Preparation is the key to success in any interview. In this post, we’ll explore crucial Residential Roofing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Residential Roofing Interview

Q 1. What are the different types of residential roofing materials?

Residential roofing materials vary widely, each with its own pros and cons regarding cost, durability, lifespan, and aesthetic appeal. Here are some of the most common types:

- Asphalt Shingles: The most popular choice due to their affordability and ease of installation. They come in various styles (3-tab, architectural), colors, and thicknesses.

- Tile Roofing (Clay or Concrete): Durable and long-lasting, offering excellent weather protection. They are heavier than asphalt shingles and require a stronger roof structure.

- Metal Roofing (Steel, Aluminum, Copper): Extremely durable, long-lasting, and energy-efficient. They are more expensive than asphalt shingles but offer a significant return on investment.

- Wood Shakes and Shingles: A natural and aesthetically pleasing option, but they require more maintenance and are susceptible to fire and rot. They are generally more expensive.

- Slate Roofing: One of the most durable and long-lasting roofing materials, but also the most expensive. They are heavy and require specialized installation.

The best choice depends on factors like budget, climate, home style, and personal preference. For instance, in a region with heavy snowfall, a metal roof might be ideal due to its weight-bearing capacity and snow-shedding properties. In a hot, sunny climate, a tile roof might be preferable for its insulation properties.

Q 2. Explain the process of installing asphalt shingles.

Installing asphalt shingles is a multi-step process requiring precision and attention to detail. Here’s a breakdown:

- Preparation: This includes removing old shingles, inspecting and repairing the underlying decking, and ensuring the roof is properly ventilated.

- Underlayment: Installing a waterproof underlayment (felt) protects the roof deck from moisture damage in case of shingle failure. This is crucial for preventing leaks.

- Starter Strip: A strip of shingles is installed along the eaves to provide a straight, even starting point for the rest of the roofing.

- Shingle Installation: Shingles are applied in overlapping rows, starting at the bottom and working upwards. Each shingle is nailed securely to the decking, ensuring proper alignment and overlap.

- Ridge and Hip Installation: Special shingles are used to finish the ridge (highest point) and hips (angled corners) of the roof, providing a weather-tight seal.

- Clean-up: Removing debris and leftover materials is essential for completing the job professionally.

Proper shingle installation involves understanding shingle alignment, nail placement, and ensuring consistent overlapping to create a seamless and leak-proof roof. Each step is vital to the longevity of the roof. For example, neglecting proper ventilation can lead to moisture build-up and premature shingle failure. A poorly installed starter strip can cause misalignment throughout the entire roof.

Q 3. Describe your experience with roof inspections and identifying damage.

My experience with roof inspections is extensive. I’ve conducted hundreds of inspections, identifying various types of damage. I approach each inspection systematically, beginning with a thorough visual assessment from the ground and then a closer examination from the roof (using appropriate safety measures, of course!).

I look for:

- Missing or damaged shingles: This is a common sign of wear and tear and potential leaks.

- Granule loss: This indicates the shingles are nearing the end of their life and are more vulnerable to damage.

- Cracked or curled shingles: These are signs of age and potential water penetration.

- Flashing problems: Flashing is the material that seals around chimneys, vents, and other roof penetrations. Improper flashing is a major cause of leaks.

- Signs of water damage: This can include stains on the ceiling or walls, soft spots in the decking, or the smell of mildew.

- Moss or algae growth: This can accelerate shingle deterioration.

I use specialized tools like a moisture meter to detect hidden damage. I meticulously document all findings with photos and detailed reports, providing clients with clear and concise information about the condition of their roof and recommended repairs.

For instance, I recently inspected a roof with significant granule loss and discovered underlying decking damage caused by a previous leak. My report detailed the extent of the damage and recommended a full roof replacement rather than just repairs, preventing future, more costly problems.

Q 4. How do you calculate the square footage of a roof?

Calculating roof square footage isn’t always straightforward due to the varied shapes of roofs. It often involves breaking the roof into smaller, simpler shapes (rectangles and triangles).

Simple roofs (rectangles): For a simple rectangular roof, it’s simply length x width.

Complex roofs: For complex roofs with multiple sections, you need to calculate the area of each section separately and then add them together.

Example: A roof with two rectangular sections:

- Section 1: 20 feet x 30 feet = 600 square feet

- Section 2: 15 feet x 25 feet = 375 square feet

- Total: 600 + 375 = 975 square feet

Triangular sections: The area of a triangle is calculated using the formula: (1/2) x base x height. Accurate measurements are crucial, and sometimes using a 3D roof modeling software can assist in more complex cases. It’s vital to include all roof sections, including dormers and valleys, to ensure an accurate calculation of material needs.

Professional roofers often use specialized software or even rely on aerial imagery for complex roof calculations to minimize error.

