The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Residential Electrical Systems interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Residential Electrical Systems Interview

Q 1. Explain the National Electrical Code (NEC) and its relevance to residential wiring.

The National Electrical Code (NEC) is a widely adopted set of standards for electrical wiring and installation in the United States. Think of it as the rule book for safe and effective electrical work. It’s not a law itself, but local jurisdictions often adopt it as the legal minimum for electrical safety. For residential wiring, the NEC dictates everything from the size and type of wire to be used, to the placement of outlets and switches, and the installation of safety devices like ground fault circuit interrupters (GFCIs) and arc-fault circuit interrupters (AFCIs). Compliance with the NEC is crucial to prevent electrical hazards like fires, shocks, and electrocution, protecting both homeowners and electricians.

For example, the NEC specifies minimum wire gauge sizes based on the amperage draw of appliances and circuits. Using undersized wire can lead to overheating and fire hazards. It also mandates the use of GFCIs in kitchens and bathrooms to protect against electrical shocks from water contact.

Q 2. Describe the different types of residential electrical panels and their applications.

Residential electrical panels, also known as breaker boxes or service panels, are the central distribution points for electricity in a home. They contain circuit breakers, which act as safety switches, protecting circuits from overloads and short circuits. Several types exist:

- Fuse panels: Older homes may have fuse panels, using fuses instead of circuit breakers. Fuses are simpler, but once blown, they need replacement, unlike circuit breakers which can be reset.

- Circuit breaker panels: These are the most common type in modern homes. Circuit breakers offer the advantage of being resettable, saving the cost and inconvenience of replacing fuses.

- Subpanels: Larger homes or those with extensive electrical needs sometimes utilize subpanels. These distribute power from the main panel to different areas of the house, simplifying wiring and load management. They’re often found in additions or detached garages.

The choice of panel depends on the home’s size, electrical load, and the age of the installation. A qualified electrician can assess the needs and recommend the appropriate type and size.

Q 3. What are the common causes of electrical fires in residential settings?

Electrical fires in homes are a serious concern, often resulting from preventable issues. Common causes include:

- Overloaded circuits: Plugging too many appliances into one circuit causes excessive current flow, generating heat and potentially igniting nearby materials. This is like trying to force too much water through a narrow pipe – it’ll overheat and potentially burst.

- Faulty wiring: Damaged or improperly installed wiring can create short circuits, resulting in sparks and heat buildup. Think of it as a frayed wire – it’s a direct pathway for electricity to ground, causing intense heat.

- Overheating appliances: Appliances with malfunctioning components can overheat and start fires. Regular appliance maintenance is crucial.

- Loose connections: Poorly connected wires create resistance, generating heat. This is like a loose lightbulb – the resistance at the contact point causes it to heat up.

- Arcing: The jumping of electricity across a gap can cause intense heat, potentially starting a fire. This often happens in older wiring or with damaged insulation.

Regular electrical inspections and maintenance can significantly reduce the risk of these hazards. Always ensure you have qualified electricians do any complex wiring work.

Q 4. How do you troubleshoot a circuit breaker tripping repeatedly?

A circuit breaker tripping repeatedly indicates an underlying problem that needs attention. It’s a safety mechanism preventing a potentially dangerous situation. Here’s a systematic approach to troubleshooting:

- Identify the affected circuit: Note which circuit breaker tripped. This helps pinpoint the problem area in your home.

- Check for overloaded circuits: Unplug unnecessary appliances from the affected circuit. Are you running too many high-wattage devices simultaneously?

- Inspect for faulty appliances: Examine appliances connected to the circuit for signs of damage or malfunction. A faulty appliance can draw excessive current.

- Look for short circuits: Check for frayed or damaged wiring, loose connections, or any signs of overheating in outlets, switches, or junction boxes.

- Check for ground faults: If the problem involves GFCI protected circuits, the issue might be a ground fault (electricity escaping to ground) and would need a more thorough inspection.

- Call an electrician: If you can’t identify the problem or feel unsafe, call a qualified electrician. Electrical work can be hazardous, and professional help ensures safety.

Remember, a repeatedly tripping breaker isn’t just an inconvenience; it’s a potential fire hazard. Addressing the root cause is crucial for safety.

Q 5. Explain the difference between series and parallel circuits.

