Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Reverse Osmosis System Cleaning interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Reverse Osmosis System Cleaning Interview

Q 1. Explain the process of cleaning an RO membrane.

Cleaning an RO membrane is crucial for maintaining its performance and extending its lifespan. The process involves a series of steps designed to remove accumulated contaminants that impede water flow and reduce purity. Think of it like cleaning a clogged filter in your kitchen faucet – regular maintenance is key.

The process typically involves these steps:

- Pre-rinse: A thorough rinse with clean water to remove loose debris.

- Chemical Cleaning: This is the core of the process, using specific chemicals to dissolve different types of fouling (scaling, organic matter, biological growth). The choice of chemicals depends on the type of fouling.

- Post-rinse: Another thorough rinse with clean water to completely remove cleaning chemicals. This is critical to ensure the water produced is safe for consumption.

- Sanitization (Optional): In some cases, particularly for high-purity applications or if biological growth is suspected, a sanitizing agent is used to eliminate bacteria and microorganisms.

The specific procedure and chemicals used will vary depending on the type and severity of fouling and the RO system’s design. Always consult the manufacturer’s instructions for your specific system and membrane.

Q 2. Describe different types of RO membrane cleaning chemicals and their applications.

Various chemicals are used for RO membrane cleaning, each targeting different types of fouling. Selecting the right chemical is crucial for effective cleaning without damaging the membrane.

- Acid Cleaners (e.g., Citric Acid, Phosphoric Acid): These are effective against mineral scaling (calcium carbonate, calcium sulfate). Think of limescale buildup in your kettle – acid cleaners dissolve this.

- Alkaline Cleaners (e.g., Sodium Hydroxide): These are used to remove organic fouling (like proteins and fats) and silicates. Imagine removing greasy residue from a pan – alkaline cleaners achieve a similar effect.

- Chelating Agents (e.g., EDTA): These bind to metal ions, preventing them from precipitating and forming scale. They help to keep the system cleaner for longer.

- Oxidizing Agents (e.g., Hydrogen Peroxide): These are used to remove biological fouling (bacteria, algae) by breaking down organic matter. Think of disinfecting a surface – these act similarly but on the membrane.

- Enzymes: Biological cleaners that break down organic matter. They are often environmentally friendly and effective in removing some types of organic fouling.

The concentration and application method for each chemical must be carefully followed to avoid membrane damage. Always refer to the manufacturer’s instructions and safety data sheets (SDS).

Q 3. What are the common signs indicating the need for RO system cleaning?

Several signs indicate the need for RO system cleaning. These are often subtle at first but become more pronounced as fouling increases. Ignoring them can lead to reduced water production, poor water quality, and ultimately, membrane failure.

- Reduced Water Production: A significant drop in the amount of permeate (clean water) produced is a primary indicator. The system is struggling to push water through the fouled membrane.

- Increased Pressure Drop: Higher pressure is required to achieve the same water flow. The clogged membrane resists the water flow, requiring more force.

- Poor Water Quality: A decrease in the quality of the permeate, such as an increase in TDS (Total Dissolved Solids) or turbidity (cloudiness), indicates that contaminants are bypassing the membrane.

- Visible Fouling: In some cases, you might see physical signs of fouling, such as scaling or slime on the membrane housing or other components.

- Unusual Noises or Vibrations: These may be indicative of excessive pressure or blockages within the system.

If you observe any of these signs, it’s time to consider cleaning your RO system.

Q 4. How do you determine the frequency of RO system cleaning?

The frequency of RO system cleaning depends on several factors, including the feed water quality, the system’s operating parameters, and the type of membrane. There’s no one-size-fits-all answer, but regular monitoring and proactive cleaning are essential.

- Feed Water Quality: Water with high levels of minerals, organics, or bacteria will require more frequent cleaning.

- System Usage: High-usage systems require more frequent cleaning compared to infrequently used ones.