Q 5. What safety precautions are essential when working on a residential roof?

Roofing is inherently dangerous. Prioritizing safety is paramount. Essential precautions include:

- Fall Protection: Always use a safety harness and anchor it securely to a solid point. Working at heights requires extreme caution.

- Proper Footwear: Wearing slip-resistant boots with good traction is essential.

- Appropriate Clothing: Loose clothing can get caught on equipment, so wear fitted attire.

- Eye Protection: Safety glasses protect from debris and falling objects.

- Hearing Protection: Power tools can be loud, so hearing protection is necessary.

- Proper Tool Handling: Secure tools and equipment to prevent accidental falls.

- Awareness of Surroundings: Be mindful of power lines, trees, and other obstacles.

- Weather Conditions: Avoid working in extreme weather conditions (high winds, rain, ice).

- Buddy System: It’s always safer to work with a partner.

I always conduct a thorough site assessment before starting any work, identifying potential hazards and implementing appropriate safety measures. Neglecting safety can lead to severe injuries or even fatalities. I personally had an instance where I nearly fell from a roof, and it was a stark reminder of how crucial it is to never compromise on safety protocols.

Q 6. What are the common problems encountered during roof repairs?

Common roof repair problems I encounter include:

- Leaks: Often caused by damaged shingles, flashing issues, or cracked roof decking. Finding the source of the leak is crucial for effective repair.

- Missing or damaged shingles: These need to be replaced to prevent further water damage.

- Damaged flashing: This needs to be repaired or replaced to prevent leaks around chimneys, vents, and other roof penetrations.

- Sagging roof: Indicates structural problems that require attention from a structural engineer.

- Moss and algae growth: Can damage shingles and reduce their lifespan.

- Ice dams: Form during winter due to poor ventilation and can cause significant damage.

- Animal damage: Birds, squirrels, and other animals can cause damage to shingles and even create entry points for pests.

Diagnosing the problem correctly is the first step in effective repair. For example, a simple leak might seem minor, but it could signal a much larger underlying issue like damaged decking or inadequate insulation. Thorough investigation is key to a long-term solution.

Q 7. How do you handle difficult clients or unexpected issues on a job site?

Handling difficult clients or unexpected issues requires professionalism, communication, and problem-solving skills.

Difficult Clients: I address concerns by actively listening, clearly explaining technical details in simple terms, and providing options. I focus on building trust and ensuring the client feels heard and understood. I might even use visual aids to explain complex concepts or show before-and-after pictures of similar projects. Documentation is key – ensuring I have a written record of agreements to avoid misunderstandings.

Unexpected Issues: When unexpected problems arise (e.g., discovering hidden rot during a repair), I immediately communicate the issue to the client, explaining the implications and suggesting solutions. Transparency and open communication are essential. I never proceed with repairs without the client’s informed consent. Often, a collaborative approach helps resolve issues smoothly and maintain client satisfaction. For example, I once discovered extensive dry rot while repairing a leak. I immediately documented the problem, discussed it with the homeowner, and jointly decided on a course of action that addressed the underlying issue before proceeding with the leak repair.

My goal is always to find a solution that satisfies both the client and maintains high standards of workmanship.

Q 8. What is your experience with different roofing ventilation systems?

Roof ventilation is crucial for extending the lifespan of a roof and preventing costly damage. I have extensive experience with various systems, including passive and powered ventilation. Passive systems rely on natural airflow, utilizing things like soffit vents (low inlets) and ridge vents (high outlets) to create a natural stack effect. This effect draws hot, moist air out from under the roof, preventing condensation and ice dams in colder climates. I’ve worked with many different soffit and ridge vent designs, from simple continuous vents to more complex, individually spaced vents.

Powered ventilation involves using fans, typically installed in the soffit or ridge, to actively force air movement. This is particularly helpful in areas with little wind or for larger homes where passive ventilation might be insufficient. I’ve specified and installed both attic fans and turbine ventilators, choosing the appropriate system based on factors like the home’s size, climate, and attic layout. For instance, a large attic in a humid climate would likely benefit from a combination of passive and powered ventilation for optimal performance. I also consider the impact of insulation and proper air sealing to maximize the efficiency of any chosen ventilation system. Poorly sealed attics negate the benefits of even the best ventilation system.

Q 9. Explain your understanding of building codes and regulations related to roofing.

Understanding and adhering to building codes and regulations is paramount in roofing. My experience encompasses familiarity with International Building Code (IBC) requirements, as well as local amendments and specific jurisdiction codes. These codes dictate aspects such as minimum slope requirements, appropriate materials for different climate zones, wind load calculations, and fire-resistant ratings. I’m proficient in interpreting these regulations to ensure each project meets all necessary safety standards and legal requirements. For example, I know the specific requirements for snow load in areas with high snowfall and adjust material selection and installation techniques accordingly. Failure to comply with these regulations can result in project rejection, costly repairs, and liability issues. I regularly consult updated code books and attend continuing education courses to stay abreast of any changes or updates in building codes.

