Cracking a skill-specific interview, like one for Reinforcement Calculations, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Reinforcement Calculations Interview

Q 1. Explain the process of calculating reinforcement for a simply supported beam.

Calculating reinforcement for a simply supported beam involves determining the amount of steel needed to resist bending moments. It’s like building a bridge – you need strong support to prevent it from collapsing under weight. The process begins with analyzing the load on the beam (from weight, snow, etc.). This load creates bending moments, which are internal forces causing the beam to bend. We use these moments to calculate the required bending stress resistance.

We then use the concrete’s compressive strength and the steel’s tensile strength, along with the beam’s geometry, to determine the necessary area of steel reinforcement. This is typically done using equations based on the bending moment and the properties of the materials involved. This area is then translated into the number and size of reinforcing bars needed. The bars are placed at the bottom of the beam to resist tensile stresses.

Example: Imagine a simply supported beam carrying a uniformly distributed load of 10 kN/m over a 5-meter span. After performing structural analysis, we might find the maximum bending moment is 62.5 kNm. Using relevant codes and material properties (concrete strength and steel yield strength), we’d then calculate the required area of steel. This area would then be converted into a practical number and diameter of reinforcement bars, such as four 16mm diameter bars.

Q 2. Describe different types of reinforcement bars and their applications.

Reinforcement bars, or rebars, come in various types, each suited for specific applications. The most common are:

- Deformed Bars: These are the most common type, featuring deformations (ribs) on their surface that improve the bond between the steel and concrete. Think of it like Velcro – the deformations create a better grip.

- Plain Bars: These bars have a smooth surface and are generally used in situations where the bond strength is not a primary concern, such as in some prestressed applications. They are less common than deformed bars.

- Epoxy-Coated Bars: These bars have an epoxy coating to enhance corrosion resistance, especially in harsh environments. They’re ideal for marine applications or areas with high chloride concentration.

Applications: Deformed bars are primarily used in beams, columns, and slabs for structural reinforcement. Plain bars might be used in non-structural applications or in situations where specific requirements necessitate their use. Epoxy-coated bars find applications where corrosion is a major concern.

Q 3. How do you determine the required area of reinforcement in a concrete column?

Determining the required area of reinforcement in a concrete column involves considering factors like the column’s axial load, concrete strength, and the steel’s yield strength. It’s similar to designing a support pillar – you need enough strength to prevent it from buckling under the weight it supports. We use interaction diagrams or simplified design equations based on code provisions to determine this area. These equations account for both the concrete and steel contribution to the column’s load-bearing capacity.

The process typically involves an iterative approach, balancing the requirements for strength and serviceability. Codes like ACI 318 or similar standards provide guidance and design equations, often requiring consideration of factors such as slenderness and eccentricity of the load.

Simplified Example: Let’s say a column has an axial load of 500 kN. Using code provisions and material properties, we’d calculate the required area of steel to resist this load while satisfying serviceability limit states like deflection and cracking. This area translates into the number and size of reinforcement bars needed for the column.

Q 4. What are the factors affecting the spacing of reinforcement bars?

Spacing of reinforcement bars is crucial for both structural integrity and workability. Too close together, and placing the bars becomes difficult; too far apart, and the concrete might not adequately restrain the steel. Several factors influence the spacing:

- Concrete Cover: A minimum concrete cover is essential to protect the steel from corrosion. This minimum cover is defined in building codes and standards.

- Maximum Bar Spacing: Codes specify maximum spacing to ensure adequate confinement of the steel and to prevent excessive cracking.

- Minimum Bar Spacing: Minimum spacing is needed to allow for proper placement and consolidation of the concrete and for ease of workability. Too close together and you won’t be able to get the concrete in between.

- Bar Diameter: The diameter of the bars influences the spacing, as larger bars require more space.

- Structural Requirements: Specific structural requirements, such as shear capacity, can impact the required bar spacing.

Q 5. Explain the concept of shear reinforcement in beams.

Shear reinforcement in beams is essential for resisting shear forces, which are forces tending to cause sliding failure along a plane within the beam. Imagine cutting a beam – shear reinforcement prevents that separation. Shear forces are particularly important to consider in beams with short spans, high loads, or low concrete strengths. Without adequate shear reinforcement, a beam could experience a sudden and catastrophic shear failure.

Shear reinforcement typically consists of stirrups (bent bars) or bent-up bars placed vertically or inclined within the beam’s web. These stirrups increase the shear capacity of the concrete by transferring the shear stress from the concrete to the steel. The design of shear reinforcement involves calculating the required spacing and diameter of stirrups based on the calculated shear force and the properties of the concrete and steel.

