Preparation is the key to success in any interview. In this post, we’ll explore crucial Repairing Drywall Damage interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Repairing Drywall Damage Interview

Q 1. Describe your experience with different types of drywall repairs (e.g., small holes, large cracks, water damage).

My experience encompasses the full spectrum of drywall repair, from minor blemishes to extensive water damage. Small holes, often caused by picture hooks or minor impacts, are a common fix. Larger cracks, frequently stemming from settling foundations or structural shifts, require more involved techniques. Water damage repairs are arguably the most challenging, demanding careful removal of damaged drywall, mold remediation, and meticulous reconstruction to prevent future problems. Each type necessitates a different approach, and my expertise lies in diagnosing the underlying cause and selecting the most appropriate repair method for long-lasting results.

For instance, a simple nail hole might only need spackle and sanding, whereas a large crack demands the use of drywall mesh tape and multiple coats of compound for strength and a seamless finish. Water damage repair often includes replacing the entire section of drywall, addressing the source of the moisture, and using specialized mold-resistant products.

Q 2. What tools and materials are essential for effective drywall repair?

Effective drywall repair demands the right tools and materials. The essentials include:

- Drywall knife (6”, 12”): For applying and smoothing compound.

- Putty knife (flexible): Ideal for reaching tight corners and applying compound smoothly.

- Drywall tape (paper or fiberglass): To reinforce seams and cracks.

- Drywall compound (joint compound): Available in different settings (lightweight, all-purpose) depending on the project.

- Sandpaper (various grits): For smoothing out the compound.

- Sanding sponge: Provides a more controlled sanding approach in tight areas.

- Utility knife: For cutting drywall and removing damaged sections.

- Measuring tape & pencil: For accurate measurements and markings.

- Safety Glasses & Dust Mask: Protecting your eyes and lungs from dust and debris.

- Primer: To ensure proper paint adhesion and prevent discoloration.

Having the right tools significantly enhances efficiency and the quality of the finished repair.

Q 3. Explain the process of patching a small hole in drywall, including surface preparation and finishing.

Patching a small hole is a relatively straightforward process. First, clean the area around the hole thoroughly, removing any loose debris. Then, use a utility knife to create clean, straight edges around the hole. This prevents the patch from cracking later. Next, apply a small amount of drywall compound to the hole, pushing it into the hole slightly with a putty knife. Let this initial coat dry completely. Once dry, carefully apply a thin layer of compound over the patch, feathering the edges to blend seamlessly with the surrounding drywall. After this layer dries, lightly sand the surface until smooth. Repeat this process as needed, until the patch is flush with the surrounding surface and a flawless finish is achieved. Finally, prime and paint to match the existing wall.

Imagine patching a small hole as applying a small ‘bandage’ to the wall. The key is ensuring the bandage blends in perfectly after all the layers dry and are sanded properly.

Q 4. How do you repair a larger crack or hole in drywall?

Repairing larger cracks or holes requires a more substantial approach. For cracks, apply drywall tape over the crack, embedding it firmly into the drywall compound. Multiple layers of compound are necessary, allowing each layer to dry completely before applying the next. For larger holes, a piece of drywall may need to be cut and installed to replace the missing section. This involves cutting a clean square or rectangular section around the hole to create a neat opening for the replacement patch. Secure the patch with screws, and then apply multiple layers of compound, taping the edges to ensure a solid bond. Sanding and finishing are crucial for a seamless repair. It’s akin to constructing a mini-wall within the larger wall, ensuring stability and a uniform finish.

Q 5. How do you match the texture of existing drywall when making a repair?

Matching existing drywall texture is crucial for a professional-looking repair. The texture of the existing drywall can vary widely (e.g., smooth, knockdown, orange peel, etc.). For smooth walls, achieving a seamless blend is relatively easier. For textured walls, the repair process needs to mimic the existing texture. This often involves using the appropriate tools to create the texture after the compound is dry. For example, a knockdown texture can be created using a special knife, and orange peel textures can be replicated using a specialized roller. Careful observation of the existing texture and employing appropriate techniques is essential to achieving a flawless match. It’s like artistic replication—you need to ‘read’ the original texture to perfectly copy it.

Q 6. What are the different types of drywall tape and which is best for certain applications?

