Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important ServSafe interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in ServSafe Interview

Q 1. What are the four main foodborne illness risk factors?

The four main foodborne illness risk factors, as outlined by ServSafe, are crucial to understand for preventing food contamination. They are:

- Biological Hazards: These are harmful microorganisms like bacteria (Salmonella, E. coli, Listeria), viruses (Norovirus, Hepatitis A), parasites (Toxoplasma gondii), and fungi. Think of them as tiny invaders that can cause illness if food isn’t handled properly.

- Chemical Hazards: These include cleaning supplies, pesticides, toxic metals, and even naturally occurring toxins like shellfish poisoning. Imagine accidentally contaminating food with a cleaning agent – that’s a chemical hazard.

- Physical Hazards: These are foreign objects in food, like glass, metal, hair, or plastic. Picture a small piece of glass accidentally falling into a batch of soup – that’s a physical hazard that needs immediate attention.

- Time-Temperature Abuse: This is the most common cause of foodborne illness. It involves letting potentially hazardous foods stay in the temperature danger zone (41°F to 135°F) for too long, allowing harmful bacteria to multiply rapidly. This is like creating a breeding ground for bacteria.

Understanding these factors is the first step towards building a safe food handling operation.

Q 2. Explain the temperature danger zone and its significance.

The temperature danger zone is the range of temperatures between 41°F (5°C) and 135°F (57°C). It’s the sweet spot where many harmful bacteria multiply rapidly. Think of it as a breeding ground for bacteria. Keeping food outside this temperature range is crucial to prevent foodborne illnesses.

Significance: If potentially hazardous foods remain in this zone for more than four hours, bacteria can grow to dangerous levels, making the food unsafe to eat. This can lead to serious illness or even death. This is why proper temperature control is critical, especially in food service.

For example, leaving cooked chicken out at room temperature for several hours will allow bacteria to grow exponentially, drastically increasing the risk of foodborne illness.

Q 3. Describe the proper handwashing procedure according to ServSafe guidelines.

Proper handwashing is a cornerstone of food safety. Here’s the ServSafe-recommended procedure:

- Wet your hands with warm water.

- Apply soap (preferably liquid).

- Scrub your hands and forearms vigorously for at least 20 seconds, including under fingernails. Think of singing ‘Happy Birthday’ twice to ensure adequate scrubbing.

- Rinse your hands and forearms thoroughly under warm running water.

- Dry your hands and forearms using a single-use paper towel or air dryer.

- Use a clean paper towel to turn off the faucet to avoid recontamination.

Handwashing should be performed frequently, especially after using the restroom, handling raw food, touching your face, and before starting work or handling food.

Q 4. How do you prevent cross-contamination in a food service environment?

Cross-contamination is the transfer of harmful bacteria or other pathogens from one food item to another. To prevent this, several strategies are necessary:

- Separate raw and cooked foods: Use separate cutting boards, utensils, and containers for raw meats, poultry, seafood, and vegetables. Think of color-coding these items to minimize confusion.

- Wash hands frequently: This prevents the spread of bacteria from one food to another. Remember the proper handwashing procedure!

- Clean and sanitize surfaces: Thoroughly clean and sanitize all work surfaces, equipment, and utensils between handling different food items. This eliminates any lingering bacteria.

- Refrigerate foods properly: Store raw meat at the bottom of the refrigerator to avoid dripping onto ready-to-eat foods. This prevents bacteria from spreading via drips.

- Prevent bare hand contact: Use utensils to serve food whenever possible to avoid accidental contamination.

These practices ensure that potentially hazardous foods don’t contaminate safe foods.

Q 5. What are the proper cooling procedures for potentially hazardous foods?

Proper cooling of potentially hazardous foods is crucial to prevent bacterial growth. The goal is to rapidly cool foods from 135°F to 41°F within four hours. Here’s how:

- Divide large portions: Break down large quantities of food into smaller, shallower containers to speed up the cooling process. This increases the surface area exposed to the cool air.

- Ice-water bath: Immerse containers in an ice-water bath, ensuring the food is completely submerged and stirring occasionally.

- Blast chilling: Use a blast chiller to rapidly cool foods to a safe temperature. This is a very effective method, common in commercial kitchens.

- Rapid cooling in refrigerator: Place food in the refrigerator, ensuring adequate air circulation around containers.

Remember to monitor the temperature during cooling using a food thermometer to ensure it reaches 41°F within four hours.

Q 6. Explain the importance of FIFO (First-In, First-Out) in food storage.

FIFO, or First-In, First-Out, is a crucial inventory management system for food storage. It means that the oldest food items should be used before the newest ones. Think of your refrigerator – you use the oldest milk first.

Importance: This prevents food spoilage and reduces the risk of foodborne illness. By using older items first, you minimize the time food spends in storage, reducing the chances of bacterial growth and spoilage. Using FIFO also helps to avoid food waste.

Example: Imagine a stack of cans. You should always take the cans from the front of the stack and place new cans at the back.

Q 7. What are the safe thawing methods for frozen foods?

Safe thawing methods are vital to prevent the growth of harmful bacteria. Here are the recommended methods:

- Refrigerator Thawing: This is the safest method. Place the frozen food in the refrigerator and allow it to thaw slowly. This typically takes several hours or even overnight, depending on the size and type of food.

- Cold Water Thawing: Submerge the food in cold running water, changing the water every 30 minutes to ensure the temperature stays consistently cold. This method is faster than refrigerator thawing but requires more attention.

- Microwave Thawing: Use the defrost setting on your microwave, but cook the food immediately after thawing. This is the fastest method but should be followed by immediate cooking.

Never thaw food at room temperature, as this allows bacteria to multiply rapidly. Always ensure food is cooked to its safe internal temperature after thawing.

Q 8. What are the guidelines for cleaning and sanitizing food contact surfaces?

Cleaning and sanitizing food contact surfaces are crucial steps in preventing foodborne illnesses. Cleaning removes visible soil and food residue, while sanitizing kills or reduces harmful microorganisms. The process involves a three-step approach:

- Cleaning: First, scrape or remove any visible food debris from the surface. Then, wash the surface with a detergent solution using hot water (at least 110°F). This breaks down and lifts away the remaining soil. Think of it like washing dishes – you need hot, soapy water to get things truly clean. For example, a heavily soiled cutting board needs a thorough scrubbing before sanitizing.

- Rinsing: Thoroughly rinse the surface with clean, hot water to remove all traces of the cleaning solution. Leaving detergent residue can affect the taste and appearance of food, and it won’t allow the sanitizer to work effectively. Imagine leaving soap on your dishes – it would be unpleasant!

- Sanitizing: Apply an approved sanitizer according to the manufacturer’s instructions. This step kills or reduces the number of harmful bacteria, viruses, and other microorganisms. Sanitizers can be chlorine-based, iodine-based, or quaternary ammonium-based. Contact time (the amount of time the sanitizer must stay wet on the surface) is critical – ensure it’s followed precisely.

