Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Safety and Training interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Safety and Training Interview

Q 1. Describe your experience with developing and delivering safety training programs.

Developing and delivering safety training programs requires a multifaceted approach, encompassing needs analysis, curriculum design, instructional delivery, and evaluation. My experience spans various industries, including manufacturing and construction. I begin by conducting a thorough needs assessment, identifying the specific hazards and risks present in the workplace and the knowledge and skills gaps among employees. This might involve reviewing incident reports, conducting job hazard analyses (JHAs), and interviewing employees at all levels.

Based on this assessment, I develop a tailored curriculum that incorporates various learning methods such as interactive presentations, hands-on simulations, videos, and case studies. For example, in a manufacturing setting, I developed a program on lockout/tagout procedures, using a combination of interactive presentations explaining the theory, followed by practical, hands-on sessions with equipment to reinforce understanding and build competency. The delivery method is crucial; I focus on clear, concise communication, active learning techniques and tailoring the language and examples to the audience’s background and literacy level. Post-training, I always follow up with reinforcement activities and ensure the program is regularly updated to reflect changes in regulations and best practices.

Q 2. How do you identify and assess workplace hazards?

Identifying and assessing workplace hazards is a systematic process. It begins with a comprehensive walkthrough of the workplace, observing physical conditions and work practices. I utilize several methods, including Job Safety Analysis (JSA), which breaks down each task into steps, identifying potential hazards at each stage. Hazard and Operability studies (HAZOP) are also employed for more complex processes. This involves a multidisciplinary team brainstorming potential deviations from the normal operating procedures and assessing their consequences. Furthermore, I conduct workplace inspections, looking for unsafe conditions such as electrical hazards, trip hazards, and inadequate ventilation. Employee input is invaluable; I encourage open communication and utilize methods such as safety suggestion boxes and regular feedback sessions to identify hazards that might otherwise be overlooked.

The assessment involves quantifying the risk associated with each hazard. This typically involves considering the likelihood of the hazard occurring and the severity of the potential consequences. A risk matrix helps to prioritize hazards based on this assessment, allowing for focused risk mitigation efforts. For instance, a high-likelihood, high-severity hazard like unguarded machinery would require immediate corrective action, whereas a low-likelihood, low-severity hazard might require less urgent attention.

Q 3. Explain your process for investigating workplace accidents.

Investigating workplace accidents requires a meticulous and impartial approach. My process starts with securing the scene, ensuring the safety of personnel, and preserving any evidence. I then gather information from various sources, including eyewitnesses, injured workers, supervisors, and any available documentation such as incident reports and maintenance logs. I use a structured approach, often employing a root cause analysis (RCA) technique such as the “5 Whys” to identify the underlying causes of the accident, moving beyond immediate factors to uncover systemic issues. For example, if an employee was injured by falling from a ladder, the immediate cause might be a faulty ladder, but further investigation (using the 5 Whys) might reveal that regular inspections were not carried out, resulting in the ladder’s deterioration and ultimately leading to the accident. This information is used to develop effective corrective actions to prevent future incidents. Finally, I document all findings and recommendations in a comprehensive report, which is then used to improve safety procedures and training programs.

Q 4. What safety regulations are you most familiar with?

My familiarity with safety regulations is extensive, covering various jurisdictions and industries. I possess a deep understanding of OSHA regulations (Occupational Safety and Health Administration) in the United States, including general industry standards, construction standards, and specific standards related to hazardous materials handling. I am also familiar with international standards such as ISO 45001 (Occupational health and safety management systems). My knowledge extends to specific regulations relevant to the industries I’ve worked in, such as those pertaining to confined space entry, lockout/tagout, personal protective equipment (PPE) usage, and emergency response procedures. Staying up-to-date on regulatory changes is crucial; I regularly review updates and attend relevant training sessions to maintain my expertise.

Q 5. How do you ensure that safety training is effective and engaging?

Effective and engaging safety training is crucial for knowledge retention and behavior change. To achieve this, I prioritize active learning methods over passive delivery. Instead of long lectures, I use interactive elements such as simulations, group discussions, and hands-on activities. For example, I’ve used virtual reality (VR) simulations to train employees on safe crane operation, providing a risk-free environment to practice critical skills. Real-world case studies, relatable examples and storytelling are also key; this helps to connect abstract concepts to the trainees’ experiences, making the learning relevant and memorable. I also ensure that the training is tailored to the specific audience, considering their literacy level, language, and cultural background. Humor and positive reinforcement are also utilized to create a supportive and engaging learning environment.

Q 6. What methods do you use to measure the effectiveness of safety training?

Measuring the effectiveness of safety training is critical to ensuring its impact. I use a multi-faceted approach, combining pre- and post-training assessments to gauge knowledge improvement. These assessments can include written tests, practical demonstrations, and observation of skills in a simulated or real-world environment. Beyond knowledge tests, I track changes in safety performance indicators such as the number of incidents, near misses, and lost-time injuries. I also conduct post-training surveys to gather feedback from employees on their understanding and perception of the training, identifying areas for improvement. Regular observation of employees’ on-the-job performance provides further insights into the training’s practical impact. Analyzing this data allows for continuous improvement of the training program to maximize its effectiveness.

