Preparation is the key to success in any interview. In this post, we’ll explore crucial Scaffolding and Ladder Use interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Scaffolding and Ladder Use Interview

Q 1. Explain the different types of scaffolding systems.

Scaffolding systems are broadly categorized based on their design and material. Understanding these differences is crucial for selecting the appropriate system for a specific task, ensuring worker safety, and meeting project requirements.

- Tube and Clamp Scaffolds: These are versatile and commonly used, constructed from metal tubes and couplers (clamps). They are adaptable to various shapes and heights, making them ideal for many construction projects. Think of them as a highly customizable Lego structure for working at heights.

- System Scaffolds: These pre-engineered systems utilize standardized components for faster and easier assembly. They often feature improved safety features and are suitable for larger or more complex projects. They are like pre-fabricated building blocks, streamlining construction.

- Frame Scaffolds: These are made of pre-assembled frames connected by ledgers and transoms. They are known for their stability and are often used for smaller projects or where quicker erection is needed. Imagine a more rigid and simpler-to-build scaffold compared to tube and clamp.

- Suspended Scaffolds: These are hung from a structure above, used where ground-based scaffolding is impossible or impractical. They’re essential for tasks like facade work on tall buildings. Think of them as hanging platforms, safe and secured from above.

- Mobile Scaffolds (Towers): These are pre-fabricated, mobile units with wheels for easy movement and positioning. Ideal for smaller tasks, they’re designed for stability and ease of use.

The choice of scaffolding system depends on factors such as the job’s height, complexity, duration, and access restrictions.

Q 2. Describe the process of erecting a tube and clamp scaffold.

Erecting a tube and clamp scaffold requires careful planning and adherence to safety regulations. Think of it like building with large metal erector sets – precision and safety are key.

- Planning: Determine the scaffold’s height, dimensions, and load capacity. Drawings or plans are essential.

- Base Preparation: Ensure a level and stable base. Use base plates or adjusters to compensate for uneven ground.

- Standard: Begin by assembling the base, typically using 4 vertical tubes connected by a base plate.

- Vertical Supports: Add vertical tubes at regular intervals, secured by clamps. Maintain consistent spacing according to manufacturer’s instructions.

- Horizontal Bracing: Install ledgers (horizontal tubes) to create platforms and add stability. Diagonal bracing is also crucial to prevent swaying.

- Platforms: Secure planks or decking boards to create working platforms, ensuring even distribution of weight and secure connections.

- Guardrails: Install guardrails and toe boards at all working levels to prevent falls. Always check guardrail heights and stability.

- Inspection: Conduct a thorough inspection of the entire structure before use. Check for loose clamps, damaged tubes, or any other safety concerns.

Remember, the precise steps may vary slightly depending on the specific scaffold design and manufacturer’s instructions, but these steps remain fundamentally the same for all tube and clamp structures.

Q 3. What are the key components of a scaffold inspection checklist?

A comprehensive scaffold inspection checklist should cover all aspects of the scaffold’s structural integrity and safety features. Think of it as a critical health check-up for the scaffold before any work commences. This prevents accidents and ensures compliance.

- Base and Ground Conditions: Check for levelness, stability, and sufficient support for the scaffold’s load.

- Vertical Supports and Bracing: Inspect for damage, corrosion, or loose connections. Ensure correct spacing and alignment of components.

- Ledgers and Transoms: Verify their secure attachment to the uprights and proper horizontal alignment.

- Platforms and Planks: Inspect for defects, damage, or loose boards. Ensure proper overlap and secure fixing.

- Guardrails and Toe Boards: Verify the presence, height, and secure fixing of guardrails and toe boards. Ensure they are compliant with regulations.

- Castors and Wheels (if applicable): Check their condition and locking mechanisms if using a mobile scaffold.

- Overall Stability: Give the scaffold a gentle push or shake to assess its stability. Any excessive movement is a cause for concern.

- Load Capacity: Confirm the scaffold’s load capacity isn’t exceeded.

A well-documented inspection checklist, along with photos of potential issues, provides a valuable record for auditing and liability purposes.

Q 4. How do you identify and address potential scaffold hazards?