Series and parallel circuits are fundamental concepts in electricity. They differ in how components are connected and how current flows.

- Series Circuit: In a series circuit, components are connected end-to-end, forming a single path for current flow. If one component fails, the entire circuit breaks. Think of it like a single lane road; if there’s a blockage, nothing gets through. The total resistance in a series circuit is the sum of individual resistances (Rtotal = R1 + R2 + …).

- Parallel Circuit: In a parallel circuit, components are connected across each other, providing multiple paths for current flow. If one component fails, the others continue to function. This is like a multi-lane highway; if one lane is blocked, others remain open. The reciprocal of the total resistance in a parallel circuit is the sum of the reciprocals of individual resistances (1/Rtotal = 1/R1 + 1/R2 + …).

Residential wiring primarily uses parallel circuits. This ensures that if one appliance malfunctions, the others remain unaffected.

Q 6. Describe the process of grounding a residential electrical system.

Grounding a residential electrical system is a critical safety measure. It provides a low-resistance path for fault currents to flow to the earth, preventing dangerous voltage buildup and reducing the risk of electric shock. The process involves connecting the non-current-carrying metal parts of the electrical system (like metal boxes, conduit, and appliance casings) to a grounding electrode, typically a metal rod driven into the earth.

This grounding electrode is then connected back to the main electrical panel through a grounding wire. If a fault occurs (e.g., a hot wire touches a metal box), the fault current flows through the grounding wire to the earth, instead of causing a dangerous voltage on the metal box. This protects anyone who might touch the box. The NEC mandates specific grounding requirements to ensure safety.

Q 7. What are the safety precautions you take when working with high-voltage electricity?

Working with high-voltage electricity is extremely dangerous. Safety precautions are paramount. Here’s a non-exhaustive list:

- Lockout/Tagout (LOTO): Always lock out and tag out the power source before working on any energized equipment. This physically prevents the power from being turned back on accidentally.

- Personal Protective Equipment (PPE): Use appropriate PPE, including insulated gloves, safety glasses, and arc-flash protective clothing. This protects against electrical shocks and burns.

- Proper Tools: Use tools specifically designed for electrical work, ensuring they are properly insulated and in good condition.

- Working Alone: Never work alone on high-voltage circuits. Always have a qualified observer present.

- Emergency Response Plan: Have a well-defined emergency response plan in place, including knowing where the nearest emergency shut-off switches are and having access to medical assistance.

- Voltage Testing: Before and after working on any equipment, always test to ensure that the circuit is truly de-energized. Never trust assumptions.

High-voltage work should only be undertaken by experienced and qualified electricians. Following these safety precautions can significantly reduce the risk of accidents.

Q 8. How do you identify and replace a faulty receptacle?

Identifying and replacing a faulty receptacle involves a series of safety precautions and systematic checks. First, always turn off the power at the breaker box to the circuit supplying the receptacle. Never rely solely on the switch; always verify power is off with a non-contact voltage tester.

Next, remove the receptacle cover plate. Carefully loosen the screws holding the receptacle in the electrical box. Inspect the receptacle for any visible signs of damage, such as burn marks, loose wires, or corrosion. A common cause of failure is a loose connection causing arcing and overheating.

If the receptacle is faulty, carefully disconnect the wires. Note the wire colors and positions; taking pictures can be helpful. Replace the receptacle with a new one of the same type and rating (e.g., 15 amp, 20 amp). Connect the wires securely to the new receptacle, matching the colors and positions of the old one. Tighten the screws firmly. Reinstall the receptacle in the box, ensuring it sits flush, and attach the cover plate.

Finally, restore power at the breaker box and test the new receptacle. If it doesn’t work, double-check your wiring connections. If you’re unsure about any step, consult a qualified electrician.

Q 9. Explain the purpose and function of GFCI and AFCI breakers.

Ground Fault Circuit Interrupters (GFCIs) and Arc Fault Circuit Interrupters (AFCIs) are vital safety devices in residential electrical systems. They protect against electrical hazards in different ways.

GFCIs detect imbalances in current flow between the hot and neutral wires. This imbalance often signifies a ground fault, where current is leaking to ground (e.g., a person touching a faulty appliance). When a ground fault is detected, the GFCI quickly interrupts the circuit, preventing potential electrocution or fire. GFCIs are commonly required in kitchens, bathrooms, and outdoor locations.

