The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Roofing Material Knowledge interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Roofing Material Knowledge Interview

Q 1. What are the key differences between asphalt shingles, tile, and metal roofing materials?

Asphalt shingles, tile, and metal roofing materials each offer distinct advantages and disadvantages. Asphalt shingles are the most common and affordable, composed of fiberglass mats coated with asphalt and granules. They’re relatively lightweight and easy to install. Tiles, encompassing both clay and concrete varieties, are heavier, more durable, and offer better fire resistance. Metal roofing, including standing seam and corrugated styles, provides exceptional longevity, energy efficiency, and weather resistance but comes with a higher initial cost.

- Asphalt Shingles: Economical, lightweight, readily available, relatively easy installation.

- Tile Roofing (Clay & Concrete): Durable, fire-resistant, aesthetically pleasing, long lifespan, but heavier and more expensive.

- Metal Roofing: Highly durable, energy-efficient (reflective), long lifespan, low maintenance, but typically more expensive and requires specialized installation.

Q 2. Describe the advantages and disadvantages of using each of the following roofing materials: asphalt shingles, clay tiles, concrete tiles, slate, metal (standing seam, corrugated).

Let’s examine the pros and cons of each roofing material:

- Asphalt Shingles:

- Advantages: Affordable, readily available, easy installation, wide variety of colors and styles.

- Disadvantages: Shorter lifespan compared to other materials (15-30 years), susceptible to damage from strong winds and hail, can degrade faster in harsh climates.

- Clay Tiles:

- Advantages: Extremely durable, fire-resistant, excellent weather resistance, long lifespan (50-100+ years), aesthetically pleasing.

- Disadvantages: Expensive, heavy, requires strong roof structure, can be brittle and prone to cracking if improperly installed.

- Concrete Tiles:

- Advantages: Durable, fire-resistant, less expensive than clay tiles, longer lifespan than asphalt shingles.

- Disadvantages: Heavier than asphalt shingles, can be prone to cracking under extreme temperature fluctuations, less aesthetically varied than clay tiles.

- Slate:

- Advantages: Extremely durable, beautiful aesthetics, extremely long lifespan (100+ years), fire-resistant.

- Disadvantages: Very expensive, heavy, requires specialized installation, can be prone to cracking if improperly installed.

- Metal Roofing (Standing Seam & Corrugated):

- Advantages: Long lifespan (50+ years), energy-efficient (reflective), durable, weather-resistant, low maintenance.

- Disadvantages: Higher initial cost, can be noisy during rain or hail, requires specialized installation.

Q 3. Explain the process of selecting appropriate roofing materials based on climate and building code requirements.

Selecting appropriate roofing materials involves careful consideration of climate and building codes. For instance, in areas with heavy snowfall, a roof needs to withstand significant weight. Metal roofing is strong enough for those conditions but it has to be carefully installed with the proper underlayment and snow guards. In regions with high winds, stronger materials like clay tile or metal are preferable to asphalt shingles. Areas prone to wildfires benefit greatly from fire-resistant materials like clay tile or slate. Building codes often dictate minimum wind resistance, fire ratings, and snow load capabilities, so compliance is crucial.

Step-by-step process:

- Assess Climate: Identify prevailing weather conditions (snow load, wind speed, rainfall, temperature extremes).

- Review Building Codes: Check local regulations for roofing material requirements.

- Material Selection: Choose a material that meets code requirements and withstands local climate conditions.

- Consult Professionals: Seek advice from roofing professionals and engineers to ensure proper selection and installation.

Q 4. How do you determine the appropriate underlayment for a specific roofing system?

Underlayment protects the roof deck from moisture damage during installation and provides an additional layer of waterproofing. The choice of underlayment depends on the roofing material and the climate. Asphalt shingles might use a standard felt underlayment, while more rugged roofing materials like metal or tile might require a more robust synthetic underlayment. In areas with heavy rainfall or snow, a higher-performance underlayment with enhanced water resistance is necessary. The purpose is to create a redundant water barrier, in the event the primary layer fails.

Example: A steep-slope roof in a high-wind area might use a self-adhering synthetic underlayment for superior wind resistance and moisture protection.

