Cracking a skill-specific interview, like one for Sheet Metal Forming and Manipulation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Sheet Metal Forming and Manipulation Interview

Q 1. Explain the difference between different sheet metal joining techniques (e.g., welding, riveting, adhesive bonding).

Sheet metal joining techniques differ significantly in their strengths, weaknesses, and applications. The choice depends on factors like material, required strength, aesthetic considerations, and cost.

- Welding: This method uses heat to melt and fuse the edges of the metal sheets. It provides excellent strength and forms a permanent joint. Different welding processes exist, like laser welding (precise, high-speed), spot welding (for joining multiple points), and arc welding (versatile but requires skilled operators). For example, laser welding is ideal for high-precision electronics enclosures, while spot welding is common in automotive body panels.

- Riveting: A mechanical fastening method, riveting involves inserting a rivet through overlapping sheets and then deforming the rivet head to create a strong, permanent joint. It’s simpler than welding and avoids heat distortion but offers slightly lower strength. Aircraft construction frequently uses rivets due to their reliability and resistance to fatigue.

- Adhesive Bonding: This technique utilizes specialized adhesives to join sheet metal parts. It’s suitable for joining dissimilar materials, complex shapes, and lightweight designs. While strength can be high depending on the adhesive, it’s usually lower than welding or riveting, and the bond’s strength is affected by temperature and environmental factors. Applications include bonding decorative trim to automotive parts.

In summary, welding offers the highest strength, riveting provides a balance between strength and simplicity, and adhesive bonding suits complex shapes and lightweight applications.

Q 2. Describe the process of designing a sheet metal part for manufacturability.

Designing a manufacturable sheet metal part requires careful consideration of several factors. The goal is to minimize waste, simplify production, and reduce manufacturing costs.

- Minimal Bends: Reduce the number of bends wherever possible. Each bend adds complexity and potential for errors.

- Consistent Bend Radii: Using consistent bend radii reduces tooling costs and ensures uniform part quality.

- Avoid Sharp Corners: Sharp corners are difficult to form and can lead to cracking. Consider using radii to ease transitions.

- Appropriate Material Selection: Choose the correct gauge (thickness) and material type for the intended application, balancing strength, cost, and formability.

- Feature Placement: Strategically place features to optimize material usage and reduce scrap. Avoid features too close to edges as this compromises structural integrity.

- Tooling Considerations: Design features with the capabilities of your chosen manufacturing processes in mind (punch presses, laser cutting, bending).

- Draft Angles: Include draft angles (tapering) on features that need to be removed from the tooling to facilitate easy part ejection.

For instance, consider a simple bracket: a well-designed bracket would use a minimal number of bends, consistent radii, and appropriate material thickness to ensure strength and ease of manufacturing. Poor design might lead to costly tooling, longer production times, and increased scrap.

Q 3. What are the common types of sheet metal defects and their causes?

Several common defects can occur during sheet metal forming. Understanding their causes is crucial for preventing them.

- Wrinkling: This occurs when excessive compressive forces cause the sheet metal to buckle. It’s often caused by insufficient blank holding force or an improper die design. Imagine trying to squeeze a piece of paper too tightly – it wrinkles.

- Flanging: Uncontrolled stretching of the sheet metal during bending. It leads to thinning and uneven surfaces. Improper die geometry or insufficient bending force can cause this.

- Springback: The elastic recovery of the sheet metal after forming. It results in the part being slightly different than the tool shape. This can be mitigated by over-bending or using specialized tooling (e.g., springback compensation).

- Fracturing: The sheet metal breaks due to excessive tensile stresses. It’s often caused by using a too thin gauge, sharp corners, or excessive bending forces.

- Earring: Uneven deformation at the edges of a bent part. This happens due to differences in friction between the sheet metal and the die.

Preventing these defects requires careful process planning, tool design, material selection, and skilled operator input.

Q 4. How do you determine the appropriate gauge of sheet metal for a given application?

Selecting the appropriate sheet metal gauge is vital for ensuring the part’s strength, durability, and cost-effectiveness. It’s a balance between strength and formability.

The process involves:

- Defining Functional Requirements: Determine the part’s required strength, stiffness, and resistance to deformation under anticipated loads. For example, an automotive bumper needs much thicker gauge than a decorative trim.

- Considering Formability: Thinner gauges are more easily formed but less strong. Thicker gauges are stronger but more challenging to form. Balance is key.

- Cost Analysis: Thicker gauges cost more. Selecting an optimal gauge minimizes material waste and cost.

- Environmental Conditions: Consider the operating environment. Parts subjected to harsh conditions may require a thicker gauge for better durability.

- Manufacturing Constraints: The capabilities of your chosen manufacturing processes must be considered. Some processes have gauge limitations.

For example, a simple bracket might only require a 16-gauge sheet, whereas a structural part in a heavy machine could need a much thicker gauge.

Q 5. Explain the concept of springback in sheet metal forming and how it’s mitigated.

Springback is the elastic recovery of the sheet metal after forming. The part returns slightly to its original shape after being removed from the forming tool. Think of bending a paperclip; it doesn’t stay exactly as bent.