Analogy: Think of shear reinforcement as safety straps in a heavy box. They prevent the box from collapsing by holding the different layers together even when under stress.

Q 6. How do you calculate the development length of reinforcement bars?

Development length is the distance required for a reinforcement bar to transfer its stress into the surrounding concrete. It’s crucial to prevent the bar from pulling out of the concrete. Imagine a nail in a wall – you need sufficient embedment depth for it to hold firmly. Development length calculations depend on several factors:

- Bar Diameter: Larger bars require a longer development length.

- Concrete Strength: Higher strength concrete generally allows for shorter development lengths.

- Steel Yield Strength: Higher yield strength steel might require a longer development length.

- Type of Bar: Deformed bars typically have shorter development lengths than plain bars.

- Stress Level in Bar: Higher stress in the bar requires a longer development length.

Formulas provided in structural design codes, based on the mentioned factors, are used to determine the required development length. These calculations ensure that the reinforcement bars are sufficiently embedded to prevent pull-out failures.

Q 7. What is the purpose of lap splices in reinforcement bars?

Lap splices are used to connect two reinforcement bars end-to-end when a single bar isn’t long enough to span the entire length of a structural member. Imagine joining two pieces of rope – you need a good knot to maintain the strength. Lap splices create a continuous reinforcing effect. The design of lap splices is crucial to ensure the splice is strong enough to transfer the stresses in the bar without failure.

The length of the lap splice is carefully calculated to ensure sufficient bond between the bars and the concrete. Factors such as bar diameter, concrete strength, stress level in the bar, and code provisions are considered to determine the minimum required lap splice length. Lap splices should be placed strategically to avoid concentrated stresses and should be staggered to prevent overlapping weaknesses.

Q 8. Explain the different types of concrete mixes and their influence on reinforcement design.

Concrete mixes are categorized based on their compressive strength, workability, and durability requirements. The mix design significantly impacts reinforcement design because it dictates the concrete’s capacity to resist stresses and transfer loads to the reinforcement. A higher strength concrete allows for smaller reinforcement sections, while a lower strength concrete necessitates larger sections to achieve the same load-bearing capacity.

- Normal Strength Concrete (NSC): Commonly used, offering a balance between strength and cost. Reinforcement design for NSC often involves standard detailing practices.

- High-Strength Concrete (HSC): Possesses significantly higher compressive strength, enabling reduced reinforcement quantities and slenderer members. However, HSC can exhibit increased brittleness, requiring careful consideration of the bond between steel and concrete.

- High-Performance Concrete (HPC): A superior concrete type engineered for specific applications requiring high durability, strength, and low permeability. Design considerations focus on the unique properties of HPC and its interactions with reinforcement.

For example, designing a column using HSC allows for a smaller cross-section due to the increased compressive strength, reducing the amount of steel required compared to an NSC design. However, the increased brittleness of HSC requires careful consideration of potential brittle failure modes.

Q 9. How do you account for shrinkage and creep in reinforcement calculations?

Shrinkage and creep are time-dependent deformations in concrete that significantly influence reinforcement design. Shrinkage refers to the reduction in volume due to moisture loss, while creep is the gradual increase in strain under sustained stress. These effects can induce tensile stresses in the reinforcement, reducing its effectiveness.

We account for these effects through several methods:

- Using design codes: Codes like ACI 318 and BS 8110 provide adjustment factors or empirical equations to estimate shrinkage and creep strains. These factors are incorporated into the stress calculations for the reinforcement.

- Finite Element Analysis (FEA): For complex structures, FEA allows for a more accurate prediction of shrinkage and creep effects. It models the material behavior over time, accounting for the non-linearity of concrete.

- Time-dependent analysis: This involves analyzing the structure at various stages of its life, considering the cumulative effects of shrinkage and creep.

Ignoring shrinkage and creep can lead to underestimation of reinforcement requirements and potential cracking or structural failure. For instance, in a long-span beam, neglecting creep can underestimate the long-term deflections, leading to serviceability issues.

Q 10. Describe the process of detailing reinforcement for a foundation.

Detailing reinforcement for a foundation involves a systematic approach ensuring adequate strength, durability, and constructability. It typically includes the following steps:

- Determine reinforcement requirements: Based on structural analysis, calculate the required area of steel for bending and shear.