Q 5. What are the common causes of premature roofing material failure?

Premature roofing failure stems from various factors:

- Poor Installation: Improperly installed roofing materials are vulnerable to leaks and early damage.

- Inadequate Underlayment: Insufficient or damaged underlayment allows moisture penetration.

- Extreme Weather Conditions: Strong winds, hail, heavy snow, and extreme temperature fluctuations can stress and damage roofing materials.

- Neglect and Lack of Maintenance: Regular inspections and cleaning can prevent minor issues from escalating into major problems.

- Material Degradation: Exposure to UV radiation, moisture, and temperature cycles can degrade roofing materials over time, shortening their lifespan.

- Improper Ventilation: Poor attic ventilation traps moisture, leading to condensation and damage.

Q 6. Describe the proper installation techniques for asphalt shingles.

Proper asphalt shingle installation is crucial for a long-lasting roof. It starts with a thorough preparation of the roof deck, ensuring it’s clean, dry, and free of debris. The underlayment is then installed, overlapping seams and ensuring proper coverage. Shingles are applied starting from the bottom edge of the roof, following the manufacturer’s instructions for shingle overlap and alignment. Each shingle is nailed securely, using the correct number of nails in designated locations. Special attention is paid to valleys, ridges, hips, and around chimneys and vents to ensure a watertight seal. Flashing is installed around these penetrations to prevent water infiltration. Finally, a thorough inspection verifies proper installation and addresses any potential issues.

Q 7. How do you assess the condition of an existing roof and determine the need for repair or replacement?

Assessing an existing roof involves a comprehensive inspection. This typically begins with a visual examination from the ground, checking for missing or damaged shingles, sagging, or signs of water damage. A detailed inspection from the roof itself is necessary; this includes checking for loose shingles, damaged flashing, signs of moisture intrusion, and assessing the overall condition of the underlayment. Careful examination of valleys, chimneys, and vents is particularly important. Tools may include a moisture meter to detect hidden water damage. Based on the findings, a determination is made regarding the need for repair or replacement; minor repairs might suffice, while extensive damage necessitates a full roof replacement.

Q 8. What are the safety procedures for working at heights on a roof?

Working at heights on a roof is inherently dangerous. Safety is paramount and requires a multi-layered approach. This begins with proper training and adherence to OSHA regulations (or equivalent in your region).

- Fall Protection: This is the most crucial element. A complete fall protection system must always be in place, including a properly anchored harness, lanyard, and potentially a safety net depending on the height and work being done. Regular inspections of all equipment are vital.

- Scaffolding and Access: Safe and stable access to the roof is essential. This may involve using scaffolding, ladders (secured at the top and bottom), or roof access points that are structurally sound.

- Personal Protective Equipment (PPE): Beyond fall protection, PPE includes hard hats, safety glasses, gloves appropriate for the roofing materials (e.g., cut-resistant gloves for metal roofing), and appropriate footwear with good traction.

- Weather Conditions: Never work on a roof during inclement weather, such as rain, snow, or high winds. Wind can dislodge workers and materials.

- Communication: Clear and constant communication with fellow workers is essential. If working as a team, establish clear hand signals for passing materials and warning of potential hazards.

- Regular Inspections: Before commencing work, conduct a thorough inspection of the roof’s structural integrity and identify any potential hazards, like weak spots or damaged areas.

For instance, on a recent project involving a steep-sloped roof, we utilized a full-body harness system anchored to a secure roof ridge, coupled with a safety net for added protection. This ensured the safety of the crew throughout the installation.

Q 9. Explain the importance of proper ventilation in a roofing system.

Proper ventilation in a roofing system is critical for preventing moisture buildup, which is a leading cause of premature roof failure. Moisture can lead to rot, mold growth, and the degradation of roofing materials. Ventilation helps to equalize the temperature and moisture levels inside the attic or building cavity and the outside air.

- Preventing Condensation: Warm, moist air rising from inside the building can condense on a cold roof surface, especially in colder climates. Ventilation allows for the escape of this moisture-laden air.