After sanitizing, allow the surface to air dry. Using a clean towel can introduce contamination, so it’s best to let it dry naturally.

Q 9. How do you properly store cleaning chemicals?

Proper storage of cleaning chemicals is essential for safety and effectiveness. They should always be stored separately from food and food contact surfaces, ideally in a designated storage area. Here are key guidelines:

- Original Containers: Chemicals must be kept in their original containers, clearly labeled with their name and any hazard warnings.

- Away from Food: Store chemicals far from food, beverages, utensils, and food preparation areas to prevent cross-contamination.

- Secure Storage: Keep chemicals in a secure location, inaccessible to unauthorized personnel, especially children. Consider using locked cabinets or storage rooms.

- Ventilation: Store in a well-ventilated area to minimize exposure to fumes. Strong chemical odors indicate poor ventilation.

- First-In, First-Out: Implement a FIFO (First-In, First-Out) system to prevent outdated chemicals from being used.

- Compatibility: Never mix different chemicals together, unless explicitly stated in the manufacturer’s instructions. Mixing can create dangerous reactions.

- Spill Kit: Maintain a readily accessible spill kit with absorbent materials and appropriate personal protective equipment (PPE) in case of an accidental spill.

Imagine a scenario where a chemical spills near food. Proper storage minimizes this risk, protecting both food and personnel.

Q 10. What are the key components of a food safety program?

A comprehensive food safety program is built on several key pillars. It’s not just about following checklists; it’s about cultivating a culture of food safety within the establishment.

- Standard Operating Procedures (SOPs): Detailed written procedures for all food handling steps, from receiving to service, ensuring consistency and training.

- Staff Training: Regular training for all employees on food safety principles, including hygiene, temperature control, and proper handling techniques. Think of it like a team working towards a common goal of food safety.

- Temperature Control: Maintaining correct temperatures throughout the food handling process, using thermometers and monitoring systems. Critical control points need strict attention.

- Supplier Approval: Selecting suppliers who maintain high standards of food safety and verifying the safety of ingredients.

- Pest Control: Implementing a robust pest control program to prevent pests from entering or contaminating the facility.

- Cleaning and Sanitizing: A comprehensive cleaning and sanitizing program, ensuring all surfaces are thoroughly cleaned and sanitized frequently.

- Monitoring and Documentation: Maintaining records of temperature checks, cleaning logs, and employee training, providing a trail for audits and traceability.

- Corrective Actions: Establishing procedures for addressing food safety violations, including prompt action and follow-up to prevent recurrence.

Think of each element as a brick in a strong wall; if one is weak, the entire structure is compromised.

Q 11. Explain the difference between cleaning and sanitizing.

Cleaning and sanitizing are distinct but equally important steps in maintaining food safety. They’re not interchangeable.

- Cleaning: Removes visible soil, food residue, and other debris from surfaces. It involves washing with detergent and hot water, mechanically removing contaminants. Think of it like scrubbing dirt off your hands.

- Sanitizing: Reduces the number of microorganisms (bacteria, viruses, etc.) to safe levels on clean surfaces. It involves using a chemical sanitizer or heat to kill or reduce these pathogens. Think of it as disinfecting your hands after washing them.

Cleaning is the foundation – you cannot sanitize a dirty surface effectively. Sanitizing is the final step to ensure that the surface is safe for food contact.

Q 12. What are the common symptoms of foodborne illness?

Symptoms of foodborne illness vary depending on the pathogen involved, but common symptoms include:

- Nausea and Vomiting: These are very common, often appearing relatively soon after consuming contaminated food.

- Diarrhea: Can range from mild to severe, often accompanied by cramping.

- Stomach Cramps: Painful abdominal contractions, often severe.

- Fever: Can indicate a more serious infection.

- Chills: A feeling of coldness, often accompanied by shivering.

- Headache: A common symptom, especially with more severe illnesses.

- Muscle Aches: Pain or soreness in the muscles.

- Dehydration: Caused by excessive fluid loss through vomiting and diarrhea. This is a serious complication requiring medical attention.

If you experience these symptoms after eating, seek medical attention, particularly if symptoms are severe or persist.

Q 13. Describe the proper procedures for handling and storing different types of food (meat, poultry, etc.).

Proper handling and storage of different food types is critical for food safety. This includes:

- Meat and Poultry: Keep raw meat and poultry separate from other foods to prevent cross-contamination. Store them at or below 41°F (5°C). Cook to a safe internal temperature to kill harmful bacteria.

- Seafood: Similar to meat and poultry, seafood should be kept chilled and cooked to a safe internal temperature. Avoid cross-contamination by keeping it separate.

- Eggs: Store eggs in their carton in the refrigerator at or below 41°F (5°C). Use eggs within their expiration date, and always cook eggs thoroughly.

- Dairy Products: Store dairy products at or below 41°F (5°C). Avoid leaving them at room temperature for extended periods.

- Produce: Wash all fresh produce thoroughly under running water before use. Store produce in the refrigerator in appropriate containers, ensuring good airflow.

Think of using different cutting boards for raw and ready-to-eat foods to prevent cross-contamination. Proper storage prevents bacterial growth, keeping food safe for consumption.

Q 14. What is the role of a food safety manager?

The Food Safety Manager is responsible for overseeing all aspects of a food safety program. This is a crucial role, ensuring the safety of food served or sold to customers.

- Developing and Implementing the Food Safety Program: Creating and implementing policies and procedures to comply with all food safety regulations.

- Staff Training: Conducting or overseeing staff training programs on food safety practices.

- Monitoring and Compliance: Regularly monitoring food safety practices, ensuring compliance with regulations and standards.

- Record Keeping: Maintaining accurate and detailed records of all food safety activities, including temperature logs, cleaning logs, and training records.

- Corrective Actions: Taking prompt corrective actions to address any food safety violations.

- Responding to Incidents: Handling and investigating any foodborne illness complaints or incidents effectively.

- Staying Updated: Keeping up-to-date with the latest food safety regulations, guidelines, and best practices.

In essence, the Food Safety Manager acts as the guardian of the establishment’s food safety reputation and the health of its patrons.

Q 15. What are the legal responsibilities of a food service establishment regarding food safety?

Food service establishments bear significant legal responsibilities concerning food safety. These responsibilities vary by jurisdiction but generally involve adhering to local, state, and federal regulations. Failure to comply can lead to hefty fines, suspension of licenses, and even criminal charges. Key areas include:

- Licensing and Permits: Obtaining and maintaining all necessary permits and licenses to operate a food service business is paramount. This demonstrates compliance and allows for regular inspections.

- Food Safety Training: Employees must be adequately trained in food safety principles, often mandated by ServSafe or equivalent programs. This ensures a knowledgeable workforce capable of preventing foodborne illnesses.