AFCIs detect and interrupt potentially dangerous arcing faults. Arcing occurs when electrical current jumps across a gap, often due to loose connections, damaged insulation, or corrosion. Arcing produces intense heat that can ignite combustible materials, leading to fires. AFCIs are often required in bedrooms.

Think of it this way: GFCIs protect against shocks, while AFCIs protect against fires.

Q 10. What are the different types of wiring used in residential construction?

Several types of wiring are commonly used in residential construction, each suited to different applications. The choice depends on factors like voltage, amperage, and installation location.

- Non-metallic sheathed cable (NM-B or Romex): This is the most common type, consisting of insulated conductors enclosed in a flexible plastic sheath. It’s widely used for interior wiring.

- Metal-clad cable (BX): This type uses insulated conductors encased in a flexible metal sheath for added protection against physical damage and electromagnetic interference. It’s often used in areas prone to damage or where grounding is critical.

- Aluminum wiring: While less common in modern construction due to its susceptibility to oxidation and loosening connections, it’s still found in some older homes. It requires special considerations and connectors.

- Armored cable (AC): Similar to BX, but the metal sheath is typically more rigid. It offers better protection from damage compared to NM-B.

- Underground feeder cable (UF): Designed for direct burial in the ground, this cable is highly resistant to moisture and damage. Used for underground services.

Q 11. How do you calculate the amperage required for a specific appliance?

Calculating the amperage required for a specific appliance is crucial for proper circuit design and safety. The appliance’s nameplate typically states its wattage (W) and voltage (V). Using Ohm’s Law (Power = Voltage x Current, or P=VI), we can calculate the current (I) in amps.

Formula: I (amps) = P (watts) / V (volts)

Example: A 1500-watt microwave operating at 120 volts requires:

I = 1500W / 120V = 12.5A

Therefore, a 15-amp circuit would be sufficient, allowing for some safety margin. However, always consult the manufacturer’s recommendations and local electrical codes. It’s crucial to account for the combined amperage of all appliances on the same circuit to prevent overloading.

Q 12. Describe the steps involved in installing a ceiling fan.

Installing a ceiling fan involves several steps, starting with safety. Always turn off the power at the breaker box to the circuit supplying the ceiling fixture. Verify power is off with a non-contact voltage tester. You’ll need appropriate tools such as a voltage tester, wire strippers, wire connectors, and a level.

First, carefully remove the existing light fixture (if any), noting the wiring connections. Consult the fan’s installation manual for specific instructions. Mount the fan’s mounting bracket securely to the ceiling electrical box. Connect the wiring according to the color codes (typically black for hot, white for neutral, and bare copper or green for ground). Ensure all connections are secure and properly insulated. Attach the fan blades and motor housing.

After wiring, carefully attach the fan blades and motor housing, following the manufacturer’s instructions. Mount the light kit (if included), and test the fan and light with the power restored. Remember, if you’re uncomfortable with any step, call a qualified electrician.

Q 13. Explain the process of installing a new electrical outlet.

Installing a new electrical outlet involves ensuring safety and following the electrical code. Begin by turning off the power at the breaker box to the relevant circuit. Verify with a non-contact voltage tester. You’ll need an outlet box, receptacle, wiring, and appropriate tools.

Install an outlet box (if needed) according to the manufacturer’s instructions, ensuring it’s securely attached to the framing. Fish the wiring through the box, connecting it to the existing circuit wires according to color codes. Connect the wires to the new receptacle, securely tightening the screws. Securely mount the receptacle in the box.

Re-install the faceplate. Restore power and test the new outlet. If it doesn’t work, check your wiring connections. Remember, neat and orderly wiring is essential for safety and future maintenance.

Q 14. How do you test for voltage and continuity using a multimeter?

A multimeter is an essential tool for testing voltage and continuity in electrical systems. To test for voltage, set the multimeter to the appropriate voltage range (AC or DC, depending on the circuit). Carefully probe the multimeter leads to the hot and neutral wires. The reading should match the expected voltage (120V or 240V for most residential circuits).

