Preparation is the key to success in any interview. In this post, we’ll explore crucial Roof Maintenance Scheduling and Planning interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Roof Maintenance Scheduling and Planning Interview

Q 1. Explain your experience with different roofing maintenance scheduling software.

My experience with roofing maintenance scheduling software spans several platforms, from simple spreadsheet-based systems to sophisticated CMMS (Computerized Maintenance Management Systems). I’ve worked extensively with programs like UpKeep, Fiix, and even customized solutions developed in-house. Each system offers different strengths. Spreadsheets are great for smaller operations or simpler tasks, allowing for quick data entry and basic reporting. However, for larger projects or more complex maintenance schedules, a CMMS is indispensable. These systems offer features such as work order management, inventory tracking, preventative maintenance scheduling, and robust reporting capabilities, which are essential for efficient management of a large roofing portfolio. For instance, using Fiix, I successfully implemented a preventive maintenance schedule across multiple high-rise buildings, significantly reducing reactive repair costs and improving the overall lifespan of the roofs.

My selection of software always depends on the specific needs of the project and the size of the operation. I consider factors like the number of buildings, the complexity of the roofing systems, the budget, and the technical skills of the team. For example, a smaller company might find a simpler, more intuitive system sufficient, whereas a large property management company would benefit from a CMMS with extensive features and integration capabilities.

Q 2. Describe your process for prioritizing roofing maintenance tasks.

Prioritizing roofing maintenance tasks involves a multi-faceted approach combining urgency, risk, and cost-effectiveness. I use a system that categorizes tasks based on these factors. First, I identify critical tasks that pose immediate safety risks or could lead to significant structural damage if neglected – for instance, immediate repairs to a leaking roof or addressing damaged flashing during a storm. These are high priority and addressed immediately. Next, I consider preventative maintenance tasks designed to extend the life of the roof. Regular inspections, cleaning gutters, and minor repairs fall into this category. These are scheduled proactively based on the manufacturer’s recommendations and the condition of the roof. Finally, there are tasks that are less urgent, such as cosmetic repairs or repainting. These are prioritized based on budget availability and overall project scheduling. This prioritization ensures that immediate safety concerns are handled first, followed by proactive maintenance to prevent larger problems, and lastly, improvements that enhance appearance and longevity.

To illustrate, imagine a scenario with multiple roofs under my care. One has a significant leak threatening interior damage, another needs routine gutter cleaning, and a third requires a minor cosmetic repair. The leaking roof takes top priority, followed by gutter cleaning (preventative) and finally the cosmetic repair. This approach allows for effective allocation of resources and minimizes potential losses.

Q 3. How do you handle unexpected roof repairs that disrupt the planned schedule?

Unexpected repairs necessitate a flexible approach to scheduling. When an unforeseen issue arises, I first assess the severity and potential impact on the building’s structural integrity and occupant safety. Urgent repairs, such as a major leak or significant structural damage, immediately supersede scheduled tasks. I re-prioritize the maintenance schedule, often using a Kanban-style approach to visualize the workflow. This involves adjusting tasks using a software system or a physical board to accommodate the urgent repair while attempting to minimize disruption to other planned tasks. Communication is crucial; I notify relevant stakeholders about the disruption and provide an updated timeline. Once the emergency repair is completed, I meticulously document the issue, the repair process, and the associated costs. This documentation helps in future planning and informs risk assessment for preventative maintenance.

For example, if a severe storm causes unexpected damage to a roof during a scheduled cleaning, I immediately redirect the crew to handle the storm damage before resuming the planned cleaning. This flexibility ensures that the most critical issues are addressed promptly while attempting to keep the overall maintenance schedule on track.

Q 4. What methods do you use to estimate the time and resources required for roof maintenance projects?

Estimating time and resources for roof maintenance requires careful planning and a deep understanding of roofing systems. My process begins with a thorough site assessment, including a detailed inspection of the roof’s condition, size, and complexity. I then consider the scope of work, which includes specific tasks required (e.g., cleaning, repairs, replacements). This informs the material requirements, and I create a comprehensive materials list using historical data and vendor quotes. Using my experience and established benchmarks for similar projects, I estimate the labor hours needed for each task. This includes accounting for potential unexpected issues and safety considerations. This detailed breakdown allows me to provide accurate estimates for both time and resources needed to complete the project. Software like project management tools can be invaluable in this step.

