Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Rehabilitation and Retrofitting of Bridges interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Rehabilitation and Retrofitting of Bridges Interview

Q 1. Explain the difference between bridge rehabilitation and bridge retrofitting.

Bridge rehabilitation and retrofitting are both crucial for extending the lifespan of aging infrastructure, but they differ significantly in their scope and objectives. Rehabilitation focuses on restoring a bridge to its original design specifications and functionality. Think of it as a comprehensive overhaul, addressing existing damage and bringing the bridge back to its ‘like-new’ condition. Retrofitting, on the other hand, modifies the bridge’s structure or components to enhance its performance beyond its original design capacity. It’s about upgrading the bridge to meet current or future demands, often addressing unforeseen challenges or increased loading requirements.

For example, rehabilitation might involve replacing deteriorated concrete deck sections and repainting the steel superstructure. Retrofitting, however, could involve adding carbon fiber-reinforced polymer (CFRP) strengthening to the bridge’s girders to increase its load-carrying capacity, or installing seismic dampers to enhance its resistance to earthquakes.

Q 2. Describe common causes of bridge deterioration.

Bridge deterioration is a complex issue influenced by numerous factors. The most common causes include:

- Environmental Exposure: This is arguably the most significant factor. Freeze-thaw cycles in colder climates cause cracking and spalling of concrete, while exposure to de-icing salts accelerates corrosion of steel reinforcement. UV radiation and moisture also contribute to material degradation.

- Traffic Loading: Repeated heavy loads from vehicles, especially overloaded trucks, cause fatigue cracking and damage to bridge components, especially the deck and girders.

- Material Degradation: The inherent properties of materials used in bridge construction can lead to deterioration over time. Concrete can experience alkali-aggregate reaction, leading to expansion and cracking, while steel can corrode due to exposure to moisture and oxygen.

- Poor Construction Practices: Deficiencies in initial construction, such as inadequate compaction of soil or use of substandard materials, can significantly shorten a bridge’s lifespan and accelerate deterioration.

- Lack of Maintenance: Regular inspections and timely repairs are essential to prevent minor damage from escalating into major problems. Neglecting maintenance allows small cracks to grow, leading to extensive repairs later on.

A combination of these factors often contributes to the overall deterioration of a bridge.

Q 3. What are the different types of bridge deck repairs?

Bridge deck repairs are essential for maintaining the structural integrity and serviceability of bridges. Several methods are used, depending on the extent and nature of the damage:

- Overlaying: This involves placing a new layer of concrete (an overlay) over the existing deck to address minor cracks, surface deterioration, and provide improved riding quality. Different types of overlays, like polymer concrete overlays, offer enhanced durability and strength.

- Partial Depth Repairs: For more significant damage, partial depth repairs involve removing deteriorated concrete to a certain depth and replacing it with new concrete. This is often followed by an overlay to provide a uniform surface.

- Full Depth Repairs: In cases of severe damage or complete deck failure, full-depth repairs require removing the entire existing deck and constructing a new one. This is the most extensive and costly option, but it is sometimes necessary to restore structural integrity.

- Crack Repair: Various methods are employed to repair cracks, from simple sealing with epoxy resins to more involved techniques like pressure grouting for larger or deeper cracks.

- Joint Repairs: Bridge deck joints, which are susceptible to damage, require specific repairs to maintain watertightness and prevent the infiltration of water and deicing salts.

The choice of repair method depends on factors like the extent of damage, the bridge’s structural condition, budget constraints, and traffic management considerations.

Q 4. How do you assess the structural integrity of a bridge?

Assessing the structural integrity of a bridge is a multi-faceted process involving a combination of visual inspection, non-destructive testing (NDT), and analytical techniques. It’s crucial for determining the bridge’s condition and identifying potential structural deficiencies.

- Visual Inspection: A thorough visual inspection identifies visible cracks, corrosion, spalling, and other signs of distress. This usually involves detailed documentation with photography and sketches.

- Non-Destructive Testing (NDT): NDT methods help assess the internal condition of bridge components without causing damage. Common NDT techniques include:

- Ultrasonic testing: Measures the thickness and detects internal flaws in concrete.

- Ground-penetrating radar (GPR): Detects voids, cracks, and other anomalies within the bridge deck and substructure.

- Cover meter testing: Measures the distance from the concrete surface to the embedded reinforcement steel, helping to assess corrosion.

- Load Testing: In some cases, controlled load testing is performed to verify the bridge’s load-carrying capacity. This involves applying controlled loads to the bridge and monitoring its response.