- Membrane Type: Different membranes have different fouling tendencies and cleaning requirements.

- Performance Monitoring: Regularly monitoring parameters like water production, pressure drop, and water quality helps in determining when cleaning is needed.

As a general guideline, some systems might need cleaning every 3-6 months, while others might need it more frequently. A preventative maintenance schedule is highly recommended, with cleaning at least annually.

Q 5. What safety precautions should be taken during RO system cleaning?

Safety is paramount during RO system cleaning. The chemicals used can be corrosive or hazardous, requiring careful handling and appropriate protective measures.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and a lab coat. This protects against chemical spills and splashes.

- Ventilation: Ensure adequate ventilation to minimize exposure to chemical fumes. Work in a well-ventilated area or use a respirator if necessary.

- Chemical Handling: Follow the manufacturer’s instructions and safety data sheets (SDS) for each chemical. Always add chemicals to water, not vice-versa, to avoid exothermic reactions.

- Proper Disposal: Dispose of cleaning solutions and wastewater according to local regulations. Do not pour them down the drain without proper neutralization.

- Emergency Preparedness: Have a plan in place in case of spills or accidents. Know the location of safety showers and eye wash stations.

Improper handling of chemicals can lead to serious injury. Prioritize safety throughout the cleaning process.

Q 6. How do you troubleshoot low water production in an RO system?

Low water production in an RO system can stem from various issues. Troubleshooting involves a systematic approach to identify the root cause.

- Membrane Fouling: This is the most common cause. Check for signs of scaling, organic matter, or biological growth. Cleaning the membrane is usually the solution.

- High Feed Water TDS: High Total Dissolved Solids in the feed water can reduce permeate production. Pre-treatment, such as a multimedia filter, may be necessary.

- Low Feed Water Pressure: Insufficient pressure can limit water flow. Check the feed water pressure and ensure the pump is functioning correctly.

- Clogged Pre-filters: Pre-filters before the RO membrane can become clogged, reducing water flow to the membrane. Replace or clean these filters as needed.

- Membrane Failure: In some cases, the membrane itself might be damaged or failing. This might require membrane replacement.

- Faulty Components: Issues with pumps, valves, or other system components can also contribute to low water production.

A systematic approach, starting with the most common causes and working through the possibilities, is usually successful in identifying and rectifying the problem.

Q 7. Explain the procedure for backwashing an RO system.

Backwashing is a crucial step in RO system maintenance, although not a cleaning process in itself, it helps prevent fouling by removing loose sediment and debris before they accumulate on the membrane. It’s like pre-rinsing dishes before washing them thoroughly.

The procedure typically involves these steps:

- Isolate the RO System: Turn off the main water supply and disconnect the product water line.

- Connect the Backwash Line: Connect a backwash line to the appropriate port on the RO system. The exact location of the port depends on the system’s design.

- Initiate Backwash: Open the backwash valve and allow clean water to flow in the reverse direction through the membrane. The exact duration depends on the manufacturer’s instructions, typically ranging from several minutes to half an hour.

- Monitor Pressure: Observe the pressure gauge during backwashing. If the pressure drops significantly, it could indicate that the system is heavily fouled and chemical cleaning may be necessary.

- Post-Backwash Rinse: After backwashing, rinse the system with clean water to remove any remaining loosened debris.

- Reconnect and Operate: Once complete, reconnect the product water line and restart the RO system.

Backwashing should be performed regularly, as per the manufacturer’s recommendations, typically on a weekly or bi-weekly basis, depending on the feed water quality.

Q 8. Describe the process of chemically cleaning an RO system.