Q 7. How do you handle resistance to safety procedures?

Resistance to safety procedures can stem from various factors, including a lack of understanding, perceived inconvenience, or even fear of reprisal for reporting near misses. My approach involves addressing these underlying issues through clear communication and building trust. I start by understanding the reasons behind the resistance. This might involve speaking to the individuals involved, listening to their concerns and addressing them openly. Addressing the lack of understanding is done through providing additional training, clear explanations, and emphasizing the reasons behind the safety procedures and the potential consequences of non-compliance. I demonstrate the benefits of adhering to procedures, highlighting both individual and organizational advantages. Collaboration is key; involving employees in the development and implementation of safety procedures helps to foster a sense of ownership and buy-in. Recognizing and rewarding safe behavior reinforces positive changes and motivates compliance. Finally, consistent enforcement of safety rules, while ensuring fairness and a positive work environment, is essential for maintaining a culture of safety.

Q 8. Describe a time you had to deal with a safety violation.

In my previous role at a construction company, I witnessed a worker operating a forklift without the required safety harness. This was a clear violation of our company’s safety protocols and OSHA regulations. I immediately intervened, stopping the operation and explaining the potential risks of falling from the vehicle. I then led the worker to a designated area where we reviewed the correct procedure, emphasizing the critical importance of the harness for preventing serious injury or even fatality. Following this, I initiated a refresher training session for all forklift operators to reinforce safe operating procedures and ensure everyone understood the consequences of non-compliance. The incident report clearly documented the violation, corrective actions, and the follow-up training, contributing to an improved safety record.

Q 9. How do you stay current on changes in safety regulations?

Staying updated on safety regulations is paramount in my field. I leverage several strategies to achieve this. First, I actively subscribe to and regularly review newsletters and publications from organizations like OSHA (Occupational Safety and Health Administration), and relevant industry-specific associations. I also participate in professional development workshops and conferences, which offer valuable insights into the latest changes and best practices. Networking with other safety professionals through online forums and professional groups helps me stay abreast of emerging trends and challenges. Finally, I maintain a detailed database of relevant safety standards and regularly update it with new information, ensuring that my knowledge remains current and accurate.

Q 10. What are some common safety hazards in [industry-specific context]?

Let’s assume the industry-specific context is construction. Common safety hazards in construction include:

- Falls from heights: This is a leading cause of injuries and fatalities. Proper fall protection systems, such as harnesses and guardrails, are crucial.

- Struck-by hazards: Workers can be struck by falling objects, swinging loads, or vehicles. Implementing safety zones, using spotters, and ensuring proper equipment maintenance are vital.

- Caught-in/between hazards: Workers can get caught in machinery, collapsing structures, or between objects. Lockout/tagout procedures, proper equipment guarding, and confined space entry procedures are essential.

- Electrocution: Contact with energized electrical equipment can be fatal. Proper grounding, insulation, and lockout/tagout procedures are crucial.

- Exposure to hazardous materials: Exposure to asbestos, lead, or other hazardous substances can cause severe health problems. Proper training, personal protective equipment (PPE), and safe handling procedures are essential.

These are just a few examples, and specific hazards vary depending on the project and environment.

Q 11. How would you create a safety plan for a new project?

Creating a comprehensive safety plan for a new project involves a systematic approach. I would begin by conducting a thorough hazard identification and risk assessment, involving all stakeholders and considering all potential scenarios. This might involve using techniques like Job Safety Analysis (JSA) or HAZOP (Hazard and Operability Study). Then, I would establish clear safety procedures and protocols addressing the identified hazards, including specifications for Personal Protective Equipment (PPE), emergency procedures, and training requirements. These procedures would be documented in a comprehensive safety plan that includes roles and responsibilities, communication protocols, and reporting mechanisms. Regular safety inspections and monitoring will be scheduled, and the plan would be reviewed and updated as needed throughout the project lifecycle. A key aspect is ensuring that the plan is accessible and understood by all project personnel. This is akin to building a house: you wouldn’t start without blueprints, and a safety plan provides that blueprint for a safe project.

Q 12. Explain your experience with conducting safety audits.

My experience with safety audits includes conducting both internal and external audits, adhering to established standards and regulatory requirements. These audits typically involve a thorough review of safety policies, procedures, training programs, and safety records. I conduct on-site inspections to assess the workplace environment, observe worker practices, and identify potential hazards. During the audit process, I employ checklists, interview key personnel, review documentation, and perform any necessary sampling or testing. I then compile a comprehensive report that outlines findings, recommendations for improvement, and a plan for addressing identified deficiencies. My objective is not just to find problems, but to facilitate continuous improvement in workplace safety.

Q 13. What is your experience with incident reporting and investigation?

My experience with incident reporting and investigation is extensive. I’ve developed and implemented incident reporting systems, ensuring that all incidents, regardless of severity, are promptly reported and investigated. My investigation process follows a structured approach, including securing the scene, interviewing witnesses, gathering evidence, and analyzing root causes using techniques like ‘5 Whys’ or fault tree analysis. The goal is to determine the contributing factors and implement corrective actions to prevent similar incidents from occurring in the future. Incident reports are thoroughly documented and shared with relevant personnel, contributing to a culture of continuous learning and improvement. Confidentiality and sensitivity are maintained throughout the entire process.