- Analytical Evaluation: Structural analysis techniques, often using computer modeling and finite element analysis (FEA), are used to predict the bridge’s behavior under different loading conditions, considering its existing damage and deterioration.

The results from all these methods are integrated to develop a comprehensive assessment of the bridge’s structural integrity, guiding decisions regarding repairs, rehabilitation, or replacement.

Q 5. Explain the process of selecting appropriate materials for bridge repairs.

Selecting appropriate materials for bridge repairs is critical for ensuring long-term durability and performance. The selection process considers several factors:

- Compatibility with Existing Materials: The new materials should be compatible with the existing materials in the bridge structure to avoid adverse chemical reactions or incompatibility issues.

- Durability and Strength: The selected materials should possess sufficient durability to withstand environmental exposure and traffic loading for the intended service life.

- Workability and Ease of Application: Materials should be easy to work with and apply to ensure efficient repair operations.

- Cost-Effectiveness: The cost of materials and labor must be considered, balancing performance with budget constraints.

- Environmental Impact: The environmental impact of the materials should be evaluated, preferring sustainable and eco-friendly options.

For example, high-performance concrete is often used for overlays due to its superior strength and durability. Fiber-reinforced polymers (FRP) are increasingly used for strengthening existing members due to their high strength-to-weight ratio and corrosion resistance. The final selection requires careful consideration of all these factors and often involves laboratory testing to ensure compatibility and performance.

Q 6. What are the common methods used for strengthening bridge beams?

Several methods are employed to strengthen bridge beams, depending on the type of beam, the extent of damage, and the desired increase in load capacity:

- External Post-Tensioning: This involves adding high-strength steel tendons to the beam’s exterior, creating additional compressive forces that counter the tensile stresses and increase the beam’s bending capacity.

- Fiber-Reinforced Polymers (FRP): FRP composites, such as carbon fiber or glass fiber reinforced polymers, are bonded to the beam’s surface to increase its tensile strength and flexural rigidity. This method is lightweight, easy to apply, and highly effective.

- Steel Jacketing: This involves encasing the existing beam with a steel section to increase its cross-sectional area and moment of inertia, enhancing its load-carrying capacity. This method is robust but can be more complex and expensive than FRP strengthening.

- Shotcrete: Shotcrete is a sprayed concrete used to increase the cross-section of the beam, particularly effective for repairing damaged or deteriorated concrete beams.

The selection of the best method depends on several factors, including the type of beam, the degree of strengthening required, the available space, and the cost.

Q 7. Describe your experience with bridge load rating and analysis.

I have extensive experience in bridge load rating and analysis. This involves determining the current load-carrying capacity of a bridge and comparing it to the anticipated loads it will experience. This process is crucial for ensuring the safety and serviceability of the bridge.

My experience encompasses various aspects, including:

- Inventory and Appraisal: I’ve participated in detailed inspections to gather data on the bridge’s geometry, materials properties, and existing damage.

- Load Rating Software and Analysis: I’m proficient in using various load rating software packages, such as

LRFR(Load and Resistance Factor Rating) and other specialized bridge analysis tools, to perform detailed structural analysis. - Development of Load Rating Models: I’ve developed accurate models accounting for various factors like material degradation, existing cracks, and uncertainties in material properties.

- Interpretation of Results: I’m capable of accurately interpreting the load rating results, determining the allowable load limits, and recommending appropriate interventions (repairs, strengthening, or load restrictions).

- Reporting and Documentation: I have experience in preparing comprehensive reports detailing the load rating methodology, results, and recommendations.

I’ve worked on numerous projects, ranging from small highway overpasses to major interstate bridges, and consistently provided accurate and reliable load rating assessments that ensure the safe and efficient operation of these structures.

Q 8. How do you manage risks associated with bridge rehabilitation projects?

Managing risks in bridge rehabilitation is paramount. It’s a multi-faceted process starting with a thorough hazard identification. We utilize techniques like Failure Mode and Effects Analysis (FMEA) to systematically identify potential problems, from material defects to unforeseen weather events. Each identified hazard is then assessed for its likelihood and consequence, allowing us to prioritize mitigation strategies. For example, if we identify a high likelihood of encountering unforeseen subsurface conditions during foundation work, we might incorporate ground penetrating radar surveys and contingency plans for remediation. Risk mitigation strategies then become part of the project plan. This could include things like specialized equipment, skilled labor, detailed safety protocols, and robust quality control procedures. We also incorporate risk transfer mechanisms like insurance and surety bonds to protect against major unforeseen financial losses. Finally, continuous monitoring and reporting allow us to track progress, identify emerging risks, and adjust our plans as needed. This proactive approach significantly reduces the chance of delays, cost overruns, and accidents.