Chemically cleaning an RO system involves a series of steps designed to remove scaling, fouling, and biological growth from the membranes and other components. It’s crucial to follow the manufacturer’s instructions precisely, as incorrect procedures can damage the system. The process typically starts with a pre-cleaning rinse with clean water to remove loose debris. Then, a cleaning solution – often a combination of citric acid for scale removal and a non-ionic detergent for organic fouling – is circulated through the system for a specific duration, typically several hours. The concentration and contact time depend on the level of fouling and the type of membrane. This is followed by a thorough rinsing with clean water to remove all traces of cleaning chemicals. Finally, a post-cleaning sanitation step might be performed using a dilute solution of bleach to eliminate bacteria and microorganisms. Think of it like deep cleaning your house; you wouldn’t use the same cleaning solution for your kitchen grease as you would for your bathroom tile, and similarly, the choice of chemicals and duration in RO cleaning is tailored to the specific contaminants.

For example, if the system is heavily scaled from hard water, a stronger concentration of citric acid and a longer circulation time might be necessary. Conversely, a system with primarily organic fouling might benefit from a higher concentration of detergent. Always record the cleaning process for future reference and troubleshooting.

Q 9. How do you identify and address membrane fouling?

Membrane fouling is identified through several methods, primarily by observing a decline in water production or an increase in permeate salinity (higher TDS in the purified water). Visual inspection of the membranes, if accessible, can reveal signs of scaling, slime, or other deposits. Regular monitoring of the RO system’s performance parameters – such as pressure, flow rate, and permeate quality – is crucial. A significant drop in these parameters often indicates fouling. Advanced techniques like measuring the membrane’s rejection rate for specific ions can also provide insights into the type and severity of fouling.

Addressing membrane fouling involves different approaches based on the nature of the fouling. For instance, scaling (mineral deposits) often requires chemical cleaning with acids like citric acid. Organic fouling, on the other hand, often necessitates cleaning with non-ionic detergents. Biological fouling may require the use of disinfectants like sodium hypochlorite (bleach). In some cases, physical cleaning methods, such as backwashing, might be employed to remove loose debris. Sometimes a combination of chemical and physical methods is necessary for effective cleaning.

Q 10. What are the potential consequences of improper RO system cleaning?

Improper RO system cleaning can lead to several negative consequences. Firstly, it can lead to reduced water production and increased energy consumption. The system will have to work harder to produce the same amount of water, increasing your operating costs. Secondly, it compromises the quality of the purified water. If cleaning is insufficient, contaminants will pass through the membranes, rendering the water unsafe for consumption or other intended uses. This can lead to potential health risks. Thirdly, improper cleaning can damage the RO membranes, leading to premature failure and the need for costly replacements. Using inappropriate chemicals or exceeding the recommended concentration and contact times can irreparably damage the membrane. Finally, it can create more operational problems, potentially leading to system downtime and maintenance issues.

Imagine trying to clean a very delicate piece of jewelry with harsh abrasive materials. The jewelry, like the RO membrane, would likely be damaged. Similarly, using improper chemicals or methods in RO cleaning can result in damaged or less effective membranes.

Q 11. How do you dispose of used cleaning chemicals safely?

Safe disposal of used cleaning chemicals is paramount for environmental protection and worker safety. Never pour cleaning solutions down the drain directly. Instead, neutralize acidic solutions with a base (like sodium bicarbonate) before disposal. For example, citric acid (acidic) can be neutralized using baking soda (a base) before discarding. Always check with local environmental regulations to determine the appropriate disposal methods for specific chemicals in your area. This might involve contacting a hazardous waste disposal company to handle the used chemicals according to their guidelines. Thoroughly rinse all containers before disposal to minimize environmental impact. Always wear appropriate personal protective equipment (PPE), such as gloves and eye protection, when handling cleaning chemicals and their disposal.

Improper disposal can lead to environmental pollution, harming aquatic life and potentially contaminating groundwater sources. Following proper disposal protocols ensures the safety of the environment and those handling the waste.

Q 12. What are the different types of RO membranes and their cleaning requirements?