Drywall tape comes in different types: paper tape and fiberglass tape. Paper tape is suitable for smaller cracks and seams where flexibility is not crucial. It’s more economical but requires multiple coats of compound to ensure adequate strength. Fiberglass tape is more durable and flexible, making it ideal for larger cracks, corners, and areas requiring greater strength. It’s a bit more expensive, but it minimizes the need for extensive sanding. The choice of tape depends on the size and severity of the damage. For simple repairs, paper tape works well, while fiberglass tape is best for more significant repairs or areas prone to movement.

Q 7. Describe your experience with drywall mud application and finishing techniques.

Drywall mud (joint compound) application is a skill honed through practice. The key is to apply thin, even coats, allowing each coat to dry completely before applying the next. Overloading the area leads to cracking and uneven surfaces. The finishing techniques involve using the appropriate tools to smooth out the compound and feather the edges, gradually blending the repair seamlessly with the surrounding wall. Sanding between each coat is crucial to achieve a smooth, even surface. This process is iterative, requiring patience and attention to detail. Imagine layering a cake – each layer needs to be even and smooth before adding the next for the final, perfect product. Mastering the application and finishing ensures a professional, durable, and aesthetically pleasing repair.

Q 8. How do you ensure a seamless finish after drywall repair?

Achieving a seamless finish after drywall repair is crucial for a professional-looking result. It’s all about meticulous preparation and careful application of the finishing compound. Think of it like baking a cake – if you don’t properly prepare your ingredients and follow the recipe, the final product won’t be as good.

The key is multiple thin coats of joint compound, carefully feathered out to blend seamlessly with the surrounding wall. Each coat needs to be completely dry before applying the next. This prevents cracking and ensures a smooth, even surface. I use a broad knife for the initial coats to cover the repair, then progressively smaller knives for subsequent coats to feather the edges. Finally, a fine-grit sanding block ensures a perfectly smooth surface, ready for paint.

For example, on a large hole repair, I might start with a 12-inch knife, then move to a 6-inch knife, and finish with a 4-inch knife for the final feathering. This gradual reduction in knife size helps blend the compound seamlessly with the existing wall.

Q 9. What are the common causes of drywall damage, and how do you address them?

Drywall damage stems from various sources. Impacts from moving furniture or accidental bumps create holes and dents. Water damage, often from leaks, causes swelling, discoloration, and potential mold growth. Improper installation can lead to cracks and weak points. Even settling foundations can stress the drywall, causing cracks to appear.

- Impacts: These are usually straightforward repairs involving patching and filling the damaged area.

- Water Damage: Requires more extensive work, often necessitating the removal of the damaged section and replacement with new drywall. Mold remediation is crucial here.

- Improper Installation: This often involves identifying and addressing the underlying issue causing the damage before attempting a repair.

- Foundation Settling: May require the expertise of a structural engineer and could involve significant structural repairs before drywall work can begin.

Addressing these issues involves assessing the extent of damage and choosing the appropriate repair technique. Minor damage can be fixed with patching compounds, while severe damage needs complete replacement.

Q 10. Describe your experience repairing water-damaged drywall.

Water-damaged drywall is one of the most challenging repairs. My approach is systematic and prioritizes safety and thoroughness. I always start by assessing the extent of the damage; sometimes, the damage extends far beyond what’s visibly apparent. I check for moisture penetration behind the drywall using a moisture meter. If the damage is extensive, the affected drywall must be removed, taking care to avoid spreading any potential mold.

Once the damaged area is removed, the underlying framing should be checked for damage. Any damaged wood should be repaired or replaced. Then, I allow the area to dry completely, often using fans and dehumidifiers. After drying, I install new drywall, ensuring proper sealing and securing. Antimicrobial primer is applied before any finishing compounds to inhibit mold growth.

I remember one job where a burst pipe caused extensive water damage to an entire bathroom wall. We had to remove the entire section, treat for mold, and replace the framing, plumbing, and then the drywall. The meticulous drying process took several days. The final result was a perfect repair, indistinguishable from the original wall.

Q 11. How do you handle mold remediation during drywall repair?

Mold remediation is critical when dealing with water-damaged drywall. Mold isn’t just unsightly; it’s a significant health hazard. I never attempt mold remediation without proper personal protective equipment (PPE), including an N95 respirator, gloves, and eye protection.

