Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Sprinkler Head Inspection and Repair interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Sprinkler Head Inspection and Repair Interview

Q 1. What are the different types of sprinkler heads and their applications?

Sprinkler heads come in various types, each designed for specific applications. The choice depends on factors like the area to be covered, water pressure, and the type of landscaping.

- Rotary Sprinkler Heads: These are common for larger areas. They rotate 360 degrees or in specific arcs, providing wide coverage. Think of the classic, spinning sprinkler you see in many lawns.

- Impact Sprinkler Heads: These heads use a spinning impact mechanism to throw water farther, making them ideal for large, open spaces. They’re known for their powerful spray.

- Spray Sprinkler Heads: Offering a gentle, close-range spray, these heads are best suited for flower beds, smaller areas, or delicate plants that need a softer watering.

- Rotor Sprinkler Heads: Similar to rotary heads, but with greater range and adjustability for water stream patterns. They’re often used in larger commercial or residential settings.

- Pop-up Sprinkler Heads: These heads are usually recessed into the lawn, only rising when the system is activated. This provides a cleaner, more aesthetically pleasing look.

Choosing the right head is crucial for efficient water usage and effective lawn coverage. For example, using a high-pressure spray head in a delicate flower bed could damage the plants. Conversely, using low-pressure spray heads for a large lawn would lead to insufficient watering.

Q 2. How do you identify a malfunctioning sprinkler head?

Identifying a malfunctioning sprinkler head often involves a visual inspection and a check of its functionality. Look for these signs:

- Low or inconsistent spray: If the sprinkler sprays weakly or unevenly, this suggests a clog, low water pressure, or a problem with the head itself.

- No spray at all: This could mean a completely clogged head, a broken nozzle, or a problem with the valve controlling the water flow to that head.

- Inconsistent spray pattern: A change in the expected spray pattern—perhaps a head suddenly spraying in a different direction or arc—indicates potential damage or misalignment.

- Physical damage: Look for cracks, breaks, or other visible damage to the head. This could be from wear and tear, impact, or frost damage.

- Leaks: Dripping or leaking water from the head, even when not actively spraying, indicates a seal problem or internal damage.

For example, I once encountered a sprinkler head that was spraying water in a complete circle instead of its programmed arc. Upon closer examination, I found that the arc adjustment mechanism had become loose.

Q 3. Explain the process of inspecting a sprinkler head for damage or obstruction.

Inspecting a sprinkler head involves a methodical approach to ensure thoroughness:

- Turn off the system: Safety first! Always turn off the water supply to the sprinkler system before starting any inspection or repair.

- Visual inspection: Carefully examine the head for any visible damage, including cracks, broken parts, or signs of wear.

- Check for obstructions: Remove any debris or dirt that might be clogging the nozzles. A small wire or brush can be helpful for this.

- Inspect the filter screen: Many sprinkler heads have a filter screen to prevent debris from entering. Check for clogs and clean if necessary.

- Check the nozzle: Examine the nozzle for damage or wear. A worn nozzle will often lead to inconsistent spray.

- Check the alignment: Make sure the head is correctly aligned and not tilted or pointing in the wrong direction.

- Check for leaks: Look for any leaks around the base of the head or from the nozzles.

Imagine you’re a detective examining a crime scene! You need to be observant and methodical to uncover the source of the problem.

Q 4. What are the common causes of sprinkler head malfunction?

Several factors can cause sprinkler head malfunctions:

- Clogs: Debris like dirt, sand, leaves, or insects can clog nozzles, reducing or stopping water flow.

- Low water pressure: Insufficient water pressure in the system can affect the spray distance and pattern of the sprinkler head.

- Damaged nozzles or parts: Cracks, breaks, or worn-out parts can compromise the head’s functionality.

- Misaligned heads: If a sprinkler head is improperly aligned, its spray pattern will be inaccurate.

- Malfunctioning valves: Problems with the valves that control water flow to the heads can prevent the head from spraying.

- Frozen pipes (winter climates): In freezing temperatures, water expansion can damage sprinkler heads or the pipes leading to them.

For instance, I once worked on a system where low water pressure was the culprit. The main water line was partially blocked, affecting the entire system’s performance.