Q 9. What are the key considerations for designing a bridge rehabilitation plan?

Designing a comprehensive rehabilitation plan requires a holistic approach. It begins with a detailed bridge inspection to assess the extent of deterioration, identifying areas requiring immediate attention and those that can be addressed later. This informs the development of a scope of work, clearly defining what needs to be done. We then consider the structural integrity of the bridge, using sophisticated analysis software to model its behavior under various loading conditions. This allows us to optimize the design, ensuring the repairs are effective and extend the bridge’s lifespan. Material selection is crucial; we prioritize durability, sustainability, and compatibility with existing materials. We also develop a realistic budget and timeline, factoring in potential delays and unforeseen challenges. Environmental considerations are always at the forefront. For example, if we’re working near a waterway, we might need to implement measures to minimize environmental impact. Finally, a clear communication plan ensures stakeholders (engineers, contractors, and regulatory bodies) are kept informed throughout the process.

Q 10. Explain your understanding of various bridge inspection techniques.

Bridge inspection techniques range from visual assessments to sophisticated non-destructive testing (NDT) methods. Visual inspections are the most common, involving a thorough examination of the bridge’s components to identify visible signs of distress like cracks, corrosion, or spalling. We use close-range photogrammetry and laser scanning to create detailed 3D models of the bridge, allowing for precise measurements and assessments. NDT methods are essential for detecting hidden defects. These include techniques like ground-penetrating radar (GPR) for subsurface investigations, ultrasonic testing to assess concrete integrity, and magnetic particle inspection to detect cracks in steel elements. We also employ structural health monitoring (SHM) techniques, deploying sensors to continuously monitor the bridge’s behavior under service loads. The data collected informs us about the bridge’s condition and can help predict potential failures, enabling proactive maintenance and rehabilitation. The choice of inspection techniques depends on factors such as the bridge’s age, type, and condition, and budgetary constraints.

Q 11. Describe your experience with different types of bridge foundations and their rehabilitation.

My experience encompasses a variety of bridge foundations, each requiring specific rehabilitation strategies. Spread footings, common for smaller bridges, might require grouting or underpinning if settlement has occurred. Pile foundations can suffer from corrosion or degradation of the pile material, requiring techniques like pile jacketing or replacement. Caissons, used for deep foundations, might need repairs to their sealing systems or internal structures. Rehabilitation strategies are tailored to the specific type of foundation and the nature of the damage. This can range from simple repairs to more extensive interventions, such as underpinning or complete foundation replacement. For instance, I’ve worked on a project where we used chemical grouting to consolidate loose soil surrounding a pile foundation, preventing further settlement. In another project, we implemented a combination of pile jacketing and concrete encasement to protect corroded steel piles from further deterioration. The selection of an appropriate technique always considers cost-effectiveness and the need to minimize disruption to traffic and the surrounding environment.

Q 12. How do you ensure compliance with relevant codes and standards during bridge rehabilitation?

Ensuring compliance with codes and standards is non-negotiable. We adhere strictly to guidelines established by organizations like AASHTO (American Association of State Highway and Transportation Officials) and local regulatory bodies. This involves using approved materials, implementing specified design procedures, and documenting every step of the process meticulously. We maintain comprehensive records of all inspections, tests, and analyses. Regular communication with regulatory bodies ensures that our work aligns with their requirements. For example, we utilize AASHTO LRFD (Load and Resistance Factor Design) specifications for structural analysis and design, ensuring the bridge’s safety and serviceability. We also rigorously document material testing results to confirm that they meet specified requirements. Furthermore, our quality control procedures encompass regular site visits and inspections by independent qualified personnel to ensure that all work conforms to the approved plans and specifications.

Q 13. What software and tools are you proficient in for bridge analysis and design?

My proficiency extends to several software packages crucial for bridge analysis and design. I’m highly experienced in using SAP2000 and ETABS for finite element analysis, allowing me to model complex structural systems and assess their behavior under various load scenarios. I also utilize AutoCAD for drafting and design, and Revit for creating detailed 3D models. For specialized applications, I am familiar with software packages designed for bridge inspection data management and processing, allowing for efficient analysis and interpretation of survey results. My expertise also includes using specialized software for geotechnical analysis, ensuring proper design of bridge foundations. This combination of software expertise allows me to handle every phase of the rehabilitation project from initial assessment and design through to detailed drawings and specifications.

Q 14. Describe your experience with working with contractors and subcontractors on bridge projects.