To test for continuity, set the multimeter to the continuity setting (usually indicated by a diode symbol or a ‘beep’ function). Probe the leads across the component or wire you’re testing. A continuous connection should result in a beep or a low resistance reading, indicating the path is unbroken. This is useful for checking for breaks in wires or determining if a switch or other component is working correctly.

Remember, always exercise caution when using a multimeter and follow the manufacturer’s instructions. Always turn off the power before testing. Incorrect usage can lead to damage to the equipment or personal injury.

Q 15. What are the common causes of electrical shorts in a home?

Electrical shorts, a dangerous condition where electricity takes an unintended path, usually to ground, are commonly caused by several factors. Think of it like a shortcut in a road system; instead of taking the designated route, the current finds a shorter, often less safe path.

Damaged Insulation: Worn or frayed wiring, often due to age, rodents, or physical damage, exposes bare wires, creating a pathway for a short circuit. Imagine a cracked garden hose spraying water everywhere – that’s similar to exposed wiring.

Loose Connections: Over time, vibrations or temperature fluctuations can loosen connections at outlets, switches, and junction boxes. This creates high resistance points that can overheat and lead to shorts. It’s like a wobbly plug in a socket; the loose connection can cause sparking and damage.

Overloaded Circuits: Plugging too many appliances into one circuit can overload it, leading to overheating and potential short circuits. Picture a highway overloaded with cars; eventually, something will break down.

Water Damage: Water conducts electricity, and moisture getting into wiring or electrical components can cause shorts. Think of water as a highly conductive path, bypassing the intended wiring.

Foreign Objects: Metal objects or debris inside wall cavities can come into contact with live wires, causing a short circuit. It’s like a metal object falling onto exposed wires, creating an immediate short.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting electrical problems in older homes.

Troubleshooting older homes presents unique challenges. Often, the wiring is outdated, using knob-and-tube systems or aluminum wiring which are prone to failure. These older homes often lack adequate grounding, posing safety risks. My approach involves meticulous inspection. I start with a visual inspection, carefully examining visible wiring for signs of damage or deterioration. Then I use a non-contact voltage tester to verify the presence and absence of voltage at various points in the system. I also use a multimeter to measure resistance and voltage drops to pinpoint issues. For knob-and-tube systems, I carefully check for loose connections, overheated areas, and signs of corrosion. Working with aluminum wiring requires careful attention to proper termination techniques to prevent future problems. I always prioritize safety and adherence to modern electrical codes, even when working with old systems. One memorable instance involved tracing a mysterious intermittent short in a 1920s home; after hours of careful investigation, we discovered a corroded connection hidden inside a plaster wall.

Q 17. How do you ensure compliance with local electrical codes?

Ensuring compliance with local electrical codes is paramount. I always begin by obtaining a copy of the relevant codes for the specific location of the project. These codes vary by region and are updated regularly; therefore, staying current is crucial. I meticulously follow every aspect of the code during the design and installation phases. This includes proper grounding, wire sizing, circuit protection, and installation practices. Before energizing any system, I conduct thorough inspections to verify that the work conforms to all codes. I also maintain detailed records, including permits, inspection reports, and as-built drawings, all documenting the project’s compliance. If any discrepancies are found during inspections, I address them promptly and obtain the necessary approvals. This comprehensive approach helps me build safe and legally compliant electrical systems.

Q 18. What are your preferred methods for electrical system documentation?

Thorough documentation is crucial for any electrical system. My preferred methods utilize a combination of digital and physical records. I use digital tools to create detailed schematics showing the layout of the electrical system. These schematics include the location of all outlets, switches, circuits, panelboards, and other components. I annotate these drawings with key information like wire sizes, breaker ratings, and circuit descriptions. I supplement digital schematics with physical labels on all circuit breakers and junction boxes. These labels clearly show the circuits they serve and any relevant information. Finally, I maintain a comprehensive file for each project, including permits, inspection reports, and any change orders. This ensures that all documentation is readily available and easily accessible for future reference or troubleshooting.

Q 19. Explain your experience with various electrical testing equipment.

I’m proficient in using a variety of electrical testing equipment. My go-to tools include:

Multimeters: These versatile devices measure voltage, current, and resistance, allowing for comprehensive troubleshooting and testing of circuits and components.

Clamp Meters: Used for measuring current without breaking the circuit, providing a safer and quicker way to assess circuit loads.