- Select bar sizes and spacing: Choose standard bar sizes that meet the area requirements, considering factors like concrete cover, spacing limitations, and bar placement restrictions.

- Develop reinforcement layout: Draw detailed plans showing the location, size, and spacing of bars in the foundation, including laps, bends, and anchorages.

- Prepare detailed drawings: Create comprehensive drawings including sectional views, details of bar arrangement, and specifications for bar bending and placement.

- Check for conflicts: Ensure that bars are properly spaced to allow for adequate concrete cover and avoid congestion.

- Document bending details: Indicate the dimensions and angles of bends in bars on the drawings.

For example, a footing might require a grid of reinforcing bars both in the top and bottom layers, with additional bars to handle shear forces at the edges. The drawings must accurately depict this arrangement, including bend details and bar spacing to ensure correct construction.

Q 11. Explain the significance of cover concrete in reinforcement design.

Cover concrete is the layer of concrete surrounding the reinforcement bars. It’s crucial for several reasons:

- Protection from corrosion: Cover protects the steel from environmental factors like moisture and chlorides, which can lead to corrosion. Insufficient cover accelerates corrosion, reducing the reinforcement’s lifespan and structural integrity.

- Fire resistance: Cover concrete provides fire protection by acting as a thermal barrier, delaying the temperature increase to the reinforcement and preventing its strength loss.

- Bond strength: Adequate cover enhances the bond between the concrete and steel, ensuring effective stress transfer.

Codes specify minimum cover requirements based on exposure conditions, concrete strength, and bar diameter. For example, a structure exposed to harsh marine environments will require significantly more cover than one in a dry interior environment. Neglecting adequate cover can lead to premature structural failure due to corrosion or fire damage.

Q 12. How do you handle detailing for congested reinforcement areas?

Congested reinforcement areas occur when many bars are closely spaced, hindering concrete placement and compaction. Handling this requires careful planning and detailing:

- Optimize bar sizes and spacing: Use larger diameter bars to reduce the number of bars needed, while maintaining adequate spacing for concrete placement.

- Stagger bar placements: Arrange bars in different layers, avoiding direct overlap and ensuring uniform distribution.

- Use different bar diameters: This helps manage congestion, improving both concrete compaction and flow.

- Employ supplementary reinforcement: If congestion is unavoidable, consider using smaller diameter bars as supplementary reinforcement in addition to the primary reinforcement.

- Consult detailing standards: Ensure compliance with relevant standards to mitigate potential construction challenges.

For example, in a heavily loaded column, using a combination of larger and smaller diameter bars, along with staggered layers, can help to effectively address congestion, providing optimal compaction while meeting structural requirements.

Q 13. What are the common codes and standards used for reinforcement calculations (e.g., ACI, BS)?

Several codes and standards govern reinforcement calculations, ensuring structural safety and consistency. Examples include:

- ACI 318 (American Concrete Institute): Widely used in North America, providing detailed guidelines for the design and construction of concrete structures.

- BS 8110 (British Standard): Commonly applied in the UK and other parts of the world, offering similar guidance to ACI 318.

- Eurocode 2: The European standard for concrete design, used extensively throughout Europe.

- AS 3600 (Australian Standard): Used in Australia and New Zealand for concrete structures.

These codes dictate aspects like material properties, load combinations, design methods, and detailing requirements. Engineers must adhere to the relevant code for their region to ensure the safety and compliance of their designs. For instance, the minimum cover requirements for reinforcement will vary depending on the specific code.

Q 14. Describe the process of checking reinforcement drawings for errors.

Checking reinforcement drawings for errors is crucial to prevent construction issues and structural failures. The process typically involves:

- Verify calculations: Check that the reinforcement quantities accurately reflect the structural analysis results.

- Check bar sizes and spacing: Ensure that the chosen bar sizes meet the required area and that spacing complies with code requirements and concrete cover constraints.

- Review bar arrangement: Verify the bar placement and arrangement to ensure proper stress transfer, avoiding congestion and enabling concrete compaction.

- Examine bending details: Check that bar bends are accurately depicted and compatible with the overall design.

- Inspect laps and splices: Ensure that lap lengths satisfy code requirements for the specified bar sizes and stress levels.

- Review dimensions and tolerances: Verify that the dimensions are consistent and tolerances are respected.

- Cross-reference with other drawings: Ensure compatibility with other structural elements, minimizing conflicts and ensuring a coherent design.

A common error might be incorrect lap lengths, which can result in reduced strength and potential failure. A thorough review process, involving multiple engineers, can significantly minimize such errors, protecting against potential structural failures and costly rework.

