Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Shipboard Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Shipboard Operation Interview

Q 1. Describe your experience with ballast water management.

Ballast water management is crucial for preventing the spread of invasive aquatic species. My experience encompasses all aspects, from understanding the regulations (like the IMO Ballast Water Management Convention) to the practical application of various treatment methods.

- Treatment Systems: I’ve worked extensively with both UV-based and electrochlorination ballast water management systems. This includes routine maintenance, troubleshooting malfunctions (like UV lamp failures or electrode fouling), and ensuring the systems meet the required discharge standards.

- Ballasting and De-ballasting Procedures: I’m proficient in the safe and efficient execution of these procedures, adhering to all safety protocols and ensuring the integrity of the ship’s hull. This involves careful monitoring of tank levels, ensuring proper valve operations, and documenting all activities in the ship’s logbook.

- Record Keeping and Reporting: Accurate record-keeping is paramount. I have extensive experience maintaining ballast water management logs, including details of treatment system performance, ballast water exchange procedures, and any anomalies encountered. This data is essential for compliance audits and reporting to port authorities.

- Compliance Audits: I’ve been actively involved in numerous port state control inspections related to ballast water management, ensuring our ship always meets or exceeds regulatory requirements. This includes providing documentation and responding to queries from inspectors effectively.

For example, on one voyage, we encountered a malfunction in the UV system. By systematically troubleshooting, identifying a faulty sensor, and implementing a temporary fix, we avoided any delays and ensured compliance with discharge standards in the next port.

Q 2. Explain the procedures for conducting a cargo inspection.

Cargo inspection is a vital process to ensure the quality and quantity of cargo received and shipped are as per the agreed specifications. It helps prevent disputes and ensures safety.

- Pre-Inspection: This involves reviewing the cargo manifest, bills of lading, and other relevant documents to understand the cargo type, quantity, and condition expected. We check for any potential hazards like hazardous materials or incompatibility issues.

- Visual Inspection: This involves a thorough visual examination of the cargo during loading and discharging. We check for any signs of damage, contamination, or discrepancies between the manifest and the actual cargo. This often includes checking packaging integrity, labeling, and securing arrangements.

- Quantity Survey: This step involves measuring the quantity of cargo received or shipped. This can be done using various methods, including tallying, weighing, or volume measurement, depending on the cargo type. Accurate recording and documentation are critical.

- Quality Checks: Depending on the cargo type, specific quality checks may be needed. For example, we might test the moisture content of grain or the temperature of refrigerated cargo. These checks help verify the cargo is of acceptable quality.

- Documentation: All findings from the inspection, including any discrepancies or damages, are meticulously documented. Signed copies are exchanged between the ship and the shore party, providing a clear record of the transaction.

Imagine inspecting a container of frozen fish. We’d check the temperature, verify the seal integrity, look for any signs of leakage or damage, and compare the actual quantity with the manifest details. Any discrepancies are immediately reported.

Q 3. How do you ensure compliance with SOLAS regulations?

SOLAS (Safety of Life at Sea) compliance is paramount in maritime operations. It’s not just about adhering to regulations; it’s about fostering a safety culture onboard.

- Regular Inspections and Maintenance: We conduct regular inspections of life-saving appliances, fire-fighting equipment, and other safety systems, ensuring everything is in perfect working order. This involves scheduled maintenance and timely repairs, following manufacturer guidelines and SOLAS requirements.

- Crew Training and Drills: All crew members participate in regular safety drills, including fire drills, abandon ship drills, and emergency response exercises. This ensures everyone understands their role in an emergency situation.

- Documentation and Record Keeping: We maintain comprehensive documentation of all safety-related activities, including inspections, maintenance records, and training certificates. This documentation is vital during audits and inspections by port state control.

- Compliance with Port State Control Regulations: We prepare thoroughly for port state control inspections, ensuring all relevant documentation is readily available. We actively engage with inspectors and answer their questions transparently.

- Continuous Improvement: SOLAS compliance isn’t static. We actively look for areas of improvement in our safety procedures and implement best practices to enhance the overall safety standards onboard.

For example, if a fire extinguisher inspection reveals a malfunction, we immediately take it out of service, report it, and arrange for its repair or replacement, documenting the entire process meticulously.

Q 4. What is your experience with emergency response procedures?

Emergency response is a critical aspect of shipboard operations. My experience covers a wide range of scenarios, from minor incidents to major emergencies.

- Fire Fighting: I’m proficient in using various fire-fighting equipment and techniques, including using fire extinguishers, fire hoses, and sprinkler systems. I’ve participated in numerous fire drills and understand the importance of rapid response and containment.

- Man Overboard Procedures: I’m trained in implementing man overboard procedures, including launching life rafts, deploying rescue boats, and using search and rescue techniques. This involves understanding the use of GPS and communication systems for effective rescue operations.

- Medical Emergencies: I have a basic understanding of first aid and possess experience in managing various medical emergencies until professional medical help arrives. I’m familiar with using medical supplies and communication procedures to seek assistance.

- Grounding and Collision Response: I understand the procedures for dealing with grounding or collision situations. This includes damage control, communication with shore authorities, and implementing emergency plans.

- Abandon Ship Procedures: I’m thoroughly trained in abandon ship procedures, ensuring I’m familiar with the location of lifeboats, life rafts, and personal protective equipment. I’ve participated in numerous drills to ensure smooth execution.

During a recent voyage, a crew member suffered a severe cut. I immediately provided first aid, contacted the medical authorities ashore, and coordinated with the ship’s doctor through satellite communication, ensuring the injured crew member received timely medical attention.

Q 5. Describe your experience with GPS navigation systems.