Identifying and addressing scaffold hazards requires a proactive approach and thorough understanding of potential risks. Proactive hazard identification is critical for preventing accidents.

- Visual Inspection: Regularly inspect the scaffold for any signs of damage, wear, or deterioration. Look for bent or damaged tubes, loose clamps, cracked or broken planks, and any other structural defects.

- Load Assessment: Ensure the scaffold is not overloaded. Consider the weight of materials, tools, and workers.

- Environmental Factors: Account for weather conditions, such as strong winds or rain, which can affect scaffold stability.

- Access and Egress: Ensure safe access and egress points to and from the scaffold.

- Housekeeping: Maintain a clean and organized workspace to prevent trip hazards and falls.

Addressing hazards involves immediate corrective action. This may include replacing damaged components, reinforcing weak points, or temporarily suspending work until the hazard is eliminated. Documentation of identified hazards and corrective actions is paramount.

Q 5. What are the legal requirements for scaffold tagging and certification?

Legal requirements for scaffold tagging and certification vary depending on the jurisdiction, but the core principle remains consistent: ensuring the scaffold is safe for use. This involves proper documentation and verification of safety.

Typically, scaffolding requires tagging that indicates its safe working load, erection date, and inspection details. Certification often involves a qualified professional’s inspection and verification that the scaffold meets all safety standards. This certification may be required for specific projects or by certain regulatory bodies. Failure to comply with these requirements can lead to significant penalties and legal repercussions.

The tags and certificates provide proof of compliance and a record of the scaffold’s history and condition. This is vital in case of accidents or inspections by authorities.

Q 6. Explain the importance of fall protection when working at heights.

Fall protection is paramount when working at heights. Falls from scaffolds can result in serious injuries or fatalities. Implementing effective fall protection is non-negotiable.

Fall protection systems aim to prevent falls or minimize their impact. This is achieved by using different systems and equipment to either stop a fall before it happens or to mitigate the consequences of a fall. These systems act as a safety net, offering a second chance should the primary safety measures fail.

The importance lies in safeguarding workers’ lives and preventing devastating accidents. The costs associated with workplace injuries far outweigh the cost of implementing robust fall protection measures. Investing in safety is an investment in your workforce and your business.

Q 7. Describe different types of fall protection equipment.

Several types of fall protection equipment are available, each suited to different situations and working environments. The choice depends on the specific application and work environment.

- Full Body Harnesses: These are worn by workers and provide secure anchor points for fall arrest systems.

- Lanyards: These connect the harness to an anchorage point, restricting movement and preventing falls.

- Shock Absorbers: Incorporated into lanyards, these reduce the impact force during a fall.

- Anchorage Points: These are secure attachment points above the worker, typically structural components of the building or scaffold.

- Self-Retracting Lifelines (SRLs): These automatically retract the lifeline, limiting fall distance.

- Guardrails and Toe Boards: These are passive fall protection systems offering a physical barrier to prevent falls.

- Safety Nets: These are used as a secondary fall protection system, catching a worker if they fall.

Proper training and selection of appropriate fall protection equipment are crucial for effectiveness and safety. Workers must be trained to properly use and maintain all equipment.

Q 8. How do you select the appropriate ladder for a specific task?

Choosing the right ladder depends entirely on the job. Think of it like choosing the right tool for a specific task – a screwdriver for screws, a hammer for nails. First, determine the working height. Measure from the ground to the highest point you need to reach, then add at least 3 feet (1 meter) for safety. This extra height ensures you won’t overreach.

Next, consider the type of ladder. Stepladders are ideal for short-reach tasks, while extension ladders are necessary for higher reaches. For uneven terrain, a tripod ladder provides extra stability. Always check the ladder’s weight capacity to make sure it can support you, your tools, and any materials. A 300 lb (136kg) rated ladder is fine for most people but heavier users and those carrying lots of equipment will need a higher rating. Finally, inspect the ladder carefully before each use – check for any damage to the rungs, rails or feet. A damaged ladder is a dangerous ladder.

For instance, painting the exterior of a two-story house requires an extension ladder, carefully selected based on the house’s height and the weight of the painter and equipment. In contrast, changing a lightbulb on a high ceiling in a room would use a step ladder or possibly a single extension ladder. The decision always hinges on safety and suitability.