Reverse osmosis membranes are categorized based on their material and properties. Common types include cellulose acetate (CA), thin-film composite (TFC) polyamide, and aromatic polyamide membranes. Each type has its specific cleaning requirements. CA membranes are generally more susceptible to chemical damage and require milder cleaning agents and shorter contact times. TFC membranes, particularly polyamide types, are more robust but can still be damaged by excessive chemical exposure. Aromatic polyamide membranes are known for their high salt rejection but may require specialized cleaning protocols.

For example, cleaning a CA membrane might involve using a dilute citric acid solution for a shorter duration compared to a TFC membrane, which might tolerate a stronger solution and longer contact time. Always consult the manufacturer’s cleaning recommendations for your specific membrane type to avoid damage and ensure optimal performance.

Q 13. How do you test the water quality before and after RO system cleaning?

Water quality testing is crucial before and after RO system cleaning to assess its effectiveness. Before cleaning, tests should include parameters like total dissolved solids (TDS), pH, conductivity, and specific ion concentrations (e.g., calcium, magnesium). These measurements establish a baseline for comparison after the cleaning process. After cleaning, the same parameters should be tested to evaluate the reduction in contaminants and the improvement in water quality. If the water quality doesn’t improve significantly after cleaning, it suggests the cleaning procedure may need to be revised or that the membrane might require replacement. Additionally, microbiological testing can be performed to assess the presence of bacteria or other microorganisms, especially after sanitation steps.

Using a TDS meter is a straightforward method to monitor the effectiveness of the cleaning process. A lower TDS value after cleaning indicates that the system is successfully removing dissolved solids.

Q 14. What are the common causes of RO membrane scaling?

RO membrane scaling primarily results from the precipitation of dissolved minerals in the feed water. Hard water, rich in calcium and magnesium ions, is a major contributor to scaling. High concentrations of other minerals, such as silica, iron, and sulfate, can also contribute. The pH of the feed water plays a significant role; higher pH levels often promote scaling. Temperature also influences scaling; warmer water tends to favor mineral precipitation. Poor pre-treatment of feed water, such as inadequate filtration or softening, can exacerbate scaling issues. Finally, variations in water chemistry, such as fluctuations in mineral content or pH, can make the membranes more susceptible to scaling.

Think of it like boiling water in a kettle; over time, mineral deposits form on the heating element, similar to how minerals precipitate on RO membranes. Regular cleaning and pre-treatment are essential for preventing scaling and maintaining optimal performance.

Q 15. How do you prevent biofouling in an RO system?

Preventing biofouling, the growth of microorganisms within the RO system, is crucial for maintaining efficiency and water quality. Think of it like keeping your kitchen sink clean – neglecting it leads to unpleasant build-up. We achieve this through a multi-pronged approach:

- Regular Cleaning and Sanitization: Scheduled chemical cleaning, typically with chlorine or peracetic acid, eliminates existing biofilms and prevents future growth. The frequency depends on water quality and system usage, ranging from monthly to quarterly.

- Pre-Treatment: Effective pre-treatment, like filtration and disinfection, removes a significant portion of organic matter and microorganisms before they reach the RO membranes, significantly reducing biofouling potential. This is the most important preventative measure.

- Proper System Design and Operation: A well-designed system includes features that minimize stagnant water, such as proper piping layouts and regular flushing. Maintaining the correct operating pressure and flow rate also helps prevent biofouling.

- Membrane Selection: Choosing membranes with inherent biofouling resistance can also play a role. Some membranes have surface treatments that deter microbial attachment.

- Monitoring: Regular monitoring of parameters like transmembrane pressure (TMP) and permeate quality helps detect early signs of biofouling, allowing for timely intervention.

For example, in a large commercial RO system, we might implement a chlorine dioxide injection system as part of the pre-treatment to continuously sanitize the feed water. In a smaller residential system, regular cleaning with a citric acid solution might suffice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of pre-treatment in RO system efficiency and cleaning.

Pre-treatment is absolutely vital for RO system efficiency and significantly impacts the cleaning process. It acts as a first line of defense, protecting the expensive RO membranes from damage and premature failure. Imagine trying to filter mud with a fine sieve – you’d clog it immediately. Pre-treatment is like pre-filtering the mud to remove the larger particles before it reaches the sieve.

