise can range from a low hum to a high-pitched whine.

Identifying the cause requires a systematic approach:

- Cavitation: If the valve is partially closed, creating high velocity fluid flow, it can lead to cavitation. This causes noise and can damage the valve over time.

- Fluid Hammer (Water Hammer): Rapid changes in fluid velocity can create pressure waves that cause hammering. This is often associated with fast-acting valves or pump start/stop cycles.

- Valve Sticking or Binding: Internal components might be sticking due to corrosion, debris, or misalignment.

- Loose Connections: Vibrations from loose fittings can cause noise.

- Incorrect Valve Selection: The wrong valve type for the specific application can cause increased noise and vibration.

Addressing these issues might involve: lubricating the valve, replacing worn parts, reducing fluid velocity (perhaps by using a larger diameter pipe or a different valve type), installing flow restrictors or surge suppressors to mitigate water hammer, improving valve alignment, or tightening loose connections. In some cases, complete valve replacement may be necessary.

Q 25. Describe your experience with predictive maintenance techniques for pumps and valves.

Predictive maintenance is key to avoiding costly breakdowns. For pumps and valves, this involves using various techniques to monitor their condition and predict potential failures before they occur.

My experience includes using:

- Vibration analysis: Monitoring pump and valve vibrations using accelerometers can detect imbalances, bearing wear, and misalignment. Changes in vibration patterns are early indicators of problems.

- Ultrasonic testing: Detecting leaks in valves and pumps early on. Ultrasonic sensors can detect leaks even before they’re visually apparent.

- Oil analysis: Analyzing lubricating oil for contamination, wear particles, and degradation can indicate the condition of the pump’s bearings and seals.

- Thermal imaging: Infrared cameras can quickly identify overheating components, which could indicate impending failures.

- Run-time monitoring using sensors and SCADA systems: Tracking flow rates, pressure, power consumption and other parameters. Anomalies in these readings can signal potential issues.

By implementing a predictive maintenance program, we can schedule repairs and replacements proactively, minimizing downtime and optimizing the lifespan of the equipment. For example, if vibration analysis shows increasing vibration levels in a pump bearing, we can replace it before a catastrophic failure happens.

Q 26. What software or tools do you use for pump and valve troubleshooting and analysis?

The tools and software I use for troubleshooting and analysis include:

- Data acquisition systems (DAQ): To collect data from various sensors (temperature, pressure, vibration, flow).

- SCADA (Supervisory Control and Data Acquisition) systems: For monitoring and controlling pumps and valves remotely, and providing historical data for trend analysis.

- Vibration analysis software: To interpret vibration data and identify potential problems (e.g., bearing defects).

- Pump curve software: To model pump performance and compare it to actual performance.

- Spreadsheet software (Excel, Google Sheets): For data organization, analysis, and reporting.

- Specialized diagnostic tools: For example, tools to measure alignment, check shaft runout, or test valve operation.

In addition, I use specialized software for specific pump and valve manufacturers to access their databases and troubleshooting guides, and to help ensure the selection of replacement parts and maintenance recommendations are accurate.

Q 27. How do you document your troubleshooting process and findings?

Thorough documentation is critical for effective troubleshooting. My process involves:

- Detailed logbook entries: Recording the date, time, problem description, all measurements taken (temperatures, pressures, flow rates, vibration levels), actions performed, and the outcome of each step.

- Photographs and videos: Visual records of the equipment’s condition, including any signs of damage or wear.

- Schematic diagrams: Annotating diagrams to show the location of problems and the steps taken for repair.

- Reports: Summarizing the troubleshooting process, findings, and recommendations for preventative maintenance. These reports are essential for communicating with management and other technicians.

- Digital storage: All data and documentation are stored electronically, making them easily accessible and searchable.

This ensures that future troubleshooting efforts are informed by previous experiences and that any recurring problems can be identified and addressed effectively.

Q 28. Describe a challenging pump or valve troubleshooting experience and how you overcame it.

One challenging experience involved a large centrifugal pump in a wastewater treatment plant. The pump was experiencing severe vibration and erratic flow, leading to intermittent shutdowns. The initial investigation revealed high vibration levels, but the root cause wasn’t immediately apparent. We checked for misalignment, bearing wear, cavitation, and even piping issues.

After systematically eliminating other possibilities, we discovered a subtle issue: a small crack in the pump’s impeller had developed, causing an imbalance and the high vibration. This crack was hard to detect visually because it was located in a hard-to-access area. We ultimately used advanced vibration analysis and ultrasonic testing to pinpoint the location and severity of the crack.

Overcoming this required a combination of detailed analysis, careful examination using specialized equipment, and persistent troubleshooting. Replacing the impeller resolved the problem. This highlighted the importance of utilizing advanced diagnostic techniques and having a methodical approach even when dealing with seemingly intractable problems.

