The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Respiratory Protection Selection interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Respiratory Protection Selection Interview

Q 1. What are the different types of respirators and their applications?

Respirators are devices designed to protect the wearer from inhaling harmful airborne substances. They come in various types, each suited for different applications. The primary classification is based on the filtering mechanism.

- Filtering Facepieces (FFRs): These are commonly known as dust masks or N95 respirators. They filter particles from the air, with different ratings (N, R, P) indicating resistance to oil-based aerosols. N95, for instance, filters at least 95% of airborne particles. Applications include working with dust, asbestos, or other particulate matter.

- Air-Purifying Respirators (APRs): These use filters or cartridges to remove specific contaminants from the air before it reaches the user. They can filter gases, vapors, and particles, depending on the filter type. Applications range from painting to welding, where specific chemical vapors might be present. They require proper cartridge selection based on the identified hazards.

- Supplied-Air Respirators (SARs): These provide clean air from a separate source, such as an air compressor or compressed air cylinder. They are commonly used in environments with extremely hazardous or oxygen-deficient atmospheres. Examples include confined space entry or working with highly toxic chemicals. There are two main types: Air-line respirators that provide a continuous flow of air and Self-contained breathing apparatus (SCBA) which are self-contained units with an air supply for a limited time.

- Powered Air-Purifying Respirators (PAPRs): These combine the filtering action of APRs with a motorized blower that pushes clean air through the filter and into the facepiece. They provide more comfort during prolonged use than APRs, especially in demanding physical activities. Examples include spraying pesticides or working in areas with high concentrations of dust.

Choosing the correct respirator is crucial for worker safety and depends entirely on the specific hazards present in the workplace.

Q 2. Explain the hierarchy of controls for respiratory hazards.

The hierarchy of controls for respiratory hazards prioritizes eliminating or minimizing the hazard at the source, rather than relying solely on personal protective equipment (PPE) like respirators. This is a crucial aspect of occupational health and safety.

- Elimination: Completely removing the hazard. For example, replacing a hazardous chemical process with a safer alternative.

- Substitution: Replacing a hazardous substance with a less hazardous one. For example, using a water-based paint instead of an oil-based paint.

- Engineering Controls: Modifying the workplace to reduce exposure. Examples include installing local exhaust ventilation (LEV) systems to capture fumes or installing enclosed systems to prevent the release of airborne particles.

- Administrative Controls: Implementing work practices to minimize exposure. This could include rotating workers in hazardous areas, implementing strict work procedures, or providing additional training.

- Personal Protective Equipment (PPE): Respirators are the last line of defense, used only when other controls are insufficient or not feasible. They are essential, but shouldn’t replace the previously mentioned control measures.

This hierarchical approach ensures the most effective and safest control measures are prioritized, ultimately minimizing the risk to workers. Always remember that PPE is the last resort, not the first.

Q 3. How do you select the appropriate respirator for a specific hazard?

Selecting the appropriate respirator involves a thorough hazard assessment. This involves identifying the specific hazards present, their concentration, and the duration of exposure. Then, you can select the appropriate respirator type and protection factor.

- Hazard Identification: Determine the specific substances or hazards in the air (e.g., dust, fumes, gases, vapors).

- Concentration Assessment: Determine the concentration of these hazards. This might involve air monitoring or referring to Safety Data Sheets (SDS).

- Respirator Selection: Consult the relevant respirator standards and SDS to select a respirator with the appropriate protection factor (e.g., N95, N100, specific gas/vapor cartridge). Consider factors like comfort and fit.

- Fit Testing: Ensure a proper fit is achieved to ensure the respirator performs as designed. Different fit test methods are used depending on the type of respirator.

- Training and Use: Provide thorough training on the proper use, maintenance, and limitations of the chosen respirator.

Example: If workers are exposed to high concentrations of silica dust during demolition, an N95 respirator might be insufficient. An air-purifying respirator with a high-efficiency particulate air (HEPA) filter would be a more suitable choice, or even a supplied-air respirator in extreme cases.

Q 4. Describe the process of a respirator fit test.

A respirator fit test ensures a tight seal between the respirator and the wearer’s face, preventing contaminants from leaking in. Several methods exist, each suited to different respirator types.

- Qualitative Fit Tests: These tests rely on the wearer’s ability to detect a test agent (e.g., bitrex, saccharin) that is introduced into the respirator. If the wearer detects the agent, it indicates a leak. Simpler and quicker to perform than quantitative tests.