Collaboration with contractors and subcontractors is key to successful bridge rehabilitation. Clear communication is paramount. We employ a collaborative approach, establishing strong working relationships and holding regular meetings to discuss progress, challenges, and solutions. Detailed contract documents clearly define the scope of work, payment terms, and responsibilities. We prioritize selecting reputable contractors with proven experience in bridge construction and rehabilitation. Robust quality control measures are in place, involving regular inspections and testing to ensure adherence to specifications. We also develop a comprehensive risk management plan, outlining protocols for handling unforeseen events or challenges. For instance, on a recent project, proactive communication with the contractor helped us anticipate and mitigate a potential delay caused by unexpectedly adverse weather conditions. This proactive approach and open communication have proven crucial to delivering projects on time and within budget.

Q 15. How do you manage the budget and schedule for a bridge rehabilitation project?

Managing the budget and schedule for a bridge rehabilitation project requires a meticulous approach, combining detailed planning with proactive risk management. It’s akin to orchestrating a complex symphony, where each instrument (task) must play its part in harmony and on time.

Firstly, a comprehensive cost estimate is crucial. This involves detailed breakdown of materials, labor, equipment rentals, permits, and contingency funds (for unforeseen issues). Software like Primavera P6 or MS Project is commonly used to create a detailed work breakdown structure (WBS) and schedule, assigning tasks, durations, and dependencies. Regular monitoring using Earned Value Management (EVM) helps compare planned vs. actual progress, identifying potential cost overruns or schedule delays early on. For example, if a crucial material delivery is delayed, we can proactively adjust the schedule and explore alternative materials to mitigate impact.

Secondly, effective communication is paramount. Regular meetings with stakeholders—the client, engineers, contractors, and inspectors—ensure everyone is informed about progress and potential challenges. This collaborative approach allows for quick decision-making and problem-solving, keeping the project on track.

Finally, contingency planning is essential. We build buffers into both the budget and schedule to account for unexpected issues like bad weather, material shortages, or unforeseen structural problems. This prevents minor hiccups from snowballing into major delays and cost overruns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of the environmental impact of bridge rehabilitation projects.

Environmental impact assessment is a critical aspect of any bridge rehabilitation project. We need to carefully consider potential disruptions to the surrounding ecosystem and implement mitigation strategies to minimize negative consequences. Think of it like performing delicate surgery—we need to minimize the impact on the surrounding ‘body’ (environment).

Common environmental concerns include water and air pollution from construction activities (dust, noise, chemical runoff), habitat disruption for aquatic and terrestrial life (especially during foundation work), and the disposal of construction waste. To mitigate these issues, we employ several strategies. This might include using dust suppression techniques, implementing erosion and sediment control measures, selecting environmentally friendly materials, and developing a comprehensive waste management plan that focuses on recycling and responsible disposal. For example, we may use noise barriers to reduce noise pollution near residential areas and choose low-VOC (volatile organic compound) paints to minimize air pollution.

Furthermore, regulatory compliance is vital. We must adhere to all applicable environmental regulations and obtain the necessary permits before starting the project. Regular environmental monitoring during construction ensures we stay on track and address any unforeseen environmental concerns promptly.

Q 17. How do you prioritize rehabilitation needs for a portfolio of bridges?

Prioritizing rehabilitation needs for a bridge portfolio requires a systematic approach, balancing urgency, risk, and cost-effectiveness. It’s like managing a hospital’s patient queue—we need to prioritize those in critical condition first.

We typically employ a bridge management system (BMS), a sophisticated software tool that helps us assess the condition of each bridge using a variety of data sources, including visual inspections, non-destructive testing, and load ratings. This system helps us assign a condition rating (e.g., based on the PCI – Percentage Condition Index) and predict the remaining service life of each bridge.

Prioritization then involves considering several factors:

- Structural integrity: Bridges with significant structural deficiencies posing immediate safety risks are prioritized.

- Traffic volume: Bridges carrying high volumes of traffic require quicker attention to minimize disruption in case of failure.

- Cost-effectiveness: We analyze the cost of rehabilitation versus the potential cost of failure (including disruption, repair, and potential loss of life).

- Economic impact: The potential economic impact of a bridge closure on the surrounding communities is also considered.

By combining these factors, we can develop a prioritized list of rehabilitation projects, ensuring that the most critical needs are addressed first.

Q 18. What are some common challenges encountered in bridge rehabilitation and how do you overcome them?

Bridge rehabilitation projects are often fraught with challenges, requiring creative problem-solving. One common issue is dealing with unexpected conditions discovered during demolition or excavation, like encountering unforeseen subsurface obstacles or deteriorating structural elements beyond initial assessments. It’s like discovering a hidden cavity during a dental procedure!