Q 15. Explain the importance of using appropriate software for reinforcement calculations.

Using specialized software for reinforcement calculations is crucial for accuracy, efficiency, and compliance. Manual calculations are prone to errors, especially in complex structures. Software offers several advantages:

- Accuracy: Software minimizes human error in complex calculations, ensuring precise reinforcement detailing.

- Efficiency: Automated calculations significantly reduce the time required for design, allowing engineers to handle larger projects.

- Compliance: Software often incorporates up-to-date building codes and standards, ensuring designs meet regulatory requirements.

- Optimization: Many programs optimize reinforcement layouts for cost-effectiveness and structural integrity.

- Visualization: 3D modeling and visualization features aid in understanding the reinforcement layout and potential conflicts.

Imagine designing a high-rise building manually – the sheer volume of calculations would be overwhelming and prone to errors. Software streamlines this process, making large-scale projects feasible.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you calculate the bending moment in a continuous beam?

Calculating bending moments in continuous beams involves considering the support conditions and loading patterns. We typically use the moment distribution method or the slope-deflection method, but software often automates this process.

The moment distribution method iteratively distributes moments between the supports until equilibrium is achieved. It accounts for the stiffness of the beams and the fixity of the supports. The slope-deflection method uses equations relating moments and rotations at the supports to determine the bending moments.

For example, consider a simply supported continuous beam with two spans, each carrying a uniformly distributed load (UDL). The bending moment at the interior support will be significantly larger than the moments at the outer supports. Software will calculate these values automatically, considering factors like span length, UDL intensity, and material properties.

//Simplified Example: Assume span lengths are equal (L) and UDL is 'w' //Moment at interior support ≈ -wL²/8 (Negative indicates hogging moment) //Moment at outer supports ≈ wL²/12 (Positive indicates sagging moment) In practice, we use software like ETABS, SAP2000, or similar programs that directly provide accurate bending moment diagrams for continuous beams with any loading conditions and support configurations.

Q 17. Describe the process for designing reinforcement for a slab.

Designing slab reinforcement is a multi-step process:

- Determine Loads: Calculate the total load on the slab (dead load + live load + superimposed loads). This involves considering factors like the slab thickness, finishes, and intended use.

- Analyze Bending Moments: Using software or appropriate design aids (charts, tables), determine the maximum bending moments in both directions (usually along the short and long spans).

- Calculate Required Reinforcement: Employing relevant design codes (e.g., ACI 318, Eurocode 2), determine the required amount of reinforcement based on the calculated moments, material strengths (concrete and steel), and desired safety factors.

- Design Layout: Distribute the reinforcement evenly across the slab to provide sufficient tensile strength. Consider factors like bar spacing, cover requirements, and constructability.

- Check Shear: Ensure the slab’s shear capacity is adequate to resist the applied shear stresses. This involves calculating shear stresses and providing sufficient shear reinforcement if necessary.

- Detailing: Prepare detailed drawings that clearly show reinforcement placement, bar sizes, spacing, and locations of bends. This is crucial for the contractors to accurately construct the slab.

For instance, if designing a residential slab, the process would involve calculating the dead load (weight of the slab itself), the live load (furniture, people), and then determining the bending moments. Based on this, the minimum reinforcement area can be determined, leading to the selection of appropriate bar sizes and spacing.

Q 18. What are the different types of stress experienced by reinforcement bars?

Reinforcement bars in concrete structures primarily experience two types of stress:

- Tensile Stress: This is the most common stress. When concrete is subjected to bending, it cracks in tension, and the steel reinforcement resists these tensile forces. This is the primary reason for using steel reinforcement in concrete structures.

- Compressive Stress: Although less frequently the primary concern, steel reinforcement can also experience compressive stress. This can occur in regions of compression in a member under bending or in compression members. The steel’s compressive strength is generally less critical than its tensile strength, but it’s still considered in design.

In addition, steel reinforcement also experiences other stresses, such as bond stress (between steel and concrete), shear stress (in shear reinforcement), and thermal stresses (due to temperature changes).

Q 19. How do you deal with the design of reinforcement in the presence of corrosion?

Corrosion significantly reduces the effective area and strength of reinforcement bars, compromising the structural integrity of the concrete element. Dealing with corrosion in design involves several strategies:

- Increased Reinforcement: Provide extra reinforcement to compensate for the expected loss of area due to corrosion. This involves increasing the bar diameter or the reinforcement density.

