Preparation is the key to success in any interview. In this post, we’ll explore crucial Renewable Energy System Maintenance interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Renewable Energy System Maintenance Interview

Q 1. Describe your experience with preventative maintenance on solar PV systems.

Preventative maintenance on solar PV systems is crucial for maximizing energy production and extending the lifespan of the system. It involves a proactive approach, regularly inspecting and cleaning components to prevent failures before they occur. My experience encompasses a wide range of tasks, from visual inspections to more involved electrical testing.

- Visual Inspections: This includes checking for shading, damaged panels (cracks, hotspots), loose connections, and signs of rodent activity. I once discovered a squirrel had nested within a panel array, causing a short circuit and reduced power output. A simple visual check identified and solved the issue quickly.

- Cleaning: Dust and debris significantly reduce panel efficiency. I utilize appropriate cleaning techniques, avoiding harsh chemicals that could damage the panels, to ensure optimal performance. This process is particularly important in dusty or arid climates.

- Electrical Testing: Using specialized equipment like multimeters and IR cameras, I test the performance of individual panels, strings, and the entire array. This allows me to identify issues like decreased voltage or hot spots that may indicate a failing component, far before it causes a major system failure.

- Monitoring System Checks: Modern systems include monitoring software. I regularly review this data to track performance trends, identify anomalies, and plan maintenance activities accordingly. A recent example saw a gradual decline in a specific string’s output, which we traced to a failing diode in a single panel using the monitoring data. This allowed for targeted repair instead of a full string replacement, saving time and money.

Q 2. Explain the process of troubleshooting a malfunctioning wind turbine.

Troubleshooting a malfunctioning wind turbine requires a systematic approach, combining diagnostic tools with a deep understanding of the turbine’s mechanics and electrical systems. Safety is paramount; always follow lockout/tagout procedures before commencing any work. The process typically involves these steps:

- Initial Assessment: Begin with a visual inspection. Check for obvious issues such as damaged blades, loose connections, or signs of overheating. Note any error codes displayed on the turbine’s control system.

- Data Analysis: Review the turbine’s SCADA data to identify performance deviations, such as unusual vibrations, slow rotational speed, or erratic power output. This data provides valuable clues to the problem’s location and severity.

- Component Testing: Depending on the initial findings, this might involve testing the gearbox, generator, yaw system, pitch system, or other components using specialized diagnostic tools. I use sophisticated diagnostic software to analyze vibrations and identify potential bearing failures.

- Isolation and Repair: Once the faulty component is identified, it’s isolated to prevent further damage. This often requires specialized lifting equipment and expertise. Repair might involve replacing a faulty component or performing more extensive repairs on-site, or it may require transporting components to a specialized workshop.

- Testing and Commissioning: After repairs, the turbine undergoes thorough testing to confirm proper operation and power output before being returned to service.

For example, I once diagnosed a wind turbine experiencing reduced power output through a systematic analysis of its SCADA data and vibration signatures. It turned out to be a failing main bearing, which we successfully replaced using a specialized crane.

Q 3. What are the common causes of inverter failures in solar installations?

Inverter failures in solar installations are a common occurrence, usually stemming from a combination of factors. These include:

- Overheating: Inverters generate heat during operation. Poor ventilation, shading, or exposure to extreme temperatures can lead to overheating and eventual failure. Think of it like constantly running a computer without proper cooling.

- Overloading: Connecting more panels than the inverter is designed to handle creates an overload, stressing the components and shortening its lifespan.

- Voltage Surges: Lightning strikes or grid disturbances can cause voltage spikes that damage delicate internal components of the inverter.

- Age and Wear: Like all electronic equipment, inverters have a limited lifespan. Continuous operation and the effects of weather will eventually lead to wear and tear.

- Poor Installation: Improper wiring, inadequate grounding, or insufficient protection from the elements during installation can create conditions that hasten inverter failure.

Regular inspection, proper ventilation, and surge protection devices can significantly mitigate these risks. I always emphasize proper installation procedures to avoid many of these common problems.

Q 4. How do you identify and address grid connection issues in renewable energy systems?

Grid connection issues in renewable energy systems can severely impact power production and even create safety hazards. Identifying these problems requires a combination of technical skills and knowledge of grid codes and regulations. My approach involves the following:

- Monitoring System Data: SCADA systems often provide real-time data on grid synchronization and power quality. Anomalies like frequency deviations, voltage fluctuations, or reactive power imbalances are key indicators of grid connection issues.

- Testing Equipment: Specialized meters and analyzers are used to measure voltage, current, frequency, power factor, and other grid parameters. This data is crucial for understanding the nature and severity of the issue.