- Removing Heat: Proper ventilation helps to remove heat that builds up in the attic space, reducing the strain on the roofing materials and extending the life of the roof.

- Preventing Ice Dams: In colder regions, proper ventilation can help to prevent ice dams, which form when warm air escapes and melts snow on the roof, leading to ice buildup at the eaves.

The type of ventilation needed depends on the roof design and climate. Common ventilation methods include ridge vents, soffit vents, and gable vents. A balanced ventilation system, ensuring adequate intake and exhaust, is crucial for effectiveness. For example, a recent project on a historic building involved installing new soffit vents and improving existing gable vents to address a significant moisture problem.

Q 10. How do you handle a roofing material shortage on a job site?

Material shortages are an unfortunate reality in the construction industry. Effective handling requires proactive planning and swift problem-solving.

- Verify the Shortage: First, confirm the extent of the shortage and the specific materials affected. Contact the supplier immediately to understand the cause of the delay and get an estimated delivery date.

- Explore Alternative Materials: If the delay is significant, explore using comparable alternative materials that meet project specifications. This might involve submitting a change order for approval from the client or architect.

- Adjust the Schedule: Revise the project schedule to accommodate the delay. Prioritize tasks that don’t require the missing materials.

- Communicate Effectively: Keep the client, architect, and subcontractors informed about the situation, providing regular updates and managing expectations.

- Document Everything: Meticulously document all communications, changes, and decisions related to the shortage. This protects you from potential disputes or liability.

In one instance, we experienced a sudden shortage of a specific type of asphalt shingle. We promptly contacted the supplier, who identified a logistical issue. While awaiting delivery, we temporarily paused work on the affected area and focused on other parts of the project. We kept the client informed via email and progress reports. This transparent communication helped manage expectations and maintain a positive working relationship.

Q 11. What are some common roofing material defects and how are they addressed?

Several common roofing material defects can significantly impact a roof’s performance and longevity.

- Blistering (Asphalt Shingles): This occurs when moisture gets trapped under the shingles, causing them to bubble. Addressing this often requires removing and replacing the affected shingles.

- Granule Loss (Asphalt Shingles): Loss of granules reduces the shingle’s UV resistance and lifespan. Minor loss is often acceptable, but severe loss requires replacement.

- Cracking (Tile, Concrete): Cracks can be caused by settling, impacts, or freeze-thaw cycles. Minor cracks might be sealed, while extensive cracking necessitates replacement.

- Leaks (All Roofing Types): Leaks are a serious issue requiring prompt attention. Locating the source is crucial, often involving visual inspections and potentially moisture detection tools. Repairs range from simple sealant applications to extensive repairs or replacements.

- Corrosion (Metal Roofing): Corrosion weakens metal roofing. Addressing this may involve cleaning, applying protective coatings, or replacing affected sections.

For example, during a recent inspection, we discovered extensive granule loss on a section of asphalt shingles. This warranted partial roof replacement, as sealing wouldn’t provide sufficient long-term protection.

Q 12. Explain the difference between modified bitumen and built-up roofing systems.

Both modified bitumen and built-up roofing (BUR) systems are low-slope roofing systems known for their durability and water resistance, but they differ significantly in their composition and installation.

- Modified Bitumen: This system uses asphalt-based sheets modified with polymers (like APP or SBS) to enhance flexibility and durability. They’re applied using heat or adhesive, often overlapping and adhering to a base layer. They are relatively easy to install compared to BUR.

- Built-Up Roofing (BUR): BUR systems are composed of multiple layers of asphalt felt, saturated with hot bitumen, and topped with a surfacing material such as gravel or cap sheet. It’s a labor-intensive process requiring specialized equipment and skilled labor. It is very durable and offers high resistance to punctures and weathering, but it is less flexible.

The key difference lies in their application: modified bitumen is a prefabricated sheet that’s relatively quick to install, while BUR is a field-applied, multi-layered system. Modified bitumen is often preferred for its speed and ease of installation, especially on larger projects, while BUR’s multiple layers provide exceptional durability in high-traffic areas.

Q 13. What is your experience with various types of flashing and their applications?