- Protective Coatings: Use corrosion-resistant steel bars or apply protective coatings to the reinforcement, preventing contact with corrosive agents.

- Design for Durability: Consider the environmental conditions carefully. For example, structures exposed to aggressive environments (chlorides from de-icing salts, seawater) require specific protection measures. This might involve using high-quality concrete, corrosion inhibitors, or protective coatings.

- Regular Inspection: Implement a regular inspection and maintenance program to monitor the condition of the reinforcement and address any corrosion issues promptly.

- Repair and Rehabilitation: If corrosion has already occurred, repair or rehabilitation methods may be necessary to restore the structure’s load-carrying capacity.

For instance, designing a bridge deck exposed to de-icing salts necessitates using corrosion-resistant steel bars or increasing the reinforcement area significantly to account for the anticipated corrosion losses over the structure’s lifespan.

Q 20. Explain the concept of bond stress between concrete and steel.

Bond stress is the shear stress that develops at the interface between the concrete and the steel reinforcement. It’s the force that transmits tensile forces from the cracked concrete to the reinforcement bars. A good bond is essential for the composite action between steel and concrete, ensuring that the reinforcement acts effectively to resist tensile forces.

The magnitude of bond stress depends on several factors, including the concrete strength, the surface condition of the steel bar (ribbed bars generally provide better bond than smooth bars), and the amount of reinforcement. Insufficient bond can lead to bond failure, where the steel bar slips within the concrete, causing premature failure of the member.

Imagine trying to pull a nail out of a wooden board. The bond between the nail and the wood prevents the nail from slipping out easily. Similarly, the bond between the concrete and the steel reinforcement resists the pulling forces and ensures that the reinforcement can effectively carry the tensile loads.

Q 21. What is the importance of detailing drawings in reinforcement calculations?

Detailing drawings are essential for reinforcement calculations because they provide the visual representation of the reinforcement layout that guides the construction process. Without accurate detailing, the structure might not be built as intended, compromising its safety and functionality.

Detailing drawings include precise information like bar sizes, spacing, bending details, locations of splices, and other necessary dimensions. They serve as the communication link between the structural engineer, the detailer, and the construction crew. Accurate and clear detailing drawings are critical for ensuring that the reinforcement is installed correctly and that the designed structural integrity is achieved.

Imagine a scenario where the detailing drawings are incorrect and the construction crew follows those flawed plans. The final structure might not have the required reinforcement in critical areas, significantly compromising its safety and leading to potential failure.

Q 22. How do you calculate the amount of reinforcement needed for a retaining wall?

Calculating reinforcement for a retaining wall is a crucial step in ensuring its stability and longevity. It involves analyzing the soil pressure acting on the wall and designing a reinforcement scheme that can resist these forces. This process isn’t a single formula but a multi-step procedure.

Step 1: Soil Pressure Calculation: First, we determine the active and passive earth pressures acting on the wall using soil mechanics principles and appropriate design codes (like Eurocode or ACI). Factors like soil type, density, and the wall’s inclination are considered. The active pressure pushes the wall outward, while the passive pressure resists this movement. The difference between these pressures determines the net lateral force.

Step 2: Force Analysis: This net lateral force is then analyzed using structural mechanics. We consider the wall’s geometry, material properties (concrete strength), and the reinforcement’s contribution to resisting the bending moment and shear forces. This often involves drawing shear force and bending moment diagrams.

Step 3: Reinforcement Design: Based on these calculations, we determine the required amount of reinforcement. This involves selecting the size and spacing of reinforcing bars (rebar) to ensure the wall’s tensile strength meets or exceeds the calculated demands. We check for both flexural (bending) and shear reinforcement requirements. Design codes dictate minimum reinforcement ratios.

Step 4: Detailing: Finally, detailed drawings are produced showing the location, size, and spacing of all reinforcing bars. This also includes considerations for bar anchorage, lap lengths, and concrete cover.

Example: Imagine a 5-meter high retaining wall. Let’s say the calculated bending moment at the base is 100 kN-m. Using the appropriate concrete strength and steel grade, we’d calculate the required area of steel reinforcement needed to resist this moment. This would dictate the number and size of reinforcing bars needed at the base of the wall.

Q 23. Describe your experience using various software for reinforcement calculations.

Throughout my career, I’ve extensively used various software packages for reinforcement calculations. My experience encompasses both general-purpose structural analysis software and specialized reinforcement detailing programs. I’m proficient in programs like:

- SAP2000: A powerful finite element analysis software capable of handling complex structural systems, including retaining walls. I use it for the overall structural analysis and determining the forces on the retaining wall.