Q 9. What are the safe practices for using ladders?

Safe ladder use is paramount. Always inspect the ladder before use, checking for cracks, broken rungs, or loose parts. Ensure the ladder is placed on a stable, level surface. The base should be one-quarter of the working length away from the wall. For example, for a 12-foot ladder, the base should be 3 feet from the wall. Never place the ladder on loose material or soft ground. Face the ladder when climbing and maintain three points of contact (two hands and one foot or two feet and one hand) at all times. Never overreach. If you need to reach further, reposition the ladder. Avoid using ladders in windy conditions or near electrical lines. Finally, someone should always be present as a spotter if possible.

- Proper Placement: Level ground, away from hazards.

- Three-Point Contact: Maintain while climbing and descending.

- Avoid Overreaching: Reposition ladder as needed.

- Weather Conditions: Avoid use in strong winds or rain.

- Electrical Safety: Keep away from power lines.

Q 10. What are the limitations of ladder use?

Ladders have limitations. They shouldn’t be used in extremely high winds. The ground must be stable and level, and they aren’t suitable for working on unstable surfaces like rooftops with fragile material. Ladders are also unsuitable for long-term work at height, and should not be used to support heavy loads or materials exceeding their weight rating. Furthermore, always avoid using metal ladders near overhead power lines, as this poses a severe electrical shock hazard. Finally, ladders are generally not appropriate for prolonged periods of work, as fatigue can compromise safety.

For example, you wouldn’t use a ladder to install solar panels on a steep roof, or to work on a high-rise building. In those scenarios, more robust systems like scaffolding would be necessary.

Q 11. How do you ensure stability when using a ladder?

Ladder stability is crucial. Proper placement is key – a level surface is essential. The ladder’s feet should be firmly planted and the base should be positioned at the appropriate distance from the wall (one-quarter of the working length). For example, with a 12-foot ladder, position the base 3 feet from the wall. If the ground isn’t level, use leveling boards under the ladder feet to create a stable base. For added stability, consider using ladder stabilizers or outriggers, especially on uneven or soft ground. If working on a slope, ensure the ladder is angled appropriately. If unsure about safety, use spotters or engage experienced workers.

Q 12. Explain the proper techniques for setting up and securing a scaffold.

Scaffolding setup and securing require a systematic approach. Begin by carefully examining the ground conditions and ensure a stable, level base. The base should be large enough to support the scaffold’s weight and any workers and materials. Next, assemble the scaffold according to the manufacturer’s instructions, ensuring all components are properly connected and tightened. Use the correct number of base plates and adjusters to ensure the scaffold is level. Check alignment regularly and brace the scaffold with diagonal braces for increased stability. The height of each level should be consistent and checked with a level. Finally, secure the scaffold to the building or structure using appropriate tie-off points, ensuring they’re strong enough to handle the scaffold’s load. Regular inspections are crucial during assembly and use.

Imagine building a tower of Lego bricks – each piece needs to be correctly aligned and secured to ensure stability. Scaffolding is the same – each component must be firmly connected and braced to prevent collapse.

Q 13. What are the signs of scaffold instability?

Recognizing signs of scaffold instability is vital for preventing accidents. Look for any visible sagging, swaying, or misalignment of components. Check for loose connections or bolts. Uneven leg lengths or a noticeable lean are major warning signs. Creaking sounds or shifting components indicate potential instability. Any signs of overloading, such as bending or buckling of the scaffold structure, are cause for immediate concern. If you notice any of these problems, stop work immediately, and rectify the problem before continuing. Never compromise on safety.

Q 14. Describe the procedures for dismantling a scaffold.

Dismantling a scaffold is as important as setting it up. Follow a systematic approach, working from the top down, removing one level at a time. Never remove multiple components at once. Ensure that all components are properly detached before lowering them to the ground and ensure that other workers are aware of the procedure. Use appropriate lifting equipment if necessary. Inspect each component before storing it, setting aside any damaged parts. Secure and store components in a designated area, following company and regulatory guidelines. Organize dismantling in a way that prevents components falling, causing injury or damage. Always have a spotter and follow a pre-planned sequence.