- Grid Code Compliance: I ensure that the renewable energy system adheres to all applicable grid codes and standards. Non-compliance can lead to grid instability and rejection of power by the utility company. These codes dictate factors like voltage and frequency limits.

- Communication with Utility Providers: If a grid connection problem is detected, open communication with the utility provider is crucial. They possess valuable insight into the grid’s characteristics and can pinpoint utility-side problems.

For example, I once identified a problem where a solar farm wasn’t feeding power optimally into the grid because of a mismatch between the inverter’s output and the grid’s characteristics. By working with the utility and adjusting the inverter’s settings, we resolved the issue and significantly increased the efficiency of the system’s grid integration.

Q 5. What safety procedures do you follow when working on high-voltage renewable energy equipment?

Safety is my top priority when working on high-voltage renewable energy equipment. I strictly adhere to a comprehensive set of safety procedures, including:

- Lockout/Tagout (LOTO): Before commencing any work, I always apply LOTO procedures to isolate the equipment from the power source, preventing accidental energization. This involves physically locking out circuit breakers and switches and tagging them to clearly indicate that work is in progress.

- Personal Protective Equipment (PPE): I wear appropriate PPE, including insulated gloves, safety glasses, arc flash protective clothing, and safety shoes. The specific PPE required varies depending on the voltage and nature of the work.

- Safety Training and Certifications: I maintain up-to-date certifications and training in high-voltage safety practices, demonstrating my competency and adherence to industry best practices.

- Permit-to-Work System: A formal permit-to-work system is often used, requiring authorization from supervisors and safety personnel before high-voltage work can begin. This ensures that all safety precautions are in place.

- Grounding and Bonding: Proper grounding and bonding are essential to prevent electrical shocks. All exposed conductive parts must be properly grounded to dissipate stray currents.

Following these procedures consistently has prevented numerous potential accidents. It’s not just a matter of following rules; it’s about protecting myself and my colleagues.

Q 6. Explain your experience with battery storage system maintenance.

Battery storage systems are becoming increasingly important in renewable energy, providing energy storage and grid stabilization services. Maintenance of these systems is crucial for safety and longevity, involving:

- Visual Inspections: Regular inspections of battery banks for signs of damage, corrosion, leaks, or loose connections. I look for any signs of overheating or bulging, which could indicate a failing cell.

- Voltage and Current Monitoring: Monitoring battery voltage, current, and temperature using specialized monitoring systems. This allows for early detection of problems before they lead to major issues. Anomalies in these readings can indicate cell imbalance or other problems.

- Thermal Imaging: Using thermal imaging cameras to detect hot spots within the battery system, indicating potential cell failures. This technology is non-invasive and allows for early detection of overheating problems.

- Battery Management System (BMS) Checks: The BMS controls and monitors the battery system’s performance. Regularly reviewing BMS data for any faults or errors is crucial for preventing problems.

- Cell Balancing: Some battery systems require regular cell balancing to ensure that all cells are operating within their optimal voltage range. This helps extend battery lifespan.

I have experience maintaining various battery chemistries, including lead-acid, lithium-ion, and flow batteries. Each chemistry has unique maintenance requirements, and it’s essential to follow the manufacturer’s recommendations closely.

Q 7. Describe your knowledge of SCADA systems used in renewable energy monitoring.

SCADA (Supervisory Control and Data Acquisition) systems play a vital role in monitoring and controlling renewable energy systems. My knowledge encompasses their functionality, applications, and troubleshooting. SCADA systems gather data from various sources within the renewable energy system, including:

- Weather Stations: Providing data on solar irradiance, wind speed, and ambient temperature. This data helps optimize system operation and predict energy production.

- Inverters and Rectifiers: Monitoring voltage, current, frequency, and power output. This allows for quick identification of any anomalies.

- Meters and Sensors: Gathering information on energy production, consumption, and grid interaction. This is critical for efficient energy management.

- Turbine and Generator Sensors: In wind turbine applications, sensors monitor turbine speed, blade pitch, vibrations, and other parameters essential for diagnosing potential problems.

SCADA systems use this data to create real-time visualizations and allow for remote control and monitoring of the renewable energy assets. I can interpret SCADA data to diagnose malfunctions, optimize system performance, and enhance maintenance planning. This data-driven approach allows for preventative maintenance measures rather than reactive repairs.

For example, using SCADA data, I once helped identify a pattern of low energy output from a specific section of a solar farm during midday. By analyzing the data, we found that shading from nearby trees was impacting production. This allowed us to coordinate tree trimming to significantly improve energy output.

Q 8. How do you interpret data from a renewable energy system’s monitoring system to identify potential problems?