Q 10. Describe your experience with estimating roofing projects.

Accurate estimating is vital for project profitability and client satisfaction. My approach begins with a thorough on-site inspection, where I meticulously measure the roof area, identify existing conditions (damage, material type), and note any complexities like multiple roof levels, chimneys, skylights, or dormers. I then develop a detailed scope of work that lists all materials needed, labor hours, and potential contingencies. My estimates are built using industry-standard pricing databases, updated regularly to reflect current material and labor costs.

I always account for waste factors, which can vary based on material type and roof complexity. For example, a complex shingle installation will have a higher waste factor than a simple flat roof. I also include markups for overhead and profit margins, transparently outlining the cost breakdown for the client. I’ve developed efficient processes to minimize errors and ensure the estimates accurately reflect the actual project costs. I’ve found that strong communication with the client during the estimating phase prevents misunderstandings and sets a positive tone for the project. Providing detailed, easy-to-understand estimates, with visuals where necessary, is essential for securing client trust.

Q 11. What software or tools are you proficient in using for roofing projects?

I’m proficient in various software and tools commonly used in the roofing industry. I utilize estimating software like On-Screen Takeoff and PlanSwift to create accurate and detailed project estimates. These programs help with efficient measurements, material calculations, and cost analysis. For project management, I rely on software like CoConstruct or similar platforms to track project timelines, manage communication, and maintain client records. I’m also comfortable using CAD software for detailed roof plans and diagrams when necessary. In the field, I use laser measuring tools for precision measurements and a variety of hand tools specialized for different roofing materials. Proficient use of these tools and software ensures accuracy, efficiency, and effective communication throughout the entire roofing project.

Q 12. How do you manage a roofing crew and ensure efficient workflow?

Managing a roofing crew effectively requires strong leadership, communication, and organization. I begin by clearly outlining project expectations, safety protocols, and individual roles to each team member. I emphasize teamwork and collaboration, fostering a positive and productive work environment. Daily communication is vital; I conduct regular briefings to discuss progress, address any challenges, and ensure everyone is on the same page. I’m adept at delegating tasks according to skillsets and experience levels. I also prioritize safety by consistently reinforcing safety procedures, providing necessary personal protective equipment (PPE), and conducting regular site safety inspections.

Efficient workflow management involves careful planning and scheduling. I strive to optimize material handling, ensuring materials are delivered and staged strategically to minimize wasted time and movement. I also monitor progress against the schedule, addressing any delays proactively. Regular toolbox talks cover relevant safety information, quality control techniques, and industry best practices. Building a strong, reliable team with good communication is critical for success. I firmly believe that a well-trained, motivated team directly translates to superior project outcomes and enhanced client satisfaction.

Q 13. What is your experience with different flashing types and their applications?

Flashing is crucial for preventing water intrusion, a common cause of roofing problems. I have experience with various flashing types, including step flashing (used around chimneys and walls), counter flashing (installed over step flashing), apron flashing (used at valleys and around dormers), and metal flashing (used for transitions between different roof materials). Each type serves a specific purpose, protecting vulnerable areas from water penetration.

For example, step flashing consists of individual pieces of metal installed in a staggered pattern to provide a watertight seal around a chimney. Counter flashing, installed from the top, overlaps the step flashing, creating a double barrier against water. Proper installation is critical to prevent leaks. I ensure all flashing is correctly installed, using appropriate sealant to create a watertight bond. I often incorporate high-quality, durable materials like copper or galvanized steel for enhanced longevity. Proper flashing installation is fundamental to a long-lasting, leak-free roof, and I emphasize the importance of quality workmanship in this critical aspect.

Q 14. How do you determine the best roofing solution for a particular home?

Determining the best roofing solution involves a multifaceted assessment. I begin by considering the homeowner’s budget, aesthetic preferences, and the home’s architectural style. Next, I evaluate the climate, considering factors like average snowfall, intense sunlight, and potential for extreme weather. For example, a home in a snowy region may require a roofing system that can withstand heavy snow loads, while a home in a sunny climate may need a system with high UV resistance. The existing roof’s condition plays a crucial role, determining whether a simple repair, a re-roof, or a complete roof replacement is needed. I then explore various roofing materials, analyzing their lifespan, maintenance requirements, energy efficiency, and cost-effectiveness.