Q 5. Describe the steps involved in replacing a sprinkler head.

Replacing a sprinkler head is relatively straightforward:

- Turn off the water supply: Again, safety is paramount. Ensure the water is completely off before proceeding.

- Locate the valve: Find the valve controlling the water flow to the affected sprinkler head and turn it off. You might need a valve key for this.

- Unscrew the old head: Use an appropriate wrench (usually a socket wrench) to carefully remove the old sprinkler head.

- Clean the area: Remove any debris or dirt from the riser (the pipe the head sits on).

- Install the new head: Carefully screw the new head onto the riser, ensuring a tight but not overly forceful connection.

- Turn the water back on: Once the new head is securely in place, slowly turn the water back on and check for leaks.

- Test the spray pattern: Ensure the new head is spraying correctly and the pattern is as expected.

Think of it like changing a lightbulb; it’s a simple process once you have the right tools and understand the steps.

Q 6. How do you test the water pressure of a sprinkler system?

Testing water pressure is crucial for maintaining a properly functioning sprinkler system. You can do this using a pressure gauge:

- Locate the main water supply valve: This is typically located near the water meter.

- Turn on the water supply: Turn on the water supply to the sprinkler system.

- Attach the pressure gauge: Connect a pressure gauge to the system’s main line, typically near the water meter or backflow preventer.

- Check the pressure reading: Observe the pressure gauge and record the reading. This reading should be compared to the manufacturer’s recommended pressure for your system. Most residential systems operate between 40 and 60 PSI.

- Check for pressure fluctuations: Turn on different zones to ensure consistent pressure throughout the system. Significant pressure drops indicate potential issues like leaks or clogs.

It’s like checking your car’s tire pressure; regular checks ensure optimal performance and prevent issues from developing.

Q 7. What are the safety precautions you take during sprinkler head inspection and repair?

Safety is paramount during sprinkler head inspection and repair. Always follow these precautions:

- Turn off the water supply: Before performing any work on the sprinkler system, always turn off the main water supply to prevent accidental injury or water damage.

- Wear appropriate safety gear: Depending on the task, you may need gloves, eye protection, and potentially work boots.

- Be aware of underground utilities: Before digging, call your local utility companies to locate underground utilities (gas, electrical, cable) to prevent damage and injury. Utilize a call-before-you-dig service.

- Use proper tools: Use tools appropriate for the job, and handle them carefully to prevent injury.

- Work with a partner if necessary: For large or complex tasks, it’s often safer to work with a partner.

- Understand your sprinkler system: Familiarize yourself with your system’s layout and components before starting any work.

Remember, neglecting safety can lead to serious consequences. It’s always better to be overly cautious than to risk injury or damage.

Q 8. How do you identify the type and flow rate of a sprinkler head?

Identifying the type and flow rate of a sprinkler head involves a multi-step process. First, visually inspect the head itself. Manufacturers often stamp their name and model number directly onto the head, providing crucial information for identifying the type. This identification is key to finding replacement parts and understanding its specifications.

Next, determining the flow rate requires a bit more investigation. The most accurate method is to use a flow meter, attaching it directly to the sprinkler head’s output. This device will precisely measure the gallons per minute (GPM) the head discharges. Alternatively, you can often find the flow rate information printed on the head’s manufacturer’s documentation or in their online catalogues.

For example, a Rain Bird 1804 head is easily identifiable by its markings and generally has a flow rate around 0.8 GPM. Understanding these characteristics is crucial for balancing the overall sprinkler system and ensuring uniform water distribution across your lawn.

Q 9. Explain the importance of regular sprinkler head maintenance.

Regular sprinkler head maintenance is paramount for several reasons. Firstly, it ensures optimal water distribution across your landscape. Clogged heads lead to uneven watering, potentially damaging your plants and wasting water. Secondly, it extends the lifespan of your sprinkler system. Early detection and repair of damaged heads prevents more extensive and costly repairs down the line.

Regular maintenance also increases efficiency. A correctly functioning sprinkler system uses the precise amount of water necessary, saving you money on water bills. Finally, it promotes safety. Malfunctioning sprinkler heads can create hazards such as water runoff or even physical damage if parts break and project out.