My approach involves first removing the affected drywall and thoroughly cleaning the area with a solution specifically designed for mold removal. I then allow the area to dry completely. Sometimes, a professional mold remediation specialist is necessary for extensive mold infestations. Once the area is confirmed mold-free by testing, if necessary, new drywall can be installed, and an antimicrobial primer is essential before applying any finishing compounds.

Safety is paramount. Improper mold removal can spread spores, exacerbating the problem. I always follow all local and national guidelines and regulations for handling mold.

Q 12. Explain your approach to sanding and prepping the surface for painting after drywall repair.

Sanding and prepping for painting are the final, crucial steps in achieving a flawless finish. It’s about achieving a perfectly smooth surface to ensure the paint adheres evenly. Think of it as preparing a canvas for a masterpiece – a smooth surface ensures a flawless painting.

I use progressively finer grits of sandpaper, starting with a coarser grit to remove any significant imperfections, gradually moving to a finer grit for a smooth finish. I use a sanding block to ensure even sanding and prevent creating low spots. After sanding, I thoroughly clean the area with a tack cloth to remove all dust. This is crucial to prevent the dust from interfering with the paint’s adhesion.

For example, I might start with 80-grit sandpaper to remove any larger bumps and finish with 220-grit sandpaper for a super-smooth finish. Then, a light dusting with a tack cloth is essential. This attention to detail is what separates a good repair from a great one.

Q 13. What safety precautions do you take while working with drywall?

Safety is my top priority. Drywall work involves potential hazards, including dust inhalation, cuts from sharp tools, and falls from ladders. I always wear appropriate safety gear, including safety glasses, a dust mask (ideally a respirator), work gloves, and sturdy closed-toe shoes.

When working at heights, I use a stable ladder and ensure it’s properly positioned. I always follow proper lifting techniques to prevent back injuries. I dispose of all waste materials properly, following local regulations. The workspace is kept clean and organized to prevent trips and falls.

Regularly inspecting and maintaining my tools is essential to prevent accidents. A dull tool is more dangerous than a sharp one because it requires more force, increasing the risk of injury.

Q 14. How do you manage your time effectively on a drywall repair project?

Effective time management on a drywall repair project is crucial for meeting deadlines and staying within budget. I begin by thoroughly assessing the job, creating a detailed plan that outlines all the necessary steps, including material acquisition and scheduling.

I break the project down into manageable tasks, prioritizing critical steps like mold remediation and structural repairs. I allocate realistic timeframes for each task, accounting for potential delays. Maintaining a clean and organized workspace allows me to work efficiently and prevents time wasted searching for tools or materials.

Communication with clients is also key. Keeping them informed of progress and addressing any concerns promptly prevents misunderstandings and delays. This organized approach ensures efficient project completion and client satisfaction.

Q 15. Describe your experience working with various types of drywall (e.g., fire-resistant, moisture-resistant).

My experience encompasses a wide range of drywall types, crucial for achieving both aesthetic appeal and structural integrity. I’ve worked extensively with standard drywall, which forms the basis of most interior walls. However, my expertise also extends to specialized types such as fire-resistant drywall (often denoted as Type X), which features a gypsum core with added fiberglass for superior fire protection. I understand the importance of its proper installation in areas demanding enhanced fire safety, like stairwells or around fireplaces. Similarly, I’m proficient in working with moisture-resistant drywall (often green-board), essential for high-humidity environments such as bathrooms and kitchens. This type of drywall is designed to withstand moisture without significant deterioration, preventing mold and mildew growth. Understanding the properties of each type – from its density and strength to its reaction to moisture and fire – is key to delivering a successful and long-lasting repair.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate repair method for different types of drywall damage?

Determining the right repair method depends entirely on the nature and extent of the damage. Minor dents or holes, for instance, can often be repaired using a simple patching technique involving joint compound and sanding. This involves cutting a clean, square hole, applying a mesh tape, and carefully filling with joint compound in several thin coats. Larger holes might require cutting out a section of drywall and replacing it with a new piece. For cracks, the approach varies. Hairline cracks often require only filling and smoothing, while wider, more significant cracks could indicate structural issues, requiring investigation and possible reinforcement before repair. The type of drywall is also a factor. Repairing a hole in moisture-resistant drywall requires using compatible materials to maintain the integrity of the moisture barrier. In essence, I employ a diagnostic approach, carefully assessing the damage and choosing the most appropriate and effective solution.