- Quantitative Fit Tests: These use instruments to measure the amount of leakage around the respirator. They provide a more objective measure of the fit and are typically required for high-risk environments. Different techniques are used (e.g., Portacount, TSI).

The process typically involves:

- Pre-test preparation: The individual should clean their face, avoid using skincare products, and follow any other specific requirements.

- Donning the respirator: The individual puts on the respirator according to the manufacturer’s instructions.

- Fit test procedure: The selected fit test is performed according to the established protocol.

- Post-test evaluation: The results are evaluated to determine whether the respirator provides an acceptable fit.

Regular fit testing is crucial, as facial hair, weight changes, or even the type of face mask underneath can affect the seal. Retesting should be done at regular intervals and whenever relevant factors change.

Q 5. What are the limitations of different respirator types?

Every respirator type has limitations. Understanding these limitations is crucial for safe and effective use.

- Filtering Facepieces (FFRs): Limited protection against gases and vapors. Effectiveness depends on the fit; a poor fit renders them ineffective. They can also become less effective over time with prolonged use or exposure to moisture.

- Air-Purifying Respirators (APRs): Protection is limited to the contaminants the cartridges are designed for. Cartridges have a limited lifespan and must be replaced when depleted. Not suitable for oxygen-deficient atmospheres.

- Supplied-Air Respirators (SARs): Can be cumbersome and restrictive, especially SCBAs. Dependent on an external air supply, so there is a need for proper maintenance and air source monitoring. SCBAs have limited air supply duration.

- Powered Air-Purifying Respirators (PAPRs): Require battery power, which needs monitoring. Can be heavier than other respirators and might be less suitable for some tasks.

It’s essential to select a respirator that addresses the specific hazards while acknowledging its inherent limitations. Training should also highlight these limitations to the users.

Q 6. How do you ensure the proper maintenance and storage of respirators?

Proper maintenance and storage are essential for ensuring respirator effectiveness and longevity. This includes cleaning, inspection, and storage in a controlled environment.

- Cleaning: Respirators should be cleaned regularly following the manufacturer’s instructions. This usually involves wiping the exterior with a damp cloth. Always allow the respirator to dry completely before storing.

- Inspection: Regularly inspect the respirator for damage, such as cracks, tears, or missing parts. Replace damaged components or the entire respirator if necessary.

- Storage: Store respirators in a clean, dry, and cool place away from direct sunlight, heat, or chemicals. Use appropriate storage containers to prevent damage and contamination.

- Cartridge/Filter Replacement: Replace cartridges and filters as needed, based on manufacturer recommendations or when they reach their service life. Never reuse expired or damaged cartridges/filters.

A well-maintained respirator will provide optimal protection. Neglecting maintenance can compromise its effectiveness and pose a significant risk to the wearer.

Q 7. What are the OSHA regulations regarding respiratory protection?

OSHA (Occupational Safety and Health Administration) regulations regarding respiratory protection are comprehensive and aim to protect workers from airborne hazards. Key aspects include:

- Hazard Assessment: Employers must conduct a thorough hazard assessment to identify potential respiratory hazards in the workplace.

- Respiratory Protection Program: A written respiratory protection program is required in workplaces where respirators are necessary. This program covers aspects like selection, use, maintenance, training, and medical evaluations.

- Medical Evaluation: Employees required to use respirators must undergo medical evaluations to ensure they are physically fit to use them.

- Training and Fit Testing: Employees must receive appropriate training on the proper use, care, and limitations of their respirators. Fit testing is also required to ensure a proper seal.

- Record Keeping: Employers must maintain records of medical evaluations, training, and fit testing.

- Compliance with Standards: Employers must comply with the relevant OSHA standards, which include specific requirements for different respirator types.

OSHA’s regulations are designed to ensure that workers using respirators are properly protected. Non-compliance can lead to significant penalties.

Q 8. Explain the importance of respiratory protection training.

Respiratory protection training is paramount because it bridges the gap between possessing the right equipment and effectively using it to safeguard health. Without proper training, even the best respirator is useless. Think of it like owning a sophisticated camera – you need to understand its functions to capture the perfect shot. Similarly, a respirator’s effectiveness depends entirely on the user’s knowledge and skill.

Effective training covers several crucial areas:

- Respirator Selection: Understanding different respirator types and their applications (e.g., knowing when a half-mask is sufficient versus needing a full-face respirator).

- Fit Testing: Learning how to properly perform fit checks to ensure a tight seal, preventing contaminants from leaking in. A poor fit renders even the most advanced respirator ineffective.