- ETABS: Similar to SAP2000, ETABS is another robust finite element analysis software suitable for modeling and analyzing various structures. It provides detailed results that inform the reinforcement design process.

- Autodesk Robot Structural Analysis: This program offers a user-friendly interface for structural analysis and is useful for both linear and non-linear analyses.

- Revit: While not solely a reinforcement calculation software, Revit’s integration with detailing programs allows for seamless design and documentation.

- Specialized Reinforcement Detailing Software: I have also used several specialized software packages for creating detailed reinforcement drawings, allowing for efficient and accurate bar placement and quantity calculations. These programs often integrate directly with structural analysis software.

My expertise extends beyond simply running the software; I possess a deep understanding of the underlying principles and algorithms used in these programs. This allows me to critically evaluate the results, identify potential errors, and adapt the models as needed to represent real-world complexities.

Q 24. Explain your understanding of different types of structural analysis methods.

Structural analysis involves determining the response of a structure to external loads. Several methods exist, each with its own advantages and limitations. My understanding encompasses various methods, including:

- Linear Elastic Analysis: This method assumes that the structure behaves linearly (i.e., stress is directly proportional to strain) and the material remains within its elastic range. It’s the most common approach for many structural elements, offering simplicity and speed.

- Non-linear Analysis: This method accounts for non-linear material behavior (e.g., plasticity) and large deformations, offering greater accuracy for complex scenarios such as those involving cracking or significant yielding. It is more computationally intensive.

- Finite Element Analysis (FEA): A numerical method that divides a structure into numerous small elements, allowing for detailed analysis of stress and strain distributions. I’ve used FEA extensively for complex structures and situations where accurate stress prediction is essential. Software like SAP2000 and ETABS utilizes FEA.

- Limit State Design: This approach focuses on predicting the structure’s behavior under ultimate and serviceability limit states. It allows for a more realistic evaluation of structural safety and performance, considering potential failure modes. It’s widely adopted in modern design codes.

The choice of method depends on the specific project requirements, the complexity of the structure, and the accuracy level needed. Often, a combination of methods is used to ensure a comprehensive analysis. For retaining wall design, usually linear elastic analysis suffices for preliminary designs, but non-linear analysis might be needed if there are complex soil-structure interactions or if the potential for significant cracking exists.

Q 25. How do you ensure the accuracy of your reinforcement calculations?

Ensuring accuracy in reinforcement calculations is paramount. My approach is multi-faceted:

- Code Compliance: I meticulously follow relevant design codes and standards (e.g., ACI 318, Eurocode 2) to ensure the calculations are compliant and safe.

- Independent Verification: I always independently verify my calculations, often employing different methods or software to cross-check results. A second pair of eyes can catch overlooked errors.

- Peer Review: When working on critical projects, I involve experienced colleagues in a formal peer review process to scrutinize the calculations and design.

- Software Validation: I understand the limitations of the software and ensure that the model accurately reflects the real-world conditions. This includes careful meshing in FEA and proper consideration of boundary conditions.

- Material Property Consideration: Accurate material properties (concrete strength, steel yield strength) are crucial. I ensure that these values are obtained from reliable testing and are appropriately factored in the calculations.

- Sensitivity Analysis: I often perform sensitivity analyses to assess how the results change with variations in input parameters (e.g., soil properties, loads). This helps identify critical parameters and ensure robustness in the design.

Accuracy isn’t just about getting the right numbers; it’s also about understanding the implications of those numbers and ensuring the design meets all safety and serviceability requirements.

Q 26. Describe a challenging reinforcement calculation project and how you overcame it.

One challenging project involved designing the reinforcement for a large retaining wall on a sloping site with complex geological conditions. The soil was heterogeneous, containing layers of varying densities and strengths. This made accurate soil pressure calculations extremely difficult. The standard methods proved inadequate. To overcome this, we employed advanced geotechnical investigations, including in-situ testing and detailed soil profiling. We then used sophisticated FEA modeling, incorporating the detailed soil profile and non-linear material behavior. This allowed us to accurately predict the soil-structure interaction and design a robust reinforcement scheme that could handle the uneven soil pressures. Through iterative refinement of the FEA model and close collaboration with the geotechnical engineer, we successfully delivered a safe and stable design that met all requirements. The key to success was the combination of thorough site investigation, advanced analytical methods, and effective teamwork.