- Safe Food Handling Practices: Maintaining proper food temperatures, preventing cross-contamination, and ensuring appropriate sanitation are legally required. This involves following strict procedures outlined in the regulations.

- Record Keeping: Detailed records of food temperatures, deliveries, employee health, and pest control are usually mandatory. These records provide evidence of compliance and aid in tracing foodborne illnesses.

- Reporting: Immediate reporting of suspected foodborne illnesses to relevant health authorities is crucial. This allows for prompt investigations and prevents wider outbreaks.

For example, failing to maintain proper refrigeration temperatures can result in significant fines and legal repercussions. Similarly, inadequate employee training can lead to severe consequences if a foodborne illness outbreak occurs, with liability falling on the establishment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor food temperatures accurately?

Accurate food temperature monitoring is crucial for preventing bacterial growth and ensuring food safety. This involves using calibrated thermometers and following proper procedures. Imagine a thermometer as a crucial tool – just like a doctor uses a thermometer to check a patient’s temperature, we use one to check our food’s temperature.

- Thermometer Calibration: Calibrate thermometers regularly using an ice bath (32°F/0°C) or boiling water (212°F/100°C) to ensure accuracy. This simple step prevents inaccurate readings and ensures food safety.

- Proper Thermometer Use: Insert the thermometer into the thickest part of the food item, avoiding contact with bones or surfaces.

- Recording Temperatures: Record temperatures regularly, especially for high-risk foods. This creates a traceable record, crucial for identifying potential problems and for responding to health inspections.

- Types of Thermometers: Utilize appropriate thermometers for various applications. Bimetallic stemmed thermometers are ideal for checking cooking temperatures while thermistor or thermocouple thermometers are often used for faster readings. Digital thermometers offer precision and ease of reading.

For instance, checking the internal temperature of a chicken breast during cooking ensures it reaches a safe temperature of 165°F (74°C), preventing the growth of Salmonella. Without proper temperature monitoring, it becomes impossible to guarantee food safety.

Q 17. What actions should be taken if a foodborne illness outbreak is suspected?

Suspecting a foodborne illness outbreak requires immediate and decisive action. This is a critical situation requiring quick response and coordinated action.

- Isolate Affected Individuals: Separate individuals experiencing symptoms to prevent further spread. Providing appropriate care to the afflicted individuals is also a responsibility.

- Document Symptoms and Affected Foods: Gather information on symptoms, onset times, and foods consumed. Thorough documentation can help determine the cause and prevent future outbreaks.

- Contact Health Authorities: Report the suspected outbreak immediately to the local health department. Prompt reporting allows for a faster and more effective investigation.

- Discard Potentially Contaminated Food: Remove any food items suspected to have caused the illness. This prevents further contamination and helps contain the outbreak.

- Implement Enhanced Sanitation Procedures: Conduct a thorough cleaning and sanitizing of all surfaces, equipment, and utensils involved in food preparation.

- Review Food Handling Practices: Evaluate the food handling procedures for any areas of weakness that may have contributed to the outbreak. Training and process improvements may be necessary.

For example, if multiple patrons experience similar symptoms after eating at your establishment, you must immediately contact the health department, discard potentially contaminated food, and improve your food handling practices to prevent future occurrences.

Q 18. What is the importance of pest control in a food service setting?

Pest control is an essential element of food safety. Pests like rodents, insects, and birds can contaminate food with pathogens, allergens, and filth. It’s a critical preventative measure that shouldn’t be overlooked.

- Preventative Measures: Regular cleaning, proper food storage, sealing cracks and crevices, and using appropriate pest-proofing measures are key. This involves routinely inspecting the establishment for potential entry points and addressing them.

- Professional Pest Control: Employing a licensed pest control operator is often necessary, particularly for regular inspections, preventative measures, and targeted treatment. This ensures a systematic approach to pest control.

- Record Keeping: Maintain accurate records of pest control activities, including treatments, inspections, and any pest sightings. Maintaining detailed records is essential for inspections and audits.

- Employee Training: Educate employees about pest prevention and control measures. Proper employee training enhances the efficacy of pest control efforts.

Imagine a cockroach crawling across a countertop. That single cockroach could contaminate numerous surfaces and potentially cause a serious foodborne illness outbreak. Proactive pest control is the best way to prevent such scenarios and ensure the safety of your establishment.

Q 19. Explain the importance of proper personal hygiene in food handling.

Proper personal hygiene is foundational to food safety. Food handlers are the primary vectors of contamination. Consider personal hygiene as the first line of defense.

- Handwashing: Frequent and thorough handwashing is crucial, especially after using the restroom, handling raw food, or touching potentially contaminated surfaces. This is arguably the single most important hygiene practice.

- Clean Clothing and Aprons: Wearing clean uniforms and aprons helps prevent contamination of food. Regularly changing these garments is critical.

- Hair Restraints: Hair must be restrained to prevent hair from falling into food. This prevents the contamination of food by hair and other potentially dangerous contaminants.

- Gloves: Use gloves when appropriate to prevent contamination, especially when handling ready-to-eat foods or when wounds are present. Gloves are an additional layer of protection.

- No Jewelry: Avoid wearing jewelry, especially rings, as they can harbor bacteria and potentially contaminate food.

Think about a cook who doesn’t wash their hands after using the restroom. They could easily transfer pathogens to the food they prepare, causing a foodborne illness outbreak. Strict personal hygiene protocols are non-negotiable.

Q 20. How do you identify and address potential food safety hazards in your workplace?

Identifying and addressing food safety hazards requires a proactive and systematic approach. Think of it as a detective’s approach to ensuring food safety.

- Hazard Analysis and Critical Control Points (HACCP): Implement a HACCP plan to identify potential hazards at each stage of food production. This involves systematically identifying potential dangers and establishing measures to control them.

- Regular Inspections: Conduct regular inspections of the facility and equipment to identify potential hazards. This includes systematically checking for potential risks and addressing issues before they escalate.

- Temperature Monitoring: Monitor food temperatures at critical control points to prevent bacterial growth. Maintaining accurate temperature logs is vital.

- Employee Training: Ensure that all employees are adequately trained in food safety procedures. Investing in thorough and repetitive training is key.

- Supplier Verification: Verify the safety of food and supplies from suppliers. This involves verifying the safety of ingredients and ensuring reliable sources.

- Corrective Actions: Implement corrective actions to address any identified hazards or deviations. Having a systematic approach for implementing necessary corrections is essential.

For example, if you discover a broken refrigerator, you need to immediately address it, discard potentially compromised food, and put preventative measures in place to avoid future occurrences. Reactive correction is key, as is preventing recurrences.

Q 21. What are the different types of foodborne pathogens?

Foodborne pathogens are microorganisms that can cause illness when consumed. These are the unseen enemies in food safety.

- Bacteria: Salmonella (poultry, eggs), E. coli (undercooked beef, contaminated produce), Listeria (ready-to-eat foods, soft cheeses), Staphylococcus aureus (improperly handled food), Clostridium botulinum (improperly canned foods).