Interpreting data from a renewable energy system’s monitoring system is crucial for proactive maintenance. Think of it like a doctor using vital signs to diagnose a patient. We look for deviations from expected performance. This involves analyzing various parameters, such as power output, voltage, current, temperature, and operational hours.

For example, a sudden drop in solar panel voltage across multiple strings could indicate shading issues or faulty connections. A consistent rise in the temperature of a wind turbine’s gearbox might signal impending lubricant degradation and potential mechanical failure. We use data visualization tools and sophisticated software to identify trends and anomalies. Statistical analysis helps to differentiate between normal fluctuations and actual problems. If a parameter consistently falls outside a pre-defined acceptable range, we investigate further. Alert systems often flag these deviations automatically, allowing for rapid response.

- Power Output: Unexpected dips or inconsistencies compared to historical data and predicted output based on weather conditions.

- Voltage/Current: Significant deviations from nominal values could indicate wiring problems, inverter malfunctions, or issues within the panels/turbine itself.

- Temperature: Elevated temperatures beyond operational limits suggest potential overheating and require immediate attention.

- Operational Hours: Tracking operational hours helps with predictive maintenance, scheduling preventative servicing before components reach their operational limits.

Q 9. What are your troubleshooting skills when dealing with malfunctioning renewable energy components?

Troubleshooting malfunctioning renewable energy components requires a systematic approach. I follow a structured methodology that combines my theoretical knowledge with practical experience. My process usually begins with a visual inspection, checking for obvious physical damage or loose connections. I then move to checking the electrical systems, using multimeters and other diagnostic tools. This is followed by more detailed analysis using the system’s monitoring data.

For instance, if a solar inverter isn’t functioning, I’d first check its breaker and the fuses. I’d then verify the AC and DC voltage inputs. If the problem persists, I’d examine the inverter’s communication logs for error codes. Similarly, if a wind turbine is experiencing reduced power output, I would begin by assessing wind speed and direction, then checking the blade pitch mechanism and eventually checking the gearbox and generator.

Documentation is key. I meticulously record all observations, measurements, and troubleshooting steps, facilitating communication with other team members and providing a history of the issue. This process helps ensure the problem is solved efficiently and effectively and prevents recurrence.

Q 10. Describe your experience with the maintenance of different types of renewable energy systems (solar, wind, hydro, etc.)

My experience spans various renewable energy systems. I’ve worked extensively on solar PV systems, including the design, installation, and maintenance of both ground-mounted and rooftop arrays. This includes handling everything from troubleshooting individual panel malfunctions to managing large-scale system performance optimization. I’m also experienced in wind energy, having worked on both onshore and offshore wind farms. This includes routine maintenance tasks such as lubrication and gear box inspections, as well as more complex repairs like blade replacement and generator overhauls. I have limited but growing experience with smaller-scale hydropower systems, focusing primarily on preventative maintenance for turbines and related electrical systems.

Each system has its unique challenges. Solar panels are vulnerable to shading, soiling, and extreme weather. Wind turbines face mechanical stresses and corrosion due to exposure to the elements. Hydropower systems can be impacted by sedimentation and water quality. Understanding the specific requirements of each technology is critical to effectively maintaining them.

Q 11. How familiar are you with different types of inverters used in solar systems?

I’m familiar with a wide range of inverters used in solar systems, including string inverters, microinverters, and power optimizers. String inverters are the most common type, converting power from multiple solar panels into usable AC power. They are cost-effective but can be affected by shading on even one panel. Microinverters, on the other hand, are located on each individual panel, providing improved energy optimization and fault tolerance. Power optimizers offer a balance between these two approaches. They’re located on each panel but are still connected to a centralized inverter.

My experience also includes working with different inverter manufacturers and understanding their specific monitoring and communication protocols. This is important for both diagnosing faults and integrating inverters effectively into the broader monitoring system. Different inverters have different strengths and weaknesses regarding efficiency, reliability, and maintenance needs.

Q 12. Explain the process of cleaning and inspecting solar panels.

Cleaning and inspecting solar panels are crucial for maintaining optimal system performance. It’s a two-pronged approach. The inspection involves visually assessing the panels for any damage, such as cracks, discoloration, or hotspots. I also use thermal imaging to detect subtle abnormalities that might not be visible to the naked eye. Cleaning is usually done using deionized water and soft brushes or microfiber cloths to avoid scratching the panels. High-pressure washing should be avoided to prevent damage.

The frequency of cleaning depends on the environmental conditions. In dusty or arid areas, more frequent cleaning might be necessary, perhaps every few months. In cleaner environments, cleaning might be required only once or twice a year. Safety is paramount during cleaning; proper fall protection and electrical safety protocols must be followed, especially for rooftop systems.