GPS navigation systems are indispensable for modern shipping. My experience involves using various GPS-based navigation tools for safe and efficient voyages.

- Chart Plotting and Navigation: I’m proficient in using electronic chart display and information systems (ECDIS) integrated with GPS, ensuring accurate plotting of the vessel’s position and course.

- Route Planning and Optimization: I’m skilled in planning optimal routes considering factors such as weather conditions, traffic density, and navigational hazards. GPS data aids in choosing the safest and most efficient route.

- Position Monitoring and Error Detection: I’m capable of continuously monitoring the vessel’s position, identifying and addressing any discrepancies between the GPS data and the charted course.

- Integration with other Systems: I understand the integration of GPS data with other navigational and shipboard systems, like the Automatic Identification System (AIS) and the ship’s radar, to improve overall situational awareness.

- Emergency Navigation: I know how to use GPS for emergency navigation in case of equipment failure or unexpected situations.

For example, during a heavy fog, our radar experienced a temporary malfunction. The GPS system was crucial in maintaining accurate position awareness and navigating the vessel safely through the fog until the radar was restored.

Q 6. Explain the process for handling a medical emergency onboard.

Handling medical emergencies onboard requires a prompt and well-coordinated response. My experience involves both immediate first aid and coordinating with medical professionals ashore.

- Initial Assessment: The first step involves assessing the situation and the patient’s condition to determine the severity of the emergency. This includes checking vital signs and providing basic first aid.

- Communication: We immediately contact medical professionals ashore via satellite communication or radio, providing detailed information about the patient’s condition, symptoms, and any relevant medical history.

- First Aid and Stabilization: We administer first aid, aiming to stabilize the patient’s condition until professional medical assistance can be provided. This includes managing pain, controlling bleeding, and addressing any immediate life-threatening issues.

- Medical Supplies: Our ship’s medical kit is stocked with essential medications and supplies to handle common medical emergencies. We maintain an inventory and ensure all supplies are in good condition.

- Documentation: We meticulously document all aspects of the medical emergency, including the initial assessment, treatment administered, and communication with medical professionals ashore. This documentation serves as a record for future reference.

In one instance, a crew member experienced a severe allergic reaction. I quickly assessed the situation, administered an epinephrine injection (following proper training), contacted the medical assistance service, and provided updates until a medical evacuation was arranged.

Q 7. Describe your experience with maintaining ship’s logs and documentation.

Maintaining accurate ship’s logs and documentation is critical for compliance, safety, and efficient operations. This involves a structured approach to record-keeping and data management.

- Official Logbooks: I am experienced in maintaining various official logbooks as per international regulations. This includes the engine room log, deck log, and cargo log, documenting all relevant events, maintenance activities, and operational data.

- Electronic Record-Keeping: I’m proficient in using electronic systems for data logging and reporting. This ensures accurate and readily accessible records, improving efficiency and streamlining the process.

- Data Integrity: I understand the importance of data integrity and strive for accurate and complete documentation. This involves regular data verification and reconciliation to prevent errors or inconsistencies.

- Retention Policies: I understand the legal requirements for retaining ship’s documents and ensure all records are archived according to the specified retention policies.

- Audits and Inspections: I’m experienced in supporting audits and inspections by providing access to required records and explaining any information requested.

For example, when performing routine engine room maintenance, I meticulously record the date, time, performed work, parts replaced, and any observations or anomalies in the engine room logbook. This detailed record-keeping is essential for tracking maintenance history and preventing future problems.

Q 8. How do you handle a collision avoidance situation?

Collision avoidance is paramount in shipboard operations. It’s a constant vigilance based on the COLREGs (International Regulations for Preventing Collisions at Sea). My approach involves a layered strategy beginning with proper lookout procedures, utilizing radar and AIS (Automatic Identification System) to track nearby vessels.

If a potential collision is detected, I immediately assess the situation using the standard ‘give-way’ and ‘stand-on’ rules detailed in the COLREGs. This involves considering factors like vessel size, speed, course, and visibility. I’d then take decisive action, potentially altering course, speed, or sounding the ship’s horn to communicate my intentions to the other vessel. Documentation is crucial; I’d record all actions, observations, and communications in the ship’s logbook. For example, if a slower vessel is crossing my bow, I am the stand-on vessel and may only take evasive action if a collision is deemed imminent. However, if the other vessel is not taking appropriate action, a course alteration may be necessary, ensuring safety and legal compliance.

Regular training on COLREGs interpretation and practical collision avoidance exercises are vital to sharpening my skills and reacting appropriately under pressure.

Q 9. What is your experience with ship maintenance and repairs?

My experience in ship maintenance and repairs is extensive. I’ve been involved in both preventative maintenance schedules and emergency repairs, encompassing everything from routine engine checks and hull cleaning to resolving complex machinery breakdowns. I am familiar with the importance of complying with classification society regulations (e.g., DNV, ABS) and ensuring all maintenance is properly documented.

For instance, I oversaw the complete overhaul of a main engine’s fuel injection system, which involved coordinating a team of engineers, ordering spare parts, and managing the entire process to ensure minimal downtime. This required a deep understanding of the engine’s operational parameters, adherence to safety protocols, and effective communication to prevent further issues and keep the vessel operational.

Proactive maintenance is crucial. We’ve implemented predictive maintenance programs using data analytics from various ship systems to anticipate potential failures before they occur, significantly reducing downtime and repair costs. This involves analyzing sensor data and identifying patterns that signal potential issues.

Q 10. How do you manage a diverse crew effectively?

Managing a diverse crew effectively requires strong leadership, communication, and cultural sensitivity. I believe in creating a positive and inclusive work environment where everyone feels valued and respected, regardless of their background or nationality.