Imagine a clogged sprinkler head; the water pressure builds up, causing the head to spray erratically or not at all, leading to brown patches and wasted water. Preventative maintenance is a simple way to avoid such issues.

Q 10. What are the common codes and regulations related to sprinkler systems?

Codes and regulations related to sprinkler systems vary by location but often adhere to national standards like those set by the International Fire Code (IFC) and the National Fire Protection Association (NFPA). These codes generally address aspects such as water pressure, flow rates, spacing between heads, system capacity, backflow prevention, and the use of approved materials.

For instance, the IFC outlines requirements for the minimum water pressure needed to effectively operate a fire sprinkler system, ensuring sufficient coverage in case of an emergency. Similarly, NFPA standards address aspects of fire sprinkler system design, installation, and testing procedures. Local authorities often implement their own regulations that are stricter than national standards, based on the local climate, water availability, and fire risk profile. Always consult your local building codes and relevant authorities for precise requirements in your area.

Q 11. How do you troubleshoot a sprinkler head that is not deploying properly?

Troubleshooting a non-deploying sprinkler head involves a systematic approach. Begin by checking the simplest things first. Is the zone valve for that area turned on? Are there any obvious obstructions blocking the head? Does the water reach the area?

If the water supply is confirmed, the next step is to inspect the head itself. Look for any debris clogging the nozzles. A simple cleaning with a small wire or pin often solves this. If the problem persists, check the internal components. Sometimes a small spring or internal mechanism malfunctions. In this case, the entire head may need replacement.

Finally, check the water pressure. If the pressure is too low, it may be necessary to adjust the system’s main valve or check for leaks in the piping system. By following this step-by-step process, most problems with a non-deploying sprinkler head can be resolved efficiently.

Q 12. What tools and equipment are essential for sprinkler head inspection and repair?

Essential tools and equipment for sprinkler head inspection and repair include a variety of items. Firstly, you’ll need a good set of screwdrivers (Phillips and flathead), wrenches (adjustable and possibly socket wrenches), and pliers. These are necessary to disassemble and reassemble sprinkler heads and components.

A flow meter is crucial for accurate flow rate measurements. A pressure gauge helps identify issues with water pressure in the system. A small wire or pin is handy for unclogging sprinkler nozzles. Protective gear, such as gloves and safety glasses, is essential to protect against sharp components or water pressure.

Additional tools depending on specific jobs could be a pipe cutter or repair kits for damaged piping. Having these readily available will streamline the inspection and repair process, leading to efficiency and more effective repairs.

Q 13. Describe your experience with different sprinkler head manufacturers and models.

Over the years, I’ve worked extensively with various sprinkler head manufacturers and models. My experience spans across a wide range, from well-known brands like Rain Bird and Hunter to other niche manufacturers. Rain Bird heads, for example, are known for their reliability and wide array of models catering to diverse landscape needs. Hunter heads also provide a robust and efficient solution, with excellent performance and precision.

Each manufacturer has its own design specifications and proprietary components. For instance, the internal mechanisms, nozzle types and flow rates often differ, highlighting the need for familiarity with the specifics of different brands. Understanding these differences allows for better repair work and proper selection of replacement parts.

This broad experience is what enables me to troubleshoot and resolve issues effectively, regardless of the manufacturer or model of the sprinkler head.

Q 14. How do you document your inspection findings and repairs?

Thorough documentation is key to efficient and responsible sprinkler system maintenance. My documentation typically includes detailed records of the inspection date, location of the inspected area, and the specific sprinkler heads examined. I use a combination of digital and paper methods.

For each head, I note the manufacturer, model number, condition (e.g., functioning correctly, clogged, damaged), and any repairs performed, including replacement parts used. Digital documentation is often done using a tablet or smartphone with a field service app, which allows for easy record keeping. Digital photos are also included as visual documentation of the head’s condition before and after any repairs. I also maintain a comprehensive log of all repairs, including the date of repair and the materials used.

This detailed documentation ensures that future maintenance is streamlined, allowing for easier tracking of repairs, parts replacements, and potential problem areas. It also demonstrates accountability and professional performance.

Q 15. How do you handle unexpected issues during a sprinkler head inspection?