- Viruses: Norovirus (fecal contamination), Hepatitis A (contaminated food or water).

- Parasites: Toxoplasma gondii (undercooked meat), Giardia (contaminated water), Cryptosporidium (contaminated water).

- Fungi: Mold (various sources), Yeast (often in sugary products).

Each pathogen has specific characteristics and risks, emphasizing the importance of proper food handling, cooking, and storage practices to prevent their growth and transmission.

Q 22. What is a HACCP plan, and what are its key principles?

A HACCP (Hazard Analysis and Critical Control Point) plan is a preventative food safety system that identifies potential food hazards and puts controls in place to minimize or eliminate risks. Think of it as a proactive approach, preventing problems before they occur, rather than just reacting to them. It’s a systematic, science-based approach to food safety management.

The seven key principles of HACCP are:

- Conduct a hazard analysis: Identify potential biological, chemical, and physical hazards in your food production process. For example, Salmonella in poultry or improper temperatures allowing bacterial growth.

- Determine critical control points (CCPs): Identify steps in the process where you can prevent, eliminate, or reduce the hazards identified in the first step. Cooking poultry to a safe internal temperature is a CCP.

- Establish critical limits: Set specific measurable criteria for each CCP. For example, the internal temperature of cooked poultry must reach 165°F (74°C).

- Establish monitoring procedures: Implement procedures to monitor each CCP and ensure that critical limits are being met. This might involve using thermometers to monitor poultry temperatures.

- Establish corrective actions: Develop procedures to follow if monitoring indicates that a critical limit has not been met. If the poultry doesn’t reach 165°F, it needs to be recooked.

- Establish verification procedures: Develop procedures to ensure that the HACCP plan is working effectively. This could include regular audits and employee training.

- Establish record-keeping and documentation procedures: Maintain accurate records of all HACCP procedures, including monitoring results and corrective actions.

Q 23. Describe your experience with developing and implementing food safety procedures.

Throughout my career in the food service industry, I’ve been directly involved in developing and implementing food safety procedures for various establishments. In my previous role at a large catering company, I collaborated with the management team to create and implement a comprehensive HACCP plan, which included training materials for employees, standardized operating procedures, and a system for monitoring and correcting deviations. We focused on temperature control, proper sanitation procedures, and allergen awareness training. This resulted in a significant decrease in foodborne illness incidents.

In another role, I was instrumental in transitioning a smaller restaurant from a reactive to a proactive food safety approach. This involved implementing a new inventory management system to better control food stock rotation (FIFO—First In, First Out), establishing a rigorous cleaning and sanitizing schedule, and improving employee training programs. The results included higher customer satisfaction due to improved food quality and safety, and a reduction in food waste.

Q 24. How would you address an employee who is not following proper food safety guidelines?

Addressing an employee who isn’t following food safety guidelines requires a calm, professional, and constructive approach. I’d start by privately addressing the issue, focusing on the specific behavior rather than making personal attacks. I’d explain why the guideline is crucial for food safety and the potential consequences of non-compliance. For example, if they’re not washing their hands properly, I’d emphasize the risk of cross-contamination and potential illnesses.

My approach involves:

- Observation and documentation: First, I’d make sure I’ve observed the behavior accurately and documented it with specific details, date and time. This avoids accusations.

- Private conversation: A one-on-one conversation provides a safe space for the employee to explain their actions and receive feedback. I’d ask open-ended questions to understand the root cause. Did they forget the procedure? Do they not understand it?

- Retraining or refresher course: If the issue stems from a lack of understanding, I’d offer retraining or a refresher course on the relevant food safety guidelines. Providing a clear, understandable explanation is key.

- Disciplinary action: If the behavior continues despite training and warnings, more formal disciplinary actions may be necessary, according to company policy. Consistency is key for ensuring food safety across the board.

Q 25. How do you maintain accurate food safety records?

Maintaining accurate food safety records is crucial for demonstrating compliance and identifying potential problems. I utilize a combination of digital and physical records, ensuring that all information is easily accessible, organized, and verifiable. This includes:

- Temperature logs: Regularly monitoring and recording temperatures of refrigerators, freezers, and food during cooking and holding. These are kept both digitally and a paper copy is retained.

- Cleaning and sanitizing logs: Documenting the cleaning and sanitizing of equipment and surfaces, including dates, times, and the employee’s initials.

- Supplier documentation: Maintaining records of supplier certifications and deliveries, ensuring that all products meet food safety standards.

- Employee training records: Tracking employee participation in food safety training programs, including completion dates and scores.

- Pest control logs: Documenting any pest control activities, including inspections and treatments.

- Incident reports: Maintaining records of any food safety incidents, including corrective actions taken.

The system is designed for ease of retrieval during inspections and to help identify trends and potential areas of improvement.

Q 26. What is your understanding of allergen awareness and control?

Allergen awareness and control are paramount in food safety. I understand that even trace amounts of allergens can trigger severe reactions in susceptible individuals. My understanding covers all aspects, from ingredient sourcing to final food preparation and service.

Key aspects of my approach include:

- Ingredient labeling and sourcing: Carefully reviewing ingredient labels and working with suppliers to ensure the accurate identification of allergens.

- Preventing cross-contamination: Implementing strict procedures to prevent cross-contamination between allergenic and non-allergenic foods. This includes dedicated equipment, utensils, and preparation areas, proper handwashing techniques and using clean gloves.

- Menu labeling: Clearly labeling menus to identify all allergenic ingredients in each dish, meeting all regulations regarding allergen information disclosure.

- Employee training: Thoroughly training employees on allergen awareness, handling procedures, and the importance of avoiding cross-contamination. The training emphasizes the seriousness of allergic reactions and the potential legal ramifications of non-compliance.

- Customer communication: Openly communicating with customers regarding allergens and providing clear information to assist them in making informed choices.

Q 27. Describe a situation where you had to solve a food safety issue. What was your approach?

In a previous role, we experienced a situation where a batch of chicken was inadvertently left out at room temperature for an extended period. This posed a significant food safety risk. My immediate approach involved:

- Immediate removal: The compromised chicken was immediately removed from the serving area and discarded. Safety was prioritized.

- Temperature checks: I performed a thorough check of all refrigeration units to ensure other products were at appropriate temperatures.

- Investigation: I investigated the root cause of the issue, determining that a staff member forgot to refrigerate the chicken after preparing it.

- Employee retraining: I arranged for additional retraining of the staff on proper food handling and storage procedures.

- Documentation: I meticulously documented the incident, including the steps taken to mitigate the risk, the employee involved, and the corrective actions implemented.

This approach ensured a swift resolution and helped to prevent future occurrences of this type of food safety hazard. Thorough documentation assisted in a root cause analysis and created an opportunity for improvement of our procedures.

Q 28. How would you train new employees on ServSafe food safety guidelines?