Other challenges include:

- Limited access: Working on existing bridges often restricts access, making construction and material delivery difficult.

- Traffic management: Minimizing disruption to traffic flow during construction requires careful planning and coordination.

- Weather delays: Inclement weather can significantly delay progress.

- Material availability: Sourcing specialized materials for older bridges can be challenging.

- Coordination with multiple stakeholders: Effectively managing communication and collaboration amongst engineers, contractors, and regulatory bodies is essential.

To overcome these challenges, we rely on thorough planning, contingency planning, innovative construction techniques (like prefabrication and accelerated bridge construction methods), proactive communication, and a flexible approach. For instance, we might use temporary supports to manage traffic flow, schedule work around weather patterns, and prefabricate bridge components off-site to reduce on-site construction time.

Q 19. Describe your experience with using non-destructive testing methods for bridge inspection.

Non-destructive testing (NDT) methods are indispensable for bridge inspection, providing a detailed assessment of the bridge’s condition without causing damage. It’s like using a medical ultrasound—we can get a clear picture of the internal structure without invasive procedures.

I have extensive experience with several NDT techniques, including:

- Ultrasonic testing (UT): Uses sound waves to detect internal flaws and measure the thickness of concrete or steel members.

- Ground-penetrating radar (GPR): Used to locate subsurface voids, rebar, and other features in concrete structures.

- Magnetic particle inspection (MPI): Detects surface and near-surface cracks in ferromagnetic materials like steel.

- Visual inspection: While not strictly NDT, it remains a crucial initial step, observing the bridge for obvious signs of distress.

The data collected through NDT is crucial in informing rehabilitation strategies. For example, UT might reveal significant internal corrosion in a steel girder, prompting its replacement rather than simple surface treatment. The analysis of NDT data guides our decision-making, leading to more effective and cost-efficient repairs.

Q 20. How do you address unexpected issues discovered during a bridge rehabilitation project?

Addressing unexpected issues during a bridge rehabilitation project requires a calm, systematic approach. It’s like handling a medical emergency – quick thinking and a clear plan are vital.

Our first step is to thoroughly document the unexpected issue, including its location, nature, and potential impact on the project schedule and budget. We then convene a meeting involving the project engineers, contractors, and relevant stakeholders to assess the situation. We explore several options for addressing the issue, including potential design modifications, alternative construction techniques, and revised schedules. Cost-benefit analyses are conducted to evaluate each option. The preferred solution is then selected based on feasibility, cost, safety, and schedule impact.

Transparency with the client is critical. We provide regular updates, explaining the situation, the chosen solution, and its implications on the project’s timeline and budget. Comprehensive documentation of the unexpected issue, the decision-making process, and the implemented solution is maintained for future reference.

Q 21. Explain your familiarity with different types of bridge coatings and their applications.

Bridge coatings play a vital role in protecting the structure from environmental degradation and extending its service life. It’s like applying sunscreen to your skin – protecting it from harmful UV rays.

Different coatings are suitable for various bridge components and environmental conditions. Examples include:

- Epoxy coatings: Excellent for protecting steel from corrosion in aggressive environments. They offer high chemical resistance and durability.

- Zinc-rich primers: Provide cathodic protection to steel, preventing corrosion by acting as a sacrificial anode.

- Acrylic coatings: Offer good UV resistance and are commonly used on concrete surfaces to improve aesthetics and prevent deterioration.

- Polyurethane coatings: Known for their flexibility and abrasion resistance, making them suitable for areas subject to high traffic or wear.

- Silicone-modified coatings: Used on concrete to improve water resistance and reduce cracking.

The selection of the appropriate coating depends on factors such as the type of material being coated (steel, concrete), the environmental conditions (humidity, temperature, exposure to de-icing salts), and the required lifespan of the coating. Proper surface preparation is crucial before application to ensure good adhesion and longevity.

Q 22. How do you ensure the safety of workers during bridge rehabilitation projects?

Worker safety is paramount in bridge rehabilitation. It’s not just a legal requirement; it’s an ethical imperative. We implement a comprehensive safety plan tailored to each project, starting with a thorough risk assessment. This identifies potential hazards, such as working at heights, exposure to heavy machinery, and confined space entry.

- Engineering Controls: We utilize scaffolding systems, fall protection harnesses, and specialized access equipment to minimize risks. For example, on a recent project involving deck replacement, we employed a sophisticated suspended scaffolding system that allowed workers to move freely and safely across the bridge deck.