Q 27. Explain the impact of using different grades of steel reinforcement.

Using different grades of steel reinforcement significantly impacts the design and cost-effectiveness. Higher-grade steels (e.g., Grade 60, Grade 80) have higher yield strengths than lower-grade steels (e.g., Grade 40). This means that for the same load-bearing capacity, you can use less higher-grade steel. This translates to:

- Reduced Reinforcement Quantity: Higher-grade steel allows for smaller diameter bars or wider spacing, leading to less steel consumption and potentially lower material costs.

- Improved Structural Efficiency: This leads to smaller and potentially lighter structural elements, making it beneficial in space-constrained projects.

- Increased Strength: The higher yield strength of higher-grade steel ensures greater safety and reliability, especially in critical structures.

- Cost Considerations: While higher-grade steel has a higher unit cost, the reduced quantity often results in overall cost savings, even if not always.

However, the choice of steel grade involves careful consideration of factors like weldability, availability, and compatibility with the overall structural system. Design codes often stipulate allowable grades for specific applications. Selecting the appropriate steel grade requires a balanced approach, considering strength, cost, and constructability factors.

Key Topics to Learn for Reinforcement Calculations Interview

- Fundamental Concepts: Understanding stress, strain, and the behavior of reinforced concrete under load. This includes mastering basic material properties of concrete and steel.

- Design Codes and Standards: Familiarity with relevant building codes (e.g., ACI, Eurocode) and their application in reinforcement detailing.

- Flexural Design: Calculating bending moments, shear forces, and determining the required reinforcement for beams and slabs. Practice applying different design methods.

- Shear Design: Understanding shear stresses and mechanisms of failure, and designing for shear reinforcement (stirrups).

- Development Length and Anchorage: Ensuring adequate bond between the reinforcement and concrete to prevent pull-out failure. This includes understanding different hook types and their applications.

- Compression Members: Design of columns and other compression members, including considerations for buckling and slenderness effects.

- Torsion Design: Understanding torsional stresses and designing for torsion reinforcement.

- Practical Applications: Working through detailed examples of reinforcement calculations for various structural elements, such as beams, columns, and slabs. Consider different loading scenarios.

- Software Proficiency: Demonstrating familiarity with relevant software packages used for structural analysis and design (mention specific software if applicable, without links).

- Problem-Solving Approach: Develop a structured approach to tackle reinforcement calculation problems, showing your understanding of the underlying principles and detailing your work clearly.