Key Topics to Learn for Pump and Valve Troubleshooting Interview

- Pump Fundamentals: Understanding centrifugal, positive displacement, and other pump types; their operating principles, performance curves, and limitations.

- Valve Types and Functions: Familiarity with various valve types (gate, globe, ball, check, etc.), their applications, and proper selection criteria. This includes understanding valve actuators and control systems.

- Troubleshooting Methodologies: Systematic approaches to diagnosing pump and valve problems, including visual inspection, pressure/flow analysis, and the use of diagnostic tools.

- Hydraulic and Pneumatic Systems: Understanding the principles of fluid power and how pumps and valves interact within these systems. This includes pressure drops, flow rates, and energy losses.

- Safety Procedures: Knowledge of lockout/tagout procedures, proper handling of hazardous materials, and safety regulations related to pump and valve maintenance.

- Common Pump and Valve Failures: Identifying and diagnosing typical malfunctions such as cavitation, leakage, vibration, and binding. Understanding root cause analysis techniques is crucial.

- Preventive Maintenance: Developing and implementing effective maintenance schedules to prevent failures and extend the lifespan of equipment.

- Instrumentation and Control: Familiarity with pressure gauges, flow meters, level sensors, and other instruments used to monitor and control pump and valve systems.

- Practical Application: Being able to relate theoretical knowledge to real-world scenarios, such as troubleshooting a specific pump failure or optimizing a valve control system.

Next Steps

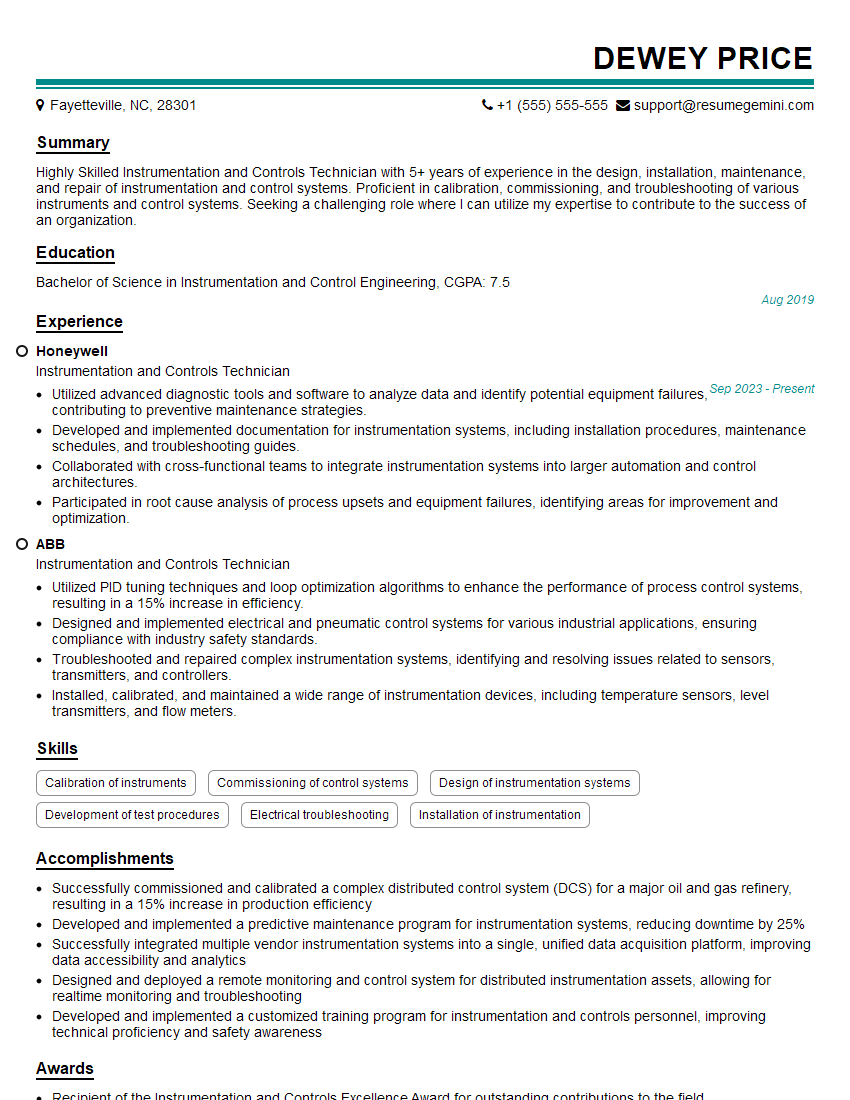

Mastering pump and valve troubleshooting is essential for career advancement in many industries. A strong understanding of these systems demonstrates valuable technical skills and problem-solving abilities, leading to increased responsibility and higher earning potential. To maximize your job prospects, it’s vital to create a resume that effectively highlights your expertise. An ATS-friendly resume is key to getting past applicant tracking systems and landing interviews. We recommend using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Pump and Valve Troubleshooting to help you showcase your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.