For instance, when planning a re-roofing project, I would consider factors like the roof area, the type of roofing material, the complexity of the design, and the weather conditions. I’d use historical data from similar projects to estimate labor hours and material costs, adding a contingency buffer to account for potential unforeseen complications. This helps to create a realistic budget and schedule that is acceptable to the client.

Q 5. How do you ensure compliance with safety regulations during roof maintenance?

Safety is paramount during roof maintenance. I ensure compliance with all relevant safety regulations, including OSHA (Occupational Safety and Health Administration) standards and any local regulations. This involves several key steps: pre-job safety briefings for all personnel, providing and ensuring proper use of personal protective equipment (PPE) such as harnesses, safety lines, and fall protection systems, regular inspections of equipment, and a thorough risk assessment before commencing work. Work permits are obtained as necessary, and the work area is properly secured to prevent accidents. Furthermore, ongoing safety training is mandatory for all team members. Emergency response plans are in place and regularly reviewed, including access to emergency communication devices and first aid supplies.

To ensure adherence to safety standards, I regularly conduct safety audits and inspections. For example, before starting any work at height, I ensure that proper fall protection systems are in place and that all team members are trained and certified in their use. This commitment to safety creates a secure and productive work environment for my team while ensuring the safety of everyone around the job site.

Q 6. Describe your experience with creating and managing a roof maintenance budget.

Creating and managing a roof maintenance budget necessitates a systematic approach. I begin by forecasting annual maintenance costs based on historical data, anticipated repairs, and planned preventative maintenance. This includes the cost of materials, labor, equipment rentals, and any potential unforeseen expenses. The budget is then categorized based on different aspects of roof maintenance, such as preventative maintenance, repairs, and larger projects like re-roofing. To control costs, I regularly monitor spending, comparing actual expenses against the budget. I use software to track expenses, ensuring accurate and timely reporting. Regular review and adjustments of the budget are crucial to ensuring fiscal responsibility and efficient resource allocation.

For example, if unexpected repairs exceed a certain threshold, I’ll review the budget, potentially prioritizing tasks or seeking additional funding. This ensures that the maintenance program remains financially sustainable and aligns with the overall business goals.

Q 7. How do you track the progress of roof maintenance projects and report on their status?

Tracking the progress of roof maintenance projects and reporting on their status is a crucial aspect of efficient management. I utilize a combination of software and manual methods. Software solutions, like project management tools, offer real-time tracking of progress, allowing me to monitor task completion, resource allocation, and overall project timelines. This data is used to generate regular progress reports for stakeholders. In addition to this, I use visual management tools like Kanban boards to monitor the workflow and identify potential bottlenecks. These reports include key metrics such as project completion rates, cost overruns, and any safety incidents. I also conduct regular on-site inspections to verify progress and identify potential issues. These inspections are documented with photos and notes, which are added to the project records. This integrated approach allows me to effectively monitor and communicate project status in a timely manner to relevant parties.

For instance, a weekly progress report would include a summary of completed tasks, a list of ongoing tasks with estimated completion dates, and any potential risks or challenges. This transparency fosters trust and allows stakeholders to stay informed throughout the project lifecycle.

Q 8. Explain your experience with different types of roofing materials and their maintenance requirements.

My experience encompasses a wide range of roofing materials, each with unique maintenance needs. Think of it like caring for different plants – a succulent needs less water than an orchid. For instance, asphalt shingles, the most common type, require regular cleaning of debris and occasional sealant application to prevent leaks. Their lifespan is typically 15-30 years, depending on climate and quality. Tile roofs, known for their durability, need periodic inspections for cracks or missing pieces. They’re much longer-lasting, often exceeding 50 years. Metal roofs, while extremely durable, can suffer from corrosion in harsh climates and may need repainting or protective coatings. Finally, flat roofs, often found on commercial buildings, necessitate regular inspections for ponding water, which can lead to premature failure. Each material’s maintenance schedule is tailored to its properties and vulnerabilities; for example, I’d schedule more frequent inspections for a flat roof in a high-rain area compared to an asphalt shingle roof in a dry climate.

- Asphalt Shingles: Annual cleaning, sealant application every 5-7 years.

- Tile Roofs: Semi-annual inspection, crack repair as needed.

- Metal Roofs: Inspection every 2-3 years, repainting or coating every 10-15 years.