Pre-treatment typically involves multiple stages:

- Sediment Filtration: Removes suspended solids like sand and silt.

- Carbon Filtration: Removes chlorine and organic compounds that can foul membranes or impact water quality.

- Ultrafiltration (UF) or Microfiltration (MF): Removes smaller particles and microorganisms.

- Disinfection (e.g., Chlorination): Kills bacteria and other harmful microorganisms.

Efficient pre-treatment reduces the frequency and intensity of cleaning needed. Less fouling means higher permeate flux (water production rate), longer membrane lifespan, and lower operating costs. Without adequate pre-treatment, cleaning becomes more frequent and potentially more aggressive, potentially damaging the membranes.

Q 17. Describe your experience with different RO system cleaning techniques.

My experience encompasses a wide range of RO system cleaning techniques, tailored to the specific system and fouling characteristics. These include:

- Chemical Cleaning: This is the most common method, employing various chemicals like citric acid, sodium hypochlorite (bleach), and specialized cleaning agents depending on the type of fouling (e.g., organic, inorganic, biological). The process involves circulating the cleaning solution through the system for a specific duration, followed by thorough rinsing.

- Physical Cleaning: This involves physically removing foulants, often through backwashing or membrane scrubbing. Backwashing uses reverse flow to dislodge loosely attached foulants. Membrane scrubbing is a more aggressive approach used in specific situations.

- Electro-Cleaning: In some cases, electro-cleaning techniques are applied to assist in removing foulants, particularly scaling.

- Enzymatic Cleaning: Enzymatic cleaners target specific biofouling components, offering a more environmentally friendly approach in certain instances.

I’ve successfully employed these techniques in various settings, adapting the cleaning protocol based on water quality analysis and system performance data. For instance, in one case involving severe biofouling in a municipal RO system, a combination of enzymatic and chemical cleaning proved highly effective in restoring system performance.

Q 18. How do you handle emergencies during RO system cleaning?

Emergencies during RO system cleaning are rare but require swift and decisive action. These typically involve unexpected equipment failure or a significant drop in system performance. My approach follows a structured procedure:

- Assess the situation: Quickly identify the problem – is it a pump failure, chemical leak, or unexpected membrane damage?

- Isolate the affected area: If possible, isolate the problem area to prevent further damage or contamination.

- Implement emergency procedures: This might involve shutting down the system, contacting maintenance personnel, or activating emergency alarms.

- Take corrective action: Based on the problem, take appropriate corrective action, such as repairing the equipment, removing the contaminated chemical, or switching to a backup system.

- Document the incident: Meticulously document the entire process, including the cause, the actions taken, and the outcome. This is crucial for preventing future incidents.

For example, if a chemical leak occurs, immediate evacuation of the area, containment of the spill, and notification of emergency services are paramount. Thorough documentation is essential for incident reporting and future safety protocols.

Q 19. What are the key performance indicators (KPIs) for an efficient RO system?

Key Performance Indicators (KPIs) for an efficient RO system are crucial for monitoring performance and identifying issues. These include:

- Permeate Flux: The rate of water production, indicating membrane efficiency.

- Rejection Rate: The percentage of dissolved solids removed, reflecting membrane selectivity.

- Transmembrane Pressure (TMP): The pressure difference across the membrane; a significant increase often indicates fouling.

- Recovery Rate: The percentage of feed water converted into permeate.

- Energy Consumption: The amount of energy used per unit of permeate produced.

- Cleaning Frequency: Indicates the level of fouling and the effectiveness of pre-treatment.

By regularly monitoring these KPIs, we can optimize system operation, identify potential problems early, and plan for necessary maintenance and cleaning to maintain optimal performance and prolong equipment lifespan.

Q 20. How do you document and report RO system cleaning activities?