Mitigation techniques:

- Overbending: The part is intentionally bent beyond the desired final shape to compensate for springback. This is common practice and requires careful calculation of the overbend angle.

- Springback Compensation in Tool Design: Design the tooling to account for the expected springback, such as by using specialized software or conducting finite element analysis.

- Material Selection: Choosing materials with lower springback characteristics.

- Multiple Stages Forming: Using multiple forming steps rather than attempting a single, severe bend.

- Improved Lubrication: Reducing friction between the sheet metal and the die can minimize springback.

Accurate prediction and compensation of springback is essential for achieving precise part dimensions.

Q 6. What are the different types of sheet metal presses and their applications?

Several types of sheet metal presses are used, each suited for different applications.

- Mechanical Presses: These use a crankshaft to convert rotary motion into linear force. They are versatile, reliable, and capable of high tonnage. They are common in high-volume production lines.

- Hydraulic Presses: Employ hydraulic cylinders to generate force. They provide more consistent force than mechanical presses and offer better control over the forming process. They’re ideal for deep drawing and complex forming operations.

- Pneumatic Presses: Use compressed air to power the press. They are often smaller and less expensive than hydraulic or mechanical presses and are suited to lower-force applications.

- Servo Presses: These offer precise control over the forming process, allowing for adjustments in force and speed throughout the stroke. They’re excellent for applications requiring high precision and repeatability.

The choice of press depends on the part complexity, required tonnage, production volume, and budget. For instance, a high-volume automotive part might use a high-speed mechanical press, while a complex aerospace component may require a more precise hydraulic or servo press.

Q 7. Describe your experience with CAD/CAM software for sheet metal design.

I have extensive experience utilizing CAD/CAM software for sheet metal design and manufacturing. My expertise encompasses several popular packages like SolidWorks, Autodesk Inventor, and AutoCAD.

My skills include:

- 3D Modeling: Creating accurate 3D models of sheet metal parts, incorporating features like bends, flanges, and cutouts.

- Flat Pattern Development: Generating accurate flat patterns from 3D models. This is crucial for efficient material usage and minimizing waste.

- Tooling Design: Designing and optimizing tooling for various sheet metal forming operations, ensuring proper clearances and functionality.

- NC Code Generation: Generating numerical control (NC) code for CNC machines such as laser cutters, punch presses, and bending machines. This ensures precision and accuracy during manufacturing.

- Simulation and Analysis: Utilizing simulation tools to predict springback, wrinkling, and other potential manufacturing defects.

For instance, in a recent project, I used SolidWorks to design a complex chassis component, generated its flat pattern, designed the necessary tooling, and then created the NC code for laser cutting and bending. The simulation helped us identify and resolve potential springback issues, leading to a successful production run.

Q 8. How do you interpret engineering drawings for sheet metal parts?

Interpreting sheet metal engineering drawings requires a keen eye for detail and a solid understanding of manufacturing processes. I begin by identifying the overall dimensions and shape of the part. Then, I meticulously examine the details: bend radii, bend angles, material specifications (thickness, type, and grade), and any special features like holes, cutouts, or embossments. I look for datum features – points or planes used as references for locating other features – which are crucial for accurate part creation. I also pay close attention to tolerances, which dictate acceptable variations in dimensions and angles. For example, a drawing might specify a 90-degree bend with a +/- 1-degree tolerance, indicating that bends between 89 and 91 degrees are acceptable. Finally, I review the bill of materials to ensure I have all necessary components and information. Understanding the view conventions (top, side, front views and section views) is essential for visualizing the finished 3D part from the 2D drawing. I often use CAD software to verify the drawing and perform interference checks to ensure the design is feasible.

Q 9. What are the safety precautions you take when operating sheet metal machinery?

Safety is paramount in sheet metal work. Before operating any machinery, I always ensure proper Personal Protective Equipment (PPE) is worn, including safety glasses, hearing protection, and appropriate gloves. Loose clothing or jewelry are never worn to avoid getting caught in moving parts. I thoroughly inspect the machine for any damage or loose parts before starting it. I carefully follow all manufacturer’s instructions and lockout/tagout procedures for maintenance or repairs. I never operate equipment if I am tired or under the influence of drugs or alcohol. Safe operation also includes being mindful of my surroundings and ensuring that the work area is clear of obstructions and other people. Proper feeding and ejection of sheet metal is critical to avoid injuries caused by pinch points and shearing. Finally, I regularly participate in safety training to stay updated on best practices and new technologies.

Q 10. Explain your experience with different types of sheet metal materials (e.g., aluminum, steel, stainless steel).

My experience spans various sheet metal materials. Aluminum is lightweight and readily formable, ideal for applications needing corrosion resistance and reduced weight, such as automotive parts. However, its softness can lead to scratches and dents easily. Steel offers high strength and durability but can be susceptible to rust unless treated with protective coatings like galvanizing or painting. I’ve worked extensively with different grades of steel, each having different properties in terms of formability and strength. Stainless steel is known for its corrosion resistance, making it perfect for applications in harsh environments, like food processing equipment. It is more difficult to form than mild steel, requiring specialized tooling and techniques. Choosing the right material depends on the application’s specific requirements, considering factors like strength, formability, corrosion resistance, cost, and weight. For example, I chose stainless steel for a food processing application due to its hygiene and corrosion resistance requirements, but selected a high strength low alloy steel for a structural component in an outdoor enclosure to ensure longevity and withstand harsh weather.