- Flat Roofs: Quarterly inspections, immediate repair of any ponding water.

Q 9. How do you identify potential roof problems during inspections and plan for their repair?

Identifying roof problems starts with a thorough inspection, which I conduct systematically. I use binoculars to examine hard-to-reach areas, checking for missing or damaged shingles, signs of water damage (dark stains, sagging), loose flashing (metal pieces around chimneys and vents), and evidence of pest infestation. I also check gutters and downspouts for blockages. For example, a small crack in a shingle might seem insignificant, but it’s a potential entry point for water that can lead to extensive damage down the road. Identifying potential problems involves careful observation combined with understanding the potential consequences of minor damage. Once identified, I prioritize repairs based on urgency and potential impact, using a risk assessment matrix that considers factors like cost, severity, and the potential for escalation of damage. This matrix allows for systematic planning of repairs, ensuring that critical issues are addressed promptly.

For example, a leaky roof needs immediate attention to prevent water damage to the building’s interior, while minor cosmetic issues can often wait until a scheduled maintenance visit. Detailed reports with photos are provided to clients, including proposed repair plans and estimated costs. This transparency ensures informed decision-making.

Q 10. How do you communicate effectively with roofing contractors and other stakeholders?

Effective communication is crucial for successful roof maintenance. I utilize a multi-faceted approach. I maintain clear and concise written communication via detailed reports and email updates, keeping all parties – clients, contractors, and relevant stakeholders – informed throughout the entire process. Regular meetings or conference calls are essential for discussing progress, addressing concerns, and ensuring everyone is on the same page. For example, if a contractor encounters unexpected issues during a repair, immediate communication allows for quick adjustments to the plan and prevents delays. This includes using visual aids like photos or diagrams to illustrate problems and solutions, which is especially helpful when explaining technical issues to non-technical clients.

Using a project management platform for shared documentation is a great way to ensure everyone has access to the latest updates. Active listening and empathy are also crucial. Understanding the needs and perspectives of each party helps to resolve potential conflicts and maintain positive relationships.

Q 11. What are your strategies for preventing roof damage and extending the lifespan of roofs?

Preventing roof damage focuses on proactive measures. Regular cleaning of gutters and downspouts prevents water overflow, which is a leading cause of damage. Regular tree trimming near the roof eliminates branches that could damage shingles during storms. Proper attic ventilation prevents moisture buildup, extending the lifespan of the roof significantly. Think of it like regular car maintenance – oil changes and tire rotations prevent bigger, more expensive problems down the line. Applying sealant to vulnerable areas, such as flashings and valleys, prevents water penetration. Regular inspections allow for early detection of minor problems before they escalate into major repairs. For example, addressing a small leak immediately prevents rot, mold growth, and potential structural damage.

Beyond that, educating clients on the importance of proper roof maintenance is critical. This may involve providing guidance on avoiding walking on the roof unnecessarily, carefully clearing snow, and promptly addressing any obvious damage they may observe.

Q 12. How do you incorporate preventative maintenance into your roofing schedule?

Preventative maintenance is woven into my roofing schedules using a combination of techniques. I use a computerized maintenance management system (CMMS) to track inspections, repairs, and upcoming maintenance tasks, ensuring nothing falls through the cracks. This system allows for scheduling regular inspections based on the type of roof and its specific needs (e.g., annual inspections for asphalt shingles, semi-annual for flat roofs). I also utilize seasonal maintenance schedules, focusing on gutter cleaning in the fall, snow removal in winter, and assessing for storm damage in spring. This systematic approach ensures timely intervention, minimizing costly repairs and extending the roof’s lifespan. The CMMS also generates alerts reminding us of upcoming tasks, ensuring a preventative approach is consistently implemented and documented.

Clients are also informed of the planned preventative maintenance to enable their cooperation and facilitate efficient implementation.

Q 13. Describe your experience with developing and implementing a roof maintenance program.

I’ve developed and implemented numerous roof maintenance programs, tailoring each to specific building types, climates, and budgetary constraints. The process usually begins with a thorough assessment of the existing roof condition, which includes detailed inspections, material identification, and evaluation of potential risks. Next, I create a customized maintenance schedule based on the findings. This schedule outlines specific tasks, frequencies, and responsibilities. I then create a budget that outlines the costs associated with the maintenance schedule. Communication materials, including a clear outline of the program, are then developed for the client.