- Donning and Doffing Procedures: Mastering the correct steps for putting on and taking off the respirator to avoid contamination and maintain its integrity.

- Maintenance and Storage: Understanding how to clean, store, and inspect respirators to maintain their effectiveness and extend their lifespan.

- Limitations and Emergency Procedures: Recognizing when a respirator might not be suitable for a specific hazard and knowing what to do in case of an emergency or respirator malfunction.

For example, training might involve hands-on practice with different respirators, simulated emergency scenarios, and written tests to ensure understanding. Regular refresher training is also vital, as procedures and best practices may evolve.

Q 9. How do you assess the effectiveness of a respiratory protection program?

Assessing the effectiveness of a respiratory protection program requires a multifaceted approach, focusing both on the program’s structure and its impact on worker health. It’s not simply about providing respirators; it’s about a comprehensive system.

Key assessment methods include:

- Medical Surveillance: Regularly monitoring the health of workers using respirators, looking for any signs of respiratory issues. This can involve lung function tests and health questionnaires.

- Program Audits: Reviewing the program’s policies, procedures, training materials, and records to ensure compliance with regulations and best practices. This includes verifying that fit testing is conducted properly and that respirators are appropriately selected and maintained.

- Exposure Monitoring: Measuring the concentration of airborne hazards in the workplace to verify the effectiveness of the respiratory protection in reducing worker exposure. This might involve air sampling and analysis.

- Worker Feedback: Gathering input from workers who use respirators to identify any issues or areas for improvement. This can involve surveys, interviews, or focus groups. Understanding the challenges faced by users is crucial.

- Incident Reporting and Investigation: Analyzing any incidents or near misses related to respiratory protection to identify root causes and prevent future occurrences. Thorough investigation is essential for continuous improvement.

Imagine a scenario where a worker reports discomfort while using a respirator. This feedback indicates a potential problem with fit or selection. A thorough investigation might reveal the need for retraining, a respirator change, or adjustments to the work process.

Q 10. What are the common causes of respirator failure?

Respirator failure can stem from various causes, broadly categorized into user-related, equipment-related, and environmental factors. It’s crucial to understand these factors to prevent failures and protect workers.

User-Related Failures:

- Improper Fit: The most common cause; a loose seal allows contaminants to bypass the respirator.

- Incorrect Donning/Doffing: Failure to follow proper procedures can compromise the respirator’s seal or contaminate the user.

- Inadequate Training: Lack of knowledge about respirator limitations and usage.

- Beard Interference: Facial hair can prevent a proper seal on many respirators.

Equipment-Related Failures:

- Damaged or Worn Parts: Faulty filters, straps, or facepieces compromise the respirator’s integrity.

- Improper Maintenance: Lack of cleaning or storage can damage the respirator.

- Expired Cartridges/Filters: Expired filters lose their effectiveness.

Environmental Failures:

- High Temperatures/Humidity: Extreme conditions can cause discomfort and compromise the seal.

- Incompatible Respirators: Using the wrong respirator for the hazard.

For example, a worker might experience respirator failure due to a poorly fitted respirator, leading to contaminant exposure. Addressing this requires a re-fit test and potentially retraining on proper donning procedures.

Q 11. Describe the process of conducting a hazard assessment for respiratory hazards.

A hazard assessment for respiratory hazards is a systematic process to identify potential airborne contaminants and determine the risk they pose to workers. It’s a critical first step in selecting appropriate respiratory protection.

The process typically involves:

- Identify Potential Hazards: This involves identifying all substances present in the workplace that could be inhaled – gases, vapors, dusts, fumes, mists, and biological agents. Consider both routine tasks and potential emergencies.

- Determine the Level of Exposure: Estimate the concentration of the hazards in the air, frequency, and duration of exposure. This might involve reviewing Safety Data Sheets (SDS), conducting air monitoring, or consulting historical data.

- Evaluate the Risk: Combine the hazard identification and exposure assessment to determine the overall risk level. This often involves considering the toxicity of the substance and the level of exposure. Higher concentrations and more toxic substances pose greater risks.

- Implement Controls: Before considering respiratory protection, explore other control measures, such as engineering controls (ventilation), administrative controls (work practices), and substitution (replacing hazardous materials). Respiratory protection is usually the last line of defense.

- Select Appropriate Respirators (If Necessary): If other controls are insufficient, select respirators that provide adequate protection based on the identified hazard and exposure level.