Q 11. How do you calculate bend allowances for sheet metal parts?

Bend allowance is the crucial calculation determining the flat blank size needed to produce a bent part. It accounts for the added length due to the material stretching on the outside of the bend. The formula is not a simple one-size-fits-all and depends on several factors. A common approximation uses the bend deduction, a subtractive factor that depends on the bend angle and the material thickness. There are several different formulas, some simpler than others, that can be used to calculate bend allowance. Most modern CAD software calculates the bend deduction automatically, but a thorough understanding is vital for verification and troubleshooting. For instance, the simplified formula Bend Allowance = (Bend Radius + Material Thickness/2) * Bend Angle (in radians) provides a reasonable estimate. However, more sophisticated methods account for material properties like springback. It’s essential to consider the specific material, the bend radius, the die geometry, and the bend angle. In practice, I often use software for precise calculation, but also verify the results with known reference tables or hand calculations to ensure accuracy. I also account for material springback which causes the part to partially unbend after forming. The amount of springback depends on the material, geometry and forming process.

Q 12. Describe your troubleshooting experience with sheet metal forming equipment.

Troubleshooting sheet metal forming equipment involves a systematic approach. I start by identifying the problem precisely. Is it a dimensional inaccuracy, a surface defect, or a machine malfunction? Once the problem is defined, I check the simplest causes first. For instance, if the bends are inconsistent, I check the tooling for wear or damage, verify the press brake settings, and inspect the material for imperfections. If the problem persists, I may investigate the machine’s control system, hydraulics, or mechanical components. For example, I once encountered a situation where parts were consistently undersized. After eliminating tooling and material issues, I found a problem with the press brake’s backgauge—the device used to position the material accurately—being slightly miscalibrated. A detailed understanding of the machine’s mechanisms and the forming process is essential for effective troubleshooting. I utilize various diagnostic tools, including pressure gauges, and multimeters to pinpoint the root cause of the issue, and meticulous record-keeping helps track the success of implemented solutions.

Q 13. What are the common tooling used in sheet metal forming?

Sheet metal forming utilizes a wide array of tooling. For bending, press brakes use a variety of punches and dies, varying in shape, size, and material to match the part geometry and material properties. Punching operations require punches and dies to create holes or cutouts. Embossing and debossing use specialized tools to create raised or indented features. For more complex shapes, progressive dies combine several operations in a single tool, drastically improving efficiency. Roll forming uses rollers to bend sheet metal into continuous shapes such as channels and tubes. The selection of tooling greatly impacts the quality, efficiency, and cost of production. Tool wear and maintenance are crucial factors in maintaining consistent product quality. Specialized tooling may be needed for exotic materials or difficult geometries. For example, when working with very thin gauge material, I would use a smaller radius punch and die set to avoid cracking.

Q 14. Explain the different types of sheet metal finishes.

Sheet metal finishes enhance the appearance and performance of parts. Common finishes include powder coating for durability and corrosion resistance; painting for aesthetics and protection; plating (e.g., chrome, zinc) for corrosion protection and decorative appeal; and anodizing for aluminum parts, providing corrosion resistance and color. Other finishes include polishing for a mirror-like shine, brushing for a textured appearance, and bead blasting for a matte finish. The selection of the finish depends on the application’s needs. A powder-coated finish is preferred for outdoor applications due to its superior durability, while a polished finish is used for aesthetic parts that need a high-end look. The choice also impacts cost and manufacturing time. The application method also influences the final appearance. For instance, a powder-coated finish is typically thicker and provides more protection than a painted finish.

Q 15. How do you ensure quality control in sheet metal fabrication?

Quality control in sheet metal fabrication is paramount. It’s a multi-faceted process ensuring the final product meets specifications and is free from defects. We use a layered approach, starting with incoming material inspection. This involves verifying material properties like thickness, tensile strength, and surface finish against the specified requirements using tools like calipers, tensile testers, and surface roughness meters.

During the fabrication process, we implement in-process checks at each stage: blanking, punching, bending, welding, etc. This includes dimensional checks with CMMs (Coordinate Measuring Machines) or simpler tools like height gauges and calipers to ensure parts conform to drawings. We also visually inspect for defects such as scratches, dents, or burrs. Statistical Process Control (SPC) charts track key process parameters, flagging potential issues before they lead to widespread defects. Finally, we perform final inspections on 100% of the parts, using both automated and manual methods, checking for cosmetic appearance, functionality, and dimensional accuracy. Any non-conforming parts are rejected and the root cause is identified through a thorough investigation to prevent recurrence. This data is then fed back into the process to continuously improve quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of sheet metal forming processes (e.g., stamping, bending, drawing)?

My experience spans a wide range of sheet metal forming processes. I’ve worked extensively with stamping, which involves using dies to punch, form, or pierce metal sheets. This includes progressive dies for high-volume production and more flexible, single-stage dies for lower-volume or prototype parts. I’m proficient in various bending techniques, both press brake bending and roll forming, understanding the importance of bend radius, material properties, and die selection for achieving precise bends. I’m also experienced in deep drawing, a process used to create complex cup-shaped parts. I understand the critical role of blank holder pressure in preventing wrinkling and achieving uniform wall thickness. Throughout my career, I’ve gained proficiency in selecting the most suitable forming process for a given part design and production volume, always considering factors like material properties, part complexity, and cost-effectiveness.