Materials like asphalt shingles, tile, metal, and slate each offer unique advantages and disadvantages. Asphalt shingles are economical, readily available, and come in various colors and styles. Metal roofing is durable and long-lasting but can be more expensive. Tile offers excellent durability and aesthetic appeal, while slate provides exceptional longevity but is significantly more expensive. After a comprehensive analysis, I present the homeowner with several options, outlining the pros and cons of each, allowing them to make an informed decision that aligns with their needs and budget. This collaborative approach ensures client satisfaction and a roof system tailored to their specific requirements.

Q 15. Explain your knowledge of different types of roof structures (e.g., gable, hip).

Residential roofs come in various structural styles, each with its own characteristics and suitability for different climates and aesthetics. Understanding these structures is crucial for proper design, construction, and maintenance.

- Gable Roof: This classic design features two sloping sides that meet at a ridge, creating a triangular shape. It’s simple, effective at shedding water, and allows for good ventilation. Think of the quintessential house shape in children’s drawings.

- Hip Roof: A hip roof has sloping sides on all four sides, meeting at a ridge. It’s known for its strength and resistance to high winds, making it a popular choice in areas prone to severe weather. It’s a more complex design than a gable roof.

- Gambrel Roof: Characterized by two slopes on each side, a steeper lower slope and a shallower upper slope. It offers more usable attic space compared to a gable roof. You often see these on barns and some colonial-style homes.

- Mansard Roof: Similar to a gambrel but with even more vertical sides. It provides significant attic space and is a visually distinctive architectural feature.

- Flat Roof: While technically a very low slope, flat roofs require specialized construction and maintenance to prevent water ponding. Proper drainage is paramount.

Understanding these structural differences informs material selection, load calculations, and overall roof longevity. For instance, a gable roof might use simpler flashing details compared to a complex hip roof.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you address moisture problems in a roof?

Addressing moisture problems is paramount to preventing significant damage to the roof and the entire structure. My approach involves a multi-pronged strategy:

- Identify the Source: A thorough inspection is essential, focusing on areas prone to leaks like chimneys, valleys, flashing around vents, and skylights. I use specialized tools like moisture meters to pinpoint wet areas, even within seemingly dry areas of the roof.

- Repair Damaged Components: Once the source is identified, damaged shingles, flashing, or underlayment must be repaired or replaced. This often requires precise work to ensure a watertight seal.

- Improve Ventilation: Inadequate ventilation can trap moisture, leading to problems. This often involves installing or repairing soffit and ridge vents to create a proper airflow system, pulling moisture out from under the roofing.

- Address Grading Issues: Water pooling around the foundation can cause water to infiltrate the roof through the foundation walls. I’ll assess and suggest improvements to the grading and drainage around the building to divert water away from the foundation.

- Preventative Measures: Regular roof maintenance, such as cleaning gutters and inspecting flashing, plays a critical role in preventing future moisture issues.

For example, I once discovered a leak caused by improperly installed flashing around a chimney. By meticulously removing and reinstalling the flashing with proper sealant, the leak was resolved permanently.

Q 17. What are your problem-solving skills when dealing with leak detection and repair?

Leak detection and repair requires a systematic approach. My process emphasizes careful observation, diagnostic tools, and precise execution.

- Visual Inspection: I begin with a thorough visual inspection of the roof, looking for obvious signs of damage like missing shingles, cracked flashing, or damaged seals around penetrations.

- Moisture Meter Testing: If visual inspection is inconclusive, I utilize a moisture meter to detect hidden moisture within the roof structure. This helps pinpoint the exact location of the leak.

- Water Testing (if needed): In some cases, I might perform a controlled water test to further pinpoint the leak’s origin. This involves carefully applying water to suspect areas and observing the results.

- Repair Strategy: Once the source is identified, I develop a repair plan that addresses the root cause of the problem. This might involve replacing shingles, repairing or replacing flashing, or sealing cracks. I ensure the work is both functional and aesthetically pleasing.

- Post-Repair Inspection: After repairs, I perform a final inspection to verify that the leak is resolved and there are no new issues.

For instance, I once tracked a persistent leak to a hairline fracture in a chimney flashing that was invisible to the naked eye. By using a moisture meter, I located the exact problem area, enabling precise repair and a long-term solution.

Q 18. How familiar are you with various roofing underlayments?

Roofing underlayments are crucial for providing an extra layer of protection against moisture. Different types offer varying levels of protection and are chosen based on the project’s specific needs and budget.

- Felt Underlayment: This traditional asphalt-saturated felt is relatively inexpensive but offers less protection than synthetic options.

- Synthetic Underlayments: These are typically made from polypropylene or other durable materials. They offer superior water resistance, tear strength, and often have features such as self-adhesion for easier installation. They are more expensive than felt but offer greater protection.

- Rubberized Asphalt Underlayment: A combination of both types, offers good protection and is relatively affordable.