Q 15. What are the responsibilities of a scaffold supervisor?

A scaffold supervisor’s responsibilities are paramount to worker safety and project success. They’re essentially the guardians of the scaffolding system, ensuring its safe erection, use, and dismantling. This involves a multifaceted role encompassing planning, execution, and oversight.

- Planning: This includes reviewing project plans, selecting appropriate scaffolding types, and ensuring sufficient materials are available. They’ll create a detailed scaffolding plan outlining erection, usage, and dismantling procedures.

- Erection and Inspection: Supervisors oversee the actual building of the scaffold, ensuring that it adheres to all safety regulations, manufacturer’s instructions, and the approved plan. They conduct regular inspections, checking for stability, proper tie-ins, and any signs of damage or weakness. Think of them as the quality control manager for the scaffolding system.

- Training and Communication: They’re responsible for training workers on safe scaffolding practices, including proper use, fall protection procedures, and emergency response plans. Clear communication with workers and other site personnel is crucial to prevent accidents.

- Maintenance and Dismantling: Supervisors manage the ongoing maintenance of the scaffolding, addressing any repairs or replacements promptly. They meticulously supervise the dismantling process, ensuring it’s done safely and in reverse order of erection.

For instance, a supervisor might identify a potential weakness in a scaffold’s baseplate during inspection and order an immediate replacement before any work commences on that section, preventing a potential collapse.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle a scaffold collapse?

A scaffold collapse is a serious emergency requiring immediate and decisive action. The primary goal is to ensure the safety of personnel and prevent further injuries or damage.

- Evacuate the Area: Immediately clear the area around the collapsed scaffold. Warn others to stay away, as there might be unstable debris or hidden hazards.

- Assess the Situation: Check for injured personnel. Administer first aid if qualified and call emergency services (ambulance, fire department) immediately. Document the scene as much as possible, taking pictures and noting the condition of the collapsed scaffold.

- Secure the Area: Prevent unauthorized access to the collapsed scaffold and the surrounding area. If there’s a risk of further collapse, establish a wider exclusion zone.

- Investigate the Cause: A thorough investigation is needed to determine the root cause of the collapse. This might involve reviewing the scaffold’s erection plans, inspecting remaining scaffolding sections, and interviewing workers. This information is crucial for preventing future incidents.

- Report the Incident: Report the incident to the appropriate authorities (OSHA, etc.) and the project management team, following established procedures. Keep detailed records of all actions taken.

Imagine a scenario where a scaffold collapses due to overloading. Following these steps systematically will minimize casualties, protect the surrounding area, and ensure a proper investigation to avoid similar accidents in the future.

Q 17. What are the different types of ladder materials and their uses?

Ladders are categorized by their material, each offering distinct advantages and disadvantages. The choice of material depends on factors such as intended use, weight capacity, and environmental conditions.

- Aluminum Ladders: These are lightweight, easy to transport, and relatively inexpensive. However, they are less durable than fiberglass and are not suitable for use near electrical hazards because they are conductors. They are commonly used for household or light-duty commercial tasks.

- Fiberglass Ladders: These ladders are non-conductive, making them ideal for working near electricity. They are stronger and more durable than aluminum ladders but are heavier and more expensive. These are favoured in electrical work and situations where electrical contact is possible.

- Wooden Ladders: Traditionally used, wooden ladders are generally less expensive than fiberglass but require more maintenance and are susceptible to rot and damage from moisture. They are not as strong as fiberglass or aluminum and are rarely used in modern professional settings.

- Steel Ladders: These are robust and heavy-duty, ideal for situations demanding high weight capacities. They are commonly used in industrial applications. However, steel ladders are susceptible to rust and are heavier than aluminum or fiberglass, making them difficult to maneuver.

For example, an electrician would always use a fiberglass ladder when working on a power line, as opposed to using an aluminum ladder, which could lead to electrocution.

Q 18. Explain the importance of regular scaffold inspections.

Regular scaffold inspections are critical for preventing accidents and ensuring worker safety. Think of them as a proactive approach, identifying potential problems before they escalate into serious incidents.