Q 17. Describe your experience with automated sheet metal forming systems.

I have significant experience with automated sheet metal forming systems. This includes working with CNC press brakes, automated punch presses, and robotic welding cells. My expertise lies in programming and operating these systems, ensuring efficient and precise production runs. I’ve worked with various programming languages, such as Fanuc and Siemens PLC programming, to create and optimize programs for automated processes. I’m also familiar with various automation components, such as robotic arms, vision systems, and conveyor systems, and understand how to integrate them into a seamless production workflow. For example, I once worked on a project that involved integrating a vision system into a robotic welding cell, improving weld quality and reducing scrap significantly. My hands-on experience allows me to troubleshoot issues effectively, minimizing downtime and ensuring continuous production.

Q 18. Explain your understanding of sheet metal tolerances.

Sheet metal tolerances define the acceptable range of variation from the nominal dimensions specified in the design. They are crucial for ensuring parts fit together correctly and function as intended. These tolerances are typically expressed as plus or minus values (e.g., ±0.1 mm). The acceptable tolerance depends on factors such as the part’s function, its size, and the manufacturing process. For example, a small, cosmetic part might have looser tolerances than a critical component in a complex assembly. Understanding these tolerances is key to selecting appropriate manufacturing processes and tooling. For instance, tighter tolerances often require more precise machining or specialized tooling, which can increase the cost of production. Throughout my career, I’ve worked closely with design engineers to determine the appropriate tolerances for different parts, balancing cost, functionality, and manufacturability. Improper tolerance selection can lead to costly rework or scrap, highlighting the importance of thorough understanding and careful consideration.

Q 19. How do you manage production schedules and meet deadlines in sheet metal fabrication?

Managing production schedules and meeting deadlines in sheet metal fabrication requires a structured approach. We use techniques such as lean manufacturing principles and project management software to plan and track our work. This includes carefully estimating production times, considering factors like setup times, processing times, and potential delays. We also allocate resources effectively, ensuring that we have the necessary personnel, equipment, and materials available to meet the schedule. Regular progress meetings are held to track progress, identify potential issues, and take corrective action. A critical path analysis helps to pinpoint tasks that are crucial to meeting the overall deadline. In addition, we build buffer time into the schedule to account for unexpected delays, such as equipment malfunctions or material shortages. This proactive approach allows us to stay ahead of schedule and meet deadlines consistently. Effective communication with clients is also crucial to ensure that expectations are clearly understood and any necessary adjustments are made promptly.

Q 20. What are the common challenges in sheet metal fabrication and how do you overcome them?

Common challenges in sheet metal fabrication include material handling, achieving consistent part quality, and minimizing scrap. Material handling can be challenging, especially with large sheets, requiring efficient storage and transport systems. Inconsistent part quality can arise from factors such as tool wear, variations in material properties, or inconsistencies in the manufacturing process. We address this through rigorous quality control measures, including regular tool maintenance and calibration, incoming material inspection, and in-process checks. Minimizing scrap is crucial for cost-effectiveness. This involves optimizing nesting strategies to minimize material waste, employing advanced programming techniques for precise cutting, and implementing continuous improvement initiatives. Other challenges include meeting tight tolerances and managing production costs. We overcome these by selecting appropriate materials and processes, investing in advanced equipment, and optimizing the overall workflow. The key is continuous monitoring, analysis and improvement through data-driven decision making.

Q 21. Describe your experience with robotic systems used in sheet metal processing.

My experience with robotic systems in sheet metal processing is extensive. I’ve worked with robots for tasks such as material handling, laser cutting, welding, and deburring. The use of robots increases production speed, improves part consistency, and enhances worker safety by automating repetitive or hazardous tasks. Programming and integration of these robotic systems require specialized skills, including experience with robot programming languages (e.g., RAPID for ABB robots) and knowledge of industrial communication protocols. For instance, I was involved in a project where we integrated a six-axis robot into a laser cutting system, significantly increasing the throughput and accuracy of the process. I’m adept at troubleshooting robotic system issues, minimizing downtime, and ensuring optimal performance. The use of robots with vision systems allows for enhanced accuracy and adaptive handling of different part geometries and orientations. This technology is crucial in modern sheet metal fabrication for efficiency and high-quality output.

Q 22. How do you ensure the proper functioning of sheet metal equipment?

Ensuring the proper functioning of sheet metal equipment is paramount for safety and productivity. It involves a multi-pronged approach encompassing regular maintenance, operator training, and proactive monitoring.

- Preventative Maintenance: This is crucial. We follow a scheduled maintenance plan, checking for things like lubrication levels in presses, ensuring proper blade sharpness in cutting machines, and verifying the integrity of safety mechanisms like light curtains and emergency stops. Think of it like servicing a car – regular checks prevent major breakdowns.