Non-Contact Voltage Testers: Essential for safety, they quickly identify the presence of voltage without direct contact, helping prevent accidental shocks.

Meggers: These measure insulation resistance, helping identify potential problems in wiring before they lead to shorts or other failures.

Ground Testers: Used to verify proper grounding, ensuring the safety and integrity of the electrical system.

My expertise lies in selecting the appropriate equipment for specific tasks and interpreting the results accurately to diagnose and resolve electrical issues efficiently and safely.

Q 20. Describe your experience working with different types of lighting systems.

My experience encompasses a wide range of lighting systems, including incandescent, fluorescent, LED, and low-voltage lighting systems. I understand the unique characteristics and installation requirements of each type. For example, incandescent systems are straightforward, while fluorescent systems require ballasts and appropriate wiring. LED lighting presents energy-efficient solutions, requiring different power supplies and careful consideration of heat dissipation. Low-voltage systems, such as landscape lighting, need transformers and specific wire gauges. I’m familiar with dimming systems and smart lighting controls. I always choose lighting systems appropriate for the specific needs and aesthetics of a project, ensuring energy efficiency and longevity. A recent project involved designing a smart lighting system for a new home, integrating various types of lighting for both functional and ambient illumination.

Q 21. How do you handle a situation where you encounter unexpected wiring during a renovation?

Encountering unexpected wiring during a renovation is a common occurrence. My response is always methodical and safety-conscious. The first step is to de-energize the circuit completely before proceeding. I then carefully expose the wiring, noting its type, gauge, and routing. I use a non-contact voltage tester to double-check that the power is truly off. I document the findings meticulously, taking photos and detailed notes of the existing wiring. I then compare the discovered wiring to any available blueprints or documentation. I consult with the building inspector to determine if the existing wiring meets current code requirements. If the wiring is outdated or unsafe, I propose a plan to upgrade it to comply with current codes. If the wiring is sound but presents a challenge to the planned renovation, I adjust my plans to accommodate it safely and effectively. My goal is always to ensure the safety of the occupants and the longevity of the electrical system.

Q 22. What are the key differences between 110V and 220V circuits?

The primary difference between 110V and 220V circuits lies in the voltage, naturally. In the US, 110V (more accurately 120V) is used for most household circuits powering things like lights, small appliances, and outlets. 220V (or 240V) circuits, on the other hand, provide higher power for energy-intensive appliances like ovens, dryers, and air conditioners. Think of it like this: 110V is like a small stream, capable of handling a small water wheel, while 220V is a larger river, powering a much bigger water wheel.

This difference stems from the wiring and power delivery systems. 220V circuits utilize two ‘hot’ wires, each carrying 120V, with opposite polarities, resulting in a 240V potential difference. 110V circuits use one hot wire and a neutral wire. This higher voltage in 220V circuits allows for significantly higher amperage, meaning more power can be delivered without overheating the wiring.

- Safety: While higher voltage poses a greater risk, proper safety measures mitigate this. 220V outlets are designed differently to prevent accidental connection with lower-voltage devices.

- Appliance Compatibility: Appliances are designed to operate on either 110V or 220V, depending on their power requirements. Plugging a 110V appliance into a 220V outlet can result in damage or fire, while the opposite results in a lack of power.

Q 23. Explain the importance of proper wire sizing in a residential setting.

Proper wire sizing is critical for safety and efficiency in residential electrical systems. Undersized wires, carrying currents exceeding their capacity, overheat, posing a significant fire hazard. Oversized wires, while safer, are wasteful and costly. The correct wire gauge depends on the amperage the circuit needs to handle, which is dictated by the load (appliances and other devices).

Think of it like plumbing: A tiny pipe won’t handle the flow from a firehose, and a giant pipe is unnecessary for a gentle stream. The National Electrical Code (NEC) specifies the appropriate wire gauge for different amperages. For example, a 15-amp circuit generally requires 14-gauge wire, while a 20-amp circuit requires 12-gauge wire. These gauges are standardized to ensure sufficient current-carrying capacity. Improper sizing can lead to voltage drops, reduced appliance performance, and ultimately, fire hazards.

Example: A 20-amp circuit with 14-gauge wire is unsafe because 14-gauge wire is only rated for 15 amps.Q 24. Describe your experience with electrical system upgrades.