Q 13. Describe your experience working with different types of wind turbine generators.

My experience encompasses various wind turbine generator types, including horizontal-axis wind turbines (HAWTs) and, to a lesser extent, vertical-axis wind turbines (VAWTs). I’ve worked on both geared and gearless turbines. Geared turbines use a gearbox to increase the rotational speed of the generator, while gearless designs use direct-drive generators. Each design has its own maintenance requirements. Geared turbines require more frequent lubrication and gear inspection, whereas gearless turbines have fewer moving parts, potentially simplifying maintenance but making repairs more complex.

My experience also includes working with different manufacturers and understanding their specific maintenance procedures and component designs. This involves working on both onshore and offshore wind turbines, understanding the unique challenges each environment presents, including salt corrosion in offshore installations.

Q 14. What are the common causes of gear box failures in wind turbines?

Gearbox failures in wind turbines are a significant concern, often leading to costly downtime. Several factors contribute to these failures. One major factor is fatigue loading due to the constant cyclical stress from the rotating components. This is exacerbated by misalignment, improper lubrication, and overloading. Lubricant degradation, either due to insufficient lubrication or contamination, can also lead to wear and tear on the gears and bearings. The entry of debris into the gearbox can also cause damage. Environmental factors, such as extreme temperatures and exposure to the elements, contribute to corrosion and accelerated wear.

Proper lubrication schedules, regular inspections, and vibration monitoring can help detect early signs of gearbox problems. Preventative maintenance is crucial to mitigate the risk of failure and extend the operational lifespan of the gearbox.

Q 15. How familiar are you with the different types of hydro power generation technologies?

My familiarity with hydropower generation technologies is extensive. I’ve worked with various systems, from the simplest run-of-river plants to complex pumped hydro storage facilities. The key technologies include:

- Run-of-River: These harness the natural flow of a river with minimal impoundment. Maintenance focuses on efficient water intake, turbine cleaning, and minimal impact on the river ecosystem.

- Impoundment (Reservoir): These use dams to create reservoirs, storing water for later release through turbines. Maintenance here is more complex, involving dam integrity checks, spillway management, sediment removal, and monitoring reservoir water quality.

- Pumped Hydro Storage (PHS): These systems pump water uphill during low-demand periods and release it to generate electricity during peak demand. Maintenance includes monitoring the pumps and turbines, ensuring efficient water transfer between the upper and lower reservoirs, and preventing leaks.

- Tidal Power: Harnessing the energy from the ebb and flow of tides. Maintenance demands expertise in marine engineering, corrosion protection, and adapting to challenging environmental conditions.

Understanding the specific technology is crucial for effective maintenance, as each type presents unique challenges and requires specialized knowledge.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental concerns related to renewable energy system maintenance?

Environmental concerns related to renewable energy system maintenance are significant and should never be overlooked. They include:

- Waste Disposal: Proper disposal of oils, lubricants, and other hazardous materials from turbines and other components is vital to preventing soil and water contamination. Recycling programs and adherence to stringent environmental regulations are key.

- Noise Pollution: Some renewable energy systems, particularly wind turbines, can generate noise pollution. Regular maintenance, including lubrication and bearing replacements, can mitigate this issue. Proper siting and noise barriers are also critical considerations.

- Habitat Disturbance: Construction and maintenance of hydro projects can impact aquatic ecosystems. Careful planning, environmental impact assessments, and employing fish-friendly turbines help minimize the damage.

- Water Quality: Hydropower operations can alter water flow and temperature, affecting downstream aquatic life. Regular water quality monitoring is necessary to ensure compliance with regulations and protect biodiversity.

- Visual Impacts: The visual impact of large-scale solar farms or wind farms can be a concern. Careful planning of placement and aesthetic considerations during maintenance can minimize these impacts.

Implementing environmentally sound practices is not just a regulatory requirement; it’s a moral and ethical responsibility for sustainability.

Q 17. How do you manage and maintain the documentation and records for renewable energy system maintenance?

Maintaining comprehensive and well-organized documentation is essential for efficient and effective renewable energy system maintenance. We utilize a computerized maintenance management system (CMMS) to track all aspects of maintenance. This includes:

- Preventive Maintenance Schedules: Detailed schedules for regular inspections and servicing of all system components, including dates, tasks, and responsible personnel.

- Corrective Maintenance Records: Documentation of all repairs, including problem descriptions, solutions implemented, parts used, and labor hours. This is crucial for identifying recurring issues and implementing improvements.

- Inspection Reports: Detailed reports from regular inspections, noting any potential problems or areas requiring attention. These reports often include photos or videos.