For example, one program involved implementing a preventative maintenance program for a large apartment complex. This included establishing a schedule for regular gutter cleaning, roof inspections, and minor repairs. The success of this program is evident in the reduced number of major roof repairs and a significant extension in the lifespan of the roof compared to their past experience.

Q 14. How do you handle conflicts or disagreements between different parties involved in roof maintenance?

Conflicts can arise between different parties during roof maintenance. My approach emphasizes proactive communication and conflict resolution strategies. First, I clearly define roles and responsibilities at the outset of any project, ensuring that all parties understand their contributions. When disagreements occur, I facilitate open dialogue, fostering a collaborative environment where each party can express their concerns. I act as a neutral mediator, focusing on identifying the root cause of the disagreement rather than placing blame. Finding common ground is key; seeking mutually beneficial solutions is prioritized. For example, if a disagreement arises between a client and a contractor regarding the cost of repairs, I work to find a compromise that considers both parties’ perspectives and aligns with industry standards and best practices. If necessary, I consult with legal professionals or industry experts to ensure fair and equitable resolutions.

Documentation is essential to avoid misunderstandings and to ensure accountability. Thorough records of inspections, repairs, and communications can be invaluable in resolving disputes and preventing future conflicts.

Q 15. What are your experience with using CMMS (Computerized Maintenance Management System) software?

My experience with CMMS software is extensive. I’ve used several platforms, including Fiix, UpKeep, and Limble CMMS, to manage all aspects of roof maintenance. I’m proficient in setting up preventative maintenance schedules based on roof type, age, and manufacturer recommendations, tracking work orders, managing inventory of repair materials, and generating insightful reports on maintenance costs and efficiency. For example, using Fiix, I was able to implement a predictive maintenance program for a large retail complex by integrating sensor data from weather stations and roof-mounted monitoring systems. This allowed us to proactively address potential issues before they became major repairs, saving the company thousands in unexpected costs. The ability to generate customized reports allows stakeholders to easily understand the program’s ROI and make informed decisions about future maintenance strategies. Furthermore, I’m adept at training staff on the effective use of these systems, ensuring seamless data entry and accurate record-keeping.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage the documentation and records of roof maintenance activities?

Documentation and records are crucial for effective roof maintenance. My approach involves a multi-layered system. Firstly, I utilize the CMMS to meticulously log every maintenance activity, including date, time, work performed, materials used, and the technician’s notes. This system provides a central repository accessible to all relevant personnel. Secondly, I maintain physical files containing original invoices, warranty information, and inspection reports. This offline backup ensures data security and provides easy access for audits or in the event of system failure. Finally, high-resolution photographic and videographic records are kept, providing visual evidence of the roof’s condition over time. This visual documentation is invaluable for identifying trends, assessing damage, and making informed decisions regarding future maintenance or repairs. For instance, documenting minor leaks over time with photos can help trace the progression of a problem and determine the root cause much more effectively.

Q 17. What are your skills in risk assessment and mitigation in relation to roof maintenance?

Risk assessment and mitigation are paramount in roof maintenance. I employ a systematic approach, starting with a thorough roof inspection using drones and/or detailed physical assessments. This identifies potential hazards such as leaks, damaged flashing, deteriorated roofing material, and potential structural weaknesses. I then assess the likelihood and potential consequences of these hazards, prioritizing those with high likelihood and severe impact. Mitigation strategies involve developing and implementing preventative maintenance schedules, replacing compromised materials, addressing structural issues, and implementing safety protocols for all maintenance activities. For example, if we identify a section of deteriorated roofing material near a frequently used walkway, we would prioritize its repair to prevent a fall hazard. The results of these risk assessments are documented and incorporated into the CMMS, serving as a living document that evolves as the building and its roof age.

Q 18. How do you handle emergency roof repairs?

Emergency roof repairs demand immediate action. My response protocol begins with immediate assessment of the damage to determine the extent of the issue and potential safety hazards. This often involves securing the area to prevent further damage or injuries. I then contact pre-approved emergency contractors who are on-call and familiar with the building’s roof. I communicate the urgency and severity of the situation, ensuring a swift response. The repair is documented comprehensively, and all actions are logged within the CMMS. Following the emergency repair, a thorough assessment is performed to identify the root cause of the failure, implementing preventative measures to avoid future incidents. For example, a sudden, heavy storm might cause damage to a section of the roof. Our response involves securing the area, contacting the emergency contractor for temporary repair to prevent leaks and further damage, and then planning a more thorough repair post-storm.