Documentation and reporting are integral to responsible RO system management. We maintain detailed records of all cleaning activities using a combination of electronic and physical logs. These records include:

- Cleaning Date and Time: Precise timing of cleaning events.

- Cleaning Chemicals Used: Type, concentration, and quantity of chemicals employed.

- Cleaning Procedure: Detailed steps followed during the cleaning process.

- Pre- and Post-Cleaning Data: KPIs measured before and after cleaning, such as TMP and permeate flux, to assess the effectiveness of the cleaning process.

- Observations and Anomalies: Any unusual observations during cleaning, such as leaks, membrane damage, or unexpected results.

- Personnel Involved: Individuals responsible for performing the cleaning.

These records are then compiled into comprehensive reports, which are shared with relevant stakeholders and used for trend analysis, performance optimization, and compliance purposes. This systematic documentation allows for effective tracking of cleaning schedules, prediction of future cleaning needs, and identification of potential operational issues.

Q 21. What is your experience with different types of RO systems (e.g., residential, commercial, industrial)?

My experience spans a broad spectrum of RO system types, from small residential units to large-scale industrial applications. While the fundamental principles of RO remain consistent, the scale, complexity, and specific cleaning requirements vary considerably.

- Residential Systems: These are typically simpler systems with less stringent cleaning requirements. Regular cleaning with citric acid solutions and occasional sanitization is often sufficient.

- Commercial Systems: These systems are larger and may require more sophisticated cleaning techniques and more frequent maintenance due to higher water usage and potential for higher fouling.

- Industrial Systems: These systems are the largest and most complex, often handling high volumes of water with varying feed water qualities. They necessitate stringent cleaning protocols, advanced equipment, and specialized cleaning chemicals to ensure efficient and reliable operation. Detailed monitoring and regular maintenance programs are essential to prevent disruptions.

Adaptability is key. I’ve developed my expertise by tackling the unique challenges associated with each system type, always prioritizing efficiency, safety, and water quality.

Q 22. Explain your understanding of osmosis and reverse osmosis principles.

Osmosis is the natural process where a solvent, like water, moves across a semipermeable membrane from a region of lower solute concentration to a region of higher solute concentration. Think of it like this: if you have a glass of pure water separated from a glass of salty water by a membrane that only water can pass through, the water will naturally move from the pure water side to the salty water side to try and dilute the salt. Reverse osmosis (RO) flips this process. We apply pressure to the side with higher solute concentration (the salty water), forcing the water to move *against* its natural tendency, leaving the salts and other impurities behind. This results in purified water.

In an RO system, this membrane acts as a highly selective filter. Water molecules are small enough to pass through, while larger molecules like salts, minerals, and contaminants are blocked. The pressure applied is crucial; insufficient pressure will not effectively reverse the osmosis process. The quality of the purified water is directly related to the membrane’s integrity, the applied pressure, and the feed water quality.

Q 23. What is the importance of regular maintenance in extending the lifespan of RO membranes?

Regular maintenance is paramount for extending the lifespan of RO membranes and ensuring consistent water quality. Over time, membranes become fouled with sediments, organic matter, and biological growth. This fouling reduces the membrane’s permeability, leading to decreased water production, increased operating pressure, and compromised water quality. A fouled membrane also becomes more susceptible to damage and failure. Regular cleaning helps remove these contaminants, restoring the membrane’s efficiency and prolonging its operational life. Neglecting maintenance can drastically shorten the membrane’s lifespan, requiring premature and costly replacements. Think of it like regularly servicing your car – neglecting it leads to expensive repairs or even complete engine failure.

Q 24. How do you interpret the results of water quality tests?