Q 14. How do you promote a positive safety culture within a workplace?

Promoting a positive safety culture is not merely about following rules; it’s about fostering a shared commitment to safety at all levels of an organization. This starts with strong leadership that visibly champions safety, ensuring that it’s not just a priority but a value. I achieve this through open communication, actively engaging workers in safety discussions, and soliciting their feedback. Effective training is crucial, offering both theoretical knowledge and practical skills. Regular safety meetings, toolbox talks, and engaging activities keep safety top-of-mind. Recognition and rewards for safe behavior and contributions to safety improvements reinforce positive actions. Finally, addressing unsafe conditions promptly and fostering a blame-free reporting culture ensures that incidents become learning opportunities rather than sources of fear or retribution. A successful safety culture is built on trust, mutual respect, and a shared commitment to creating a safe and healthy work environment.

Q 15. How do you adapt training materials for different learning styles?

Adapting training materials for diverse learning styles is crucial for effective knowledge transfer. People learn in different ways – visually, auditorily, kinesthetically, or a combination. My approach involves creating a multifaceted learning experience.

- Visual Learners: I incorporate charts, graphs, diagrams, videos, and presentations with strong visuals. For example, when training on lockout/tagout procedures, a visually clear flowchart showing each step is essential.

- Auditory Learners: I utilize audio lectures, podcasts, group discussions, and role-playing exercises. For safety training on proper lifting techniques, a recorded demonstration followed by a group discussion allows for questions and clarifies any uncertainties.

- Kinesthetic Learners: Hands-on activities, simulations, and practical exercises are key. In a fire safety training, a hands-on demonstration of using a fire extinguisher is far more effective than a simple lecture.

- Multimodal Approach: To cater to all learning styles, I combine various methods. A training on hazard communication might involve a presentation with visuals, a short audio clip explaining specific regulations, and a hands-on activity identifying hazardous materials in a simulated workplace environment.

Regular feedback and assessment throughout the training process help identify areas where adjustments are needed to optimize learning for everyone.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your preferred methods for evaluating employee training effectiveness?

Evaluating training effectiveness is paramount to ensure its impact and ROI. I utilize a blended approach encompassing several methods:

- Pre- and Post-Training Assessments: These measure knowledge gained. I employ quizzes, tests, or practical demonstrations to assess understanding before and after the training. A significant improvement indicates effective learning.

- On-the-Job Observation: Direct observation of trainees applying learned skills in real-world scenarios provides valuable insight into practical application. For example, observing employees following proper PPE usage after safety training.

- Performance Metrics: Tracking key performance indicators (KPIs) like accident rates, near misses, and safety violations post-training reveals a direct impact. A reduction in these metrics validates the training’s effectiveness.

- Feedback Surveys and Focus Groups: Gathering feedback from trainees enhances understanding of the training’s strengths and weaknesses, paving the way for future improvements. Anonymous feedback allows for honest and constructive criticism.

- Return on Investment (ROI) Analysis: This assesses the cost-effectiveness of the training program by comparing the investment against the reduction in accidents, injuries, and associated costs.

By combining these methods, a comprehensive picture of the training’s success is obtained, enabling data-driven improvements.

Q 17. Describe your experience with emergency response planning.

My experience with emergency response planning encompasses developing, implementing, and testing comprehensive plans for various scenarios. This involves a systematic approach:

- Hazard Identification and Risk Assessment: Identifying potential hazards and assessing the likelihood and severity of incidents, such as fires, chemical spills, or natural disasters.

- Emergency Response Team Formation and Training: Establishing a well-trained team with defined roles and responsibilities. Regular drills and training maintain preparedness.

- Evacuation Procedures and Communication Plans: Creating clear evacuation routes, assembly points, and communication protocols for notifying employees and emergency services.

- Emergency Equipment and Supplies: Ensuring availability and proper maintenance of emergency equipment, including fire extinguishers, first-aid kits, and communication systems.

- Post-Incident Analysis and Improvement: Conducting thorough post-incident reviews to identify areas for improvement in the emergency response plan. This is crucial for continuous improvement.

For example, I was instrumental in developing a comprehensive emergency response plan for a manufacturing facility that included detailed evacuation procedures, designated assembly points, and a robust communication system. Regular drills ensured the plan’s effectiveness and team preparedness.

Q 18. What is your experience with developing and implementing safety policies and procedures?

Developing and implementing safety policies and procedures requires a thorough understanding of relevant regulations and best practices. My experience includes:

- Needs Assessment: Identifying workplace hazards and assessing the risks through detailed risk assessments.

- Policy Development: Creating clear, concise, and comprehensive safety policies aligned with legal requirements and industry best practices. This includes aspects like PPE usage, hazard communication, and emergency procedures.

- Procedure Creation: Developing step-by-step procedures for routine tasks and emergency situations, ensuring clarity and consistency.

- Communication and Training: Effectively communicating the new policies and procedures to employees through various training methods (as described in response to question 1).

- Monitoring and Evaluation: Regularly reviewing and updating policies and procedures based on performance data, incident reports, and feedback.