For instance, a welding operation generates hazardous fumes. The assessment would identify the types of fumes, estimate their concentration, and determine the required respirator type (e.g., an air-purifying respirator with appropriate cartridges).

Q 12. How do you determine the appropriate respirator selection for a specific task?

Selecting the appropriate respirator is crucial and hinges on a thorough hazard assessment. It’s not a one-size-fits-all approach. The choice depends on the specific hazards present and their concentration.

The selection process involves:

- Identify the Hazards: What airborne contaminants are present (gases, vapors, dusts, etc.)?

- Determine the Hazard Concentration: What is the concentration of the contaminants in the air? This influences whether an air-purifying respirator or a supplied-air respirator is needed.

- Consider the Respirator Type:

- Air-Purifying Respirators (APR): Remove contaminants from the air inhaled by the user. Appropriate for environments with sufficient oxygen and known concentrations of contaminants. They come in various classes and filter types.

- Supplied-Air Respirators (SAR): Supply clean air to the user from an external source. Suitable for environments with low oxygen levels or high concentrations of contaminants.

- Select the Appropriate Protection Factor (PF): The PF indicates the level of protection a respirator provides. Higher PF values offer greater protection. This needs to be matched to the hazard level.

- Conduct Fit Testing: Ensure a proper seal to prevent leaks. This is crucial for effective protection. Qualitative and quantitative fit testing methods exist.

For instance, if working with high concentrations of asbestos dust, a supplied-air respirator with a high protection factor would be necessary. For low concentrations of paint fumes, an air-purifying respirator with the appropriate organic vapor cartridges might suffice.

Q 13. What are the key elements of a comprehensive respiratory protection program?

A comprehensive respiratory protection program is more than just providing respirators; it’s a structured system ensuring worker safety. Key elements include:

- Written Program: A documented program outlining procedures, responsibilities, and training requirements.

- Hazard Assessment: A systematic evaluation of workplace hazards to determine the need for respiratory protection.

- Respirator Selection: A process to choose the appropriate respirators for specific tasks based on the hazard assessment.

- Medical Evaluation: Ensuring workers are medically fit to use respirators. Some individuals may have conditions precluding respirator use.

- Fit Testing: Regular testing to ensure proper respirator fit for each individual worker.

- Training: Comprehensive training on respirator selection, use, maintenance, and limitations.

- Use and Maintenance: Clear guidelines on how to properly use, clean, store, and inspect respirators.

- Record Keeping: Detailed records of training, fit tests, medical evaluations, and respirator maintenance.

- Program Evaluation: Regular reviews to assess program effectiveness and make improvements.

Think of it as a well-oiled machine; each part plays a vital role. A missing or malfunctioning element can compromise the entire system’s effectiveness, potentially endangering workers.

Q 14. Explain the difference between a half-mask and a full-face respirator.

Both half-mask and full-face respirators are air-purifying respirators, but they differ significantly in the area of the face they cover and, consequently, the level of protection they provide.

- Half-Mask Respirator: Covers the nose and mouth, protecting against airborne hazards. They’re simpler to use and generally more comfortable for shorter durations but offer less protection than full-face respirators.

- Full-Face Respirator: Covers the entire face, including the eyes, nose, and mouth. They offer superior protection against airborne hazards and splashes but can be more cumbersome and less comfortable for extended use.

The choice depends on the specific hazard. A half-mask might be sufficient for low concentrations of dust, whereas a full-face respirator would be necessary for situations involving potential eye or facial splashes of chemicals or if a higher level of protection is needed.

Q 15. How do you address employee concerns and complaints regarding respirator use?

Addressing employee concerns about respirator use is crucial for ensuring safety and compliance. It starts with open communication and a proactive approach. We need to create a safe space for employees to voice their concerns without fear of retribution. This involves regular training sessions that emphasize the importance of respiratory protection, address common misconceptions, and provide ample opportunities for questions and feedback.

For example, if an employee complains about discomfort, we investigate the fit of the respirator. We might try different respirator models or adjust the straps. If the complaint involves difficulty breathing, we conduct a medical evaluation to rule out any underlying health conditions. We also make sure the work environment is properly ventilated to reduce the burden on the respirator. Documentation of these concerns and resolutions is essential.

Ultimately, a strong focus on employee education, regular feedback mechanisms, and prompt resolution of issues builds trust and ensures respirator use doesn’t become a source of frustration or safety compromise.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the medical considerations for respirator use?