- Operator Training: Operators need thorough training on the safe and efficient operation of each piece of equipment. This includes understanding the machine’s capabilities and limitations, as well as emergency procedures. Proper training minimizes the risk of accidents and equipment damage.

- Proactive Monitoring: Regularly monitoring equipment performance through data analysis (e.g., vibration sensors, power consumption readings) helps detect anomalies early. This allows for timely intervention, preventing catastrophic failures. For example, a sudden increase in power draw during punching might indicate tool wear and should be addressed immediately.

By combining these three strategies, we ensure our equipment runs smoothly, safely, and efficiently, leading to higher quality products and reduced downtime.

Q 23. Explain your understanding of material handling procedures relevant to sheet metal.

Material handling in sheet metal work is critical for preventing damage and ensuring efficient workflow. It starts with proper storage: sheets should be stacked neatly to prevent warping or scratching, using appropriate racking systems to support the weight. The material handling process needs to consider the size and weight of the sheets throughout the entire process.

- Transportation: We use appropriate lifting equipment like forklifts or cranes for heavier sheets and carefully designed carts for smaller ones. Sheets are always secured to prevent movement and damage during transit.

- Handling during processing: During operations like cutting or bending, appropriate fixtures and handling tools are crucial to maintain the integrity of the sheet metal and the safety of the operator. For example, using vacuum lifters to handle large, delicate sheets minimizes the risk of scratches or deformation.

- Waste Management: Efficient waste disposal systems are important. This includes proper segregation and recycling of scrap metal, minimizing environmental impact and maximizing cost-effectiveness.

Effective material handling directly impacts productivity, product quality, and worker safety. A streamlined system reduces waste and ensures a smooth production flow.

Q 24. How familiar are you with different types of sheet metal cutting technologies?

I’m very familiar with a wide array of sheet metal cutting technologies. The choice depends on factors like material thickness, desired precision, and production volume.

- Shearing: This is a high-speed process ideal for straight cuts in relatively thin sheets. It’s cost-effective but can leave a slightly rough edge.

- Punching: Uses a punch and die to create holes or shapes. Efficient for high-volume production of repetitive parts, but limited in its cutting complexity.

- Laser Cutting: Precise and versatile, suitable for complex geometries and various thicknesses. It offers high quality cuts but can be more expensive for low-volume jobs.

- Waterjet Cutting: Uses a high-pressure water jet to cut through materials. This method is ideal for materials that are difficult to cut with other methods, such as very hard or brittle metals.

- Plasma Cutting: Uses an electrically conductive plasma arc to melt and cut through metals. Excellent for thicker materials but can leave a wider heat-affected zone than laser cutting.

Understanding the strengths and limitations of each technology is key to selecting the most appropriate and cost-effective method for a particular project.

Q 25. Describe a time you had to resolve a critical issue during sheet metal production.

During the production of a large batch of custom-designed housings, we encountered a significant issue with inconsistent bending radii on a critical part. The initial parts exhibited unacceptable variations, jeopardizing the fit and functionality of the assembled product.

My first step was to systematically investigate the potential causes. We checked the tooling, examining the bending dies for wear or misalignment. We also reviewed the press settings, ensuring the tonnage and bending angle were consistent with the design specifications. Through careful analysis, we discovered that the problem stemmed from inconsistencies in the material’s thickness – a slight variation in the raw sheet metal’s gauge across the batch was the culprit.

To resolve this, we implemented stricter incoming material inspection protocols, rejecting sheets outside the acceptable tolerance range. We also fine-tuned the bending process using adaptive control techniques to compensate for minor variations in sheet thickness. This combination of improved quality control and process adjustment solved the issue, ensuring consistent quality in the subsequent production runs.

Q 26. How do you maintain cleanliness and organization in your work area?

Maintaining a clean and organized workspace is essential for both safety and efficiency. It’s the foundation of a productive environment.

- 5S Methodology: We utilize the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). This systematic approach helps us eliminate unnecessary items, organize tools and materials logically, maintain cleanliness, and establish consistent procedures.

- Regular Cleaning: Regular cleaning of equipment and the work area is non-negotiable. This includes cleaning up scrap metal, oil spills, and any other debris. A clean environment prevents accidents and improves the quality of the work.

- Designated Storage: We use clearly labeled storage areas for tools, materials, and finished parts. This allows for quick retrieval of items and prevents clutter.

- Visual Management: Implementing visual management techniques, such as color-coding storage locations or using shadow boards for tools, enhances organization and reduces search time.

A well-organized and clean environment promotes safety, increases efficiency, and reduces errors in the sheet metal forming process.

Q 27. Explain your familiarity with various industry standards and certifications related to sheet metal.

My familiarity with industry standards and certifications is extensive. We adhere to various standards to ensure product quality, safety, and regulatory compliance.

- ISO 9001: This is fundamental for quality management systems, ensuring consistent quality in our processes and products.

- ASME Standards: Relevant standards for pressure vessel design and construction are followed where applicable, ensuring safety and durability.

- Material Standards (e.g., ASTM): We carefully follow relevant material standards to ensure that we use sheet metal that meets our project’s requirements for properties such as tensile strength and corrosion resistance.

- Safety Standards (e.g., OSHA): Compliance with occupational safety and health standards is crucial, protecting our workers and ensuring a safe working environment.