In a previous role, I led the development and implementation of a new safety management system that resulted in a 30% reduction in workplace accidents within a year. This involved establishing clear policies, providing comprehensive training, and implementing a robust reporting and investigation system.

Q 19. How do you ensure that safety equipment is properly maintained and used?

Ensuring proper maintenance and usage of safety equipment is vital for employee protection. My approach involves a multi-pronged strategy:

- Regular Inspections: Conducting routine inspections to identify damaged or malfunctioning equipment. This includes visual checks, functional tests, and calibration where necessary.

- Preventative Maintenance Schedules: Establishing and adhering to preventative maintenance schedules to extend equipment lifespan and ensure reliability. This might involve regular cleaning, lubrication, and component replacement.

- Training and Competency: Providing thorough training on the proper use, care, and maintenance of safety equipment. Employees need to understand the limitations and potential risks associated with improper use.

- Proper Storage and Handling: Implementing procedures for proper storage and handling to prevent damage or degradation. This includes adequate protection from the elements and preventing misuse.

- Documentation and Record Keeping: Maintaining accurate records of inspections, maintenance, and training to demonstrate compliance and track equipment history.

For instance, in a previous role, we implemented a color-coded system for labeling safety equipment based on its inspection status, ensuring timely maintenance and preventing the use of faulty equipment.

Q 20. Describe your experience with conducting safety inspections.

Conducting safety inspections involves a systematic process to identify potential hazards and ensure compliance with safety regulations. My approach includes:

- Pre-Inspection Planning: Defining the scope of the inspection, identifying specific areas or equipment to be reviewed, and assembling necessary tools and documentation.

- Systematic Inspection: Following a pre-defined checklist to systematically examine workplaces, equipment, and processes, noting any deficiencies or non-conformances.

- Hazard Identification and Documentation: Recording all identified hazards, potential risks, and non-conformances, including photographs or videos as evidence.

- Corrective Actions: Developing and implementing corrective actions to address identified hazards and non-conformances, ensuring timely resolution and follow-up.

- Reporting and Follow-up: Generating detailed inspection reports and communicating findings to relevant personnel. Following up to ensure corrective actions are implemented effectively.

A recent inspection revealed a poorly maintained fire extinguisher, resulting in immediate replacement and refresher training for employees on extinguisher use. Detailed reporting ensured accountability and prevented potential future incidents.

Q 21. How familiar are you with OSHA (or relevant regional safety regulations)?

I am very familiar with OSHA regulations (Occupational Safety and Health Administration) and other relevant regional safety regulations. My understanding goes beyond simple awareness; I actively incorporate these regulations into safety policies, procedures, training materials, and inspection processes. This ensures compliance and a safe working environment.

My knowledge covers various aspects including hazard communication, lockout/tagout procedures, personal protective equipment (PPE) requirements, emergency response planning, and record-keeping. I regularly update my knowledge to stay abreast of any changes or updates to these regulations. This includes subscribing to relevant newsletters, attending industry conferences, and participating in professional development activities.

I can confidently interpret and apply OSHA standards to real-world scenarios, ensuring a compliant and safe workplace. For example, I can readily explain the requirements of OSHA’s Hazard Communication Standard (HCS) and how to properly label and handle hazardous chemicals.

Q 22. What is your experience with risk assessment and mitigation?

Risk assessment and mitigation are fundamental to any safety program. It’s a systematic process of identifying hazards, analyzing their risks, and implementing controls to reduce or eliminate them. My experience encompasses a wide range of methodologies, from simple checklists to sophisticated quantitative risk analysis using bow-tie diagrams and fault tree analysis.

For example, in my previous role at a manufacturing plant, I led a comprehensive risk assessment for a new assembly line. We identified potential hazards such as machine guarding failures, ergonomic issues, and chemical exposure. We then analyzed the likelihood and severity of each hazard, assigning risk levels. Based on this analysis, we implemented various mitigation strategies, including installing improved machine guards, providing ergonomic training, and introducing stricter chemical handling procedures. This resulted in a significant reduction in workplace incidents.

I’m proficient in using various software tools to support risk assessments and track mitigation efforts. Regular review and updates of risk assessments are critical to ensure their ongoing relevance and effectiveness, considering changes in processes, equipment, or personnel.

Q 23. How do you handle conflicting priorities between safety and production?

Balancing safety and production is a constant challenge, but safety always comes first. It’s not a trade-off; rather, it’s about finding ways to improve both simultaneously. When conflicting priorities arise, I utilize a collaborative approach. I start by clearly defining the safety risks involved and their potential consequences. Then, I work with production teams to explore alternative solutions that address both safety concerns and production targets. This might involve adjusting work schedules, implementing new technologies, or improving training programs.

For instance, if a production line needs to increase output but poses increased safety risks, I wouldn’t simply agree to the increase. Instead, I’d engage in discussions to find solutions, such as implementing automation to reduce manual handling, enhancing training to improve worker competency, or modifying the workspace to improve ergonomics. The key is transparent communication, data-driven decision-making, and a shared commitment to both safety and efficiency.

Q 24. Describe a time you had to make a difficult decision regarding safety.