- Administrative Controls: This includes robust training programs for all personnel involved, emphasizing safe work practices and emergency procedures. We hold regular toolbox talks to address specific safety concerns and maintain a strong safety culture on site.

- Personal Protective Equipment (PPE): Every worker is equipped with appropriate PPE, including hard hats, safety vests, gloves, and eye protection. The selection of PPE is based on the specific hazards present in different work areas.

- Monitoring and Enforcement: Our safety officers conduct daily site inspections to ensure compliance with safety regulations and procedures. We maintain detailed safety records and promptly address any identified issues. We also utilize technologies like real-time worker location tracking to enhance monitoring.

Ultimately, a zero-incident goal is the only acceptable outcome. Proactive safety measures are far more cost-effective than dealing with accidents, both financially and ethically.

Q 23. What are your experience with seismic retrofitting of bridges?

Seismic retrofitting is crucial for extending the lifespan of bridges in seismically active zones. My experience encompasses various retrofitting techniques, depending on the bridge’s age, design, and the specific seismic hazards.

- Strengthening Existing Columns: I’ve worked on projects involving the jacketing of existing columns with high-strength concrete or steel to increase their load-carrying capacity and ductility. This technique helps the columns withstand seismic forces without collapsing.

- Installing Seismic Isolation Bearings: In some cases, we’ve implemented base isolation systems, where elastomeric or lead-rubber bearings are placed between the bridge superstructure and substructure. These bearings allow the bridge deck to move independently during an earthquake, reducing the impact on the bridge structure.

- Adding Shear Walls and Braces: We’ve also used shear walls and bracing systems to improve the lateral stiffness and strength of the bridge, enhancing its resistance to seismic forces. This often involves detailed structural analysis to determine optimal placement and design.

For example, on a recent project involving an older highway overpass, we implemented a combination of column jacketing and seismic isolation bearings. This approach significantly improved the bridge’s seismic performance, ensuring its safety during future earthquakes. The selection of retrofitting strategies is always driven by a comprehensive seismic assessment and detailed structural analysis.

Q 24. Describe your experience in preparing construction drawings and specifications for bridge rehabilitation projects.

Preparing construction drawings and specifications is a critical step in ensuring a successful bridge rehabilitation project. These documents must be precise, comprehensive, and unambiguous to avoid misunderstandings and delays.

- Detailed Site Surveys: This is the foundation, involving thorough assessments of the existing bridge structure, including detailed measurements, material testing, and condition assessments. The data from these surveys informs the design of the rehabilitation work.

- Design Development: This phase uses the data from the site surveys to develop the rehabilitation design. This includes selecting appropriate materials, detailing the construction methods, and addressing any structural deficiencies.

- Drawing Preparation: Construction drawings are then created using Computer-Aided Design (CAD) software. These drawings clearly show the proposed rehabilitation work, including details of the new elements and how they integrate with the existing structure.

- Specifications Writing: Specifications describe the quality of materials and workmanship required. They are written in a clear and concise manner, leaving no room for interpretation. We use standard specifications like AASHTO (American Association of State Highway and Transportation Officials) specifications where applicable but often tailor them to the project’s specific needs.

- Quality Control (QC) and Quality Assurance (QA) Measures: The drawings and specifications include provisions for QC/QA during construction to ensure that the work meets the required standards. This might include material testing and regular inspections throughout the construction process.

For instance, in a recent project involving the rehabilitation of a historic steel truss bridge, we created detailed drawings that showed the exact location and dimensions of all new steel members and connections. The specifications clearly defined the material grades, welding procedures, and surface treatment requirements for all components.

Q 25. How do you conduct post-rehabilitation inspections to evaluate project success?

Post-rehabilitation inspections are crucial to verify that the rehabilitation work meets design specifications and that the bridge is performing as expected. These inspections involve a multi-stage approach.

- Initial Inspection: This is conducted upon completion of construction to verify that all work was performed according to the plans and specifications. It covers visual inspections, dimensional checks, and assessments of the overall structural integrity.

- Load Testing (If Required): In some cases, load tests may be performed to verify that the rehabilitated structure can carry the intended loads. This typically involves applying controlled loads to the bridge and monitoring its response.

- Periodic Inspections: These inspections are performed at regular intervals (e.g., annually) to monitor the long-term performance of the rehabilitation work. This allows for early detection of any deterioration or problems.

- Instrumentation Monitoring: Sensors and instrumentation are often installed during rehabilitation to continuously monitor the bridge’s behavior under various conditions. This data helps assess the effectiveness of the rehabilitation work and identify potential problems before they become critical.