Medical considerations are paramount in respirator selection and use. Not everyone is medically cleared to use a respirator. Pre-employment and periodic medical evaluations are necessary to identify any pre-existing conditions, such as cardiovascular or respiratory diseases, that could be exacerbated by respirator use. A physician’s clearance is required to ensure that the individual can tolerate the physical demands of respirator use.

For instance, individuals with certain heart conditions might experience increased strain during respirator use, and those with asthma may have difficulties breathing. A thorough medical evaluation assesses these factors and helps determine the appropriate type of respirator, if any, that the employee can safely wear. This process is often guided by industry standards and regulations.

Q 17. Explain the concept of Assigned Protection Factors (APFs).

The Assigned Protection Factor (APF) is a numerical rating that indicates the level of protection a respirator provides against airborne contaminants. It represents the ratio of the concentration of a contaminant in the ambient air to the concentration in the air breathed by the wearer. A higher APF signifies greater protection.

For example, an APF of 10 means the respirator reduces the concentration of the contaminant inside the mask to 1/10th of the concentration outside. Different respirators have different APFs depending on their design and filtering capabilities. Selecting a respirator with an appropriate APF is crucial for ensuring adequate protection based on the specific hazards present in the workplace. OSHA and NIOSH guidelines provide recommendations for selecting appropriate APFs for different workplace scenarios.

Q 18. How do you ensure compliance with respirator standards and regulations?

Ensuring compliance with respirator standards and regulations requires a multi-faceted approach. It starts with a comprehensive respiratory protection program which includes: a written program, employee training, respirator selection and fit testing, proper use, maintenance, and medical evaluations.

We must follow OSHA’s Respiratory Protection Standard (29 CFR 1910.134) and NIOSH guidelines. This involves regular inspections to ensure that respirators are correctly used and maintained, documentation is accurate and complete, and employee training is up-to-date. We also conduct fit testing to verify that the chosen respirator provides a proper seal on each employee’s face. This ensures the respirator’s APF is effectively realized. Compliance is an ongoing process that requires vigilance, training, and attention to detail.

Q 19. What are the different types of respirator filters and cartridges?

Respirator filters and cartridges come in various types, each designed to remove specific contaminants. The choice depends on the hazards present in the work environment. Some common types include:

- Particulate Filters: These remove solid and liquid particles from the air, such as dust, mists, and fumes. They are often classified by their efficiency (e.g., N, R, P series) and their resistance to oil (e.g., N for not resistant, R for resistant, P for oil-proof).

- Gas and Vapor Cartridges: These remove specific gases and vapors, such as organic vapors, acid gases, ammonia, or carbon monoxide. Each cartridge is designed for a specific type of contaminant.

- Combination Filters/Cartridges: These combine particulate and gas/vapor protection in a single unit.

Selecting the correct filter or cartridge is critical to ensuring the effectiveness of the respirator. Mismatched protection can lead to serious health consequences.

Q 20. Describe the process of respirator cleaning and disinfection.

Cleaning and disinfecting respirators is essential for maintaining their effectiveness and hygiene. The process depends on the type of respirator. Generally, the process involves:

- Removing loose debris: Carefully brush away any loose dirt or debris from the respirator.

- Cleaning: Wash the respirator parts (if applicable) with soap and water. For some respirators, manufacturers may recommend specific cleaning solutions.

- Disinfection: After cleaning, disinfect the respirator with an appropriate disinfectant, following the manufacturer’s instructions. Ensure complete drying before reuse.

- Inspection: After cleaning and disinfection, inspect the respirator for any damage or wear and tear. Damaged respirators should be discarded.

Proper cleaning and disinfection are essential for preventing the spread of contaminants and maintaining the integrity of the respirator.

Q 21. How do you manage respirator inventory and ensure adequate supply?

Managing respirator inventory requires a systematic approach to ensure adequate supply and proper storage. This includes:

- Inventory Tracking: Implementing a system to track the number and type of respirators in stock, including their expiration dates and usage history.

- Ordering and Procurement: Establishing a process for timely ordering and receiving respirators based on projected needs and consumption rates.

- Storage: Storing respirators in a clean, dry, and well-ventilated area to prevent damage or degradation.

- Regular Inspections: Periodically inspecting the stored respirators to identify any damaged or expired units.

- Disposal: Establishing a safe and compliant method for discarding expired or damaged respirators.

Effective inventory management ensures that employees always have access to the appropriate respirators while minimizing waste and ensuring safety compliance.

Q 22. What are the signs and symptoms of respirator-related adverse health effects?