- Inventory Management: A comprehensive inventory of all spare parts and components, their locations, and their condition. This ensures quick access to necessary parts when repairs are required.

- Performance Data: System performance data such as energy generation, efficiency, and downtime are logged and analyzed to identify trends and areas for improvement.

Our system allows for easy retrieval of information, which is crucial for auditing, compliance, and making informed decisions regarding maintenance strategies.

Q 18. Explain the importance of regular preventative maintenance in extending the lifespan of renewable energy systems.

Regular preventative maintenance is paramount for maximizing the lifespan and efficiency of renewable energy systems. Think of it like servicing your car – regular oil changes, tire rotations, and inspections prevent major breakdowns and costly repairs down the road. Similarly, preventative maintenance for renewable energy systems includes:

- Regular Inspections: Visual checks for wear and tear, corrosion, or loose connections on key components.

- Cleaning: Cleaning solar panels to remove dirt and debris, which can significantly reduce energy output. Similarly, cleaning wind turbine blades improves efficiency.

- Lubrication: Regular lubrication of moving parts, such as bearings and gears in turbines, reduces friction and extends component lifespan.

- Testing: Regular testing of safety systems, such as grounding and electrical insulation, prevents electrical hazards.

By proactively addressing minor issues, we prevent them from escalating into major problems that can lead to costly downtime and premature system failure. The cost of preventative maintenance is far less than the cost of unexpected repairs or system replacements.

Q 19. What are the key performance indicators (KPIs) you use to evaluate the effectiveness of renewable energy system maintenance?

We use several key performance indicators (KPIs) to evaluate the effectiveness of our renewable energy system maintenance. These include:

- System Uptime: The percentage of time the system is operational. High uptime indicates effective maintenance and minimal downtime due to failures.

- Energy Production: Measuring the actual energy generated against the expected output. Consistent high energy production suggests efficient maintenance and optimal system performance.

- Mean Time Between Failures (MTBF): The average time between system failures. A higher MTBF indicates improved system reliability and effective maintenance practices.

- Mean Time To Repair (MTTR): The average time taken to repair a system failure. A lower MTTR shows efficient troubleshooting and repair processes.

- Maintenance Costs: Tracking the total cost of maintenance against energy produced, allowing for cost-benefit analysis of different maintenance strategies.

By regularly monitoring these KPIs, we can identify areas for improvement in our maintenance program and ensure optimal system performance and return on investment.

Q 20. Describe a time you had to troubleshoot a complex problem in a renewable energy system.

One particularly challenging situation involved a sudden drop in energy production from a large-scale solar farm. Initial inspections revealed no obvious issues. However, after thorough investigation, we discovered a subtle ground fault affecting a significant portion of the array. The fault was intermittent and difficult to locate due to the complex wiring layout.

Our troubleshooting involved:

- Systematic Testing: Using specialized equipment, we systematically tested each section of the array, gradually isolating the faulty area.

- Infrared Thermography: Infrared imaging helped to identify heat signatures, pinpointing the exact location of the fault within the affected section.

- Detailed Electrical Diagrams: Consulting detailed electrical diagrams was essential in understanding the complex wiring and tracing the fault to its source.

- Ground Resistance Testing: We conducted ground resistance tests to confirm the presence of the ground fault and its severity.

The fault was ultimately traced to a damaged underground cable, likely caused by soil erosion. The cable was replaced, and the system restored to full functionality. This experience highlighted the importance of thorough testing, advanced diagnostic tools, and a deep understanding of the system’s electrical design.

Q 21. How do you prioritize maintenance tasks in a renewable energy system?

Prioritizing maintenance tasks involves a combination of factors. We utilize a risk-based approach, prioritizing tasks based on their potential impact on system reliability and safety. This includes:

- Criticality of Components: Components essential for system operation (e.g., inverters, turbines) are prioritized higher than less critical components.

- Risk of Failure: Components with a high risk of failure, based on past experience or manufacturer recommendations, receive priority.

- Safety Concerns: Maintenance tasks related to safety hazards, such as electrical work, are given top priority.

- Regulatory Compliance: Tasks necessary for regulatory compliance, such as inspections and testing, are prioritized to avoid penalties or shutdowns.

- Cost-Benefit Analysis: Balancing the cost of maintenance with the potential cost of failure. Preventative maintenance on high-value components is prioritized to avoid costly replacements.

We use our CMMS to schedule and track these prioritized tasks, ensuring that critical maintenance is completed on time and efficiently.

Q 22. What software or tools do you use for renewable energy system maintenance and data analysis?