Interpreting water quality test results is crucial for diagnosing problems within the RO system and ensuring optimal performance. Key parameters include Total Dissolved Solids (TDS), pH, turbidity, chlorine levels, and the presence of specific contaminants. A high TDS reading in the product water indicates the membrane is failing or the system requires cleaning. High turbidity suggests the pre-filtration stages aren’t working correctly. Elevated chlorine levels can damage the membrane. Specific contaminants, such as heavy metals, need to be identified to assess the overall water quality and system efficiency. For example, consistently high TDS values in the final output might indicate scaling on the membrane, requiring chemical cleaning. A high bacterial count points towards a need for sanitization procedures.

I use these results to tailor cleaning protocols. For example, high levels of silica suggest a need for acid cleaning, while organic fouling may require enzymatic cleaning solutions. It’s a process of systematically examining the data to understand the root cause of any issue.

Q 25. What are the common problems encountered during RO system cleaning, and how do you address them?

Common problems during RO system cleaning include scaling (mineral deposits), organic fouling (bacterial biofilms), and siltation (sediment buildup). Scaling is often addressed with acid cleaning solutions, carefully chosen based on the type of scale (calcium carbonate, silica, etc.). Organic fouling requires enzymatic cleaners to break down the biological material. Siltation usually involves physical cleaning methods, like backwashing or membrane rinsing. If a problem persists after cleaning, it might indicate a problem with pre-filtration, feed water quality, or membrane damage, requiring further investigation.

For example, if I observe reduced water flow after cleaning, I’ll re-examine the pre-filters for clogging, check the system pressure, and assess the membrane integrity. If the problem persists despite these checks, a further, more in-depth investigation will be necessary. A systematic approach, starting from simple solutions and escalating to more complex troubleshooting, is key.

Q 26. Describe your experience with different types of cleaning equipment.

My experience encompasses various cleaning equipment, including high-pressure pumps for backwashing, chemical injection systems for precise dosing of cleaning solutions, and specialized cleaning tanks for soaking and rinsing membranes. I’m proficient in using both manual and automated cleaning systems, adapting my techniques based on the system’s size, type, and the specific cleaning needs. I’ve worked with both in-situ cleaning methods, where the cleaning is performed within the system itself, and with the removal of components for off-site cleaning, which allows for more thorough cleaning of particularly fouled membranes. For example, in one instance, a particularly stubborn biofilm required the removal and separate cleaning of the RO membrane using specialized equipment and chemicals, which yielded better results than trying to clean it in place.

Q 27. How do you ensure the safety of yourself and others during RO system cleaning?

Safety is my top priority. I strictly adhere to safety protocols, including the use of appropriate Personal Protective Equipment (PPE) like gloves, eye protection, and respirators when handling chemicals. I carefully follow the manufacturer’s instructions for all cleaning agents and equipment. I ensure proper ventilation to mitigate exposure to potentially harmful fumes. Before starting any cleaning procedure, I carefully assess the system’s status, ensuring it’s properly isolated and de-energized. The process involves a detailed checklist to prevent accidental exposure or damage. For example, I would never work alone and always ensure there’s someone nearby in case of any emergency.

Q 28. What are your salary expectations for this role?

My salary expectations are in line with the industry standard for a domain expert with my experience and qualifications in reverse osmosis system cleaning. I’m open to discussing a competitive compensation package that reflects my value and contribution to your organization.

Key Topics to Learn for Reverse Osmosis System Cleaning Interview

- Understanding RO System Components: Learn the function of each component (pre-filters, membranes, post-filters, pressure pumps) and how they interact.

- Membrane Cleaning Techniques: Master various cleaning methods (chemical, physical, CIP), understanding their application based on membrane type and fouling.

- Water Quality Analysis: Familiarize yourself with relevant water quality parameters (TDS, conductivity, pH) and their impact on RO system performance and cleaning needs.

- Troubleshooting Common Issues: Develop your ability to diagnose problems like low production, high TDS, and membrane fouling, and propose effective solutions.

- Chemical Handling and Safety: Understand safe handling procedures for cleaning chemicals, including proper PPE usage and waste disposal.

- Preventive Maintenance: Learn best practices for regular maintenance to prevent fouling and extend system lifespan. This includes understanding maintenance schedules and procedures.