Training new employees on ServSafe guidelines is crucial. My approach involves a multi-faceted strategy:

- Initial orientation: A comprehensive initial orientation covering basic food safety principles, handwashing techniques, proper food storage, and temperature control. This will use ServSafe materials and visual aids, including videos and interactive exercises.

- ServSafe certification: I ensure all new employees complete a ServSafe food handler certification course and pass the examination. This provides them with a nationally recognized credential and a standardized knowledge base.

- On-the-job training: Hands-on training will be provided, shadowing experienced employees and actively participating in food preparation, service, and cleaning activities under supervision.

- Regular quizzes and assessments: Regular quizzes and assessments will be conducted to ensure employees retain the information and are correctly applying what they have learned. This is crucial in retaining knowledge.

- Ongoing reinforcement: Ongoing reinforcement will occur through regular briefings and refresher training to cover important guidelines.

- Open communication: I encourage an open communication environment where employees feel comfortable asking questions and raising concerns about food safety practices.

This multi-faceted approach guarantees a solid understanding of ServSafe principles, ensuring a safe and sanitary food handling practices.

Key Topics to Learn for Your ServSafe Interview

- Food Safety Management Systems: Understand the principles of HACCP (Hazard Analysis and Critical Control Points) and its practical application in preventing foodborne illnesses. Consider how you would implement and monitor a HACCP plan in a real-world setting.

- Personal Hygiene and Employee Health: Know the importance of handwashing, proper attire, and reporting illnesses. Be prepared to discuss strategies for maintaining a clean and sanitary work environment and preventing cross-contamination.

- Temperature Control: Master the safe temperature ranges for food storage, cooking, and reheating. Practice calculating cooking times and understanding the implications of improper temperature control.

- Food Storage and Handling: Learn the proper techniques for receiving, storing, and handling food to minimize the risk of spoilage and contamination. Be ready to explain FIFO (First-In, First-Out) and its significance.

- Cleaning and Sanitizing: Understand the difference between cleaning and sanitizing and the appropriate methods for each. Be prepared to discuss the proper use of cleaning and sanitizing agents.

- Pest Control: Know how to identify and prevent pest infestations. Discuss strategies for maintaining a pest-free environment.

- Food Allergens: Understand common food allergens and how to prevent cross-contamination. Be prepared to discuss strategies for accommodating customers with food allergies.