For example, on a recent project involving the repair of a damaged bridge pier, we conducted an initial inspection to verify the quality of the concrete repairs and the installation of new reinforcement. We also installed strain gauges to monitor the stress levels in the pier under normal traffic loads, confirming the efficacy of the repairs.

Q 26. Explain your understanding of life-cycle costing for bridge infrastructure.

Life-cycle costing (LCC) is a critical concept in bridge management. It considers the total cost of ownership of a bridge over its entire service life, including initial construction, maintenance, repairs, rehabilitation, and eventual replacement. This approach allows for informed decision-making by comparing different design and maintenance strategies.

A simple LCC analysis compares the present value of all costs associated with different options. It helps prioritize investments in maintenance and rehabilitation to minimize the overall cost over the bridge’s lifespan. For example, investing in preventative maintenance might increase short-term costs but significantly reduce the need for expensive repairs in the future. Ignoring this can lead to higher costs in the long run due to increased deterioration.

Factors included in LCC analysis include initial construction costs, maintenance costs (regular inspections, cleaning, minor repairs), rehabilitation costs (major repairs, strengthening, deck replacements), and the eventual cost of replacement. Discount rates reflect the time value of money.

By utilizing LCC, we can make informed choices on materials and design, optimizing the balance between initial cost and long-term performance. It helps in selecting options that offer the best value for money over the bridge’s life, ensuring sustainable infrastructure.

Q 27. What are your experiences with documenting and reporting on bridge rehabilitation projects?

Comprehensive documentation and reporting are essential for ensuring the long-term success of bridge rehabilitation projects. This includes meticulous record-keeping throughout the entire project lifecycle.

- Project Records: We maintain detailed records of all project activities, including design calculations, construction drawings, specifications, inspection reports, material test results, and any other relevant documents. This information is crucial for future maintenance and rehabilitation efforts.

- Progress Reports: Regular progress reports are submitted to clients and stakeholders, providing updates on the project’s status, schedule, and budget. These reports include photographs and other visual aids to clearly communicate the progress of the work.

- Final Report: A comprehensive final report summarizes the entire project, including the challenges faced, the solutions implemented, the overall cost, and any lessons learned. This document serves as a valuable resource for future projects.

- As-Built Drawings: As-built drawings are updated throughout the construction process to reflect the actual construction details. These drawings are crucial for future maintenance and rehabilitation work.

We use a combination of digital and physical record-keeping systems, ensuring that all information is readily accessible and easily retrievable. The goal is to create a comprehensive historical record of the project, making it easy for future engineers and maintenance personnel to understand the bridge’s history and current condition.

Q 28. How do you stay current with advancements in bridge rehabilitation techniques and materials?

Staying current with advancements in bridge rehabilitation techniques and materials is crucial for providing the best possible solutions for our clients. We achieve this through a multi-faceted approach.

- Professional Development: We actively participate in industry conferences, workshops, and training courses to learn about the latest advancements in bridge engineering and materials science. This includes attending webinars, seminars and short courses related to relevant standards and specifications updates.

- Industry Publications: We regularly review professional journals, industry publications, and research papers to stay informed about new research findings and innovative technologies. We subscribe to relevant journals and attend industry conferences and trade shows.

- Collaboration and Networking: We collaborate with other bridge engineers and experts in the field to share knowledge and learn from each other’s experiences. Networking with peers and attending industry events helps us stay abreast of the latest developments.

- Software and Technology: We utilize advanced software and technology for bridge design and analysis, ensuring that our work is informed by the most current methods and tools. This includes investing in and utilizing cutting-edge software for structural analysis, finite element modelling and design.

Continuous learning is essential in this field. Staying up-to-date on the latest advancements allows us to optimize designs, improve durability, and reduce costs, resulting in safer, longer-lasting bridges.

Key Topics to Learn for Rehabilitation and Retrofitting of Bridges Interview

- Structural Assessment and Evaluation: Understanding methods for assessing bridge condition, identifying deterioration mechanisms (e.g., corrosion, fatigue, cracking), and evaluating load capacity. Practical application: Interpreting inspection reports and recommending appropriate interventions.

- Rehabilitation Techniques: Familiarizing yourself with various rehabilitation methods, including deck repairs and replacements, substructure repairs (e.g., pier jacketing, foundation strengthening), and strengthening techniques. Practical application: Selecting the most cost-effective and efficient method for a specific bridge condition.

- Retrofitting Strategies: Mastering techniques for increasing load capacity, improving seismic performance, and extending the service life of existing bridges. Practical application: Designing retrofitting schemes considering factors like traffic management and environmental impact.