Q 17. Explain your experience with drywall installation.

My drywall installation experience is extensive, ranging from straightforward new construction to intricate renovation projects. I’m proficient in all aspects, starting with the proper framing and ensuring a level and plumb surface. Accurate measurements and precise cutting are paramount for a flawless finish. This includes carefully measuring and cutting drywall sheets to fit, ensuring tight seams and minimal waste. Secure fastening using appropriate screws is critical for structural stability, and this necessitates understanding the spacing requirements based on the drywall thickness and the application. I am familiar with various techniques including taping and mudding, followed by sanding to achieve a perfectly smooth surface, ready for finishing. I am comfortable working with both standard and specialized drywall types and always prioritise efficient and high-quality workmanship.

Q 18. What is your experience with different types of drywall finishes (e.g., knockdown, orange peel)?

Drywall finishing encompasses a range of textures, each contributing to a unique aesthetic. I’m experienced in creating a variety of finishes, including the smooth finish preferred in modern designs, as well as textured finishes like knockdown and orange peel. Knockdown involves applying a thick coat of joint compound and then using a special tool to create a textured, slightly rough finish. Orange peel, on the other hand, involves a less pronounced, more subtle texture that resembles the skin of an orange. Achieving these finishes consistently requires skill and practice, including understanding the appropriate techniques for applying the compound and the tools needed to create the desired texture. Proper sanding and priming are also crucial for a professional finish. The choice of finish depends on the overall design and personal preference of the client.

Q 19. How do you handle difficult situations such as mismatched textures or colors?

Mismatched textures or colors can be challenging, but I approach these situations systematically. For mismatched textures, carefully blending the old and new textures is key. This could involve applying a similar texture to the newly repaired area, employing techniques that seamlessly integrate it with the existing finish. If the texture difference is significant, you may need to re-texture a larger section to ensure uniformity. Color matching demands precision. I typically take a sample of the existing paint to a paint store for color matching. In certain cases, particularly with older homes, achieving an exact match might be impossible. In such instances, I’ll suggest to the client a subtle tone that complements the existing color instead of an exact match.

Q 20. How do you ensure the structural integrity of the drywall after repair?

Maintaining structural integrity is paramount. This starts with proper preparation. When repairing holes or replacing sections, I ensure that the framing underneath is sound and properly secured. Using the right screws to fasten new drywall pieces is crucial, spaced correctly to prevent cracking and ensure stability. Applying joint compound correctly, avoiding overly thick coats that can cause cracking, also contributes. For larger repairs, I might add additional support, such as furring strips, to reinforce the area. Essentially, my approach ensures that the repair doesn’t just look good, but also adds to the overall strength and durability of the wall.

Q 21. Describe your experience working in teams.

Teamwork is fundamental in this field, particularly in larger projects. My experience includes working effectively within teams, collaborating effectively with other tradespeople. This includes clear communication, coordinating schedules, and respecting the roles of each team member. For instance, working with painters requires careful timing to ensure that the drywall repair is completely dry and ready before painting begins. On larger projects, it’s vital to have a lead person coordinating the workflow efficiently, helping prevent delays and maintain a high standard of work throughout the project. Good communication and a collaborative spirit are crucial for success in a team setting.

Q 22. What are your strengths and weaknesses in relation to drywall repair?

My greatest strength in drywall repair lies in my meticulous attention to detail and my ability to seamlessly blend repairs for an invisible finish. I’m proficient in all aspects, from minor patching to extensive wall reconstruction. I’m also highly efficient and organized, ensuring projects are completed on time and within budget. A weakness I’m actively working on is delegation. While I can handle large projects independently, learning to effectively manage a team will further enhance my project throughput and efficiency. I find that focusing on clear communication and process improvement is key to overcoming this.

Q 23. How do you stay up-to-date with the latest techniques and materials in drywall repair?