My selection of underlayment depends on factors such as climate (wetter climates necessitate better protection), the roof’s pitch (steeper roofs might need more robust underlayment), and budget. For example, in a high-wind area, I might choose a synthetic underlayment with enhanced tear resistance.

Q 19. Describe your experience with ice and water shield installation.

Ice and water shield is a crucial component in preventing ice dams and leaks in cold climates. It’s a self-adhering membrane installed in vulnerable areas of the roof.

My experience includes proper installation in critical zones such as:

- Valleys: Where two roof slopes meet, creating a potential water collection point.

- Around Chimneys and Vents: Penetrations in the roof are particularly susceptible to leaks.

- Eaves and Edges: The lower portions of the roof are vulnerable to ice dam formation.

- Under Shingles around Dormers or Skylights: providing additional protection for these vulnerable areas.

I ensure proper overlap and adhesion to create a continuous, waterproof barrier. Proper preparation of the roofing deck is crucial before applying the ice and water shield for best results. A poorly installed ice and water shield is worse than none at all, as it might give a false sense of security.

Q 20. How do you handle customer complaints and ensure satisfaction?

Customer satisfaction is my top priority. I handle complaints with professionalism and empathy, focusing on finding practical solutions.

- Active Listening: I listen carefully to the customer’s concerns without interruption, ensuring I fully understand their perspective.

- Thorough Investigation: I investigate the issue thoroughly, performing a detailed inspection to identify the root cause of the problem.

- Transparent Communication: I communicate my findings clearly and honestly to the customer, explaining the situation and the steps I’ll take to resolve it. I provide realistic timelines.

- Fair Resolution: I work with the customer to find a fair and mutually agreeable solution, whether it involves repairs, replacements, or adjustments to the original contract.

- Follow-up: I follow up with the customer after the problem is resolved to ensure their satisfaction and address any remaining concerns.

For example, I once had a customer complain about some minor cosmetic issues after a roof replacement. Though the roof was perfectly functional, I addressed their concerns by making the small adjustments, showing my commitment to their complete satisfaction.

Q 21. What are the common causes of roof leaks?

Roof leaks can stem from a variety of sources. Understanding these common causes is crucial for effective prevention and repair.

- Damaged or Missing Shingles: Wear and tear, wind damage, or impacts from falling debris can compromise shingles, leading to leaks.

- Faulty Flashing: Improperly installed or damaged flashing around chimneys, vents, and skylights is a frequent source of leaks.

- Clogged Gutters and Downspouts: Overflowing gutters can cause water to back up and infiltrate the roof.

- Poor Attic Ventilation: Inadequate ventilation can trap moisture, leading to condensation and leaks.

- Cracked or Damaged Roof Deck: Damage to the underlying structure can allow water to penetrate the roof.

- Ice Dams (in cold climates): The buildup of ice at the eaves can force water under the shingles.

- Improper Sealant: Inadequate or deteriorated sealant around penetrations can allow water to enter.

Each of these requires a different approach to repair. For example, a single cracked shingle might only need replacement, while damaged flashing might require more extensive work.

Q 22. What are your skills in using power tools and equipment for roofing?

My proficiency with power tools and equipment crucial for roofing is extensive. I’m highly skilled in operating and maintaining a wide range of tools, including pneumatic nail guns (both coil and stick), circular saws, chop saws, drills, impact drivers, and various safety equipment like harnesses and fall arrest systems. For example, I’ve consistently achieved high production rates while maintaining perfect nail placement using pneumatic nailers, significantly reducing material waste and ensuring a robust roof structure. My experience also extends to the safe and effective use of power washers for pre-roofing cleaning, ensuring a clean and sound substrate for optimal shingle adhesion.

I regularly undergo safety training and refreshers to ensure I am up-to-date on best practices and safe operating procedures for all equipment. This includes preventative maintenance, which is vital for the longevity and efficiency of the tools, directly impacting project timelines and outcomes.

Q 23. How do you ensure the quality of your work on each roofing project?

Ensuring quality is paramount in my roofing work. It starts with a meticulous inspection of the existing roof structure and a thorough understanding of the client’s needs and expectations. We use high-quality materials from reputable suppliers and meticulously follow manufacturer’s installation instructions. This includes proper ventilation strategies to prevent moisture buildup and extend the roof’s lifespan.

Throughout the project, I implement rigorous quality control checks at each stage: from underlayment installation and flashing details to the final shingle placement and clean-up. For instance, I always double-check the alignment of shingles to ensure consistent overlap and water-tight sealing, a detail that significantly impacts the longevity and weather resistance of the roof. Furthermore, I take pride in a clean and organized worksite, respecting the property and minimizing disruption to the homeowner. We take before and after photos of each job to document the process and final results.

Q 24. What is your experience with gutter and downspout installation and repair?