Respirator-related adverse health effects can range from minor discomfort to serious health problems. Early signs might be as simple as skin irritation from straps or facial discomfort from ill-fitting equipment. However, more serious issues can develop. These include headaches, dizziness, and nausea, which could indicate inadequate oxygen supply. Long-term effects could involve respiratory problems like bronchitis or even permanent lung damage, especially with exposure to hazardous substances. Specific symptoms vary based on the type of respirator, the substance being filtered, and the individual’s health. For example, using a respirator improperly or in unsuitable environments can lead to carbon dioxide buildup, resulting in headache, drowsiness, or even unconsciousness. Similarly, improper fit can lead to skin irritation and pressure sores. Regular health checks and reporting of any unusual symptoms are vital for mitigating these risks.

Q 23. Explain the importance of regular respirator inspections.

Regular respirator inspections are paramount to ensure worker safety and the effectiveness of the respiratory protection program. A damaged or improperly functioning respirator compromises the wearer’s protection, potentially exposing them to hazardous airborne contaminants. Inspections should be conducted before each use, after each use, and at regular intervals, depending on the type of respirator and the level of risk. This includes checking for physical damage to the mask, straps, filters, and cartridges. For example, look for cracks, tears, or missing parts in the facepiece; ensure the straps are intact and securely fastened; and verify the filters/cartridges are not clogged or damaged. Regular inspections help identify issues early, preventing accidents and costly repairs or replacements. Think of it like checking your car’s tires before a long drive – you wouldn’t want to risk a flat tire mid-journey, and similarly, you should never risk working with compromised respiratory protection.

Q 24. How do you handle respirator malfunctions or emergencies?

Respirator malfunctions or emergencies require immediate and decisive action. The first step is to cease work immediately and move the affected individual to a safe, clean air environment. Then, assess the situation to determine the cause of the malfunction – a damaged filter, a faulty seal, or a strap breakage. Replace the respirator if necessary, or if the malfunction is beyond simple repair, provide a new one that properly fits the employee. In some situations, immediate evacuation to fresh air might be necessary. Thoroughly document the incident, including the type of respirator, the nature of the malfunction, the actions taken, and the outcome. If an injury occurs, seek medical attention immediately, and report the incident following all company protocols. Employee training on proper respirator use and emergency procedures is essential to minimize the severity of such events. A simple example is a sudden increase in breathing resistance, which might indicate a clogged filter; in this scenario, immediate replacement of the filter is mandatory.

Q 25. What are the key performance indicators (KPIs) for a respiratory protection program?

Key Performance Indicators (KPIs) for a respiratory protection program focus on effectiveness and compliance. These KPIs track various aspects, including the number of respirators issued, the frequency of inspections and maintenance, the rate of respirator-related incidents, the number of fit tests conducted and passed, and employee training completion rates. Other important indicators might include the percentage of employees correctly using their respirators, levels of employee satisfaction with the program, and the overall cost-effectiveness of the respiratory protection program. By monitoring these KPIs, we can identify areas for improvement and ensure the program’s effectiveness in protecting workers from respiratory hazards. For instance, a high rate of respirator-related incidents suggests a need for improved training or stricter enforcement of protocols.

Q 26. Describe your experience with different respirator types and their application.

My experience encompasses a wide range of respirator types, including air-purifying respirators (APRs) and supplied-air respirators (SARs). APRs, like N95s and half-face respirators, are widely used for protecting against particulate matter, gases, or vapors. I’ve worked extensively with various APRs, selecting appropriate types based on the specific hazards in the workplace. SARs, on the other hand, provide a continuous supply of clean air and are essential in environments with high concentrations of hazardous substances. I’ve been involved in selecting and implementing SAR systems for confined space entry and other high-risk operations. For example, in a welding shop, I would recommend APRs with appropriate filters, while in a confined space with oxygen deficiency, a self-contained breathing apparatus (SCBA), a type of SAR, would be necessary. My experience also includes training employees on proper selection, donning, doffing, and maintenance procedures for each respirator type. This ensures that employees understand the limitations and proper application of their respiratory protection equipment.

Q 27. How do you stay updated on changes in respiratory protection regulations and standards?

Staying updated on changes in respiratory protection regulations and standards is crucial for maintaining a compliant and effective program. I actively participate in professional organizations, such as NIOSH and OSHA, attending conferences and webinars to stay abreast of the latest developments. I also subscribe to relevant journals and newsletters, and regularly review updated guidelines and standards. Furthermore, I maintain a network of contacts within the industry, allowing for timely information exchange. My approach involves a multi-faceted strategy, ensuring that our program is always in compliance with the most current safety standards and best practices. For example, a recent change in the standard might necessitate retraining employees on the use of certain respirators or implementing changes to our inspection procedures.