Next Steps

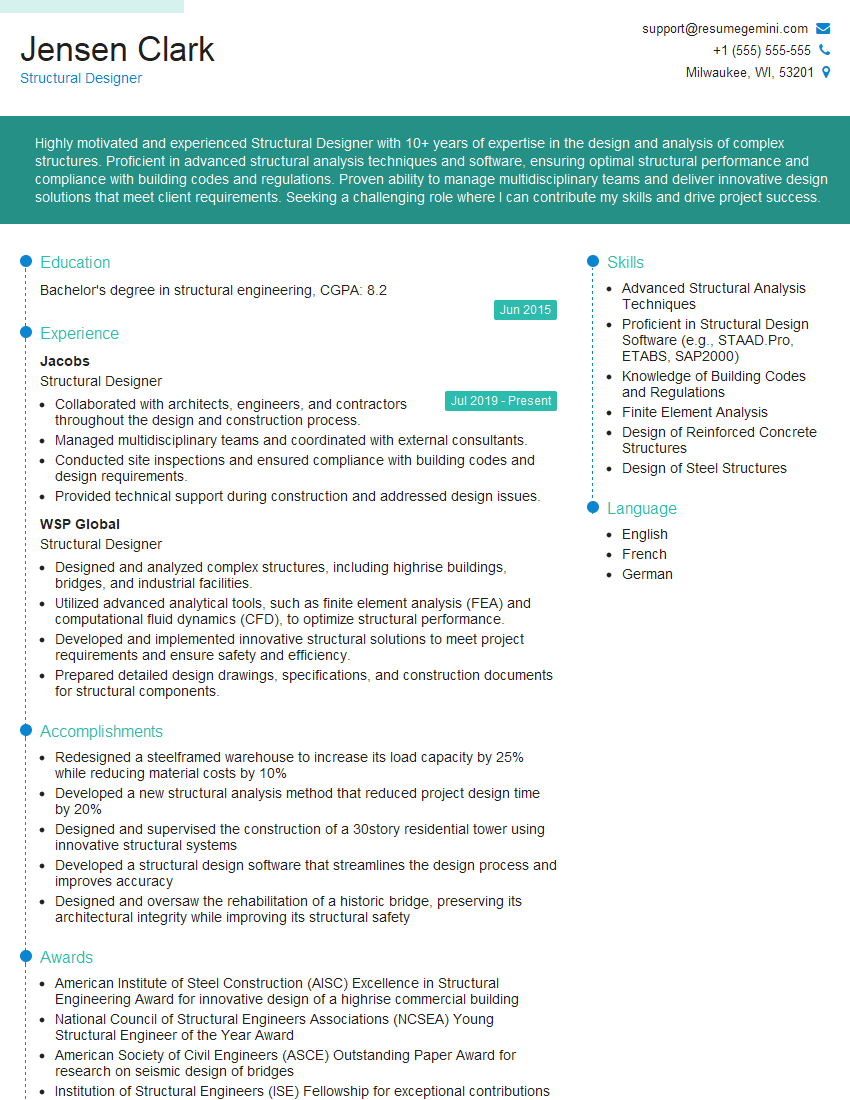

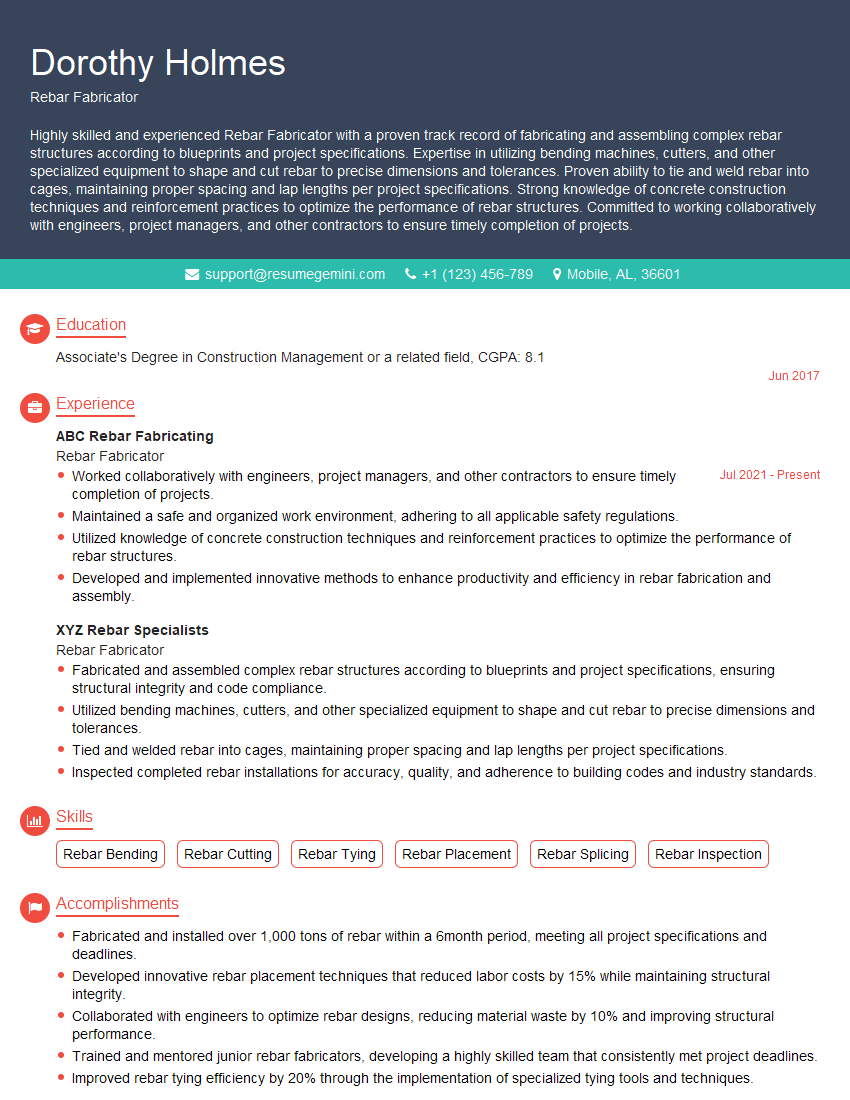

Mastering reinforcement calculations is crucial for a successful career in structural engineering, opening doors to exciting projects and opportunities for professional growth. A strong understanding of these principles will make you a highly sought-after candidate. To further enhance your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored specifically to professionals in Reinforcement Calculations to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.