I have extensive experience in electrical system upgrades, encompassing various projects. One memorable project involved upgrading a 1950s home’s outdated knob-and-tube wiring. This obsolete system posed significant fire risks. The upgrade involved replacing the entire system with modern wiring, updating the service panel, and adding new circuits to accommodate modern appliances and increased power demands. This required careful planning, precise execution, and meticulous adherence to code.

Another example includes upgrading a residential panel from an older, lower-capacity panel to a modern, higher-capacity panel to support the addition of electric vehicle charging stations and a significant increase in the number of household devices.

In both scenarios, ensuring the homeowner understood the process, the necessity of the upgrade, and the associated costs was crucial. Comprehensive communication throughout the process, from initial assessment to final inspection, is paramount.

Q 25. How do you approach a problem where a circuit breaker keeps tripping?

When a circuit breaker keeps tripping, it’s signaling an overload or a short circuit. My approach is systematic, prioritizing safety. First, I turn off the circuit breaker to prevent further issues. Then, I systematically investigate the load on that circuit. This involves:

- Identifying the connected devices: I note down all appliances and devices powered by the tripped circuit.

- Checking for overloads: Too many high-power appliances running simultaneously can overload the circuit. This includes checking for appliances that draw a lot of power such as hair dryers, space heaters, and vacuum cleaners. A simple calculation can check if the sum of the appliance wattages exceeds the circuit’s capacity (amperage x voltage).

- Inspecting for shorts: A short circuit occurs when bare wires touch, causing a surge of current. This may involve checking for damaged cords, loose wiring, or faulty appliances.

- Testing the circuit: I use a multimeter to verify the circuit’s integrity, checking for continuity and voltage.

If the problem is not immediately apparent, I might consult the wiring diagrams to trace the circuit’s path and pinpoint the potential fault location. The goal is to identify the root cause, not just reset the breaker repeatedly.

Q 26. What are your methods for ensuring the safety of yourself and others while working on residential electrical systems?

Safety is paramount in electrical work. My safety protocols always involve:

- Lockout/Tagout (LOTO): Before working on any circuit, I always use LOTO procedures to de-energize the circuit completely, preventing accidental re-energization. This involves physically locking the breaker in the ‘off’ position and attaching a tag indicating that the circuit is being worked on.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, insulated gloves, and non-conductive footwear. This minimizes the risk of electrical shock or injury.

- Working with a Partner: Whenever possible, I work with a partner. A second set of eyes helps to identify potential hazards and ensure adherence to safety procedures.

- Understanding the system: Before commencing any work, I ensure a thorough understanding of the electrical system, referring to the blueprints or schematics if available.

- Testing for Voltage: Before any touch, I use a non-contact voltage tester to verify that the circuit is indeed de-energized.

In essence, my safety procedures emphasize prevention above all else. Rushing or cutting corners can have serious consequences.

Q 27. Explain your familiarity with smart home technology integration within residential electrical systems.

I’m familiar with the integration of smart home technology into residential electrical systems. This involves the use of smart switches, smart thermostats, and home automation systems to control lighting, appliances, and other electrical devices remotely or via scheduling. This often requires understanding different communication protocols, such as Z-Wave, Zigbee, and Wi-Fi, to ensure compatibility between devices. I am experienced in integrating these systems seamlessly into existing and new installations, ensuring compatibility and reliability. This also entails proper wiring, careful planning, and understanding the potential impact on the overall electrical load of the house. I also ensure data security and privacy considerations are addressed during these installations.

For instance, I recently integrated a smart lighting system into a new construction home. The system allowed the homeowners to control and schedule lighting remotely through an app and also enabled voice control integration via a popular smart home assistant.

Q 28. Describe your experience with troubleshooting and repairing low-voltage systems (e.g., doorbells, security systems)

Troubleshooting low-voltage systems like doorbells, security systems, and intercoms requires a different approach than high-voltage systems. It often involves tracing wires, checking connections, and testing voltage levels with appropriate low-voltage multimeters. I have extensive experience in this area. For instance, I’ve successfully resolved issues with faulty doorbells by tracing the wiring to identify a broken wire or a loose connection at the transformer or button.