Q 19. Describe your experience with different roofing repair techniques.

My experience encompasses a wide range of roofing repair techniques, including those for various roofing materials. This includes repairs to asphalt shingles (involving the replacement of individual shingles, or larger sections), flat roofs (requiring patching, seam sealing, or the application of coatings), and metal roofing (involving the repair or replacement of panels, flashing, and fasteners). I’m familiar with various waterproofing techniques and have experience with the installation and repair of roof drains, gutters, and downspouts. I’m also knowledgeable about the use of specialized equipment and materials like hot-air welders for thermoplastic roofs, and specialized sealants for various roof types. My expertise allows me to select the most appropriate repair technique based on the specific roofing material, the nature of the damage, and budget constraints.

Q 20. How do you ensure the quality of roof maintenance work performed by contractors?

Ensuring quality work from contractors is achieved through a multi-faceted approach. First, I pre-qualify contractors, verifying their licensing, insurance, and experience with similar projects. Detailed scope of work documents are prepared, clearly outlining the required tasks, materials, and quality standards. Regular site inspections are conducted during the repair process, meticulously documenting progress and identifying any deviations from the agreed-upon plan. Upon completion, a thorough quality check is performed, checking for compliance with industry standards and the initially agreed-upon deliverables. Finally, payment is contingent upon satisfactory completion and acceptance of the work. Any issues or defects are documented and addressed immediately. This system ensures contractors understand the expectations and are held accountable for the quality of their work. We also solicit feedback from contractors to continuously improve our maintenance process.

Q 21. How do you measure the effectiveness of your roof maintenance program?

Measuring the effectiveness of a roof maintenance program relies on several key performance indicators (KPIs). These include the reduction in the number and cost of emergency repairs, the decrease in the frequency and severity of roof leaks, and an increase in the lifespan of the roofing system. We track these metrics through the CMMS, analyzing historical data to identify trends and measure the success of preventative maintenance strategies. Regular roof inspections provide valuable insights into the overall condition of the roof and allow for the identification of areas requiring attention before they become significant problems. The cost of maintenance per square foot is also a crucial metric, helping determine the efficiency and cost-effectiveness of the implemented strategies. By tracking these KPIs, we can make data-driven decisions to optimize the program’s performance and maximize the return on investment.

Q 22. What are your strategies for reducing the costs associated with roof maintenance?

Reducing roof maintenance costs requires a proactive, multi-pronged approach. It’s not just about saving money in the short term; it’s about investing wisely to prevent larger, more costly repairs down the line.

Preventative Maintenance: Regular inspections (at least twice a year, more frequently in harsh climates) are key. Early detection of minor issues like loose shingles or damaged flashing prevents them from escalating into major leaks requiring extensive repairs. Think of it like regular car maintenance – oil changes prevent engine damage.

Proper Material Selection: Choosing durable, high-quality roofing materials initially can significantly reduce long-term maintenance costs. While the upfront cost might be higher, the lifespan and reduced repair needs often outweigh the initial investment.

Effective Cleaning: Regularly removing debris like leaves, branches, and moss prevents water damage and premature wear. A simple gutter cleaning can save you from thousands in future repairs.

Skilled Labor: Hiring experienced and qualified roofing professionals is essential. A poorly executed repair can lead to more extensive damage and higher costs later on. Investing in quality workmanship is an investment in long-term cost savings.

Detailed Record Keeping: Maintaining detailed records of all maintenance activities, including dates, repairs made, and costs incurred, helps track expenses and identify patterns or potential recurring issues.

Q 23. How do you stay updated on the latest industry standards and best practices for roof maintenance?

Staying current in the roofing industry is crucial. I utilize several methods to ensure my knowledge remains up-to-date:

Professional Organizations: Active membership in organizations like the National Roofing Contractors Association (NRCA) provides access to industry publications, webinars, and conferences, keeping me abreast of the latest codes, materials, and techniques.

Industry Publications and Journals: I regularly read trade magazines and journals focused on roofing technology and best practices. These publications often feature articles on new materials, innovative repair methods, and emerging trends.

Continuing Education Courses: I actively pursue continuing education opportunities to earn certifications and stay informed about advancements in roofing technology and safety regulations.