Staying current in drywall repair requires a multi-pronged approach. I regularly subscribe to industry publications like Walls & Ceilings and attend workshops and seminars offered by organizations like the Gypsum Association. I actively seek out manufacturer training on new products and techniques, as material science and application methods are constantly evolving. Online forums and communities also provide valuable insights into innovative solutions and best practices from other professionals. Continuous learning is crucial in this ever-changing field.

Q 24. How do you handle unexpected problems or challenges during a project?

Unexpected problems are par for the course in construction. My approach is methodical: first, I carefully assess the situation. For example, discovering hidden plumbing during a seemingly simple patch job requires immediate problem-solving. This might involve contacting the homeowner, contacting a plumber for assistance, or re-evaluating the scope of work and adjusting the plan accordingly. Open communication with the client is paramount throughout the process. I document everything – challenges, solutions, and cost adjustments – to maintain transparency and avoid misunderstandings.

Q 25. What is your experience with estimating the cost of drywall repair?

Estimating drywall repair costs requires a keen eye for detail and experience. I begin by carefully assessing the damage, considering factors such as the size of the affected area, the type of damage (e.g., small hole vs. water damage), the need for specialized materials (e.g., moisture-resistant drywall), and the complexity of the repair (e.g., matching textures and paint). I then factor in labor costs, material costs, and potential unforeseen issues. I provide detailed, itemized estimates to ensure clients are fully informed and to minimize surprises. My years of experience have honed my ability to create accurate estimates that are both competitive and profitable.

Q 26. Describe a situation where you had to solve a complex drywall repair problem.

I once faced a challenging repair involving extensive water damage in a bathroom. The existing drywall was severely compromised, and the mold remediation was substantial. The complexity stemmed from the need to carefully remove the damaged drywall without compromising surrounding areas, then thoroughly clean and sanitize the affected area before installing new moisture-resistant drywall. The tricky part was matching the existing texture and painting, which I painstakingly matched with various techniques and multiple coats to ensure a perfect, seamless finish. The successful completion of this project highlighted my problem-solving skills and attention to detail.

Q 27. What is your preferred method for cleaning up after a drywall repair project?

Cleaning up after a drywall repair project is crucial for both client satisfaction and my own professional reputation. My process begins during the repair itself: I use drop cloths to protect the surrounding area, and I diligently clean up debris as I go. Following the repair, I carefully remove any remaining dust and debris using a shop vacuum, followed by a thorough wipe down of the area with a damp cloth. Finally, I always double-check the work area for any overlooked imperfections before leaving the jobsite. Thorough cleanup is a key element in my commitment to providing a professional and polished service.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills, and are in line with the industry standard for experienced drywall repair professionals in this region. I’m open to discussing a specific salary range after learning more about the responsibilities and benefits associated with this position. I’m confident that my contributions will quickly demonstrate the value I bring to your team.

Key Topics to Learn for Your Drywall Repair Interview

- Assessing Damage: Identifying different types of drywall damage (holes, cracks, water damage), understanding the severity and appropriate repair methods.

- Surface Preparation: Techniques for cleaning, patching, and preparing the damaged area for repair, including the proper use of joint compound.

- Patching Techniques: Mastering various patching methods for different sized holes and cracks, from small nail holes to large sections of damaged drywall. Understanding the use of mesh tape and appropriate drying times.

- Finishing Techniques: Sanding techniques for achieving a smooth, seamless finish, including the use of different grit sandpaper and understanding the importance of feathering the edges.

- Material Knowledge: Familiarity with different types of drywall (e.g., standard, moisture-resistant), joint compounds, primers, and paints. Understanding their properties and applications.

- Tool Proficiency: Demonstrating knowledge and experience with essential tools like putty knives, sanding tools, utility knives, and measuring instruments.

- Problem-Solving: Discussing approaches to common challenges such as uneven surfaces, cracks reappearing, or dealing with difficult textures.

- Safety Procedures: Highlighting awareness of safety protocols when using tools and handling materials, including dust control and proper ventilation.

- Repairing Different Materials: Understanding how to repair drywall damage in conjunction with other building materials like wood, metal, or plaster.