- Documentation and Reporting: Know how to effectively document cleaning procedures, results, and any necessary repairs.

- Regulations and Compliance: Understand relevant industry standards and regulations related to water treatment and chemical handling.

- Practical Application: Be prepared to discuss real-world scenarios involving troubleshooting, cleaning procedures, and maintenance strategies.

Next Steps

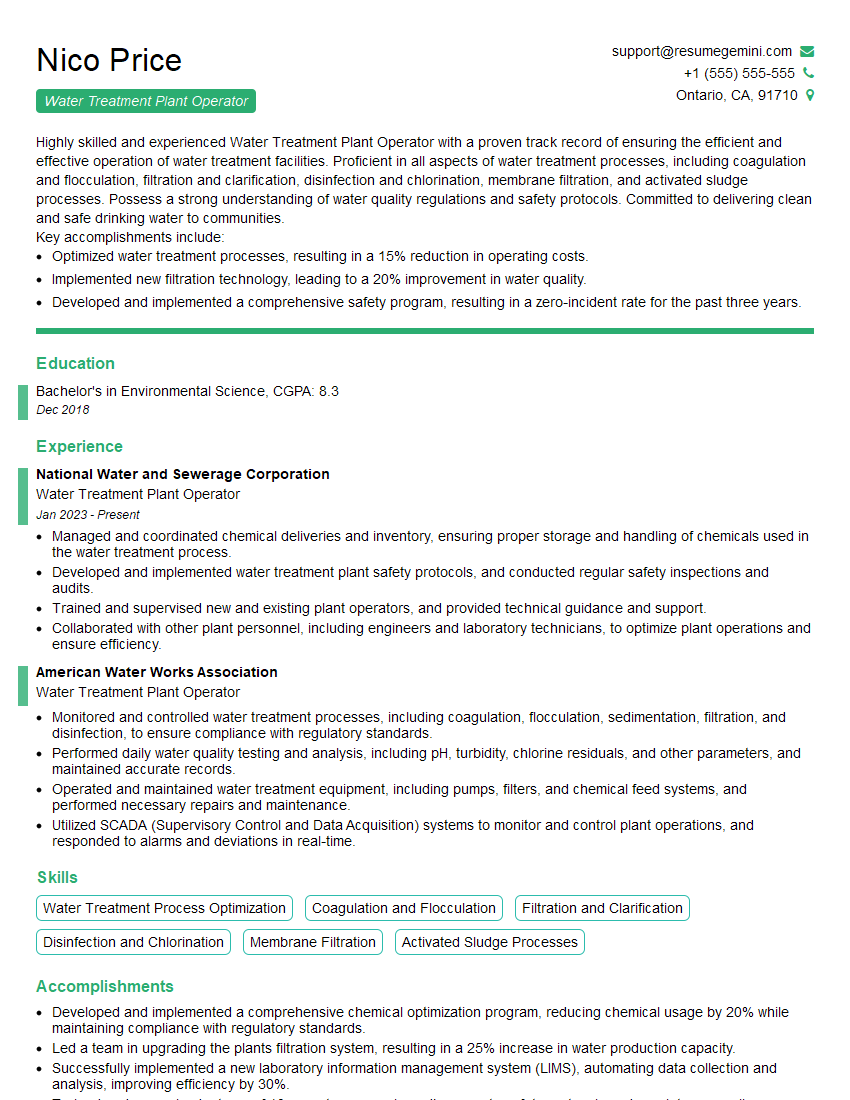

Mastering Reverse Osmosis System Cleaning opens doors to exciting career opportunities in water treatment, industrial settings, and more. A strong understanding of these systems demonstrates valuable technical skills and problem-solving abilities, making you a highly sought-after candidate. To significantly boost your job prospects, focus on creating an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to your skills and experience. Examples of resumes tailored to Reverse Osmosis System Cleaning are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.