- Early Detection of Problems: Regular inspections allow for the early detection of potential hazards like loose connections, damaged components, or overloading. Addressing minor issues immediately is far safer and less costly than dealing with a major collapse.

- Compliance with Regulations: Frequent inspections demonstrate compliance with safety standards and regulations. This is essential for maintaining legal compliance and avoiding penalties.

- Worker Confidence and Morale: Knowing that the scaffold is regularly inspected and maintained helps build worker confidence and improves morale. Workers are more likely to focus on their tasks when they feel safe.

- Extended Scaffold Lifespan: Early detection and repair of minor issues extend the lifespan of the scaffold and reduce the overall cost of maintenance.

A simple analogy is a car inspection. Regular checks prevent small issues from becoming major breakdowns. Similarly, regular scaffold inspections are far cheaper and safer than reacting to a catastrophic failure.

Q 19. Describe the process of reporting a scaffold incident.

Reporting a scaffold incident needs to be done swiftly and thoroughly to ensure accountability and prevent future occurrences. The process typically involves several steps:

- Immediate Actions: First, ensure the safety of everyone involved. Administer first aid if necessary and call emergency services. Isolate the area to prevent further accidents.

- Document the Incident: Take photographs and videos of the scene, noting the condition of the scaffolding and any injuries sustained. Gather witness statements. Record the date, time, and location of the incident.

- Internal Reporting: Report the incident to the appropriate supervisors and management within the company. Follow company protocols for incident reporting.

- External Reporting: Depending on the severity of the incident and local regulations, report the incident to relevant authorities (OSHA, etc.) within the stipulated timeframe. This often involves filing detailed reports with accompanying documentation.

- Investigation and Corrective Actions: A thorough investigation needs to follow to determine the root cause of the incident. This will help identify corrective actions and prevent similar incidents from occurring in the future.

For example, if a worker falls from a scaffold due to a faulty component, a detailed report should include information about the component’s condition, worker’s training status, and the sequence of events leading to the fall. This comprehensive documentation allows for thorough investigation and preventative measures.

Q 20. What are the common causes of scaffolding accidents?

Scaffolding accidents are often preventable, stemming from a combination of factors, often human error combined with inadequate planning or maintenance. Common causes include:

- Improper Erection: Failure to follow manufacturer’s instructions, incorrect placement of components, insufficient bracing, or inadequate base support are all significant contributors to instability and collapse.

- Overloading: Exceeding the safe working load of the scaffold is a major cause of accidents. This can occur due to excessive material storage, too many workers on one section, or improper distribution of weight.

- Lack of Proper Training: Workers unfamiliar with safe scaffolding practices are more likely to make mistakes that compromise safety.

- Inadequate Inspections: Insufficient or infrequent inspections can allow minor problems to develop into major hazards, leading to collapse or accidents.

- Environmental Factors: High winds, extreme temperatures, or wet conditions can significantly impact scaffold stability and increase the risk of accidents.

- Poor Maintenance: Damaged or worn components that are not promptly repaired or replaced create major safety risks.

For example, a scaffold might collapse because it wasn’t properly braced against a strong wind, showcasing a failure in both planning and environmental awareness.

Q 21. How do you calculate safe working loads for scaffolding?

Calculating safe working loads (SWL) for scaffolding is crucial for ensuring worker safety. It involves determining the maximum weight the scaffold can safely support without collapsing or becoming unstable. This calculation is not a simple formula but rather a complex process involving several factors.

It’s important to note that precise SWL calculations often require engineering expertise and usually involve considering:

- Scaffold Type and Design: Different scaffold types (e.g., tube and clamp, system scaffold) have varying load capacities. The specific design, including the number of levels, bracing, and baseplates, will influence the SWL.

- Material Properties: The strength of the materials used in constructing the scaffold (e.g., steel, aluminum) must be factored in. This information is generally found in manufacturer’s specifications.

- Environmental Factors: Wind load and other environmental conditions can significantly reduce the safe working load. Higher winds require a lower SWL.

- Load Distribution: The weight on the scaffold must be evenly distributed to avoid overloading any specific sections. Uneven weight distribution can lead to instability.