Flashing is crucial for preventing water penetration at critical junctions in the roofing system. Different flashing types are used depending on the specific application and roofing material.

- Step Flashing: Used where the roof meets a vertical wall. It consists of a series of overlapping pieces that create a watertight seal.

- Counter Flashing: This is installed on the wall, overlapping step flashing to provide a second layer of protection.

- Valley Flashing: Used in the valleys where two roof slopes meet. It directs water away from the intersection.

- Chimney Flashing: This protects the area where the chimney penetrates the roof. It requires careful attention to detail and multiple layers.

- Metal Flashing: Typically made of galvanized steel, copper, or aluminum. These are durable and weather-resistant, common in all flashing applications.

Proper flashing installation is essential to prevent leaks. On a recent project involving a complex roofline with multiple valleys and chimneys, we meticulously installed step flashing, counter flashing, and valley flashing to ensure a watertight seal. We used copper flashing on the chimneys for its longevity and resistance to corrosion.

Q 14. Describe your knowledge of different types of roofing insulation and their R-values.

Roofing insulation plays a vital role in energy efficiency and the overall comfort of a building. Different insulation types offer varying levels of thermal resistance, measured in R-values. Higher R-values indicate greater insulation effectiveness.

- Fiberglass Batt: A common and cost-effective option, often used in attics. R-values typically range from R-13 to R-38, depending on the thickness.

- Rigid Foam Boards (Polyisocyanurate, Polyurethane, Extruded Polystyrene): These offer high R-values (R-4 to R-8 per inch) and are excellent for improving thermal performance. They are often used under metal roofing or for flat roofs.

- Spray Foam Insulation: Applied as a liquid, it expands to fill gaps and crevices, creating a continuous air barrier. Offers high R-values (R-6 to R-7 per inch) and excellent air sealing capabilities.

- Cellulose Insulation: Made from recycled paper, it’s a sustainable option with good insulation properties (R-3.7 per inch). It is usually blown in.

The choice of insulation depends on factors such as the climate, roof design, and budget. For instance, in a colder climate, we might specify high R-value rigid foam boards to maximize energy efficiency. In a project focused on sustainability, cellulose insulation would be a suitable choice.

Q 15. How do you calculate the amount of roofing materials needed for a specific project?

Accurately calculating roofing material needs is crucial for efficient project management and cost control. It involves a multi-step process that begins with precise measurements of the roof’s surface area. This isn’t simply length times width; it requires accounting for roof pitch, valleys, hips, ridges, and any dormers or other complex features.

Step 1: Measure the Roof. Use a measuring wheel or laser distance meter for accuracy. Break the roof into simple geometric shapes (rectangles, triangles) for easier calculation. Sketch a diagram to help visualize these sections.

Step 2: Calculate the Area of Each Section. Employ standard geometric formulas (e.g., area of a rectangle = length x width, area of a triangle = 0.5 x base x height). Document each calculation carefully.

Step 3: Account for Waste. Roofing materials always involve some waste due to cutting, fitting, and unavoidable damage. This waste factor varies by material and roofing complexity; it’s typically between 5% and 15%, sometimes higher for intricate designs. Add this percentage to your total calculated area.

Step 4: Consider Material Specifications. Manufacturers provide coverage rates per square (100 square feet) or per bundle. Use this information to convert your total area (including waste) into the required number of squares or bundles. Always round up to the nearest whole unit.

Example: Let’s say a simple gable roof measures 30 feet x 40 feet. The area is 1200 square feet, or 12 squares. Adding a 10% waste factor brings the total to 13.2 squares – rounded up to 14 squares.

Software and Tools: Many roofing software programs exist that automate these calculations. They often include features to input roof dimensions and material specifications for instant estimations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with single-ply roofing membranes (TPO, EPDM, PVC)?

I have extensive experience with single-ply roofing membranes, specifically TPO (Thermoplastic Polyolefin), EPDM (Ethylene Propylene Diene Monomer), and PVC (Polyvinyl Chloride). Each has unique properties and applications.

- TPO: Known for its durability, reflectivity (reducing energy costs), and relatively easy installation. It’s a popular choice for both low-slope and some steep-slope applications. I’ve worked on numerous projects utilizing TPO, including large commercial buildings and smaller residential structures.