Staying up-to-date with these standards is vital for maintaining our reputation for quality and compliance.

Q 28. How would you determine the appropriate bending radius for a specific part?

Determining the appropriate bending radius is crucial for achieving the desired part geometry and preventing cracking or deformation. It’s not arbitrary; it depends on several factors.

- Material Properties: The material’s tensile strength, yield strength, and ductility significantly influence the minimum bending radius. Thinner sheets can be bent to tighter radii than thicker ones. Brittle materials require larger bending radii to avoid cracking.

- Die Design: The design of the bending die – particularly its radius – plays a major role. The die radius will influence the final part radius, and selecting an appropriate die is critical.

- Bend Allowance Calculation: Precise calculations are necessary to determine the bend allowance, the extra length of the sheet metal needed to account for the elongation during bending. This is done using formulas that incorporate the material thickness, bending radius, and bend angle.

- Trial and Error (with testing): In certain cases, especially when working with new materials or complex geometries, a trial-and-error approach with testing is required to fine-tune the bending parameters.

By carefully considering these factors and possibly using specialized software for bending simulation, we can determine the optimal bending radius for achieving the desired result without compromising the structural integrity of the part.

Key Topics to Learn for Your Sheet Metal Forming and Manipulation Interview

- Sheet Metal Properties: Understanding material characteristics (e.g., tensile strength, yield strength, ductility) and their impact on forming processes.

- Forming Processes: Deep dive into various techniques like bending, punching, stamping, drawing, and spinning. Be prepared to discuss the advantages and limitations of each.

- Die Design and Tooling: Familiarize yourself with the principles of die design, material selection for tooling, and common tooling issues (e.g., wear, breakage).

- Press Operation and Safety: Understand the mechanics of different press types (e.g., hydraulic, mechanical) and prioritize safety protocols in sheet metal operations.

- Quality Control and Inspection: Learn about common quality control methods used in sheet metal forming, including dimensional inspection, surface finish evaluation, and defect detection.

- Material Handling and Storage: Discuss best practices for handling sheet metal to avoid damage and ensure efficient workflow.

- Troubleshooting and Problem Solving: Prepare to discuss common problems encountered during sheet metal forming (e.g., wrinkling, tearing, cracking) and how to address them.

- Automation and Robotics in Sheet Metal Forming: Explore the integration of automated systems and robotics in modern sheet metal fabrication.

- CAD/CAM Software Applications: Demonstrate familiarity with relevant software used in designing and simulating sheet metal forming processes.

- Industry Standards and Regulations: Understand relevant safety and quality standards that govern sheet metal forming practices.