Open communication is key. I encourage regular crew meetings to address concerns, share information, and foster teamwork. I also utilize various communication channels, including daily briefings, email, and the ship’s internal messaging system. Conflict resolution is an important part of my role. I always aim to resolve disputes fairly and promptly through open dialogue and mediation, sometimes involving senior crew members where appropriate.

Understanding cultural differences is critical. I strive to be mindful of cultural norms and practices, adapting my communication style as needed to ensure effective interactions. For example, I might organize cultural events to facilitate interaction and understanding among the crew. This leads to a more cohesive and productive work environment, improving morale and overall efficiency.

Q 11. Explain the process for loading and discharging cargo safely.

Safe cargo handling is a meticulous process that begins long before the vessel arrives at port. Pre-arrival planning involves verifying cargo details, securing necessary permits, and ensuring the vessel is properly prepared for the specific cargo type.

Loading and discharging operations are carried out meticulously adhering to international safety standards (e.g., SOLAS, IMDG Code). This includes a careful check of cargo securing methods, weight distribution, and stability calculations. We utilize specialized equipment such as cranes, forklifts, and conveyors, with strict adherence to safety procedures and regular equipment inspections.

The process is overseen by dedicated personnel, and regular communication ensures coordination between the crew, stevedores, and terminal operators. Incident reporting and investigation are critical. Any accidents or near misses are thoroughly documented and analyzed to identify contributing factors and implement preventative measures. For example, during container loading, ensuring proper lashing techniques is paramount to prevent cargo shifting and potential damage during the voyage.

Q 12. What is your experience with bunkering procedures?

Bunkering procedures involve the safe transfer of fuel oil from a bunkering vessel to the ship’s tanks. My experience includes all aspects, from pre-bunkering planning and checks to the actual transfer process and post-bunkering inspection.

Safety is paramount. Prior to the start, we verify the quality and quantity of fuel, inspect the bunkering vessel’s equipment, and ensure all safety measures are in place. The operation is overseen by qualified personnel who monitor flow rates, levels in the tanks, and any potential hazards. I always ensure that the ship’s personnel receive adequate safety training and protective equipment.

Proper documentation is critical. We maintain detailed records of the fuel received, including quantity, quality, and supplier information. Post-bunkering checks are crucial to verify the correct amount of fuel has been received and that there are no leaks or other issues. We’ve used a digital bunkering system in recent years, facilitating electronic records and streamlining the entire procedure.

Q 13. Describe your experience with chart reading and navigation.

Chart reading and navigation are fundamental skills. I am proficient in using various navigational tools and techniques, including paper charts, electronic charts (ECDIS), GPS, and radar. My experience spans various navigational situations, from coastal navigation to open ocean voyages.

I am adept at interpreting nautical charts, identifying hazards like shoals, reefs, and obstructions, and planning safe routes based on weather conditions, tides, and currents. I regularly update my knowledge of navigational aids, regulations, and best practices through training courses and self-study. ECDIS proficiency is key, understanding its capabilities, limitations, and how to manage various data layers.

For example, during a recent voyage through a narrow channel, I carefully planned the route using ECDIS, considering the depth, width, and other navigational hazards. This involved considering the vessel’s draft and maneuvering capabilities. Accurate navigation and route planning are essential for avoiding collisions, groundings, and other accidents.

Q 14. How do you ensure the safety of your crew and passengers?

Ensuring the safety of crew and passengers is my top priority. This involves a multifaceted approach that begins with adherence to all relevant safety regulations and standards (e.g., SOLAS, ISM Code). I actively participate in safety drills, inspections, and training exercises.

We maintain a robust safety management system that includes regular inspections of life-saving appliances, fire-fighting equipment, and other safety systems. Crew training is also paramount, covering topics such as emergency response procedures, personal protective equipment use, and fire prevention and control.

Beyond regulatory compliance, fostering a strong safety culture is essential. I encourage crew members to report safety concerns without fear of reprisal, and we have established clear communication channels to address these issues promptly. We also promote a culture of proactive risk assessment and mitigation, identifying potential hazards before they can escalate into incidents. Regular safety meetings emphasize the importance of vigilance and teamwork in maintaining a safe working environment.

Q 15. Describe your experience with vessel stability calculations.

Vessel stability calculations are crucial for safe ship operation, ensuring the vessel remains upright and seaworthy under various loading conditions. This involves understanding factors like the ship’s displacement, center of gravity, metacentric height (GM), and the effects of cargo loading and ballasting.

My experience includes using both manual calculation methods, relying on hydrostatic tables and stability curves, and employing sophisticated software packages like STABILITY EXPERT and TRIM CALCULATOR. For example, on a recent voyage carrying a large quantity of containerized cargo, I utilized software to model different loading configurations, adjusting the placement of containers to optimize GM and ensure the vessel met stability criteria under various sea states. This involved considering the influence of free surface effects (liquids in tanks) and potential shifting of cargo. I’ve also been involved in investigating stability issues and determining corrective actions. Manual calculations are necessary for verifying software outputs and developing a deeper understanding of the underlying principles. In one case, a slight miscalculation in cargo weight distribution led to a slightly lower than ideal GM, which was corrected through appropriate ballasting, preventing potential stability issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage fuel efficiency and consumption?

Fuel efficiency is paramount for economic and environmental reasons. My approach to managing fuel consumption involves a multi-pronged strategy focusing on optimization at various operational levels.

- Optimized Vessel Speed: I analyze the relationship between speed and fuel consumption using performance curves. We aim for the optimal speed considering voyage duration, weather conditions, and fuel price fluctuations. Slightly reducing speed can significantly decrease fuel consumption without dramatically increasing voyage time.