My experience with gutter and downspout installation and repair is comprehensive. I’ve handled projects ranging from simple repairs—such as replacing damaged sections or sealing leaks—to complete gutter system overhauls, including the installation of new gutters, downspouts, and related hardware. I’m proficient in working with various materials, including aluminum, vinyl, and copper, and understand the importance of proper grading and slope to ensure efficient water runoff.

For example, I recently tackled a project where the existing gutters were severely clogged and damaged, leading to water damage to the foundation. I carefully removed the old gutters, cleaned the fascia boards, installed new aluminum gutters with proper pitch and strategically placed downspouts to direct water away from the house, preventing future water damage and improving the home’s curb appeal.

Q 25. Explain your understanding of warranty and insurance claims related to roofing.

I understand the intricacies of roofing warranties and insurance claims thoroughly. I’m familiar with various manufacturer warranties, which often cover defects in materials or workmanship for a specific period. I know how to properly document the installation process, ensuring all necessary paperwork is completed and filed. This documentation is crucial for supporting any warranty claims should issues arise. Similarly, I’m experienced in preparing comprehensive reports for insurance claims, including detailed descriptions of damages, repair costs, and supporting photographic evidence. This includes understanding different types of coverage and navigating the claims process efficiently.

For instance, I’ve successfully assisted homeowners in filing insurance claims following storm damage, ensuring they received fair compensation for repairs. My experience includes working with various insurance adjusters and understanding the nuances of their assessment processes.

Q 26. What is your experience with different types of roofing fasteners?

My experience with various roofing fasteners is broad and includes knowledge of their strengths and weaknesses in different applications. This includes understanding the differences between common fasteners like galvanized nails, stainless steel screws, and specialized roofing staples. I’m aware of the importance of using the correct fasteners for each roofing material, ensuring a secure and long-lasting installation.

For example, when working with asphalt shingles, I use galvanized nails of the appropriate length and gauge to secure them properly to the sheathing. For metal roofing, I utilize specialized screws designed for the specific metal type to guarantee a weathertight seal. The choice of fastener is directly related to the durability and longevity of the roof and is a critical aspect of my work.

Q 27. How do you stay updated with the latest roofing technologies and trends?

Staying updated on roofing technologies and trends is a continuous process. I regularly attend industry conferences, workshops, and training sessions offered by manufacturers and professional organizations. I subscribe to trade publications and online resources to stay informed about new materials, techniques, and best practices. Furthermore, I actively participate in online forums and networking groups to exchange knowledge with other professionals in the field.

For example, I recently completed a training course on the installation of a new type of high-performance roofing membrane designed for superior energy efficiency and longevity. This keeps me ahead of the curve and allows me to offer clients the latest and most effective roofing solutions.

Q 28. Describe your experience with working at heights and maintaining safety protocols.

Safety is my utmost priority when working at heights. I’m experienced in the proper use of fall protection equipment, including harnesses, lanyards, and safety lines. I meticulously inspect all equipment before each use and adhere to all relevant OSHA regulations. I always ensure there is adequate fall protection for all workers on the job, and I regularly conduct safety briefings before commencing any work at heights.

I have a proven track record of completing roofing projects safely and efficiently, without any workplace accidents. My commitment to safety is reflected in my comprehensive training and proactive approach to risk management, ensuring the well-being of myself and my team.

Key Topics to Learn for Your Residential Roofing Interview

- Roofing Materials: Understanding the properties, applications, and limitations of asphalt shingles, tile, metal, and other common residential roofing materials. Practical application: Knowing which material is best suited for a specific climate and budget.

- Roofing Installation Techniques: Mastering the proper techniques for installing various roofing materials, including underlayment, flashing, and ridge vents. Practical application: Troubleshooting common installation problems and ensuring a watertight seal.

- Roof Inspections & Repair: Developing the skills to accurately assess roof damage, identify potential problems, and propose effective repair solutions. Practical application: Creating detailed repair estimates and communicating effectively with clients.

- Safety Regulations & Best Practices: Adhering to all relevant safety regulations and best practices to minimize workplace risks. Practical application: Implementing fall protection measures and using appropriate safety equipment.

- Estimating & Project Management: Accurately estimating project costs, managing timelines, and overseeing the completion of roofing projects within budget and schedule. Practical application: Creating detailed project proposals and managing a team effectively.

- Building Codes & Permits: Understanding local building codes and the process of obtaining necessary permits for roofing projects. Practical application: Ensuring compliance with all regulations and avoiding potential legal issues.

- Customer Communication & Service: Developing strong communication skills to effectively interact with clients, address concerns, and build positive relationships. Practical application: Providing excellent customer service and building a strong reputation.