During a safety audit at a construction site, I discovered a significant lapse in fall protection procedures. Workers were operating at heights without proper harnesses or safety nets. This presented an immediate and serious danger. My decision was to halt the work immediately, even though it caused a temporary delay in the project timeline. This was a difficult decision as it impacted the project’s schedule and budget, but the potential for severe injury or fatality far outweighed these considerations.

I explained the risks clearly to the site manager and the workers, and we collaborated on a plan to implement proper fall protection measures before resuming work. This involved procuring the necessary equipment, providing refresher training, and establishing a robust system for monitoring compliance. The situation highlighted the importance of unwavering commitment to safety, even when faced with pressure to maintain production schedules. Following this incident, we improved our communication protocols and strengthened our proactive safety checks, demonstrating a commitment to continuous improvement.

Q 25. How do you communicate safety information effectively to employees?

Effective communication is crucial for a strong safety culture. I utilize a multi-faceted approach that combines different methods to cater to various learning styles. This includes regular safety meetings, toolbox talks, training programs, visual aids such as posters and videos, and digital communication channels such as emails and intranet updates.

For example, instead of just distributing a safety manual, I’d use interactive training sessions, incorporating videos, quizzes, and practical demonstrations. I focus on making the information easily accessible, relevant, and engaging. Using simple language, clear visuals, and real-life examples makes the information more relatable and memorable. I also encourage two-way communication, inviting questions and feedback to ensure understanding and foster a culture of open dialogue.

Regular feedback mechanisms, such as anonymous surveys and suggestion boxes, are essential in gathering employee feedback on safety communications and identifying any areas needing improvement.

Q 26. What is your approach to creating a safe and inclusive work environment?

Creating a safe and inclusive workplace is about fostering a culture of respect, where every employee feels valued, respected, and empowered to contribute to safety. This involves promoting diversity and inclusion at every level, ensuring fair and equitable treatment, and providing accessible resources and training.

This includes providing training that is tailored to different learning styles and language capabilities, actively encouraging participation from all employees in safety initiatives, and establishing channels for reporting concerns without fear of reprisal. Promoting a culture where employees feel comfortable reporting hazards or near misses without fear of blame is vital. Implementing inclusive leadership and encouraging open communication are crucial for building trust and ensuring everyone feels heard and respected.

Regularly reviewing policies and practices to ensure they are inclusive and accessible is key to maintaining a truly safe and inclusive work environment. This ongoing review process is vital to ensure the environment remains welcoming and supportive for all.

Q 27. What are your strengths and weaknesses as a safety and training professional?

My strengths lie in my proactive approach to safety, my ability to build strong relationships with employees at all levels, and my expertise in risk assessment and mitigation. I’m also a highly effective communicator and trainer.

One area I’m working on is enhancing my skills in advanced statistical analysis for more in-depth risk modeling. While I have a strong foundation in this area, continuous learning is essential to stay abreast of the latest techniques. I am actively seeking opportunities to expand my knowledge in this area through professional development courses and participation in industry conferences.

Q 28. Where do you see yourself in five years regarding your career in safety and training?

In five years, I see myself in a leadership role, possibly as a Safety Manager or Director of Safety and Training, where I can leverage my experience and expertise to develop and implement comprehensive safety programs for a larger organization. I’m keen to continue developing my leadership skills and mentoring other safety professionals. I aim to contribute to the advancement of safety practices through research, publications, or participation in professional organizations.

My ultimate goal is to make a significant impact on workplace safety, contributing to a reduction in workplace incidents and promoting a culture of safety excellence across various industries.

Key Topics to Learn for Your Safety and Training Interview

- Hazard Identification & Risk Assessment: Understand methods like HAZOP, Job Safety Analysis (JSA), and risk matrices. Be prepared to discuss practical application in various work environments.

- Safety Regulations & Compliance: Demonstrate familiarity with relevant legislation (OSHA, etc.) and industry best practices. Discuss how you ensure compliance within a team or organization.

- Accident Investigation & Reporting: Explain your understanding of root cause analysis techniques and effective reporting procedures. Be ready to discuss how to prevent future incidents.

- Training Methodology & Delivery: Showcase your knowledge of adult learning principles, different training methods (e.g., classroom, online, on-the-job), and how to assess training effectiveness.

- Emergency Response & Preparedness: Discuss emergency procedures, evacuation plans, and your experience (if any) in emergency response situations. Highlight your problem-solving skills under pressure.

- Safety Culture & Communication: Explain how to foster a positive safety culture, the importance of effective communication, and strategies for promoting safety awareness among diverse teams.

- Personal Protective Equipment (PPE): Demonstrate knowledge of various PPE, selection criteria, and proper use and maintenance. Be prepared to discuss relevant standards and regulations.

- Incident Prevention & Control: Discuss proactive safety measures, preventative maintenance, and strategies to minimize workplace hazards.