Next Steps

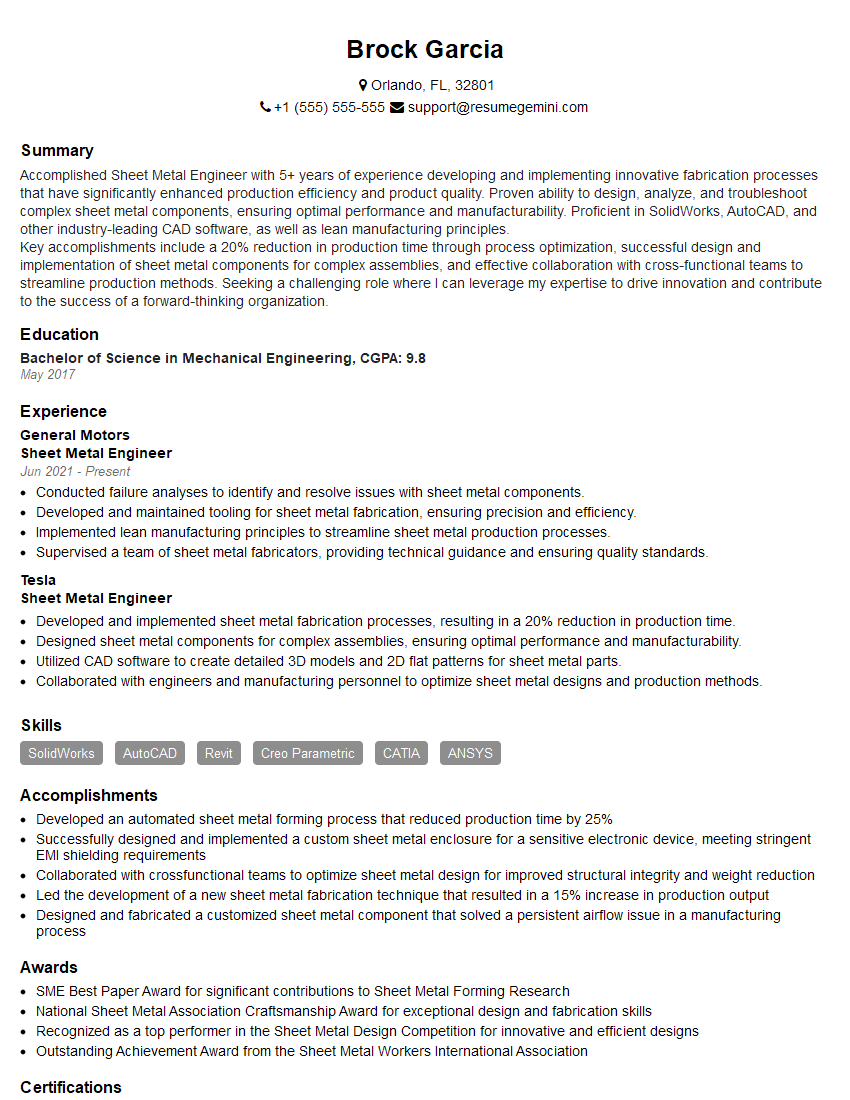

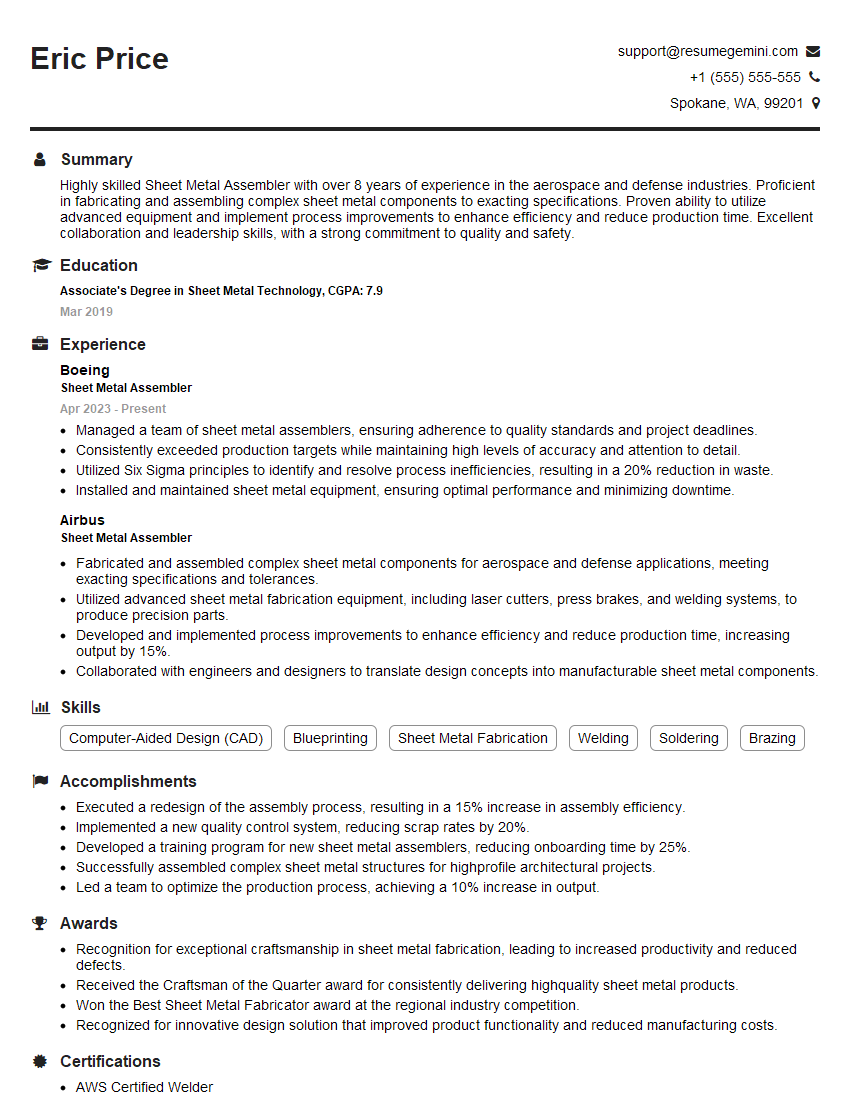

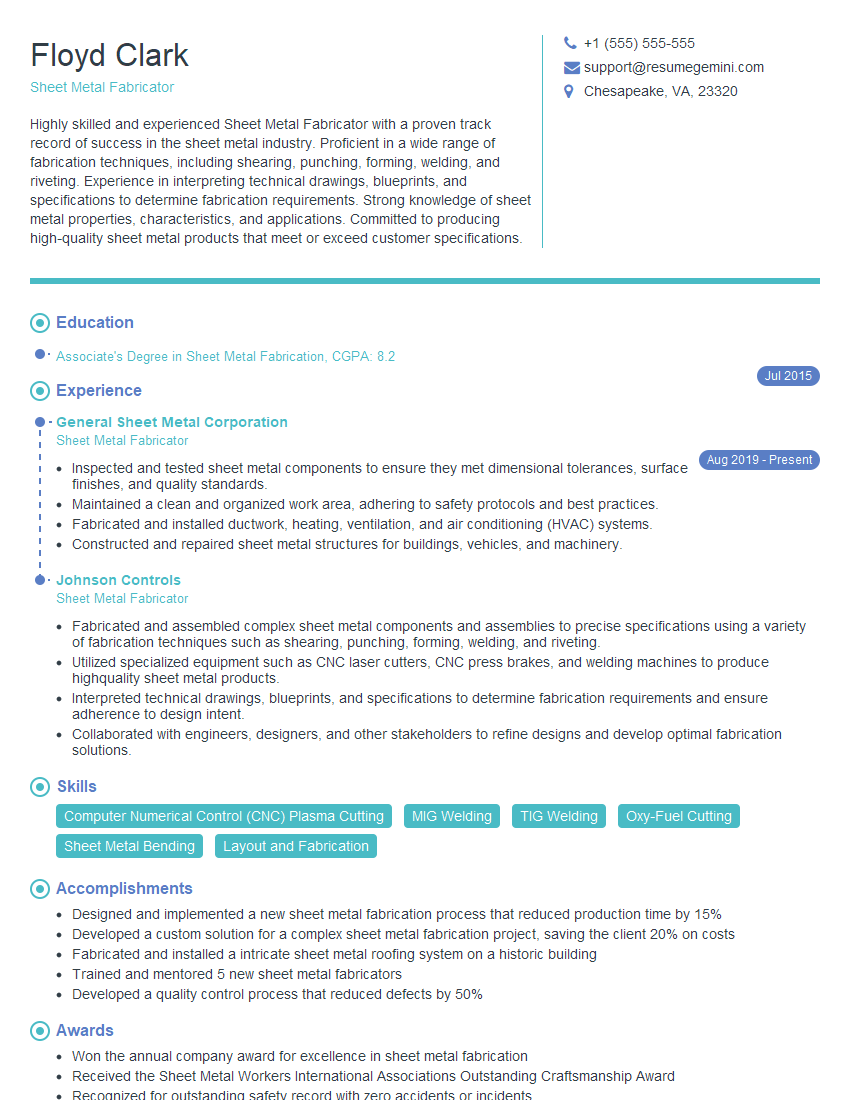

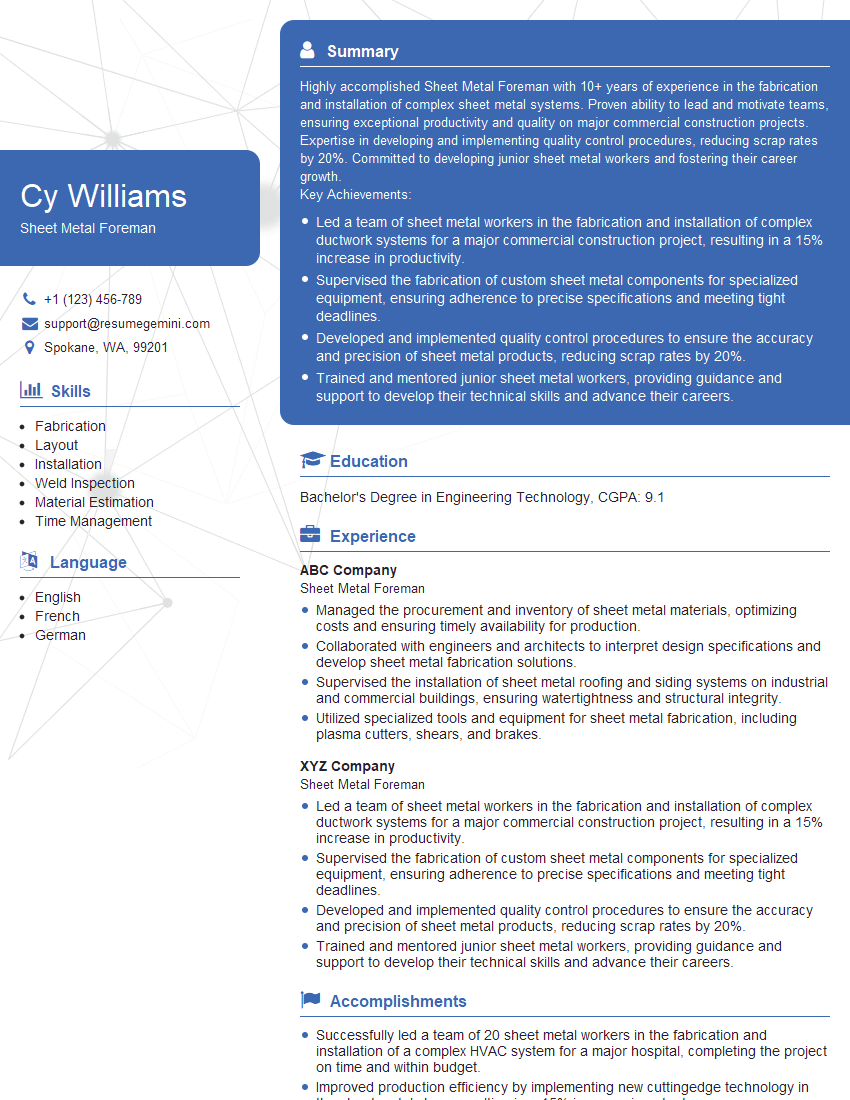

Mastering Sheet Metal Forming and Manipulation opens doors to exciting career opportunities in manufacturing, automotive, aerospace, and many other high-demand industries. To maximize your chances of landing your dream role, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is key to getting noticed by recruiters. We highly recommend using ResumeGemini to build a professional and impactful resume that showcases your expertise in this field. ResumeGemini provides examples of resumes tailored to Sheet Metal Forming and Manipulation to help you craft a compelling application. Take the next step towards your successful career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.