Next Steps

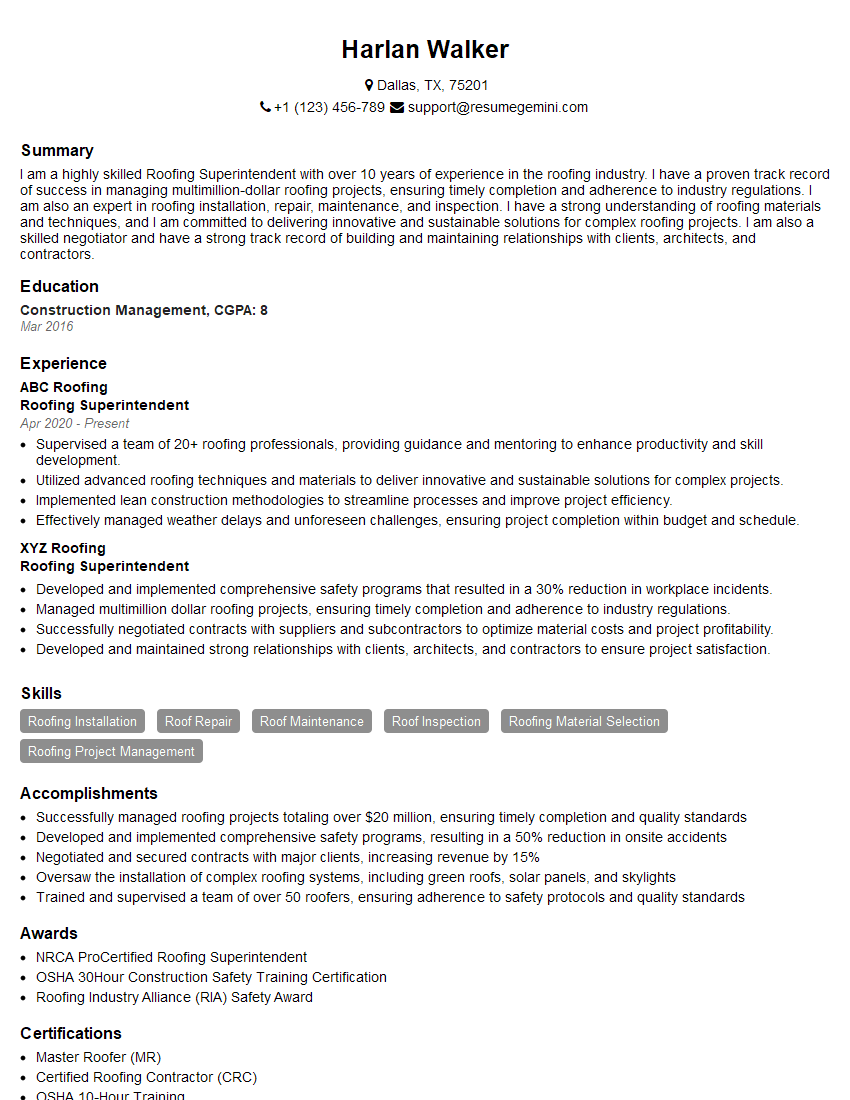

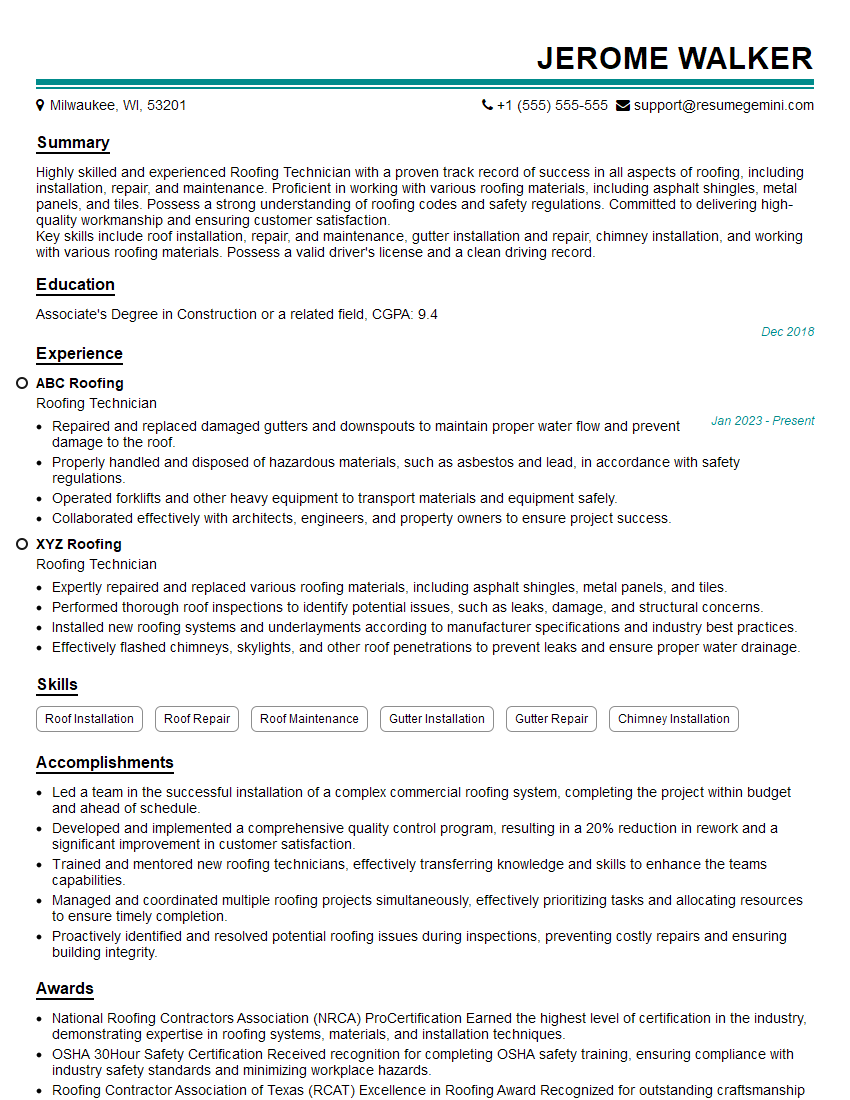

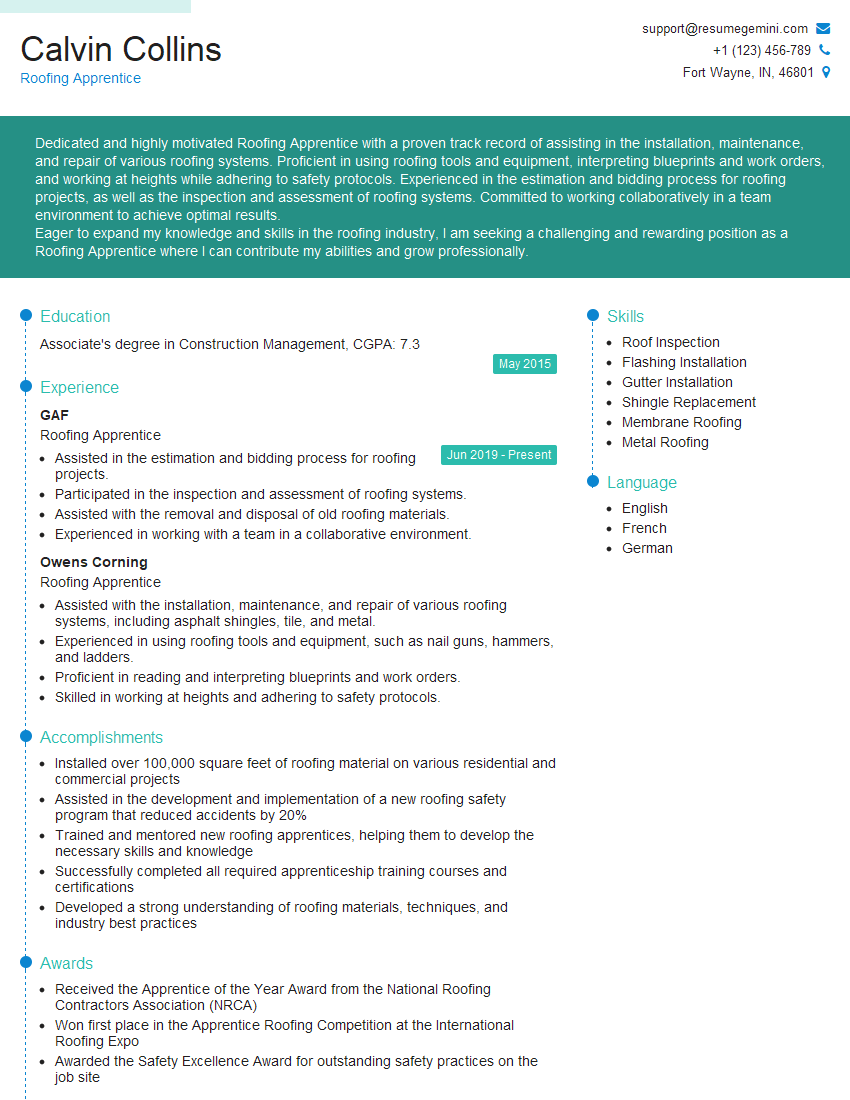

Mastering the fundamentals of residential roofing opens doors to a rewarding and stable career with excellent growth potential. To maximize your job prospects, invest time in crafting an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that catches the eye of recruiters. Examples of resumes tailored specifically to the residential roofing industry are available to help guide you. Take this opportunity to showcase your abilities and secure your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.