Similarly, troubleshooting security systems often involves checking sensors, verifying connections to the control panel, and performing signal checks to confirm proper communication between components. This includes understanding different types of sensors, wiring schemes and addressing signal degradation and interference. My systematic approach involves isolating the problem, thoroughly testing components, and replacing faulty parts. The key is patience, attention to detail, and a good understanding of the system’s architecture.

Key Topics to Learn for Your Residential Electrical Systems Interview

- Electrical Codes and Regulations: Understand NEC (National Electrical Code) requirements for residential wiring, safety standards, and code compliance procedures. This is crucial for ensuring safe and legal installations.

- Wiring Methods and Techniques: Become proficient in various wiring methods (Romex, conduit, etc.), junction box installation, and proper grounding techniques. Be prepared to discuss practical applications and best practices for each.

- Circuit Design and Calculations: Master the ability to design safe and efficient circuits, calculate voltage drops, and select appropriate wire sizes. This includes understanding the differences between series and parallel circuits and their applications in residential settings.

- Service Panels and Distribution: Gain a thorough understanding of service panel operation, breaker sizing, and the distribution of power throughout a home. Be prepared to discuss troubleshooting common issues related to service panels.

- Common Residential Appliances and Loads: Familiarize yourself with the electrical requirements of common household appliances (HVAC, lighting, kitchen appliances, etc.) and how to calculate their load demands on the electrical system.

- Troubleshooting and Diagnostics: Develop strong problem-solving skills related to identifying and resolving electrical faults in residential settings using appropriate tools and techniques. Be ready to discuss your approach to troubleshooting scenarios.

- Safety Procedures and Practices: Emphasize your understanding of safe work practices, including lockout/tagout procedures, personal protective equipment (PPE), and hazard identification.

- Electrical Drawings and Schematics: Practice interpreting and creating residential electrical drawings and schematics. This will demonstrate your ability to understand and communicate complex electrical systems.