Next Steps

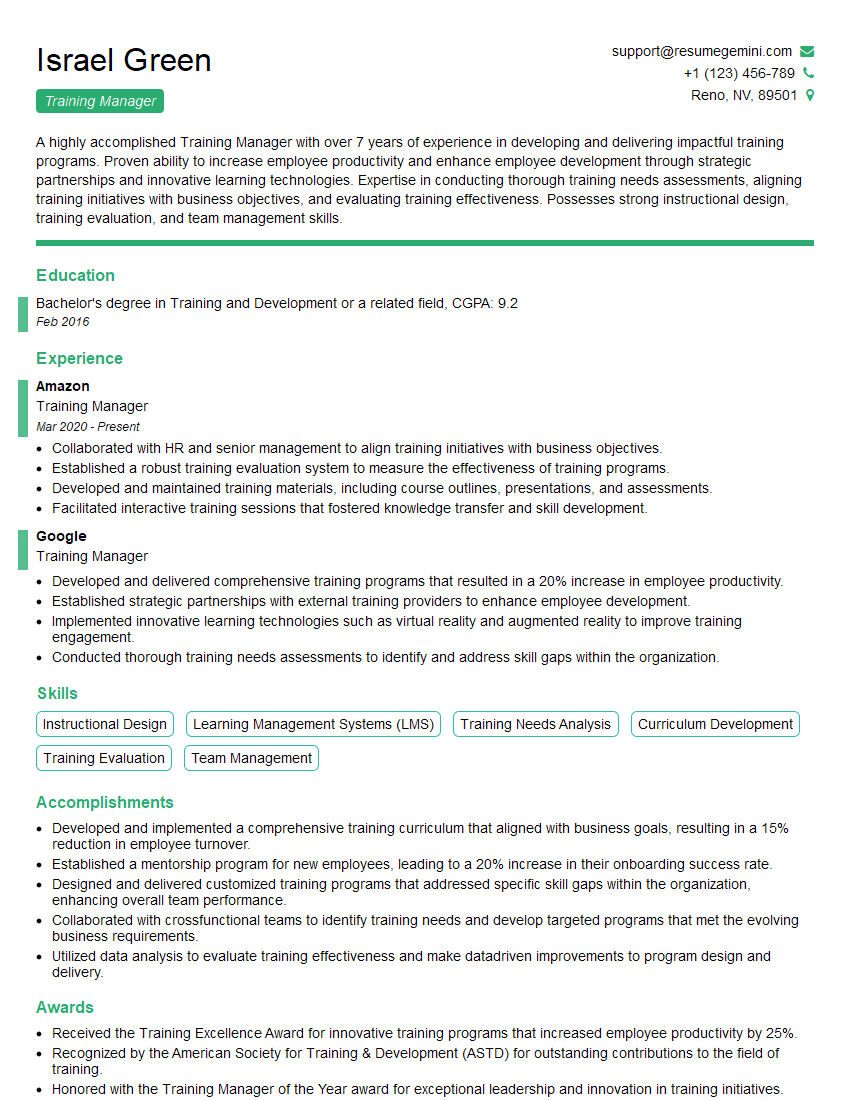

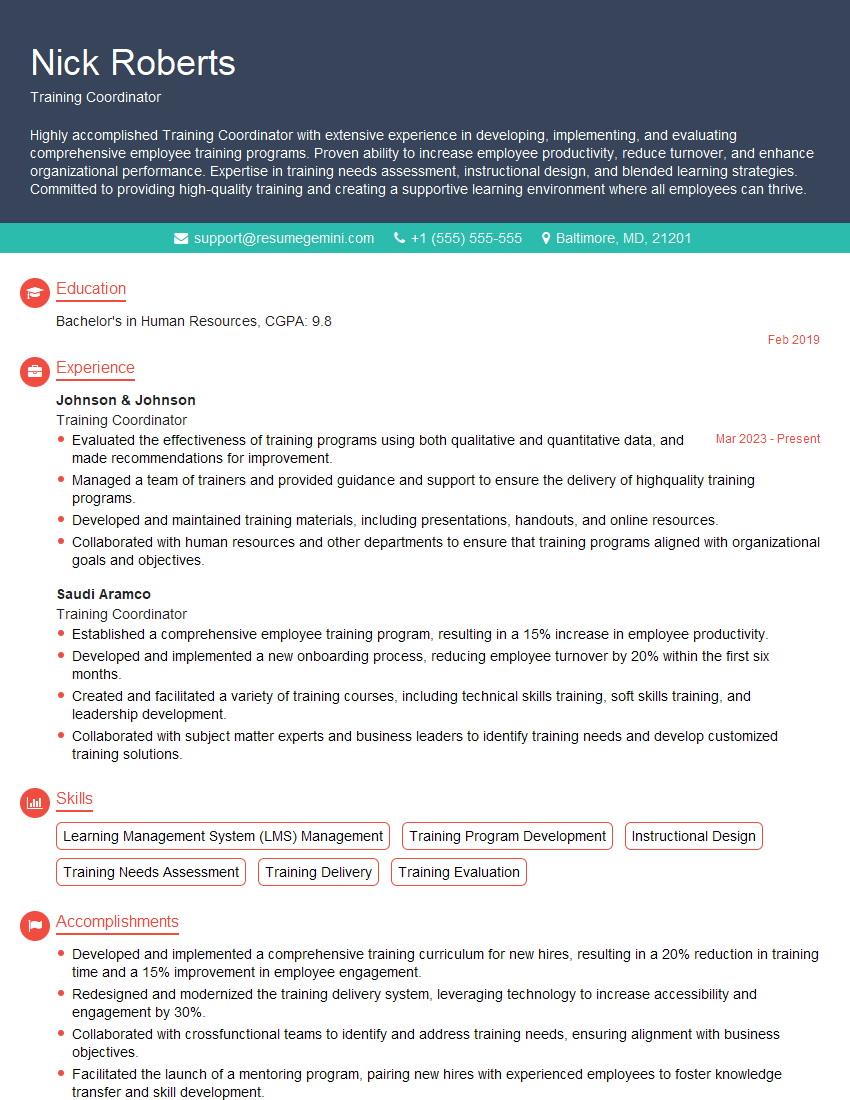

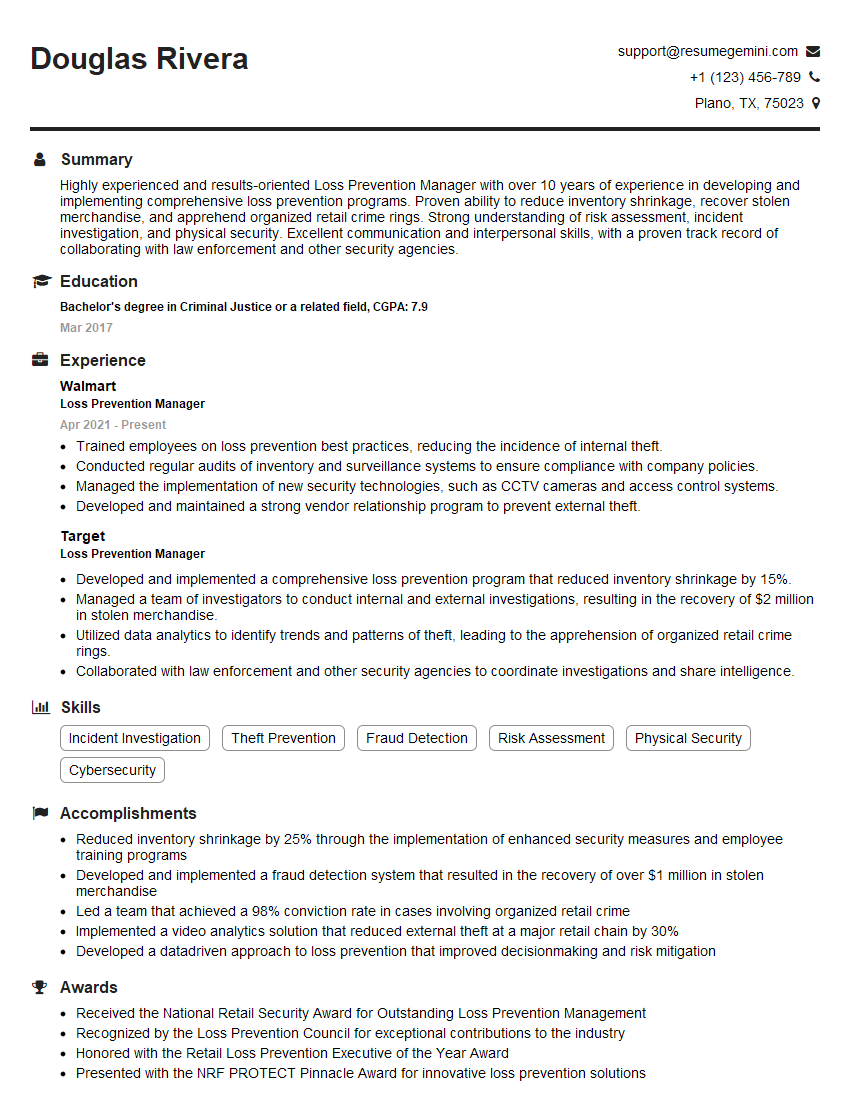

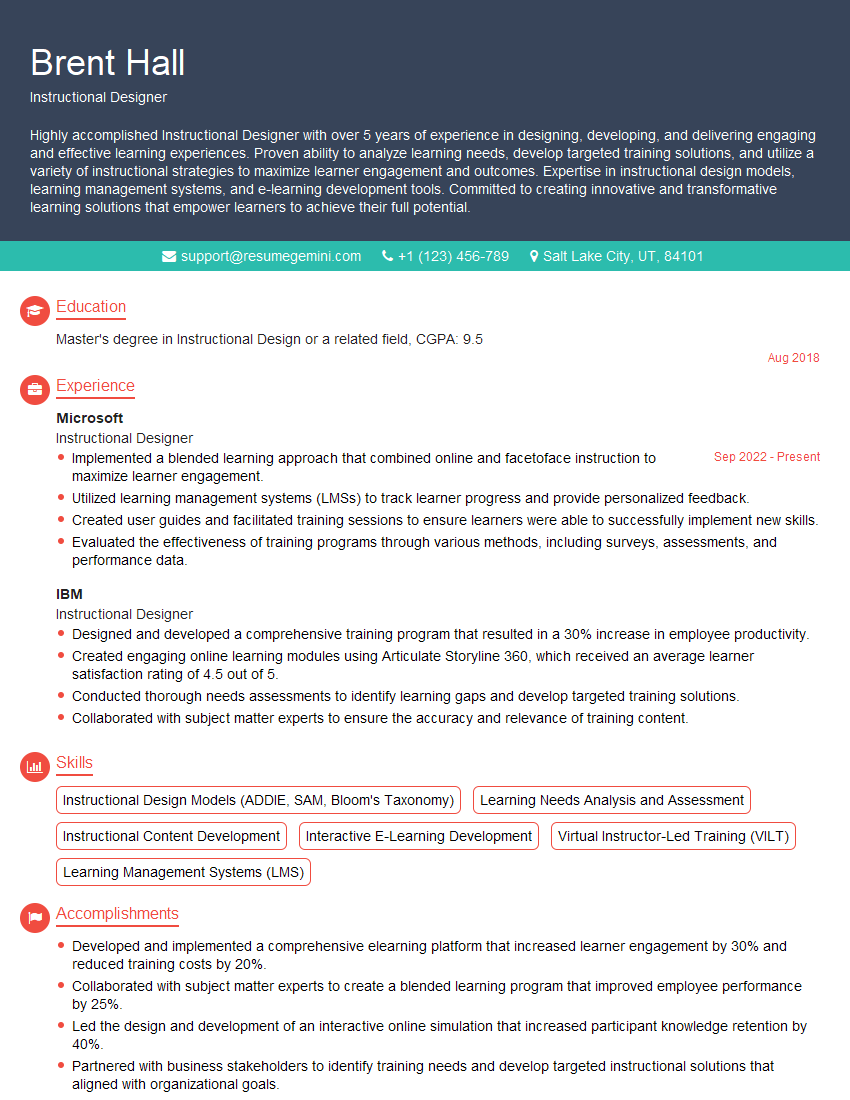

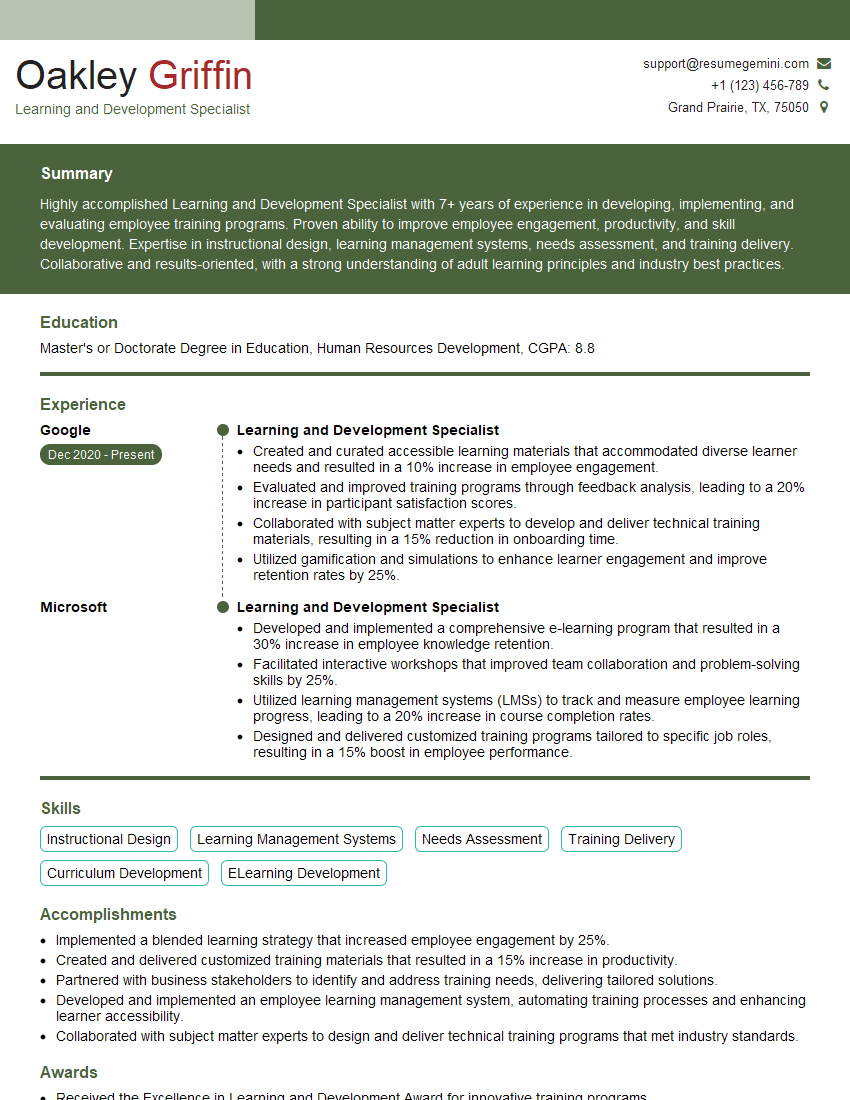

Mastering Safety and Training is crucial for a rewarding and impactful career, offering opportunities for growth and leadership within diverse industries. A strong resume is your key to unlocking these opportunities. Building an ATS-friendly resume is essential for getting your application noticed by recruiters. Use ResumeGemini to create a professional and impactful resume that highlights your skills and experience in Safety and Training. ResumeGemini offers examples of resumes tailored specifically to this field, guiding you to present your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.