For renewable energy system maintenance and data analysis, I utilize a suite of software and tools tailored to the specific technology. For example, with wind turbines, I frequently use SCADA (Supervisory Control and Data Acquisition) systems to monitor performance parameters like power output, wind speed, and component temperatures. This data is then analyzed using specialized software like PVsyst (for photovoltaic systems) or similar platforms that provide predictive maintenance capabilities and allow for detailed performance assessments. I also employ diagnostic tools such as infrared cameras for detecting thermal anomalies in electrical connections and components, and vibration analyzers to identify mechanical issues within turbines or solar trackers. Finally, data visualization tools like spreadsheets and specialized reporting software are essential for presenting findings and communicating maintenance needs to clients. For instance, identifying a recurring fault pattern in a solar inverter using SCADA data and then leveraging a predictive maintenance model within PVsyst to schedule a proactive replacement prevented costly downtime on a recent project.

Q 23. Describe your understanding of the various components of a typical wind turbine.

A typical wind turbine comprises several key components working in concert to generate electricity. Think of it like a complex machine with several interconnected parts. First, there are the blades, which capture the kinetic energy of the wind. These blades are mounted on a rotor hub, connected to a low-speed shaft. This shaft then drives a gearbox, which increases the rotational speed to a level suitable for the generator. The generator converts mechanical energy into electrical energy, which is then passed through a transformer to step up the voltage for transmission to the grid. Crucially, the entire system is supported by a nacelle (the housing unit at the top of the tower), and the nacelle sits atop a tower, which elevates the turbine to capture higher wind speeds. A yaw system is used to orient the turbine to face the wind optimally, and the entire assembly needs a robust foundation for stability. Each of these components is critical to the turbine’s function, and understanding their interactions is crucial for effective maintenance.

Q 24. What is your experience with diagnosing and repairing faults in electrical systems related to renewable energy?

My experience with diagnosing and repairing electrical faults in renewable energy systems is extensive. I’m proficient in troubleshooting issues related to inverters, transformers, wiring harnesses, and grid connection equipment. My diagnostic approach is systematic. I start with visual inspections, looking for signs of damage like burnt components or loose connections. Then I use multimeters and other testing equipment to measure voltages, currents, and resistances to pinpoint the exact location of the fault. I’m also experienced with using specialized software and tools to analyze SCADA data to identify patterns that may indicate developing electrical problems before they cause significant damage. For instance, I once traced a recurring fault in a solar array to a faulty ground connection that was initially overlooked – the problem led to arcing and would have caused a fire if left undetected. Correcting the ground resolved the issue.

Q 25. Explain your experience with hydraulic or mechanical systems in renewable energy technology.

I have significant experience with hydraulic and mechanical systems in renewable energy, particularly in wind turbines. Hydraulic systems are crucial for controlling pitch and yaw mechanisms, while mechanical systems include the gearbox, bearings, and braking systems. Diagnosing problems in these systems often involves vibration analysis using specialized tools. I’m skilled in interpreting vibration signatures to identify issues like bearing wear, gear meshing problems, and imbalances within the rotating components. Additionally, I can perform lubrication checks, hydraulic fluid analysis, and adjust mechanical components to ensure smooth and efficient operation. One project involved identifying a subtle imbalance in a wind turbine rotor that was causing excessive vibrations. Using vibration analysis, we identified and replaced a faulty bearing, preventing catastrophic failure and considerable downtime.

Q 26. What are the key differences between preventative and corrective maintenance in the context of renewable energy systems?

Preventative and corrective maintenance represent distinct approaches to maintaining renewable energy systems. Preventative maintenance is proactive; it involves scheduled inspections, cleaning, lubrication, and component replacements based on manufacturer recommendations and predictive models. The goal is to prevent failures before they occur. This includes tasks like regular inspections of solar panels for soiling or damage, lubricating wind turbine gearboxes, and conducting thermal imaging scans of electrical connections. Corrective maintenance, on the other hand, is reactive. It’s performed after a component or system has failed, focusing on repairing or replacing the broken part to restore functionality. This includes replacing a failed inverter in a solar system or repairing a damaged wind turbine blade. While corrective maintenance is necessary, preventative maintenance is significantly more cost-effective in the long run by reducing downtime, extending equipment lifespan, and mitigating the risk of major failures.

Q 27. How familiar are you with relevant safety standards and regulations concerning renewable energy system maintenance?