- EPDM: A very durable, cost-effective rubber membrane. It’s widely used in low-slope roofing due to its excellent resistance to UV degradation and ponding water. My experience with EPDM includes both new installations and repairs on existing flat roofs.

- PVC: A highly durable and aesthetically pleasing membrane, often used in high-performance roofing systems. It offers excellent resistance to chemicals and punctures. However, it requires specialized equipment and expertise for proper installation. I’ve worked on several projects using PVC, primarily in commercial and industrial sectors where high durability is a must.

My experience encompasses all aspects, from material selection and preparation to installation and seam sealing. I’m proficient in proper detailing around penetrations and flashings to ensure long-term water tightness.

Q 17. Describe the process of sealing a roof leak.

Sealing a roof leak requires a systematic approach to identify the source and then apply the appropriate repair. A rushed job often results in recurring leaks.

- Locate the Leak: This is the most critical step. Thoroughly inspect the roof, both internally and externally, looking for signs of moisture damage, staining, or water entering the building. Use a hose test (carefully) to pinpoint the exact location if necessary.

- Prepare the Area: Once the leak is identified, clean the affected area to ensure proper adhesion of the sealant. Remove any loose or damaged material. The surface should be dry and free of debris.

- Select the Sealant: The choice depends on the material type of the roof and the size of the leak. Options include roofing cement, flashing tape, or specialized sealants for specific materials (e.g., self-adhered membrane patches for single-ply roofs).

- Apply the Sealant: Follow the manufacturer’s instructions carefully. For larger leaks, a multi-layered approach might be needed. Ensure complete coverage and proper overlap of any sealant seams.

- Monitor the Repair: After the sealant has cured, inspect the repair area for any signs of leakage. Repeat as necessary until the leak is completely stopped.

Important Considerations: Safety is paramount when working on a roof. Always use appropriate safety equipment, such as harnesses and fall protection. For large or complex leaks, consult a qualified roofing professional.

Q 18. What are the key factors influencing the lifespan of a roof?

Several factors significantly influence a roof’s lifespan. These can be broadly categorized into material properties, installation quality, and environmental conditions.

- Material Quality: The inherent durability and resistance to weathering of the roofing material itself are paramount. Higher quality materials generally offer a longer lifespan.

- Installation Quality: Proper installation is crucial. Errors in flashing, seams, or underlayment can lead to premature failure. A well-installed roof, even with average materials, will typically last longer.

- Climate and Environmental Conditions: Harsh weather (extreme temperatures, heavy snow, high winds, etc.) accelerates degradation. UV exposure is a major factor in the aging of many roofing materials.

- Maintenance and Repairs: Regular roof inspections and prompt repairs of minor issues can extend the roof’s life considerably. Addressing small problems before they escalate prevents significant, costly damage.

- Building Design and Ventilation: Adequate attic ventilation helps to prevent moisture buildup, a major contributor to roof deterioration.

Example: A well-maintained roof made of high-quality asphalt shingles in a moderate climate might last 25-30 years, while a poorly installed roof in a harsh environment could fail in significantly less time.

Q 19. Explain your experience with different types of roofing fasteners.

My experience encompasses a wide range of roofing fasteners, each suited to specific materials and applications.

- Nails: Commonly used for asphalt shingles, wood shakes, and tiles. Different nail types (galvanized, stainless steel) offer varying degrees of corrosion resistance. Nail length is crucial for proper penetration and holding power.

- Screws: Often preferred for metal roofing, single-ply membranes, and some composite materials. They offer superior holding power and resistance to wind uplift compared to nails.

- Staples: Used in the installation of certain single-ply membranes. They are quick and efficient, but careful application is needed to avoid punctures and damage.

- Adhesives: Some roofing systems utilize adhesives as a primary fastening method, particularly single-ply membranes. This can provide a completely sealed system, resistant to wind uplift. Proper surface preparation is vital for successful adhesive bonding.