Manufacturer Training: Many roofing material manufacturers offer training programs on their products, providing valuable insights into proper installation and maintenance procedures.

Networking: Attending industry events and connecting with other professionals allows for the exchange of knowledge and best practices.

Q 24. Explain your experience with working with different building codes and regulations related to roofing.

Experience with various building codes and regulations is paramount. I’ve worked extensively with codes like the International Building Code (IBC) and local ordinances, understanding their implications for roof design, materials, and maintenance.

For instance, I’ve encountered situations where a building’s historical status dictated specific material choices or repair techniques, requiring careful navigation of preservation regulations alongside modern safety standards. Similarly, in high-wind zones, I’ve adapted maintenance schedules and employed reinforced fasteners to meet stricter code requirements. Every project starts with a thorough review of the applicable building codes and local regulations to ensure compliance and safety.

My approach involves:

Thorough Code Review: A comprehensive review of all relevant codes and regulations is conducted at the project’s outset.

Permitting Process: I understand the permitting process and ensure all necessary approvals are obtained before commencing any work.

Documentation: Detailed documentation of all work performed, including compliance with relevant codes, is meticulously maintained.

Q 25. How do you deal with challenging weather conditions during roof maintenance projects?

Weather is a significant factor in roof maintenance. Safety is always the top priority. I employ various strategies to address challenging weather conditions:

Weather Monitoring: Closely monitoring weather forecasts is essential. Projects are rescheduled or postponed if severe weather (high winds, heavy rain, or snow) is anticipated.

Safety Precautions: In windy conditions, additional safety measures are implemented, such as using tie-off points and employing specialized equipment to prevent falls.

Adaptive Techniques: For example, during a light rain, I’ve adjusted the work schedule to complete tasks that aren’t significantly impacted by moisture. However, tasks such as sealant application would be postponed.

Emergency Procedures: Contingency plans are in place to address unexpected weather events. This includes secure storage of materials and equipment to protect against damage.

Q 26. Describe your experience with creating and using a roof maintenance checklist.

A well-structured roof maintenance checklist is critical for efficient and thorough inspections. My checklist incorporates various aspects:

Visual Inspection: Checking for loose, missing, or damaged shingles, flashing, gutters, and downspouts.

Structural Integrity: Examining the roof deck for signs of sagging, rot, or pest infestation.

Drainage System: Assessing the functionality of the gutters and downspouts, ensuring proper water drainage.

Flashing and Seals: Inspecting areas around chimneys, vents, and skylights for leaks or damage.

Photographs: Taking detailed photographs of any damage or areas of concern.

Material Condition: Assessing the overall condition of the roofing materials.

The checklist serves as a template, adaptable to different roof types and building sizes. The data collected informs the development of a tailored maintenance plan.

Q 27. How do you manage multiple roof maintenance projects simultaneously?

Managing multiple projects requires meticulous organization and planning. I utilize a project management system to track progress, deadlines, and resource allocation. This includes:

Prioritization: Projects are prioritized based on urgency, complexity, and client needs.

Resource Allocation: Labor, equipment, and materials are allocated effectively across projects, optimizing efficiency.

Scheduling: A detailed schedule is created for each project, outlining tasks, timelines, and milestones.

Communication: Regular communication with clients and team members is maintained to ensure transparency and address any issues promptly.

Progress Tracking: Progress is monitored closely against the schedule and budget. Adjustments are made as needed to stay on track.

Using project management software allows for a centralized hub for all information and effective collaboration.

Key Topics to Learn for Roof Maintenance Scheduling and Planning Interview

- Understanding Roof Types and Lifecycles: Knowing the different types of roofing materials (e.g., asphalt, tile, metal) and their respective maintenance needs and lifespans is crucial for effective scheduling.

- Prioritization and Risk Assessment: Learn how to prioritize maintenance tasks based on urgency, potential damage, and budget constraints. This includes understanding how to assess the risk of roof failure and its consequences.

- Developing a Comprehensive Maintenance Schedule: Mastering the creation of detailed, realistic, and cost-effective maintenance schedules that account for weather patterns, seasonal variations, and potential delays.

- Budgeting and Resource Allocation: Understanding how to estimate costs, allocate resources (materials, labor, equipment), and manage budgets for roof maintenance projects is essential.