Q 28. How would you address a situation where an employee refuses to wear a respirator?

An employee’s refusal to wear a respirator is a serious safety concern. My approach would be multifaceted, beginning with a conversation to understand the reason for their refusal. This could range from discomfort to a belief that the respirator is unnecessary. Once the root cause is identified, I would address their concerns, providing appropriate training, exploring alternative respirators for better fit or comfort, and emphasizing the health risks of non-compliance. If the refusal persists despite these efforts, I would escalate the matter through appropriate channels, involving management and potentially occupational health professionals. In the interest of both the employee’s safety and workplace compliance, appropriate disciplinary actions may be necessary according to the company’s policies and legal regulations. Documentation of all communication and actions taken throughout this process is essential. The goal is to find a solution that ensures the employee’s safety without compromising the safety of others or the integrity of the workplace safety program.

Key Topics to Learn for Respiratory Protection Selection Interview

- Respiratory Hazards Identification & Assessment: Understanding different types of respiratory hazards (dusts, fumes, gases, vapors) and methods for assessing exposure risks in various work environments.

- Selecting Appropriate Respirators: Matching respirator types (e.g., N95, half-mask, full-face) to specific hazards based on OSHA standards and manufacturer guidelines. Practical application: Analyzing a workplace scenario and justifying the selection of a particular respirator.

- Fit Testing and Respirator Maintenance: The importance of proper fit testing procedures and the ongoing maintenance required for respirators to ensure optimal performance and user safety. Problem-solving approach: Troubleshooting common fit-testing issues and respirator malfunctions.

- Respiratory Protection Program Elements: Knowledge of the key components of a comprehensive respiratory protection program, including selection, training, medical evaluations, and record-keeping. Practical application: Developing a basic program outline for a specific workplace.

- Regulations and Standards: Familiarity with relevant OSHA regulations and industry standards concerning respiratory protection, including understanding compliance requirements and potential penalties for non-compliance. Problem-solving approach: Identifying compliance gaps in a hypothetical program.

- Communicating Effectively about Respiratory Protection: Explaining complex technical information about respiratory protection to workers with diverse backgrounds and levels of understanding. Practical application: Developing training materials for workers.