Next Steps: Level Up Your Drywall Repair Career

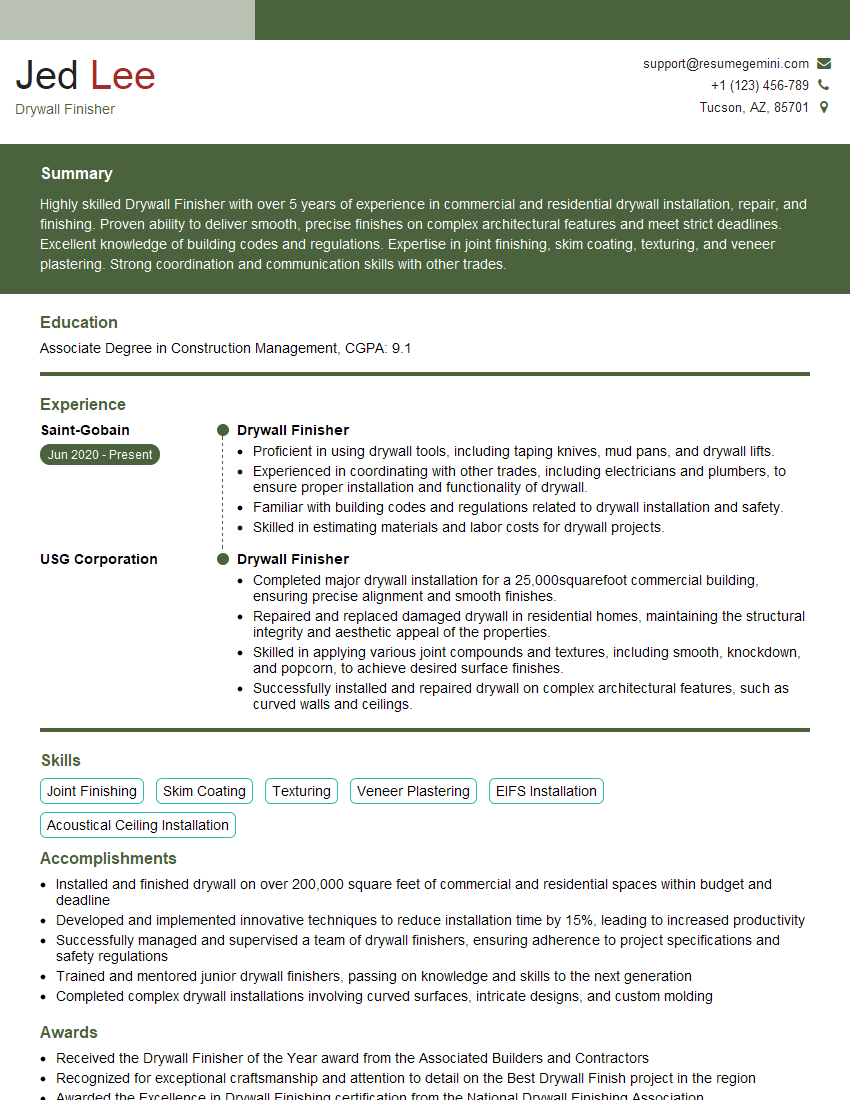

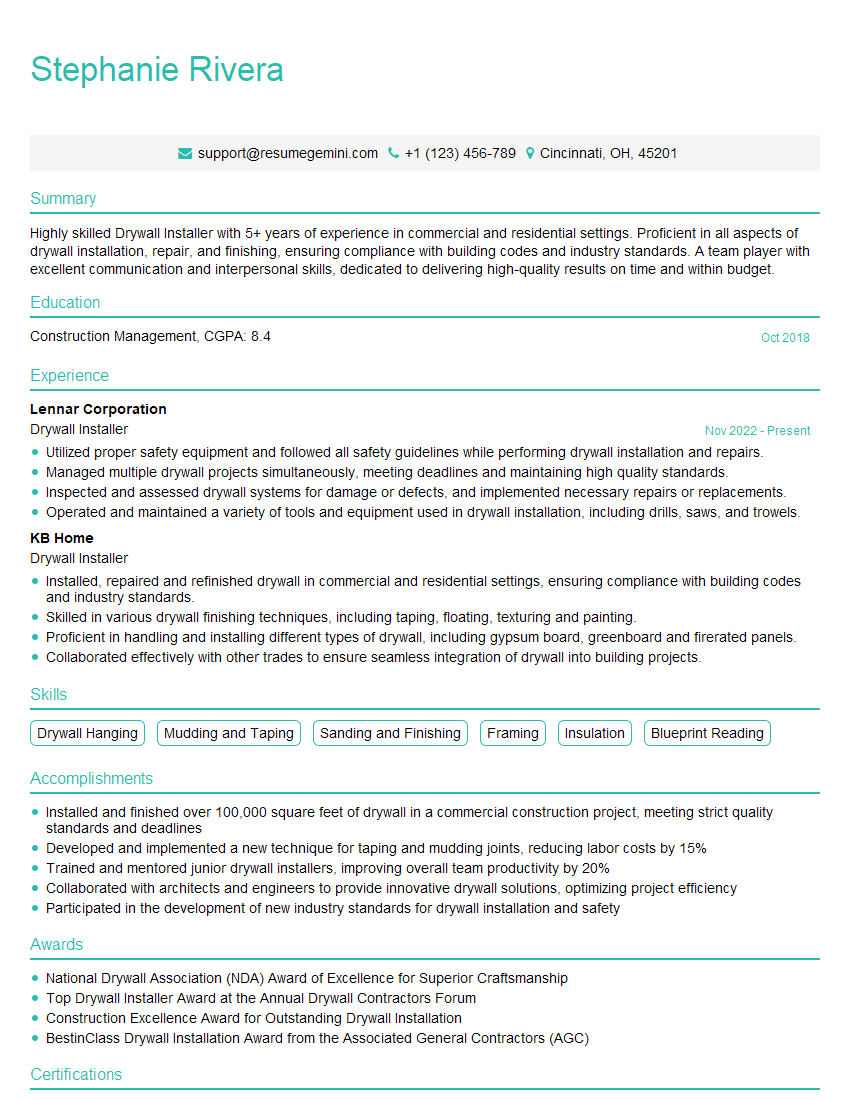

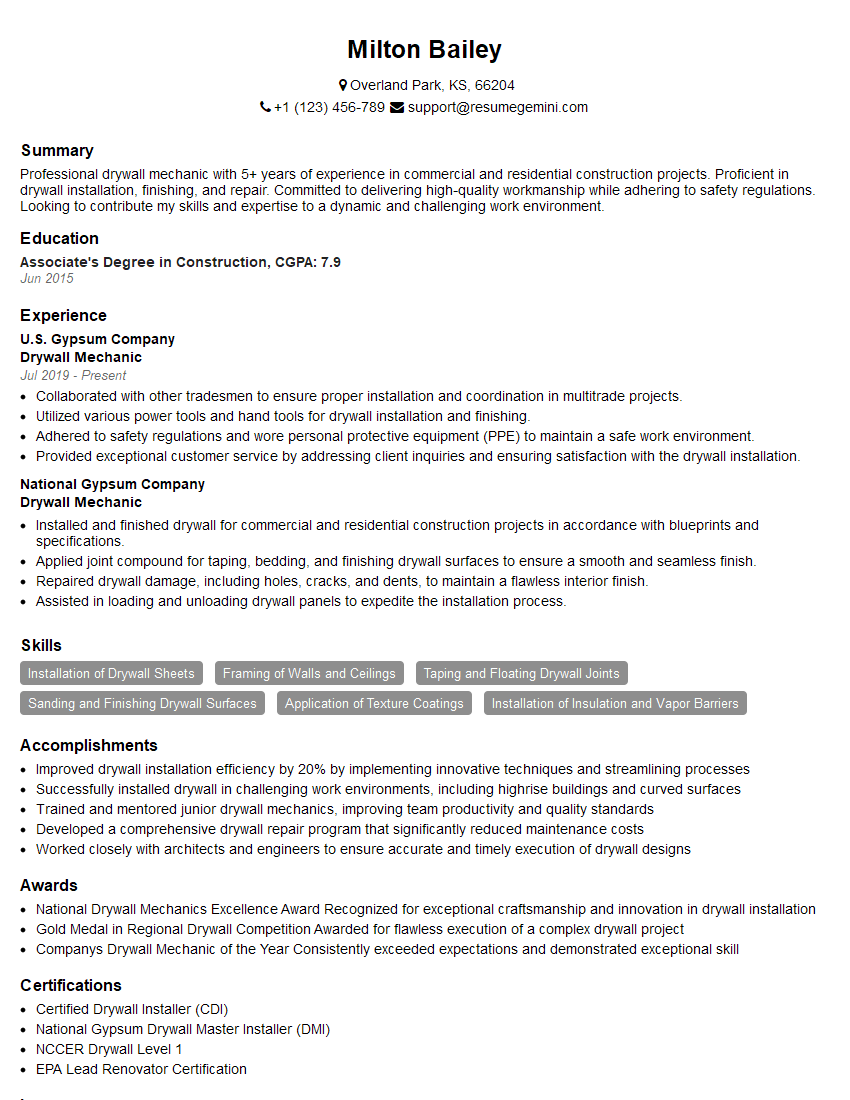

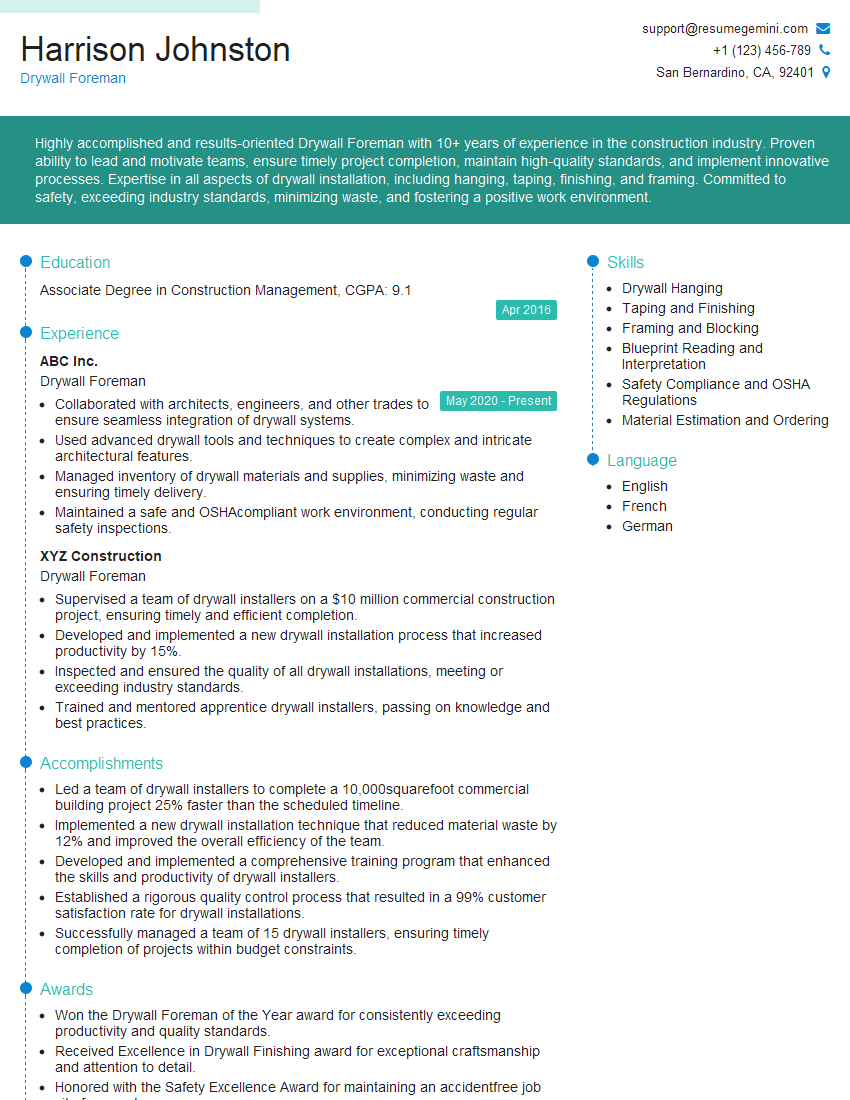

Mastering drywall repair opens doors to diverse opportunities in construction, renovation, and home improvement. To maximize your chances of landing your dream role, a strong, ATS-friendly resume is crucial. ResumeGemini can help you craft a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored to drywall repair professionals, giving you a head start in showcasing your expertise. Invest time in building a compelling resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.