- Hull Cleaning: Regular hull cleaning is essential to reduce frictional resistance. Fouling reduces fuel efficiency and it’s one of the easiest cost savings for vessels. A clean hull translates directly into lower fuel consumption.

- Engine Maintenance: Proper engine maintenance is non-negotiable. Regular servicing, including oil changes and tuning, ensures the engine operates at peak efficiency, minimizing fuel wastage. We regularly monitor engine parameters to identify potential issues early on.

- Weather Routing: Utilizing weather routing software helps us plan optimal routes to avoid adverse weather conditions that may increase fuel consumption through increased resistance and the need for slower speeds.

- Trim and List Optimization: Maintaining optimal trim and list (the angle of the ship’s deck to the horizon) minimizes resistance and improves fuel efficiency. This aspect often gets overlooked. Regular checks and ballast adjustments are crucial.

By implementing these strategies, we have consistently achieved significant reductions in fuel consumption and overall costs.

Q 17. Explain your experience with cargo securing and lashing.

Cargo securing and lashing are critical for safety and preventing cargo damage during transit. My experience encompasses securing various types of cargo, from containers and breakbulk to specialized heavy lifts.

I’m proficient in using various lashing materials and techniques, adhering to international standards like the IMO’s Code of Safe Practice for Cargo Securing and relevant guidelines from classification societies. This includes correctly calculating the required lashing forces, ensuring proper tension, and utilizing appropriate securing devices, including twistlocks for containers, chains, wire ropes, and various fittings for breakbulk cargo. The proper use of dunnage (protective materials between cargo) is often overlooked but essential to prevent shifting or damage. I regularly conduct pre-departure cargo inspections, and I have overseen the lashing of many unusual or heavy pieces of equipment, utilizing advanced systems to ensure they are properly secured in all anticipated sea conditions. For instance, securing large wind turbine components required close monitoring of stress points and deployment of specialized handling and lashing gear. Proper documentation and thorough checks are crucial to meet regulatory compliance and ensure safe transport.

Q 18. Describe your experience with communication systems onboard.

Modern vessels rely on a complex network of communication systems for safe and efficient operation. My experience covers a wide range of technologies.

- GMDSS (Global Maritime Distress and Safety System): Proficient in operating and maintaining GMDSS equipment, including EPIRB (Emergency Position-Indicating Radio Beacon), Inmarsat-C, and VHF radio, ensuring compliance with international regulations for distress calls and communication.

- VHF Radio: Daily use for communication with other vessels, port authorities, and coastal stations. I am adept at using the radio in all operational situations.

- Inmarsat/Satellite Communication: Regular use for email, weather reports, and company communication. This is crucial for remote voyages.

- AIS (Automatic Identification System): Understanding and utilizing AIS for tracking vessel position, avoiding collisions, and enhancing navigational safety.

- Internal Communication Systems: Experienced in using internal communication systems, including PA systems and ship-wide networks, for efficient crew communication.

Maintaining these systems is vital. We perform regular checks and report any malfunctions promptly to ensure uninterrupted communication, which is vital for safety and effective operations.

Q 19. How do you handle difficult situations with crew members?

Handling difficult situations with crew members requires a proactive and empathetic approach. My strategy centers on open communication, understanding, and conflict resolution.

I believe in fostering a positive and respectful working environment where crew members feel comfortable expressing concerns. I address issues promptly and directly, using active listening to understand different perspectives. For example, in a situation involving a disagreement between two crew members, I facilitated a discussion, encouraging open communication and understanding to reach a mutually acceptable resolution. In more complex situations, I utilize conflict resolution frameworks, ensuring fairness and impartiality. Sometimes, a more formal approach, following company procedures, may be necessary. My aim is always to create a productive work environment that prioritizes safety and team cohesion. It’s all about building rapport and finding solutions that benefit all involved.

Q 20. What is your experience with environmental protection measures onboard?

Environmental protection is a top priority. My experience encompasses a wide range of measures, focusing on minimizing pollution from both operational and accidental sources.

- Waste Management: Strict adherence to MARPOL (International Convention for the Prevention of Pollution from Ships) regulations, including proper segregation, storage, and disposal of garbage, oily water, and sewage. I ensure that the crew are fully trained and understand the procedure.

- Ballast Water Management: Following regulations to prevent the spread of invasive species by using effective ballast water treatment systems. I am aware of the changing regulations surrounding ballast water management.

- Air Emissions: Understanding and complying with regulations concerning air emissions, particularly SOx and NOx, using appropriate fuel and engine optimization techniques. Monitoring air emission levels and making records is very important.

- Oil Spill Prevention and Response: Regular drills and training to prepare for oil spills. Knowledge of procedures for containing and cleaning up potential spills is fundamental.

- Discharge Monitoring: Regular monitoring of discharges to ensure compliance with regulations. Maintaining detailed logs and reporting is essential.

Environmental responsibility is not just compliance but a commitment to sustainable practices. We strive to minimize our environmental footprint through proactive measures and ongoing crew training.

Q 21. Explain the different types of ship’s propulsion systems.

Ship propulsion systems have evolved significantly. Here are some common types:

- Steam Turbines: Historically dominant, steam turbines use steam generated from boilers to drive turbines connected to propellers. They are less common now due to efficiency considerations.

- Diesel Engines: The most prevalent type, diesel engines directly drive propellers or generators powering electric motors. They are efficient and reliable, with various sizes and configurations depending on the vessel.

- Gas Turbines: Used for high-speed applications or as auxiliary power units, they offer high power output but are less fuel-efficient than diesel engines at lower speeds.