Software and engineering tables are often used to assist in this process. It’s strongly recommended to consult with a qualified professional engineer or utilize manufacturer’s guidelines to ensure accurate and safe SWL calculations rather than attempting to derive a simplified formula. Improper calculation can have devastating consequences.

Q 22. What are the requirements for scaffold access and egress?

Scaffold access and egress, simply put, are the ways workers get onto and off a scaffold. Safe access and egress are paramount to prevent falls, a leading cause of workplace injuries. Requirements vary depending on the jurisdiction and specific scaffold design, but generally involve:

Properly sized and constructed access points: This could be a stairway integrated into the scaffold, a ramp, or a dedicated ladder securely attached to the scaffold structure, positioned to avoid obstructions and providing ample space for safe movement. A single, narrow ladder on a high scaffold is unacceptable.

Stable and secure landings: Platforms at each level should be wide enough and strong enough to support workers and their equipment. Handrails and toe boards are critical components that prevent falls.

Clear and unobstructed pathways: The approach to the scaffold should be free of debris, tripping hazards, and other obstructions. Workers shouldn’t have to navigate obstacles to reach the access points.

Adequate lighting: Access points and walkways must be properly illuminated, especially during nighttime or low-light conditions. Good visibility is crucial for safe navigation.

Fall protection: Consider guardrails, safety nets, or personal fall arrest systems depending on the height and risk assessment.

Imagine a painter working on a tall building. Simply having a ladder leaning against the scaffold isn’t sufficient; a safe, dedicated access point with adequate handrails and a stable landing platform at each level is essential. Neglecting these measures can lead to serious falls and injuries.

Q 23. Explain the role of tie-ins and bracing in scaffold stability.

Tie-ins and bracing are crucial for scaffold stability; they work together to resist the forces acting on the scaffold structure, preventing collapses. Think of it like building a sturdy house: you need strong walls and supports to withstand wind and other external loads.

Tie-ins: These are connections that anchor the scaffold to a stable structure, like a building’s walls or ground anchors. They transfer the weight and forces of the scaffold to the building, preventing overturning or sideways movement. Properly installed tie-ins distribute the load effectively and are crucial in preventing collapse.

Bracing: This involves adding diagonal or horizontal supports to the scaffold’s frame. Bracing reinforces the scaffold’s structure, preventing it from racking (twisting or deforming) under load. It increases the overall stability and strength of the scaffolding, enabling it to resist wind forces and the weight of workers and materials.

For example, a scaffold erected on uneven ground needs additional bracing to ensure its stability, and tie-ins are necessary to prevent the whole structure from toppling over. Ignoring tie-ins and bracing is like building a house without a foundation – it’s a recipe for disaster.

Q 24. Describe the different types of scaffolding tie-back systems.

Scaffold tie-back systems vary based on the building’s construction and the scaffold’s height and load. Some common types include:

Through-the-wall anchors: These are strong anchors that pass through the building’s wall and are secured on the inside, effectively tying the scaffold directly to the building’s structure. This is ideal for sturdy buildings.

Roof anchors: When scaffolds extend beyond the building’s walls, roof anchors provide stability by connecting the scaffolding to the roof structure. The weight is then transferred to the building’s framework.

Ground anchors: These are used when scaffolding is erected independent of a building structure. Heavy-duty anchors are embedded into the ground to secure the scaffold. This method requires a thorough ground assessment.

Wall brackets: These provide temporary attachment points to walls, acting as a form of tie-in. They typically have limited load capacity and are not suitable for all situations.

Choosing the right tie-back system requires careful consideration of factors such as the building’s structural integrity, the scaffold’s load capacity, and relevant safety regulations. Each system has its advantages and limitations; therefore, a thorough site assessment is critical.

Q 25. What are the limitations of using mobile elevating work platforms (MEWPs)?

Mobile Elevating Work Platforms (MEWPs), while offering advantages in terms of ease of use and maneuverability, have limitations:

Reach and access limitations: MEWPs have limitations on the height they can reach and the areas they can access. Complex or confined spaces might be inaccessible to some MEWP types.

Ground conditions: The stability of MEWPs relies on level ground. Uneven terrain can compromise their stability and safety.

Weight restrictions: MEWPs have weight limits for both the platform and the operator/materials. Exceeding these limits poses safety risks.