Next Steps: Unlock Your Career Potential

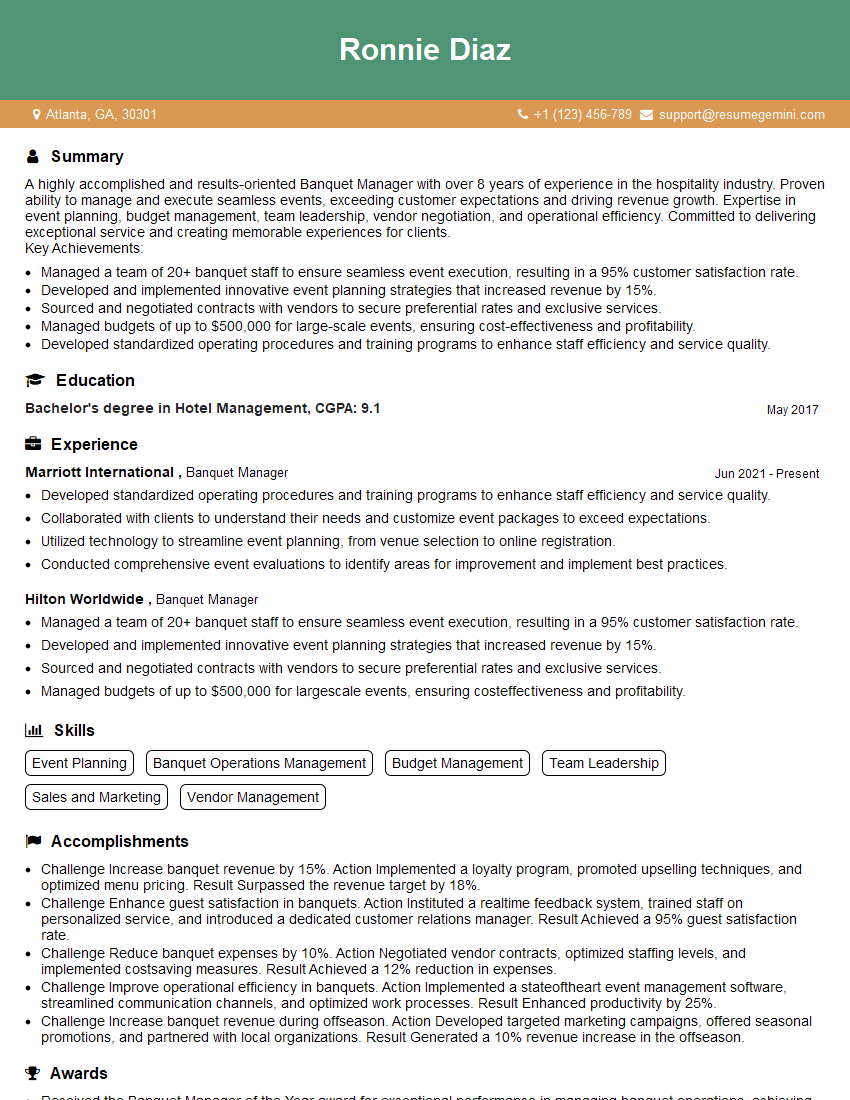

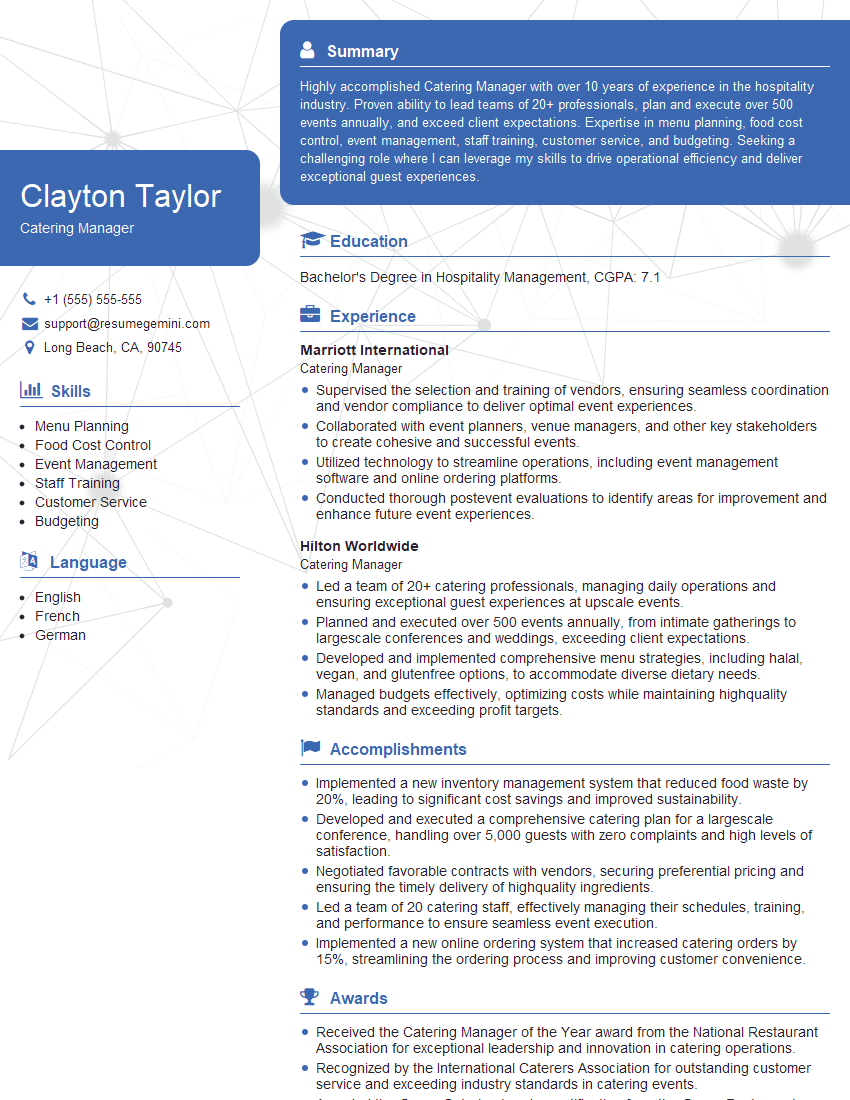

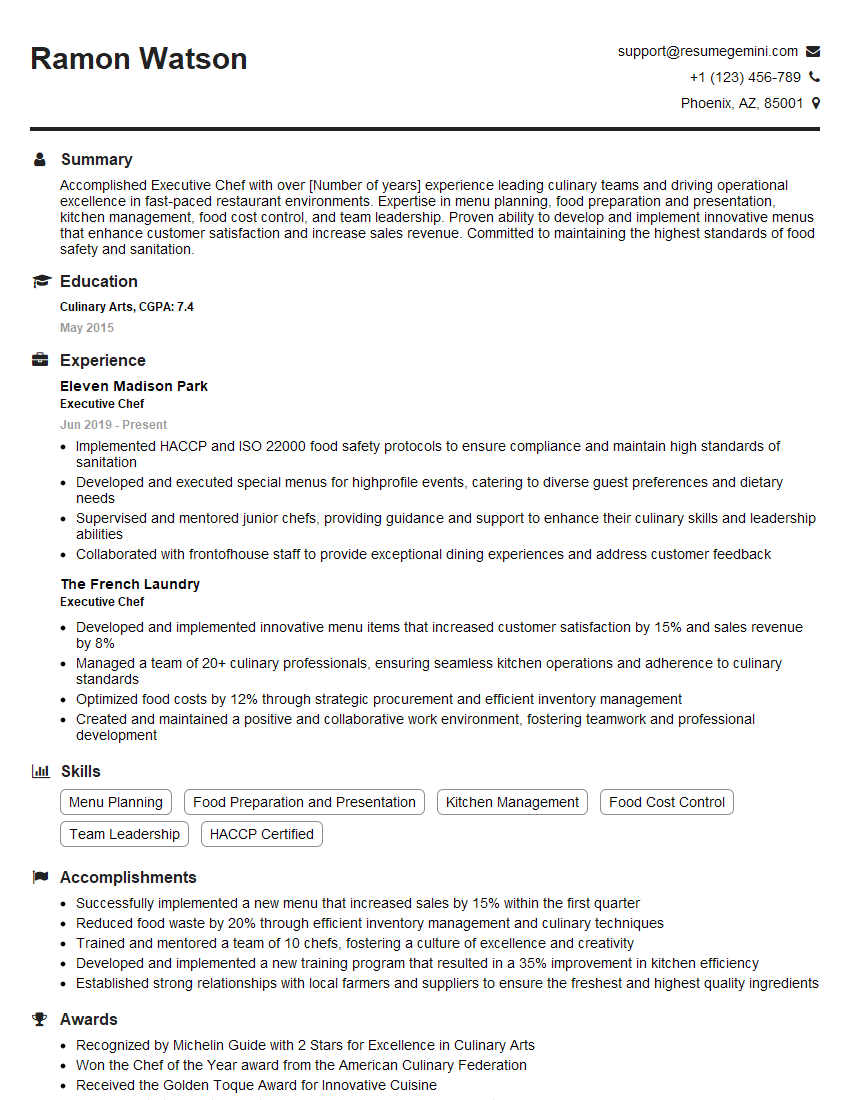

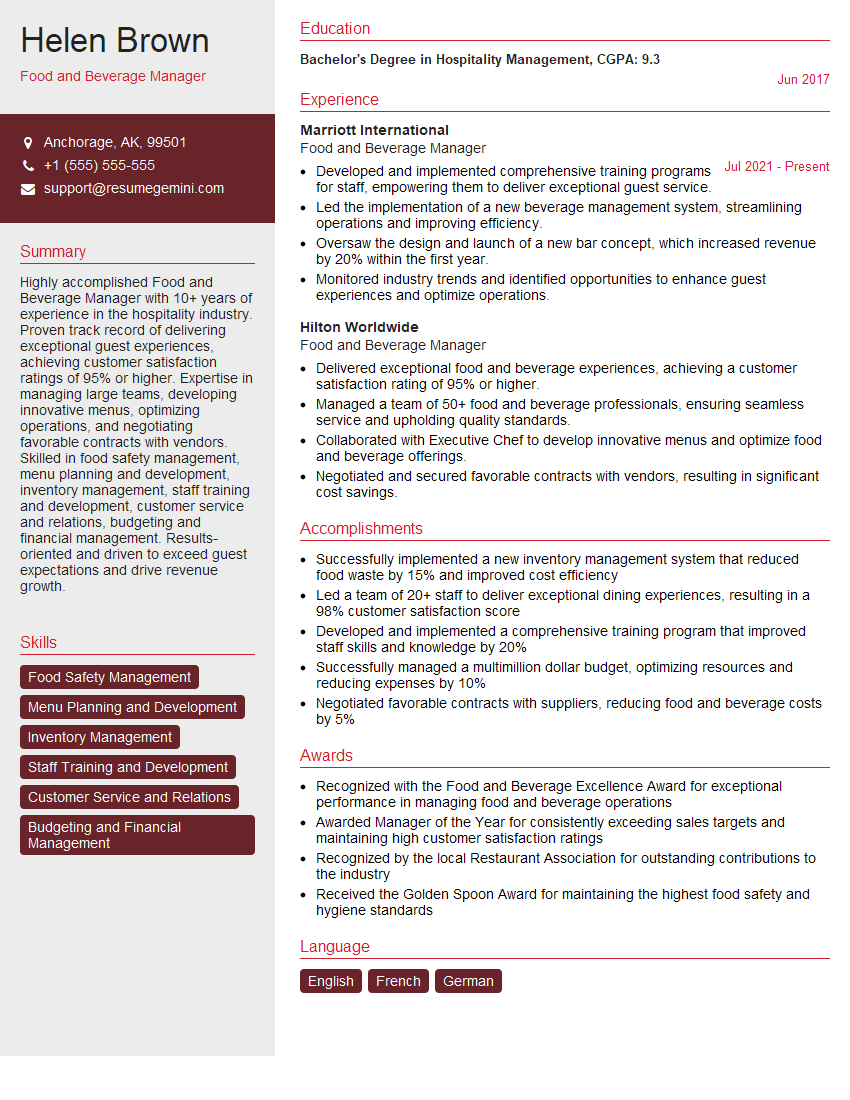

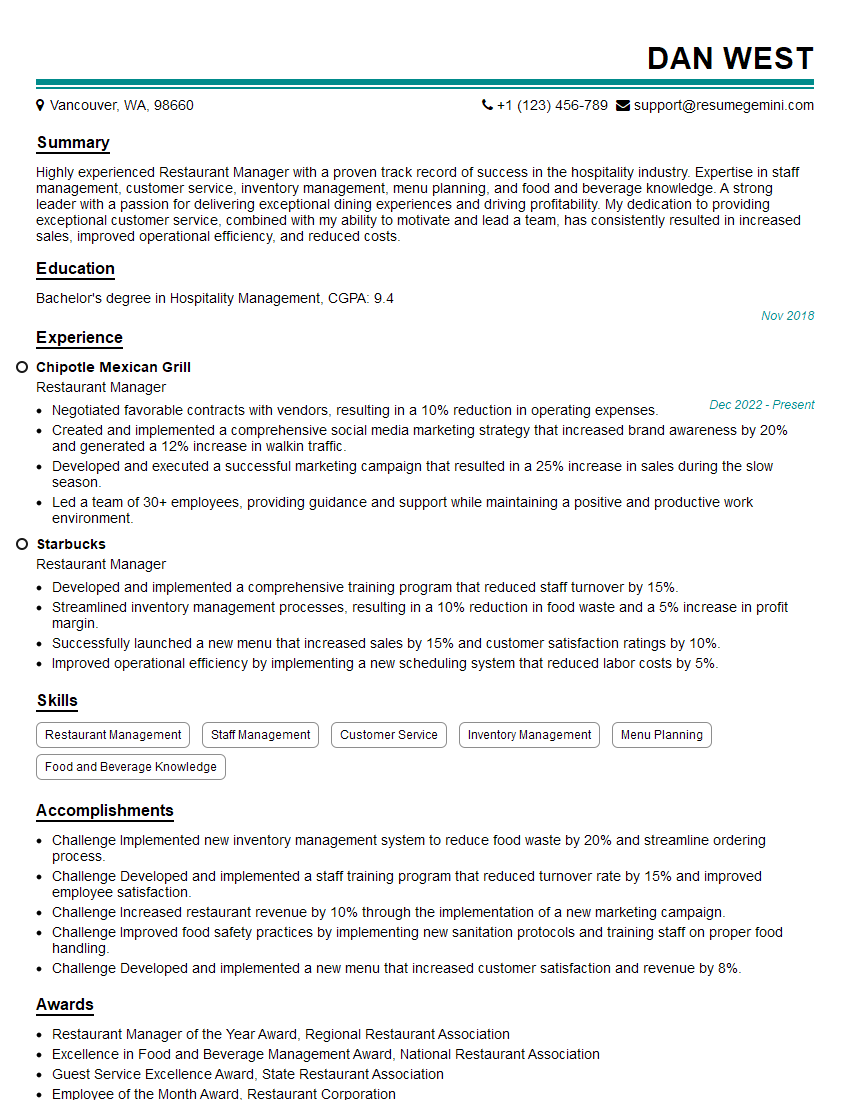

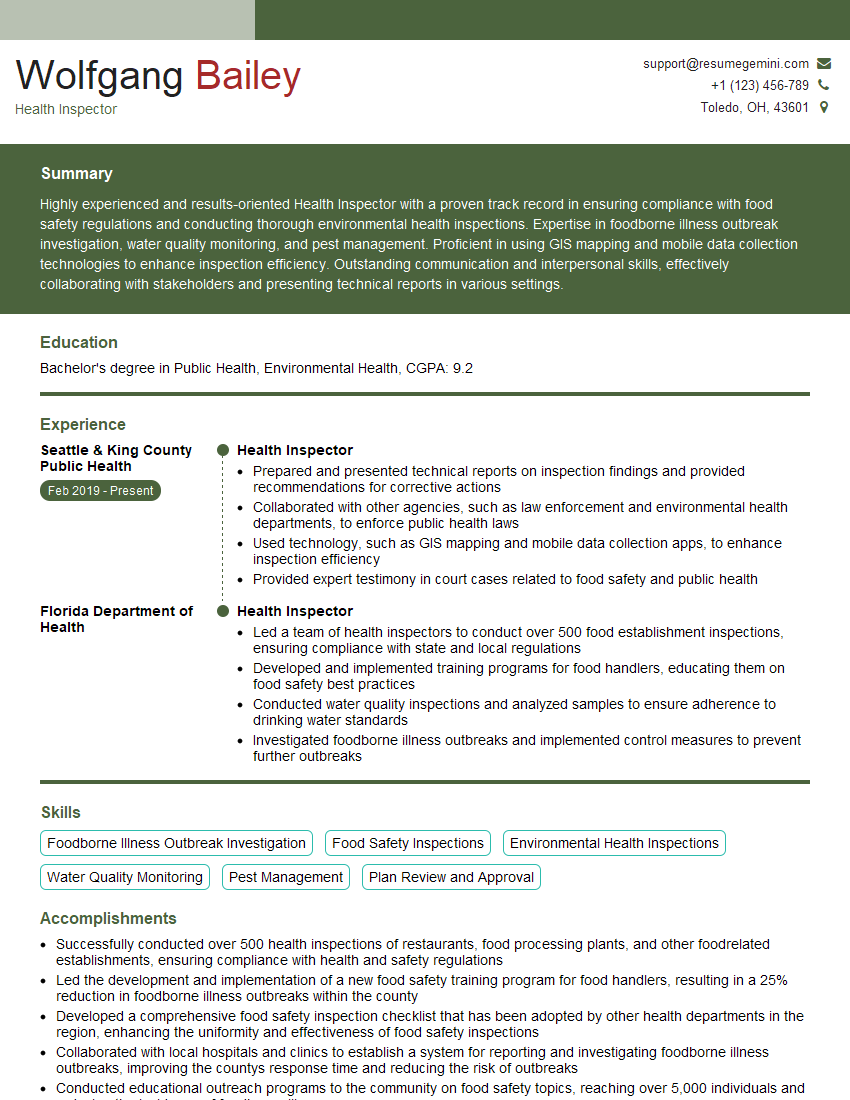

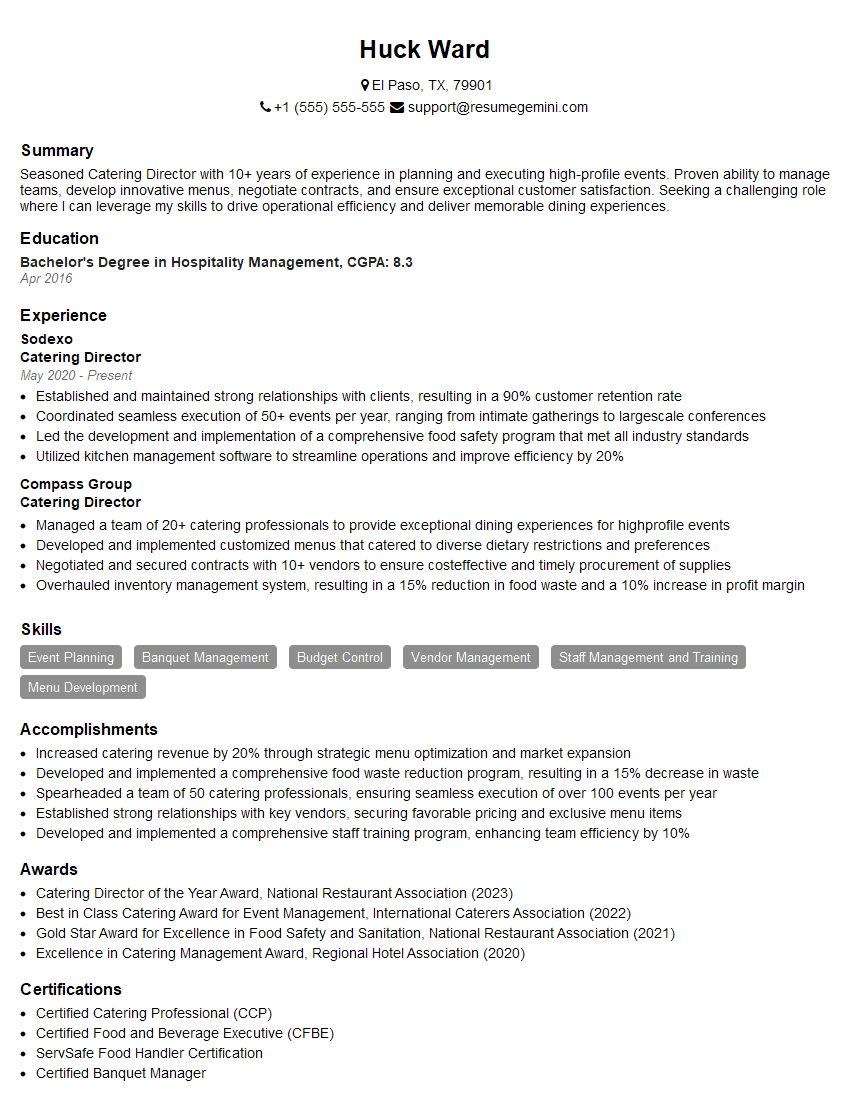