- Electric Propulsion: A modern technology that involves generators powered by diesel or gas turbines driving electric motors to turn propellers. This offers greater flexibility and efficiency.

- Hybrid Propulsion Systems: Combining different propulsion systems (e.g., diesel-electric) to optimize performance and efficiency in various operating conditions.

- Wind-Assisted Propulsion: Using sails or rotor sails to supplement conventional propulsion and reduce fuel consumption; this is gaining traction due to environmental concerns.

The choice of propulsion system depends on factors like vessel size, speed requirements, fuel economy goals, and environmental regulations.

Q 22. Describe your experience with mooring and unmooring procedures.

Mooring and unmooring are critical ship handling procedures requiring meticulous planning and execution. They involve securing a vessel alongside a berth or quay, or conversely, releasing it. My experience encompasses a wide range of vessel types and port conditions, from small container ships to large tankers, in both calm and challenging weather.

Mooring Procedure: This typically involves a coordinated effort between the bridge team, deck crew, and shore-based personnel. We start with a thorough risk assessment considering wind, current, tide, and berth characteristics. Then, we approach the berth slowly, using engines and tugs as needed for precise maneuvering. Once alongside, we use mooring lines (ropes) to secure the vessel. These lines are carefully tended, passed to shore personnel, and secured to bollards or mooring winches. We use fenders to protect the vessel’s hull from damage during contact with the pier.

Unmooring Procedure: Unmooring is the reverse process. We begin by carefully releasing the mooring lines in a planned sequence to prevent uncontrolled vessel movement. The engine and tug support are crucial for maintaining control during the process. Once all lines are released and the vessel is clear, we carefully maneuver away from the berth, ensuring there is sufficient clearance to avoid collision.

Example: During a recent unmooring operation in a strong crosswind, we utilized the vessel’s bow and stern thrusters in conjunction with tug assistance to maintain accurate control and prevent the vessel from colliding with a nearby pier.

Q 23. How do you conduct a risk assessment for a specific operation?

A risk assessment is a systematic process to identify potential hazards and assess their likelihood and severity. For a specific operation, like cargo loading, I would follow a structured approach:

- Hazard Identification: This involves brainstorming potential hazards. For cargo loading, this could include equipment failure, unsafe working conditions, incorrect cargo handling procedures, or even human error.

- Risk Analysis: We assess each hazard’s likelihood and severity. Likelihood is the probability of the hazard occurring (e.g., low, medium, high), and severity represents the potential consequences (e.g., minor injury, major injury, fatality).

- Risk Evaluation: We combine the likelihood and severity to determine the overall risk level. A risk matrix is commonly used for this, prioritizing hazards based on their risk level.

- Risk Control: We develop control measures to mitigate or eliminate identified risks. These measures could include improved equipment maintenance, enhanced safety training, implementation of stricter procedures, or additional safety equipment.

- Monitoring and Review: The effectiveness of the risk controls is regularly monitored and the risk assessment is reviewed and updated as necessary.

Example: During a heavy-lift operation, we identified the risk of crane failure. We mitigated this by conducting thorough pre-lift inspections, employing a secondary lifting system as a backup, and having emergency response plans in place.

Q 24. What is your experience with the International Maritime Organization (IMO) conventions?

I’m familiar with several key IMO conventions, including the International Convention for the Safety of Life at Sea (SOLAS), the International Convention for the Prevention of Pollution from Ships (MARPOL), and the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers (STCW). These conventions establish international standards for maritime safety, security, and environmental protection.

SOLAS: This convention covers various aspects of ship safety, including structural requirements, fire safety measures, life-saving appliances, and radio communications. Compliance is mandatory for all international voyages.

MARPOL: This aims to prevent pollution of the marine environment by ships. It sets regulations concerning oil and other harmful substances discharge. My experience involves adhering to MARPOL regulations regarding oily water separation, garbage disposal, and the management of hazardous cargo.

STCW: This convention sets minimum standards for training, certification, and watchkeeping for seafarers. It ensures competent personnel are operating ships. My experience includes obtaining certificates in accordance with STCW requirements and understanding the responsibilities of bridge watchkeeping.

Q 25. Describe your experience with port state control inspections.

Port State Control (PSC) inspections are conducted by the coastal state to verify compliance with international and national maritime regulations. I’ve experienced numerous PSC inspections across different ports worldwide. The process typically involves a thorough examination of the vessel’s documentation, crew certificates, safety equipment, and operational procedures.

Inspection Procedures: Inspectors review the ship’s certificates (e.g., International Safety Management (ISM) certificate, Cargo Securing Manual, etc.), verify the crew’s qualifications and competency, check life-saving appliances, examine cargo securing arrangements, and assess the vessel’s overall condition. They may also inspect the engine room and other critical areas.

Maintaining Compliance: To ensure a smooth inspection, meticulous record-keeping, a comprehensive safety management system, and well-trained crew are essential. Our vessel maintains a detailed record of all maintenance and repairs, ensuring easy access to documentation during PSC inspections. We also conduct regular internal audits to identify and correct any deficiencies before they are flagged by external inspectors.

Example: During a recent PSC inspection, the inspector focused on the ship’s oil record book. Our meticulous record-keeping and compliant procedures resulted in a successful inspection with no deficiencies.

Q 26. Explain the importance of maintaining proper watchkeeping.

Proper watchkeeping is fundamental to safe ship operation. It’s a continuous process of monitoring the vessel and its surroundings, ensuring its safe navigation and the well-being of the crew. Effective watchkeeping involves vigilance, situational awareness, and prompt action to prevent accidents and incidents.

Importance: A lapse in watchkeeping can have catastrophic consequences such as collisions, groundings, fires, and injuries. This is why watchkeeping procedures are strictly regulated.