Proper fastener selection and application is crucial for structural integrity and preventing leaks. I carefully consider the type of roofing material, anticipated weather conditions, and building codes when selecting fasteners. I’m also aware of different techniques such as staggered nailing and proper spacing, which directly impacts the overall lifespan of the roof.

Q 20. How do you address concerns regarding environmental impact when selecting roofing materials?

Environmental responsibility is a key consideration when selecting roofing materials. I evaluate options based on their lifecycle impact, considering factors such as embodied carbon, recyclability, and end-of-life disposal.

- Embodied Carbon: This refers to the greenhouse gas emissions associated with the manufacturing, transportation, and installation of a material. Options with lower embodied carbon are preferred.

- Recycled Content: Choosing materials with a high percentage of recycled content reduces the demand for virgin materials and minimizes waste.

- Recyclability: Selecting materials that can be easily recycled at the end of their lifespan helps to divert waste from landfills.

- Energy Efficiency: Highly reflective roofing materials (e.g., white TPO) can reduce energy consumption by lowering building cooling loads, a significant environmental benefit.

- VOC Emissions: Some roofing materials release volatile organic compounds (VOCs), which contribute to air pollution. Low-VOC or VOC-free options are preferred.

I often work with clients to find a balance between cost, performance, and environmental impact. For example, while a certain material might have a lower initial cost, the long-term environmental impact and energy savings of a more sustainable option might make it more cost-effective in the long run. I believe that informed decision-making ensures both environmental responsibility and project success.

Q 21. What is your familiarity with local building codes concerning roofing materials?

Familiarity with local building codes is essential for ensuring a roof’s compliance and structural integrity. These codes vary significantly by region and jurisdiction, encompassing slope requirements, material specifications, wind load considerations, and fire resistance ratings.

My approach involves a multi-step process:

- Identifying Applicable Codes: I begin by determining the specific building codes applicable to the project location. This may involve contacting local authorities or consulting online resources.

- Reviewing Code Requirements: I thoroughly review the relevant sections of the building code concerning roofing, paying close attention to material specifications, installation requirements, and safety standards. This includes wind and snow load calculations specific to the region.

- Specifying Compliant Materials: I select roofing materials that meet or exceed all applicable code requirements. I document these choices in the project specifications to show compliance.

- Ensuring Compliant Installation: I ensure that the installation process strictly adheres to the code requirements. This includes proper fastening methods, flashing details, and inspections.

- Obtaining Necessary Permits: I assist clients in obtaining the necessary building permits by providing the documentation required by the local authorities. This documentation includes the chosen material specifications, confirming their compliance with local building codes.

Staying up-to-date on code changes is an ongoing process. I regularly attend industry events and training to stay informed and ensure that my work consistently adheres to current regulations.

Q 22. Describe your experience with performing roofing inspections and generating reports.

Roofing inspections are crucial for assessing a roof’s condition and identifying potential problems. My process begins with a thorough visual examination, checking for missing or damaged shingles, cracks in flashing, signs of water damage, and overall structural integrity. I use specialized equipment like drones for hard-to-reach areas and moisture meters to detect hidden leaks. My reports are detailed, including photographic evidence, a precise description of the findings, and recommendations for repairs or replacements. For example, I recently inspected a commercial building’s flat roof and discovered several areas of ponding water, a major contributor to premature roof failure. My report clearly documented these areas with photos and measurements, recommending immediate repairs to prevent further damage and potential leaks. I also categorize issues by urgency, ensuring clients prioritize critical repairs.

Q 23. How do you handle unexpected problems during a roofing installation?

Unexpected problems during roofing installation are inevitable. My approach involves a combination of proactive planning and reactive problem-solving. Proactive measures include meticulous pre-installation surveys to identify potential challenges like hidden obstacles or unexpected roof designs. When unexpected issues arise, like discovering rotted decking during a shingle replacement, I immediately assess the situation, consulting with the client to discuss options and associated costs. For example, I once encountered unexpected asbestos during a tear-off. Immediately halting work, I followed proper safety protocols, contacted the appropriate authorities, and coordinated with an asbestos abatement specialist. Open communication with the client is key throughout this process. Transparency and clear communication prevent misunderstandings and ensure a positive outcome even in challenging circumstances.