- Preventive vs. Reactive Maintenance: Differentiate between the importance of preventive maintenance to reduce long-term costs and reactive maintenance for urgent repairs. Discuss the balance between the two strategies.

- Software and Technology in Scheduling: Familiarity with scheduling software and digital tools used to track maintenance tasks, generate reports, and manage communication with contractors.

- Communication and Teamwork: Discuss the importance of clear communication with stakeholders (clients, contractors, team members) and effective collaboration to ensure smooth project execution.

- Regulatory Compliance and Safety Procedures: Demonstrate understanding of relevant safety regulations, permit requirements, and best practices for working at heights.

- Problem-Solving and Contingency Planning: Describe your approach to addressing unexpected issues, delays, or changes in project scope. Showcase your ability to adapt and find solutions.

- Data Analysis and Reporting: Understanding how to collect, analyze, and present data on maintenance activities, costs, and performance to improve efficiency and decision-making.

Next Steps

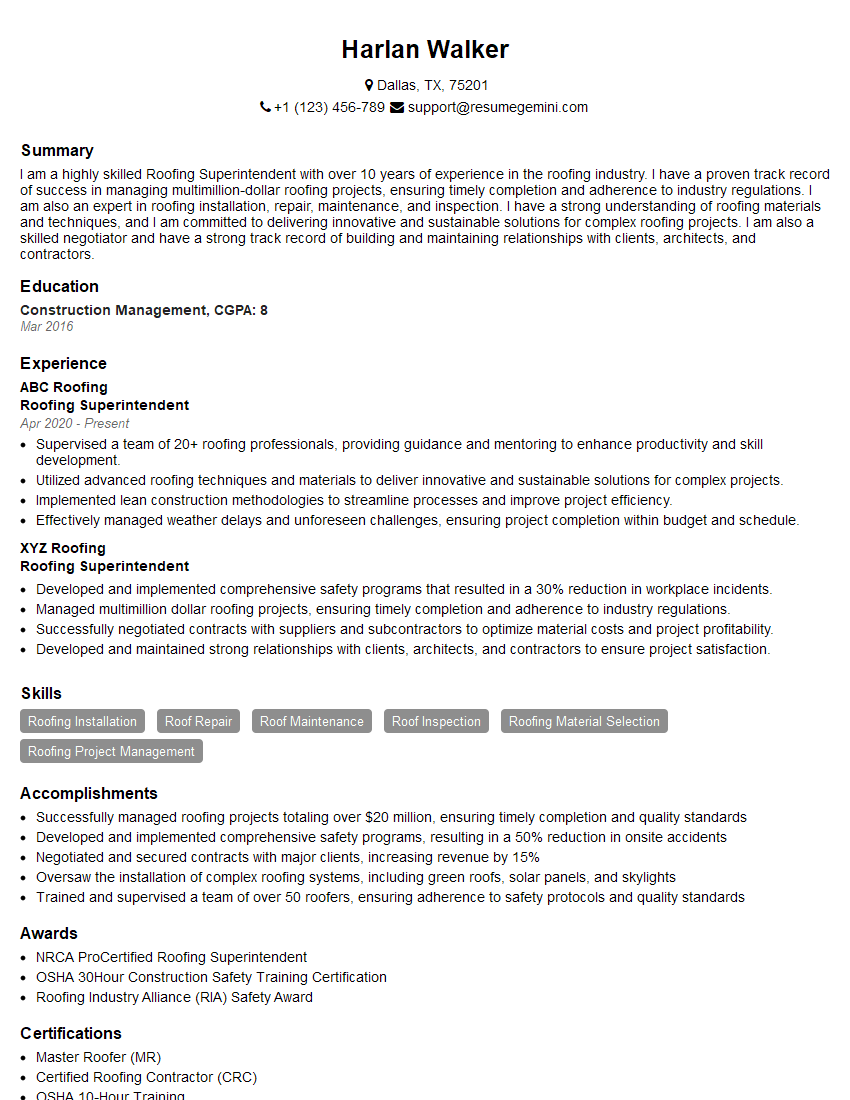

Mastering Roof Maintenance Scheduling and Planning significantly enhances your career prospects, demonstrating valuable organizational, analytical, and problem-solving skills highly sought after in the industry. To increase your chances of landing your dream job, create a strong, ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume that stands out. We provide examples of resumes tailored to Roof Maintenance Scheduling and Planning to guide you through the process. Invest time in creating a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.