Unexpected issues during a sprinkler head inspection are common. My approach is systematic and prioritizes safety. First, I’d assess the situation – is it a minor leak, a complete blockage, or something more serious like a broken pipe? I always prioritize safety first, turning off the water supply to the affected zone if necessary. For minor leaks, I might attempt a simple repair like tightening a connection or replacing a worn-out O-ring. For more significant problems, I document the issue thoroughly with photos and notes, then recommend the appropriate course of action to the client, which could include contacting a plumber specializing in sprinkler systems or scheduling a full system inspection. I always communicate clearly with the client throughout the process, keeping them informed of the progress and any associated costs.

For instance, I once encountered a sprinkler head that was spraying water at an odd angle. After inspection, I found a small rock lodged in the nozzle. A quick cleaning solved the problem. However, if the issue stems from a more serious problem like a damaged pipe, I would always recommend a professional plumber.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of sprinkler system activation mechanisms?

Sprinkler systems use a variety of activation mechanisms, all designed to release water when triggered by a fire. The most common are:

- Pressure-activated: These are the most prevalent type. A sprinkler head contains a glass bulb or fusible link that breaks at a specific temperature (typically 135-165°F or 57-74°C), releasing the water pressure and activating the spray. Think of it like a tiny glass bottle with water under pressure; the heat breaks the bottle, and the water sprays out.

- Thermal-activated: Similar to pressure-activated, but instead of a glass bulb, they employ a heat-sensitive element that melts at a specific temperature, allowing water flow.

- Quick Response Sprinkler Heads: Designed to react more quickly to a fire, often having a lower activation temperature than standard heads. These are vital in areas where fire spreads rapidly.

- Deluge Systems: These systems don’t have individual sprinkler heads with activation mechanisms. Instead, a large number of open nozzles are activated simultaneously when the system’s detection system triggers. They are used in high-risk areas where immediate, extensive water coverage is crucial.

The choice of activation mechanism depends heavily on the fire risk and the specific application of the sprinkler system. A warehouse might use a pressure-activated system, while a data center might opt for a quick-response or deluge system.

Q 17. Explain the concept of sprinkler head spacing and coverage.

Sprinkler head spacing and coverage are critical for effective fire suppression. The goal is to ensure complete and uniform water distribution across the protected area. Spacing is determined by factors like the sprinkler head’s throw (the distance the water sprays), the type of sprinkler head, and the occupancy classification of the building. The NFPA (National Fire Protection Association) standards provide guidance on appropriate spacing based on these factors. If the heads are too far apart, there are gaps in coverage, leaving areas vulnerable. If they’re too close, it can be wasteful and potentially cause more water damage than necessary.

Imagine watering your lawn. If you have the sprinkler heads too far apart, parts of your lawn will stay dry. If they’re too close, you’ll over-water and waste water. Sprinkler head design and spacing are similar; the goal is even, effective coverage.

Q 18. How do you ensure the proper orientation and alignment of a sprinkler head?

Proper orientation and alignment are vital for optimal sprinkler head performance. Misaligned heads can result in uneven water distribution, inadequate coverage, or even damage to the head itself. I use a variety of tools and techniques to ensure correct alignment. This often involves a combination of visual inspection, using a level, and referencing the manufacturer’s specifications and installation guidelines.

For example, many sprinkler heads have an adjustment mechanism that allows you to fine-tune their angle and spray pattern. I’d use a level to ensure the head is perfectly horizontal and then adjust its orientation until the spray pattern meets the desired coverage. Regular checks, especially after system maintenance or repairs, are crucial to maintaining optimal performance.

Q 19. What are the signs of corrosion or damage on a sprinkler head?

Signs of corrosion or damage on a sprinkler head can range from subtle to obvious. Common indicators include:

- Rust or pitting: This indicates corrosion and weakening of the head’s material. It is a sign that the head may fail under pressure.

- Cracks or chips in the head or nozzle: These reduce the head’s structural integrity and can lead to leaks or malfunctions.

- Discoloration or staining: Unusual discoloration might point to mineral deposits or corrosion. A change in nozzle color is another sign of damage or degradation.

- Loose connections: If any of the connections are loose or show signs of wear and tear, this could lead to a leak or malfunction.