Q 24. What are some common waterproofing methods used in roofing?

Waterproofing is paramount in roofing. Common methods vary depending on the roof type. For flat roofs, built-up roofing (BUR) systems using multiple layers of asphalt and felt are prevalent. These offer excellent waterproofing and are durable, often lasting for decades. Single-ply membranes, such as EPDM (ethylene propylene diene monomer) rubber and TPO (thermoplastic polyolefin), are also popular choices for their ease of installation and longevity. They provide seamless waterproofing, reducing the risk of leaks. For sloped roofs, proper underlayment installation is crucial. Self-adhering underlayments act as an additional barrier against water penetration, providing extra protection beneath the shingles. Proper flashing around chimneys, vents, and other penetrations is equally critical to prevent water intrusion. Think of it like sealing all the cracks and crevices in a dam to prevent water leakage.

Q 25. What is your experience with using specialized roofing equipment?

My experience with specialized roofing equipment is extensive. I’m proficient in using power tools like nail guns, roofing saws, and shingle cutters to ensure efficient and precise installation. I’m also skilled in operating aerial lifts for safe access to high-roof sections and using specialized tools for specific roofing materials, such as heat welding equipment for single-ply membranes. Safety is always my top priority, ensuring all equipment is properly maintained and operated according to manufacturer guidelines. I also understand the importance of using equipment that is appropriate for the specific job and material, optimizing efficiency and safety. For instance, using a lift for a taller building vs. a ladder for a smaller house.

Q 26. Describe your understanding of roofing warranties and manufacturer specifications.

Understanding roofing warranties and manufacturer specifications is crucial for project success and client satisfaction. I meticulously review all warranties provided by manufacturers, ensuring I understand the coverage, limitations, and required maintenance. This information is relayed clearly to clients. For example, I always explain the implications of not adhering to the manufacturer’s recommended installation methods, as this could void the warranty. I also maintain detailed records of all materials used, including batch numbers and dates of purchase, to facilitate any future warranty claims. This proactive approach protects both the client’s investment and my professional reputation.

Q 27. How do you ensure quality control throughout the roofing process?

Quality control is an ongoing process, not just a final check. It starts with meticulous planning and material selection. During installation, regular inspections are crucial, ensuring proper installation techniques are followed and materials are handled correctly. I use checklists and photographic documentation at each stage to verify compliance with building codes and manufacturer specifications. After completion, a final thorough inspection checks for any defects and ensures everything aligns with the initial plans and client expectations. This multi-layered approach minimizes the chance of errors and ensures a high-quality, long-lasting roof.

Q 28. Explain your experience with different methods of roof snow and ice removal.

Snow and ice removal from roofs requires careful consideration of safety and structural integrity. Methods range from simple shoveling (appropriate only for low-pitched roofs and light snow) to using specialized equipment like roof rakes with long handles or powered snow removal systems. In situations with heavy snow accumulation or icy conditions, I always recommend contacting experienced professionals equipped with the proper safety gear and expertise to prevent damage to the roof and potential injury. For example, using heated cables embedded in the gutters and eaves can melt snow and ice before it becomes a hazard. My approach always prioritizes safety and minimizes the risk of damage to the roof structure.

Key Topics to Learn for Roofing Material Knowledge Interview

- Asphalt Shingles: Understanding different types (3-tab, architectural, etc.), their lifespan, installation methods, and common problems like curling, cracking, and granule loss. Practical application: Troubleshooting a leaking roof and identifying the cause based on shingle type and condition.

- Tile Roofing: Clay, concrete, and slate tile properties, advantages and disadvantages of each, installation techniques, and maintenance requirements. Practical application: Estimating material costs and labor hours for a tile roof installation project based on roof size and complexity.

- Metal Roofing: Types of metal roofing (aluminum, steel, copper), gauge considerations, fastening techniques, and longevity. Practical application: Calculating the amount of metal roofing needed for a specific job, accounting for overlaps and waste.

- Membrane Roofing (EPDM, TPO, PVC): Understanding the characteristics of different membrane types, seam sealing methods, and installation best practices. Practical application: Identifying appropriate membrane types for different roof slopes and building types.