I’m highly familiar with relevant safety standards and regulations governing renewable energy system maintenance. My knowledge encompasses OSHA (Occupational Safety and Health Administration) standards, IEC (International Electrotechnical Commission) standards for electrical safety, and any specific local regulations relevant to wind or solar projects. This includes working at heights, lockout/tagout procedures for electrical safety, and proper handling of hazardous materials like lubricating oils. Safety is paramount in my work, and I always prioritize adhering to all applicable regulations and best practices. I’ve actively participated in safety training and hold certifications to demonstrate my competency in this area. A strong safety culture is essential to prevent accidents and ensure the well-being of the maintenance team and the public.

Q 28. Describe your experience collaborating with other technicians and engineers on renewable energy maintenance projects.

Collaboration is a cornerstone of successful renewable energy maintenance projects. I have extensive experience working with diverse teams, including other technicians, engineers, and project managers. My communication skills are strong; I’m adept at clearly conveying technical information, explaining complex issues in simple terms, and working effectively as part of a team to achieve project goals. I’m comfortable using project management software and tools to coordinate work, share information, and track progress. For example, during a recent wind turbine repair, I collaborated with a structural engineer to assess damage to the tower and coordinated with a crane operator for safe access to the nacelle. Effective communication and teamwork were vital to completing the repair safely and efficiently.

Key Topics to Learn for Renewable Energy System Maintenance Interview

- Solar PV System Maintenance: Understanding panel cleaning, inverter troubleshooting, string voltage monitoring, and preventative maintenance schedules. Practical application: Diagnosing and resolving performance issues in a solar array.

- Wind Turbine Maintenance: Familiarization with gearbox inspection, blade maintenance and repair, yaw system operation, and safety protocols. Practical application: Explaining the process of a scheduled blade inspection and identifying potential risks.

- Battery Storage System Maintenance: Knowledge of battery chemistry, state of charge monitoring, thermal management, and safety precautions. Practical application: Troubleshooting a battery system experiencing reduced capacity or unusual temperature fluctuations.

- Data Acquisition and Analysis: Understanding SCADA systems, performance monitoring, and data interpretation to optimize system efficiency. Practical application: Using collected data to identify and address recurring maintenance issues.

- Grid Integration and Compliance: Knowledge of grid codes, safety regulations, and interconnection requirements. Practical application: Explaining the process of ensuring a renewable energy system complies with relevant grid standards.

- Troubleshooting and Problem-Solving: Developing systematic approaches to diagnose and resolve complex issues within renewable energy systems. Practical application: Demonstrating a structured approach to identifying the cause of a system failure.

- Health and Safety Regulations: Understanding and applying relevant safety regulations and procedures for working on renewable energy systems. Practical application: Describing safe work practices for accessing and maintaining a wind turbine.