Environmental factors: Strong winds, rain, or ice can affect the stability and operation of MEWPs, requiring careful consideration of weather conditions.

Operator training and certification: Safe operation requires specialized training and certification; unqualified operators pose significant risks.

For example, a MEWP might be unsuitable for working on a narrow, uneven rooftop or in a cluttered warehouse. Always assess the task and environment carefully to determine if a MEWP is appropriate, and if so, which type is best suited for the job.

Q 26. How do you ensure the compatibility of scaffolding components?

Ensuring compatibility of scaffolding components is critical for safety. Incompatible components can lead to structural weakness and collapse. This is achieved through:

Manufacturer’s specifications: Always use components from the same manufacturer, or from manufacturers that explicitly state compatibility. Different manufacturers might use varying standards and designs that are not interchangeable.

Component markings and labels: Check components for labels indicating their load capacity, size, and material specifications. Make sure they align with the scaffold’s design and intended use.

Visual inspection: Before assembly, inspect components for any damage (bending, cracks, corrosion). Damaged components should be replaced.

Proper assembly procedures: Follow the manufacturer’s instructions precisely for assembly. Incorrect assembly can lead to instability and failure.

Think of it like assembling LEGOs; only bricks of the same type fit together properly. Using different types of scaffolding components, even if they seem similar, could create weak points that compromise the whole scaffold’s structural integrity.

Q 27. Explain the importance of risk assessments in scaffolding and ladder use.

Risk assessments are fundamental for safe scaffolding and ladder use. They are a systematic process to identify hazards, evaluate risks, and determine appropriate control measures. This prevents accidents and ensures the safety of workers.

Identifying hazards: This includes evaluating potential hazards like unstable ground, weather conditions, height of work, nearby obstacles, potential falling objects, and scaffold structure integrity.

Evaluating risks: This involves considering the likelihood and severity of the identified hazards. A high likelihood and high severity hazard requires immediate attention and stringent controls.

Determining control measures: This involves implementing solutions to reduce or eliminate risks, such as using proper scaffolding, fall protection systems, training, and safe work procedures.

Documentation: Risk assessments must be documented and reviewed regularly. This ensures that all potential hazards are identified and addressed.

For example, working on a scaffold near a busy street requires a risk assessment that considers the risk of falling objects from the street and the possibility of a scaffold collapse due to traffic vibration. The assessment should guide the selection of appropriate safety measures like safety nets and traffic management.

Q 28. Describe the emergency procedures for working at heights.

Emergency procedures for working at heights must be clearly defined and practiced regularly. Key elements include:

Emergency communication: Establish a clear communication system between workers on the scaffold and ground personnel, using radios or other reliable means.

Escape routes: Pre-plan escape routes in case of emergencies, such as fire or scaffold collapse. These should be clearly marked and kept unobstructed.

Emergency equipment: Ensure appropriate emergency equipment is available, such as harnesses, ropes, and first-aid kits. Workers must be trained in their use.

Rescue plan: Have a detailed rescue plan in place, outlining procedures for rescuing injured workers from heights. This might involve using specialized rescue equipment and trained personnel.

Emergency response training: All workers must receive comprehensive training on emergency procedures, including evacuation, rescue techniques, and first aid.

Regular drills are crucial. Imagine a fire breaking out on a scaffold; having a practiced escape route and a clear communication system could save lives. A well-defined emergency plan and training are not just requirements; they are crucial to ensuring safety and mitigating risks.

Key Topics to Learn for Scaffolding and Ladder Use Interview

- Scaffolding Types and Selection: Understanding different scaffolding systems (e.g., tube and clamp, system scaffold, mobile scaffold) and their appropriate applications based on project requirements and safety regulations.

- Scaffold Erection and Dismantling: Safe procedures for assembling, inspecting, and dismantling scaffolding, including proper use of tools and equipment, adherence to safety protocols, and understanding load-bearing capacity.

- Ladder Safety and Usage: Proper ladder selection based on task and working height, safe climbing techniques, securing ladders to prevent slips, and recognizing potential hazards.

- Fall Protection and Safety Harness Use: Understanding and applying fall protection measures, including the correct use of safety harnesses, lanyards, and anchor points on scaffolding and ladders.