- Underlayment and Flashing: The importance of proper underlayment selection and installation, and the role of flashing in preventing water intrusion at critical areas (chimneys, vents, valleys). Practical application: Diagnosing water leaks and recommending appropriate flashing repairs.

- Roof Safety and Regulations: OSHA safety standards for roofing work, fall protection, and proper use of safety equipment. Practical application: Developing a safe work plan for a roofing project.

- Estimating and Budgeting: Accurately calculating material costs, labor costs, and overhead to provide competitive bids. Practical application: Creating a detailed estimate for a roofing project.

Next Steps

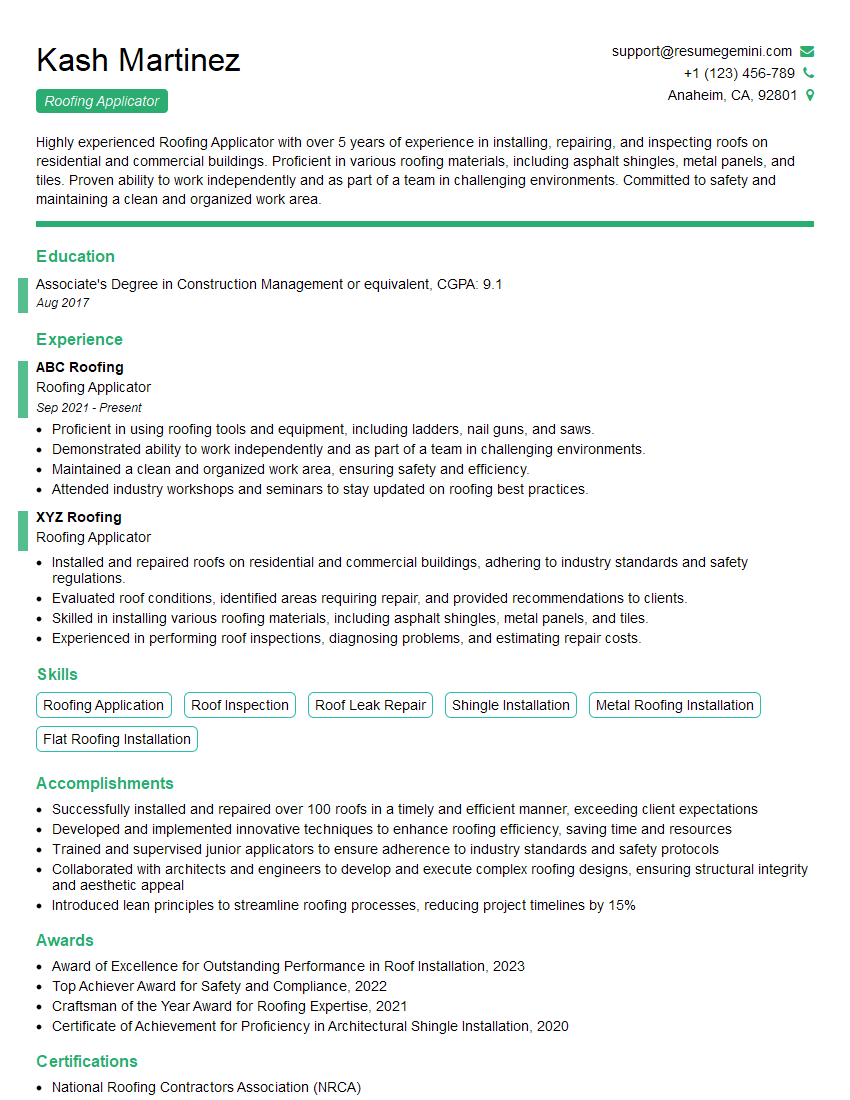

Mastering roofing material knowledge is crucial for career advancement in the roofing industry. A strong understanding of these materials translates to better job performance, increased efficiency, and greater earning potential. To further enhance your job prospects, focus on building an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you craft a professional resume that stands out to potential employers. We provide examples of resumes tailored specifically to roofing material knowledge to guide you in the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.