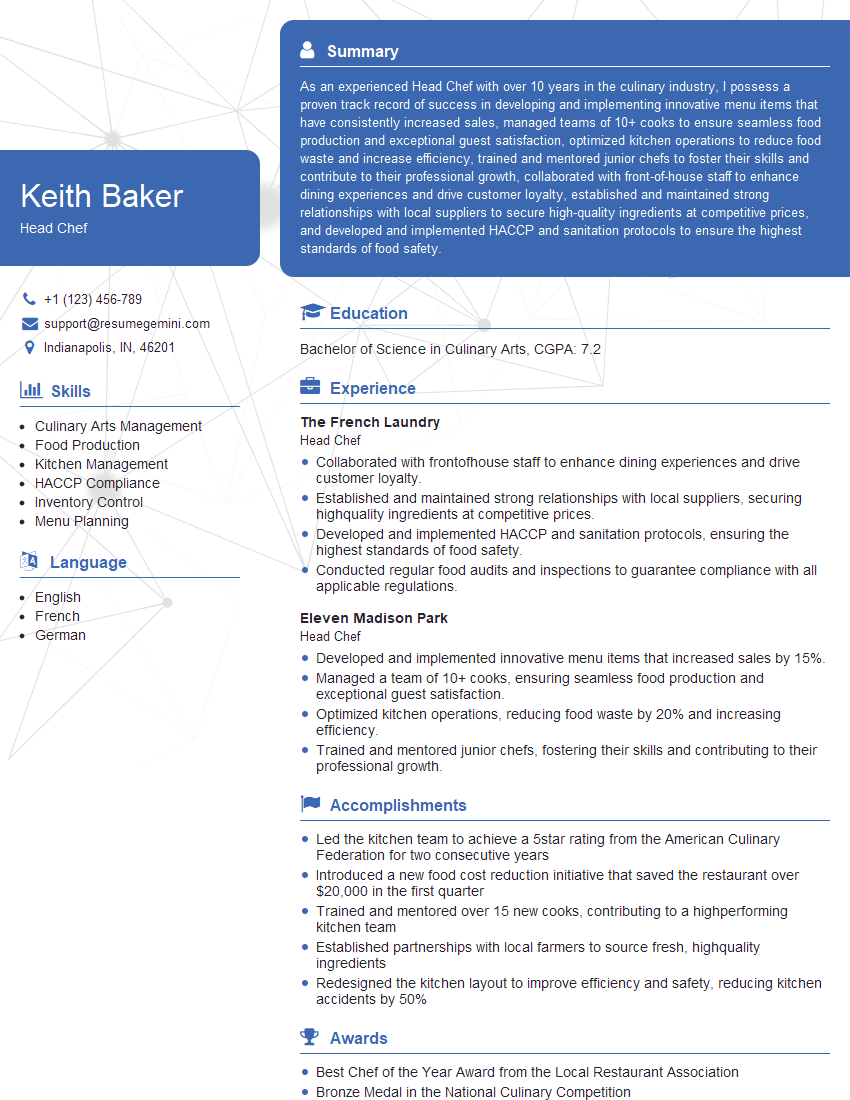

Mastering ServSafe is a significant step towards career advancement in the food service industry. It demonstrates your commitment to food safety and professionalism, making you a highly desirable candidate. To maximize your job prospects, create a compelling and ATS-friendly resume that highlights your ServSafe certification and relevant experience. We highly recommend using ResumeGemini to build a professional resume that stands out. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to ServSafe certification holders to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.