Next Steps

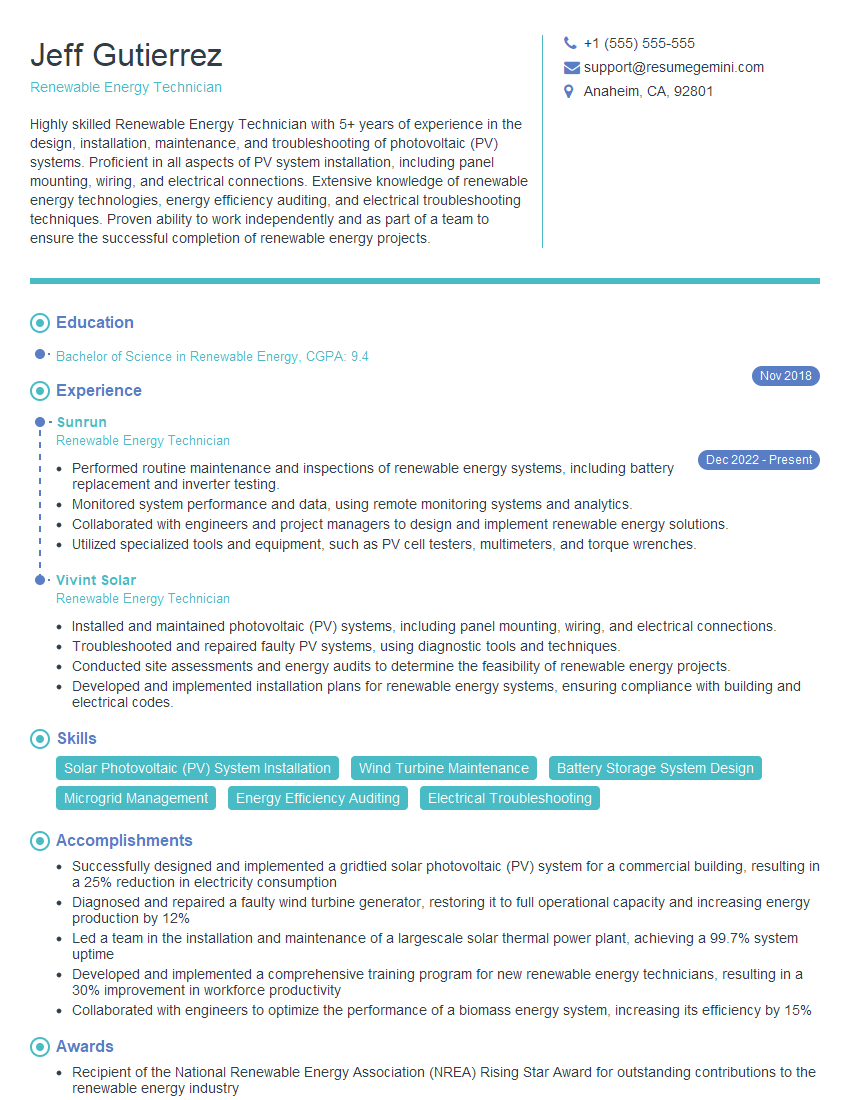

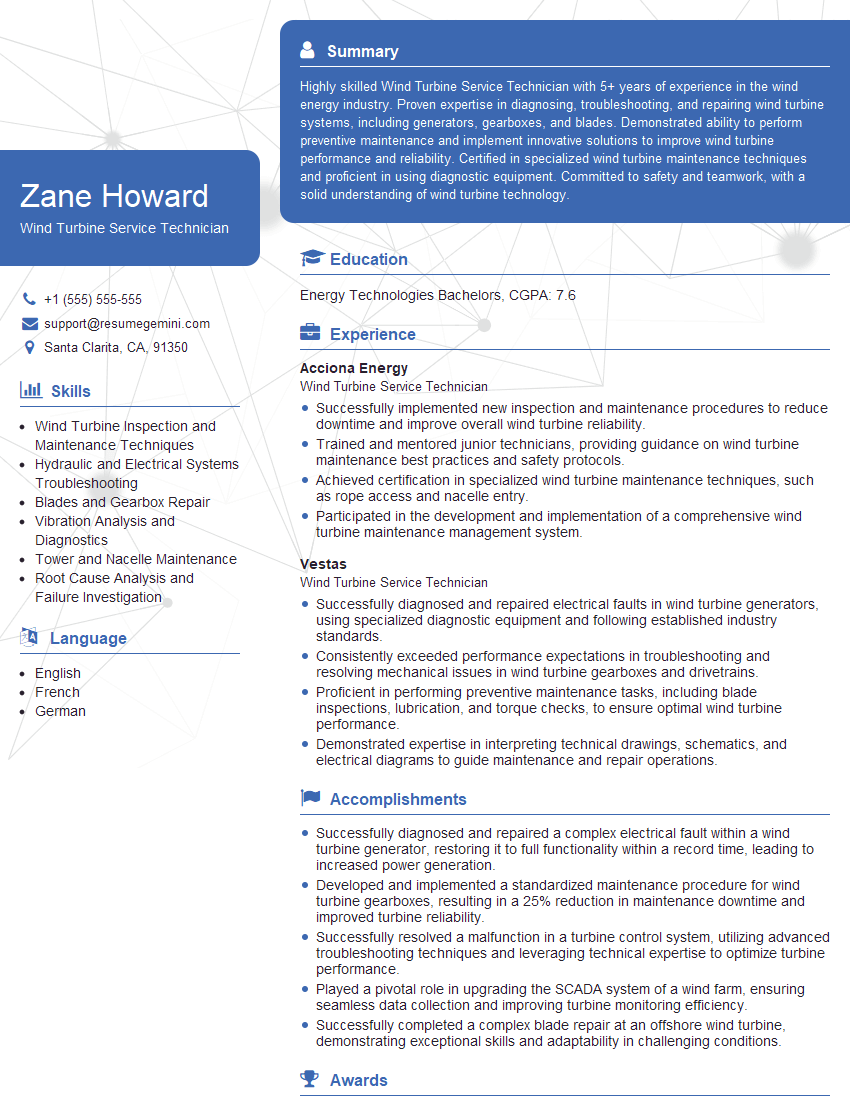

Mastering Renewable Energy System Maintenance opens doors to a rewarding and impactful career, contributing to a sustainable future. In today’s competitive job market, a well-crafted resume is crucial. An ATS-friendly resume maximizes your visibility to recruiters and hiring managers. To significantly enhance your job prospects, we recommend using ResumeGemini to create a professional and impactful resume tailored to the Renewable Energy sector. ResumeGemini provides examples of resumes specifically designed for Renewable Energy System Maintenance professionals, allowing you to craft a compelling document that showcases your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.