Next Steps

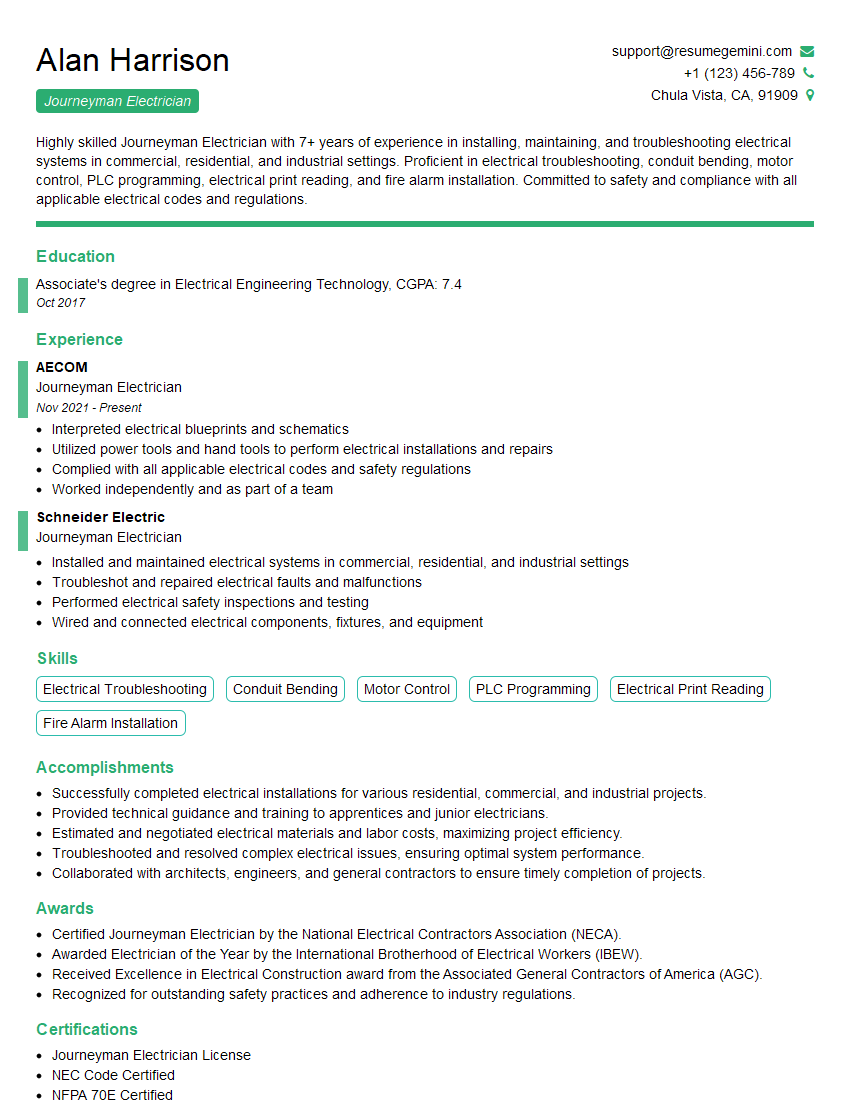

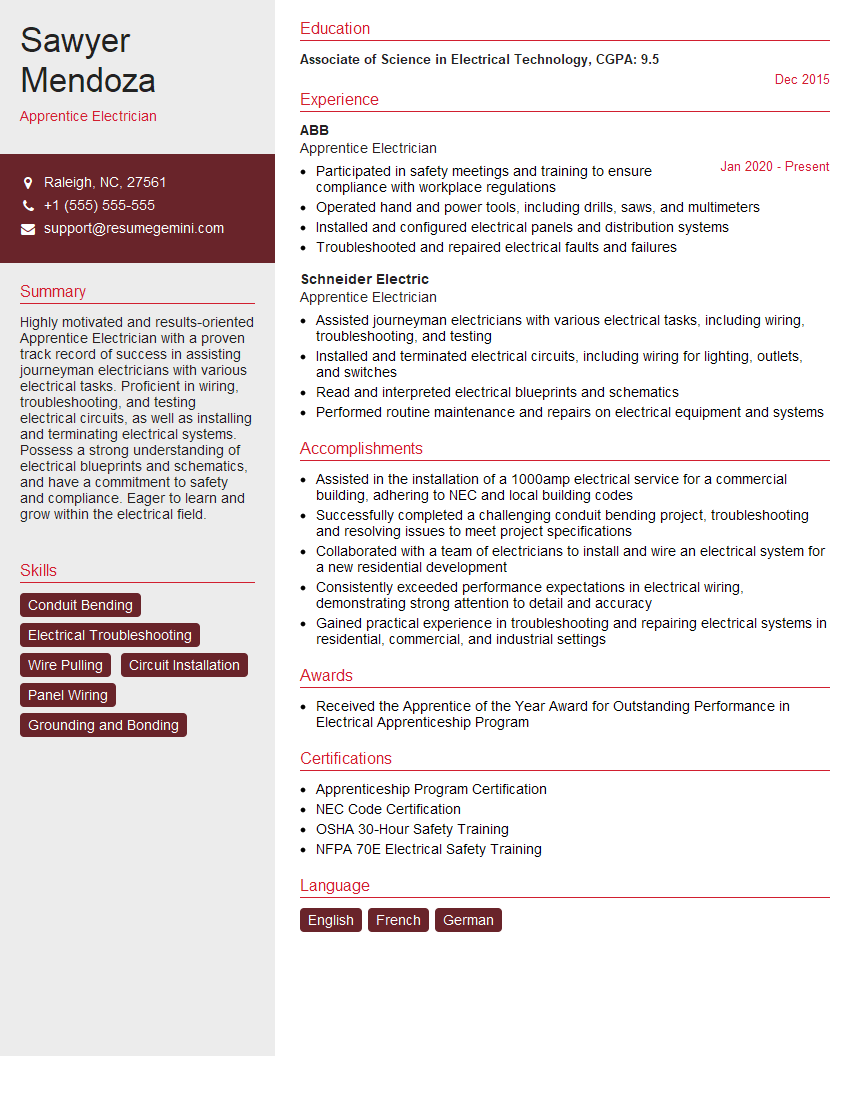

Mastering Residential Electrical Systems is key to advancing your career and securing your desired role. A strong understanding of these principles demonstrates competence and professionalism, making you a highly sought-after candidate. To maximize your job prospects, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini can be a trusted resource in this process, helping you build a compelling and impactful resume that gets noticed. Examples of resumes tailored to Residential Electrical Systems are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.