Next Steps

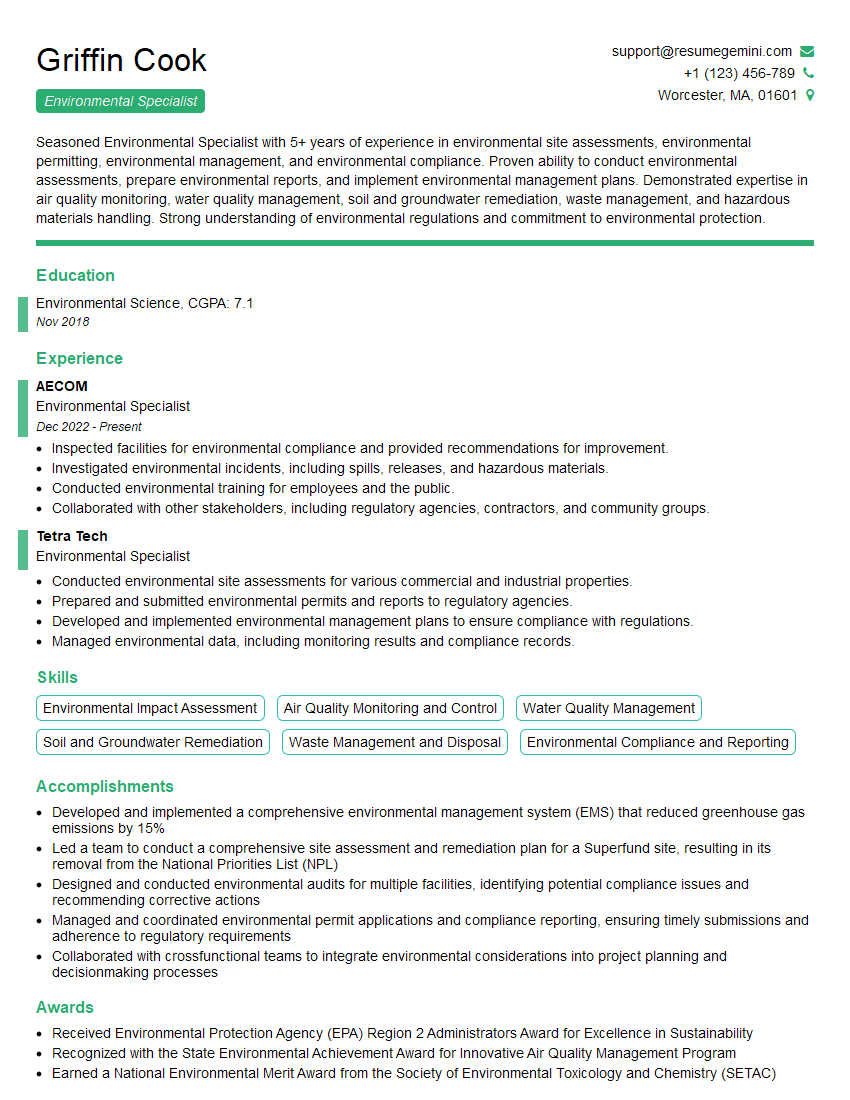

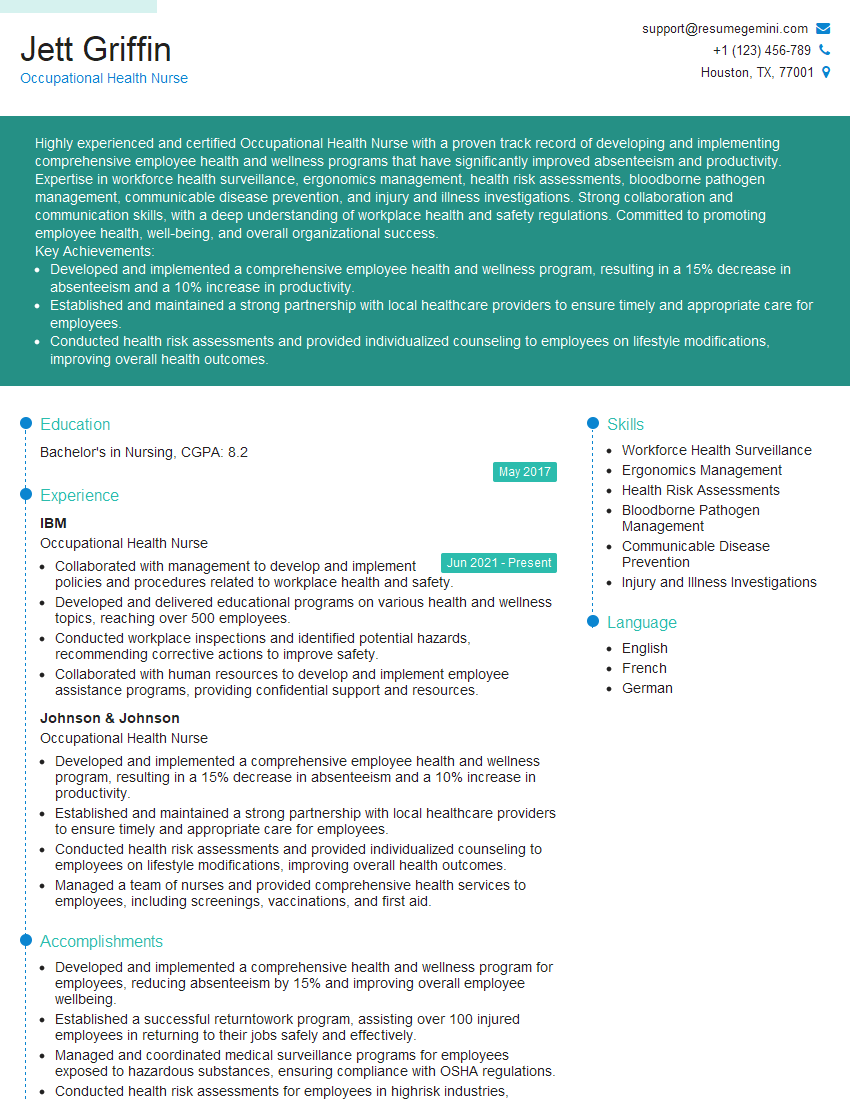

Mastering Respiratory Protection Selection is crucial for advancing your career in occupational safety and health. A strong understanding of these principles demonstrates your commitment to worker safety and opens doors to more challenging and rewarding roles. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional, impactful resumes. We provide examples of resumes tailored to Respiratory Protection Selection to help you showcase your expertise. Invest time in crafting a compelling resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.