- Material Selection and Properties: Understanding the properties of various materials used in bridge rehabilitation and retrofitting (e.g., concrete, steel, fiber-reinforced polymers). Practical application: Choosing appropriate materials based on durability, strength, and cost considerations.

- Design Codes and Standards: Thorough knowledge of relevant design codes and standards (e.g., AASHTO, ASCE) related to bridge rehabilitation and retrofitting. Practical application: Ensuring designs comply with safety and performance requirements.

- Construction Methods and Sequencing: Understanding the logistical aspects of bridge rehabilitation and retrofitting projects, including staging, temporary supports, and traffic control. Practical application: Planning a construction sequence that minimizes disruption and maximizes efficiency.

- Cost Estimation and Project Management: Developing realistic cost estimates and managing the project timeline and budget effectively. Practical application: Preparing proposals and managing resources efficiently.

- Sustainability and Environmental Considerations: Understanding the environmental impact of rehabilitation and retrofitting projects and incorporating sustainable practices. Practical application: Minimizing waste generation and choosing eco-friendly materials.

Next Steps

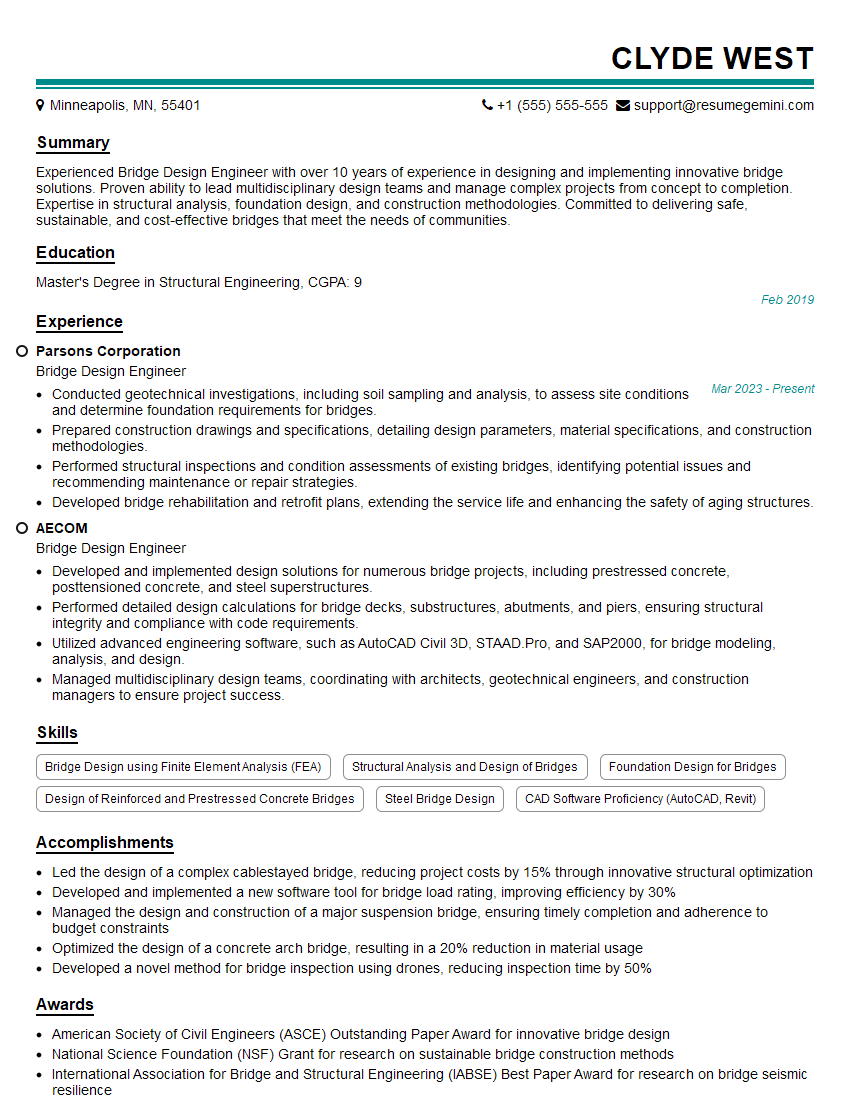

Mastering the principles of bridge rehabilitation and retrofitting opens doors to exciting career opportunities and positions you for leadership in the infrastructure sector. A strong resume is crucial for showcasing your expertise and securing your desired role. Creating an ATS-friendly resume is vital for navigating applicant tracking systems. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored specifically for Rehabilitation and Retrofitting of Bridges are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.