Elements of Effective Watchkeeping: Effective watchkeeping includes regularly checking navigational equipment, monitoring weather reports, and maintaining communication with other vessels and shore facilities. A thorough understanding of navigational charts, rules of the road (COLREGs), and emergency procedures is crucial. It also necessitates regular rounds of the vessel to check for any anomalies.

Example: During a night watch, I noticed a sudden change in wind direction and increased sea state. I immediately informed the captain and adjusted the course accordingly, preventing a potential collision with a nearby vessel.

Q 27. How do you handle a fire onboard a vessel?

Handling a fire onboard a vessel requires immediate and decisive action, following a well-rehearsed plan based on the ship’s Safety Management System. My training emphasizes rapid response, crew safety, and damage control.

Emergency Response: The immediate actions depend on the location and size of the fire. We follow the ship’s fire response plan. This involves activating the general alarm, notifying the captain, deploying fire fighting equipment, and evacuating the affected area, if necessary. We utilize fire extinguishers, fire hoses, and the fixed fire fighting system according to the type of fire. Depending on the severity of the situation we may need to contact the coast guard and other relevant authorities.

Fire Fighting Techniques: I am trained in using various fire fighting techniques, such as the PASS method (Pull, Aim, Squeeze, Sweep) for portable fire extinguishers and the proper use of fire hoses and monitors. The type of extinguisher to be used is dependent on the class of fire (A, B, C, D, and F). The goal is to confine and extinguish the fire, prevent further spread, and protect personnel.

Example: I participated in a fire drill where a simulated engine room fire was initiated. We successfully deployed the CO2 system and extinguished the fire, demonstrating the effectiveness of our training and preparedness.

Q 28. What is your experience with the use of electronic charts and navigation systems?

Electronic Chart Display and Information Systems (ECDIS) and other electronic navigation systems are now integral to modern ship navigation. My experience includes extensive use of ECDIS, GPS, radar, and Automatic Identification Systems (AIS).

ECDIS: ECDIS replaces paper charts, providing real-time navigational information, route planning capabilities, and safety alerts. It’s a key tool for navigating safely and efficiently. I’m proficient in using ECDIS features such as route planning, chart updates, and various navigational aids.

Other Systems: Radar helps in detecting other vessels and obstacles, even in low visibility conditions. GPS provides precise position information, while AIS aids in tracking the movements of other vessels. Integrating these systems provides a comprehensive navigational picture and enhances safety.

Example: During a passage through a congested waterway, I used ECDIS to plan a safe route, taking into account other vessel traffic, and monitored it constantly using radar and AIS to ensure we maintained safe distances from other vessels.

Key Topics to Learn for Shipboard Operation Interview

- Safety Procedures and Regulations: Understand international maritime regulations (SOLAS, STCW), emergency procedures, and safety drills. Be prepared to discuss practical application in various scenarios, such as fire, man overboard, and medical emergencies.

- Navigation and Chartwork: Demonstrate knowledge of navigational techniques, chart reading, GPS systems, and electronic charting systems (ECDIS). Be ready to discuss real-world applications of these skills in planning voyages and avoiding hazards.

- Cargo Handling and Management: Explain the procedures for loading, securing, and unloading different types of cargo, including safety considerations and relevant regulations. Be prepared to discuss practical challenges and problem-solving approaches related to cargo operations.

- Shipboard Maintenance and Repairs: Discuss routine maintenance tasks, preventative maintenance schedules, and troubleshooting common equipment malfunctions. Highlight your understanding of basic ship systems and your ability to contribute to a safe and efficient operation.

- Communication and Teamwork: Explain your experience in effective communication within a team environment, especially in high-pressure situations. Highlight your ability to collaborate effectively with diverse crew members and follow hierarchical command structures.

- Engine Room Operations (for relevant roles): Demonstrate understanding of main engine operation, auxiliary systems, and fuel efficiency strategies. Be ready to discuss preventative maintenance and troubleshooting related to engine room equipment.

- Ballasting and Stability: Explain the principles of ballasting and their impact on ship stability. Be prepared to discuss practical applications and the importance of maintaining stability for safe operations.