- Risk Assessment and Hazard Identification: Identifying potential hazards associated with scaffolding and ladder use, conducting thorough risk assessments, and implementing appropriate control measures to mitigate risks.

- Inspection and Maintenance: Regular inspection of scaffolding and ladders for damage or defects, performing necessary maintenance, and understanding reporting procedures for identified issues.

- Regulations and Compliance: Familiarity with relevant safety regulations, industry standards, and best practices related to scaffolding and ladder use.

- Practical Problem-Solving: Ability to analyze and solve real-world problems related to scaffolding and ladder setup, usage, and safety in various work environments.

- Communication and Teamwork: Effective communication with colleagues and supervisors regarding safety concerns, task assignments, and potential hazards.

Next Steps

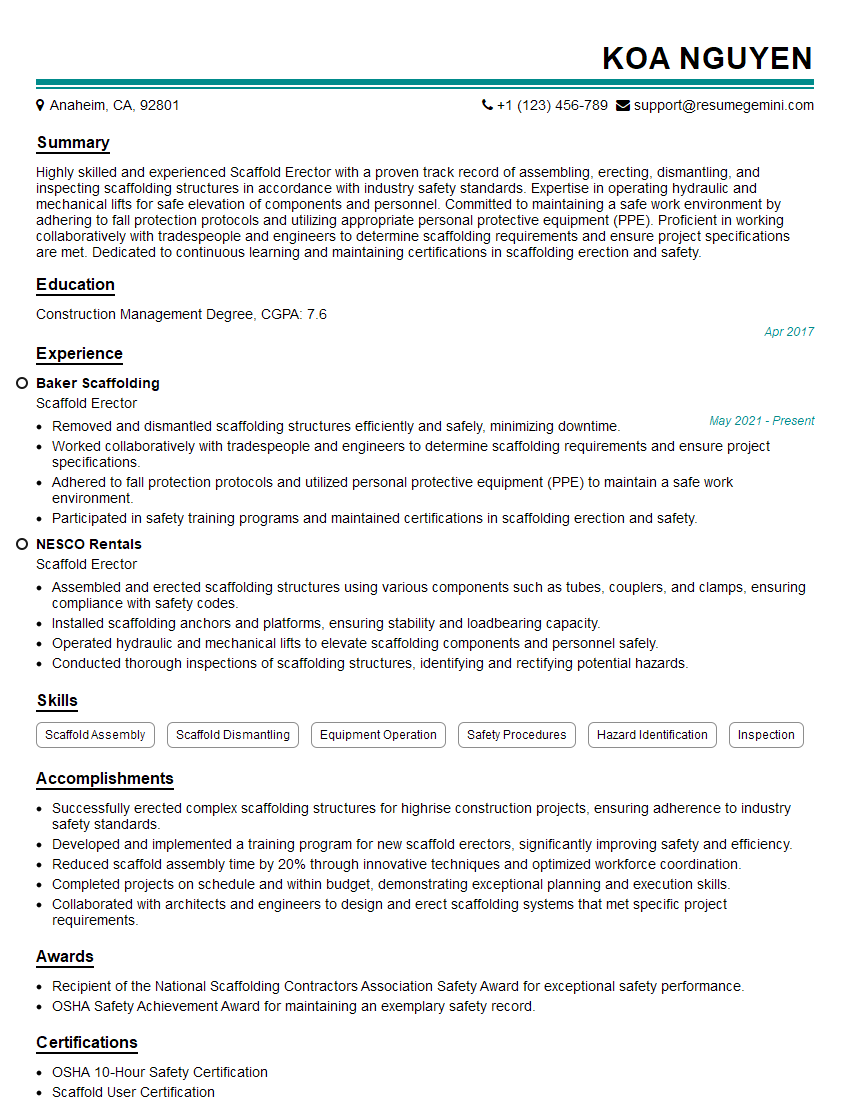

Mastering scaffolding and ladder use is crucial for career advancement in construction and related fields. It demonstrates a commitment to safety and proficiency in essential job skills, leading to increased responsibility and earning potential. To stand out to potential employers, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Scaffolding and Ladder Use are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.