Next Steps

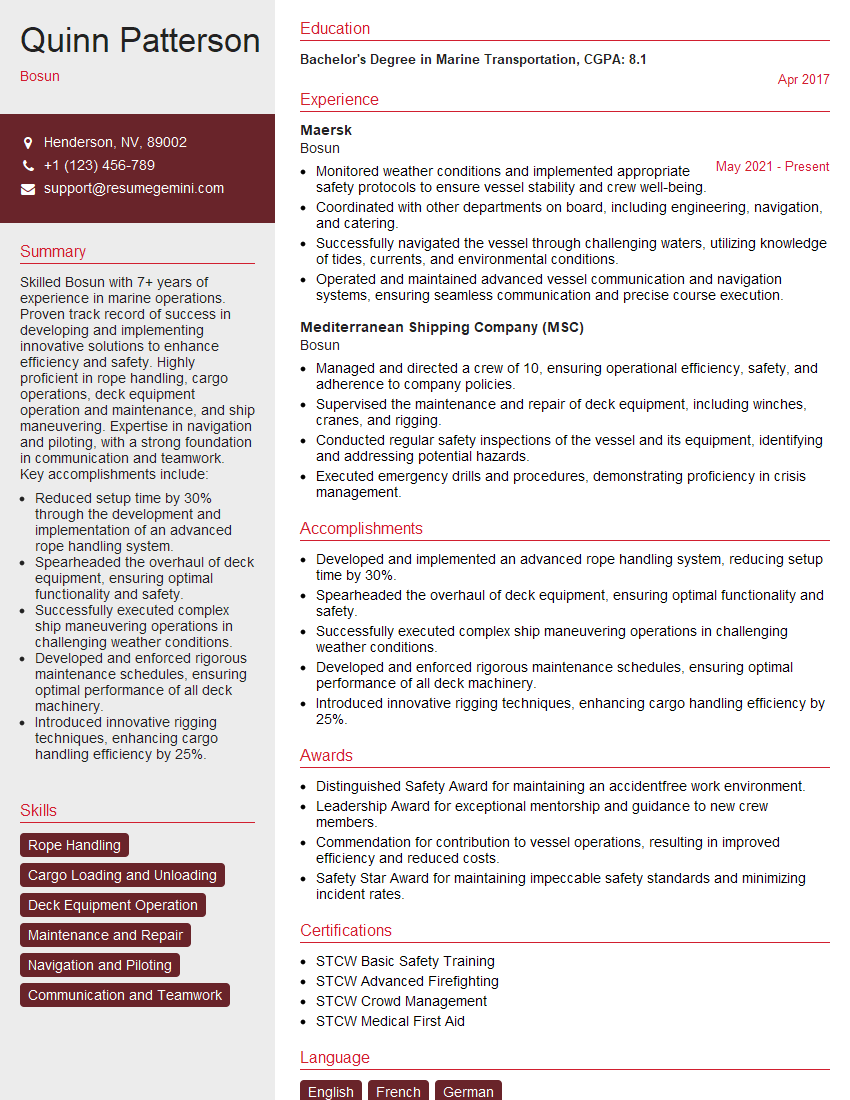

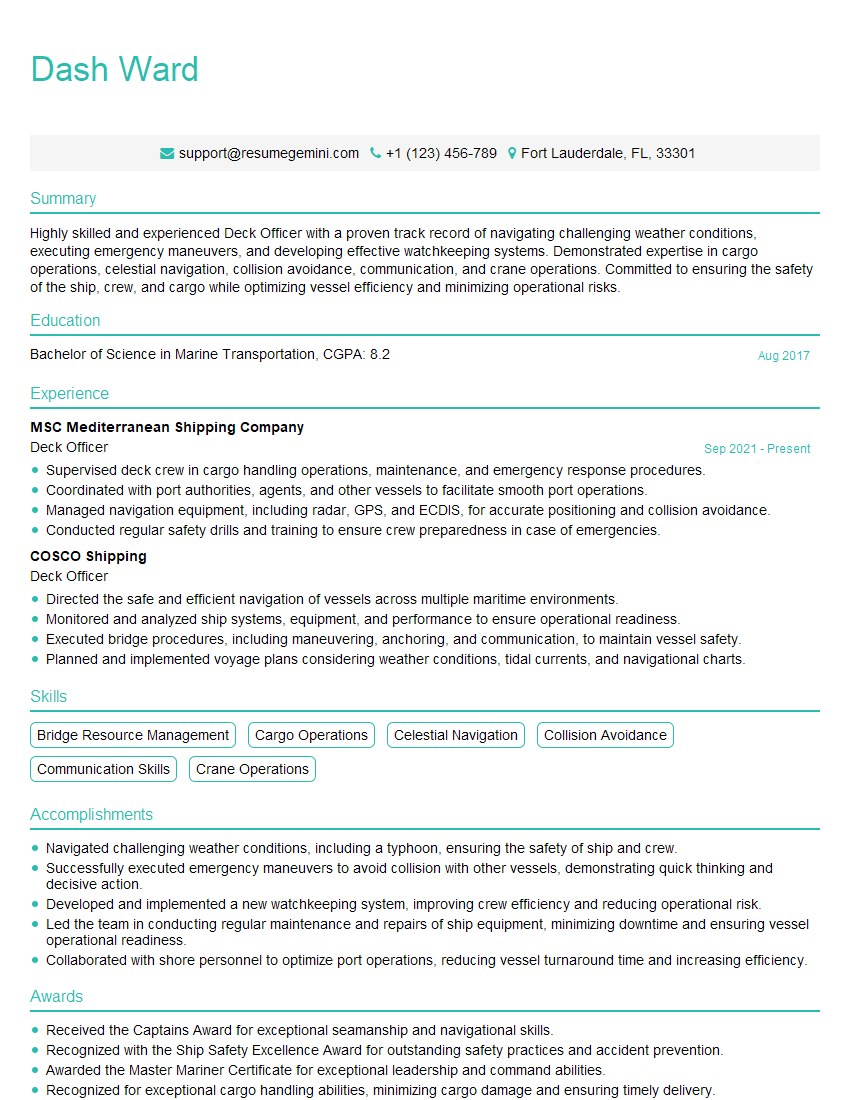

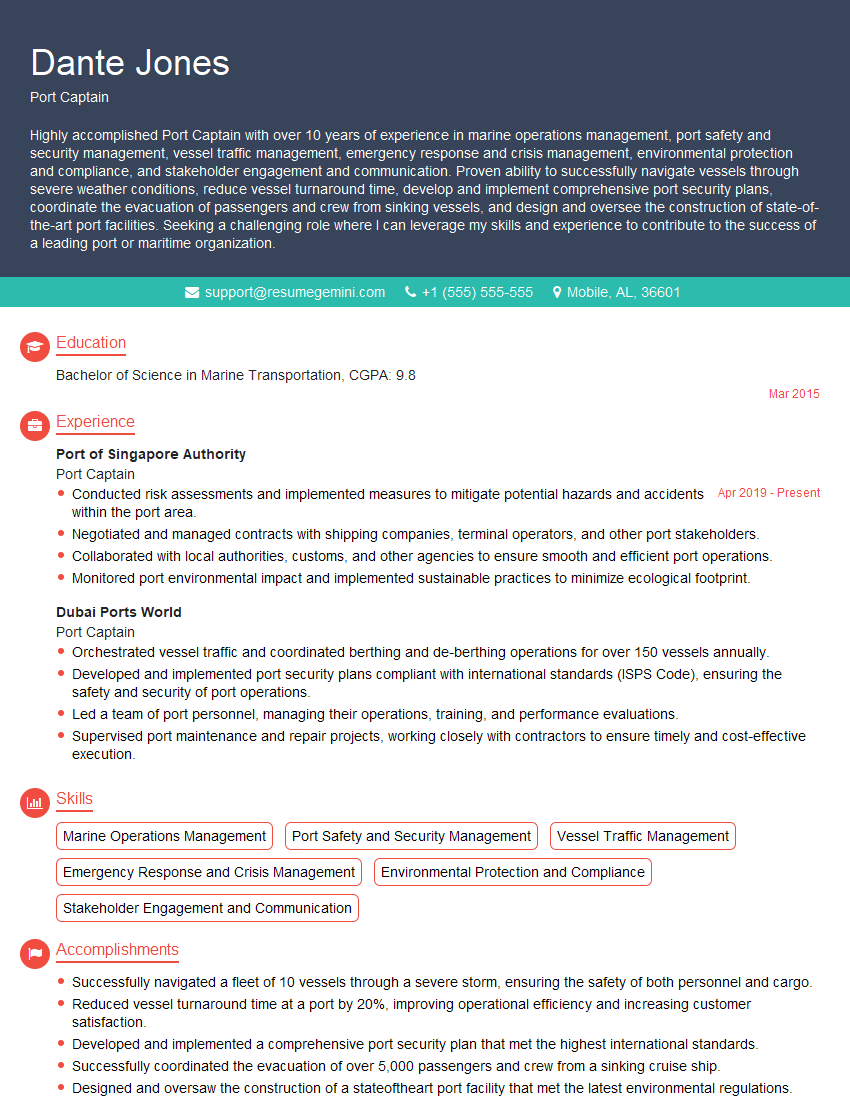

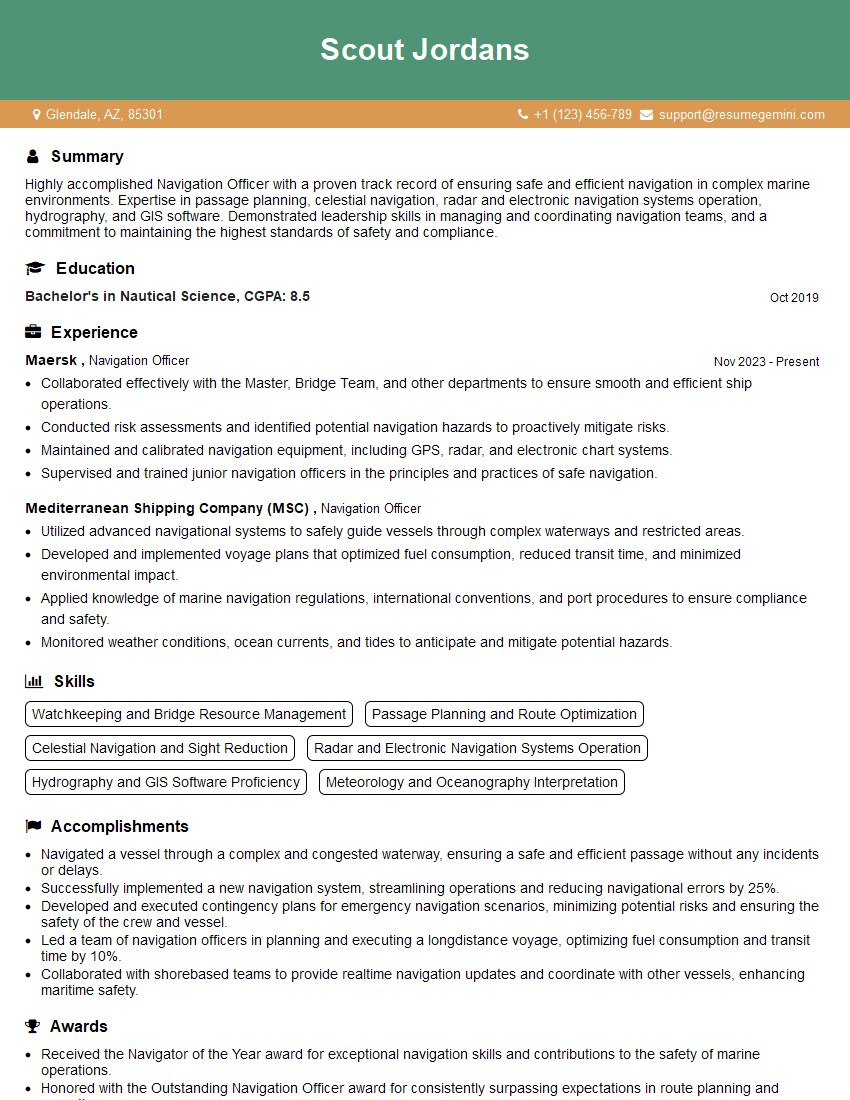

Mastering Shipboard Operation principles is crucial for career advancement in the maritime industry, opening doors to higher-paying roles and greater responsibilities. A strong, ATS-friendly resume is your first step to showcasing your skills and experience to potential employers. To help you create a compelling resume that highlights your expertise and gets noticed, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform to build professional resumes, and we have examples specifically tailored for Shipboard Operation roles available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.