- Clogged nozzles: Mineral deposits or debris can restrict water flow, significantly impacting the head’s effectiveness.

Regular inspections are crucial to identify these issues early and prevent more serious problems.

Q 20. How do you determine the appropriate replacement for a damaged sprinkler head?

Choosing the right replacement sprinkler head is paramount. I always refer to the original manufacturer’s specifications or the system’s design documentation to ensure compatibility. Factors to consider include:

- Type of sprinkler head: Upright, pendant, sidewall, etc.

- Spray pattern: Full circle, part circle, etc.

- Flow rate and pressure: The replacement must be suitable for the system’s operating pressure.

- K-factor: This value indicates the sprinkler’s water discharge coefficient.

- Material: Ensure the material of the replacement is compatible with the existing system.

In some cases, I might need to conduct a flow test to determine the appropriate K-factor for the replacement head. Substituting a head with an incompatible K-factor could disrupt the system’s balance and water pressure throughout the zone.

Q 21. What is your experience with different types of sprinkler system piping?

My experience encompasses various types of sprinkler system piping, including:

- Black iron pipe (BIP): Durable but susceptible to corrosion.

- Galvanized steel pipe (GSP): Offers corrosion resistance, but zinc buildup can restrict water flow over time.

- Copper tubing: Excellent corrosion resistance, flexible, and relatively easy to install. It is more expensive.

- CPVC (Chlorinated Polyvinyl Chloride): A common choice for residential systems; it’s lightweight, relatively inexpensive, and resistant to corrosion.

- PEX (Cross-linked polyethylene): Flexible, lightweight, and easy to install, commonly used in both residential and commercial applications. Often used with push-fit connections for ease of repair or replacement.

Understanding the properties of each material is vital. For example, I would be aware of the potential for galvanic corrosion if using different metals in the same system. The selection of piping material depends largely on factors such as budget, application, and local regulations.

Q 22. Describe your experience working with different types of sprinkler system valves.

My experience encompasses a wide range of sprinkler system valves, from the common ball valves and butterfly valves used for main line control to the more specialized check valves and pressure-reducing valves. I’m proficient in identifying valve types, understanding their functionalities, and diagnosing potential issues. For instance, a faulty check valve could lead to water hammer, and I know how to detect and replace it effectively. I’ve worked extensively with both manual and automated valves, including those controlled by fire alarm systems or sophisticated building management systems (BMS). Understanding the nuances of each valve type is crucial for efficient system operation and maintenance. For example, I’ve had to troubleshoot a situation where a butterfly valve was sticking due to mineral deposits, requiring a thorough cleaning and lubrication to restore proper operation.

- Ball Valves: Simple, reliable on/off control.

- Butterfly Valves: Provide throttling capabilities for flow regulation.

- Check Valves: Prevent backflow.

- Pressure-Reducing Valves: Maintain consistent downstream pressure.

Q 23. How do you maintain accurate records and documentation of inspections and repairs?

Maintaining accurate records is paramount. I utilize a combination of digital and physical methods. Each inspection is documented using a standardized checklist on a tablet, ensuring consistent data collection. This checklist captures key details such as the date, location, observed issues, and completed repairs. Digital images and videos are incorporated to provide visual evidence of any damage or malfunction. All this information is then transferred to a centralized database, allowing for easy retrieval and analysis. A physical copy of the inspection report is also left on site. This dual system ensures data backup and accessibility. For repairs, I maintain detailed logs including parts used, labor hours, and cost breakdowns. This comprehensive record-keeping system is essential for preventative maintenance planning and compliance with industry standards.

Q 24. How do you prioritize repairs in a multi-sprinkler system?

Prioritizing repairs in a multi-sprinkler system requires a systematic approach. I assess the severity of each issue using a tiered system. Critical issues, such as a major leak causing water damage or a malfunction impacting fire safety, are addressed immediately. Less urgent repairs, like a slightly misaligned head or minor drip, are scheduled for routine maintenance. This prioritization process ensures efficient resource allocation and minimizes disruption. Furthermore, I consider factors like the affected area and potential impact on building occupants. For instance, a leaking head in a populated area might be given higher priority than a similar issue in a less frequented space.

Q 25. What is your experience with hydraulic calculations for sprinkler systems?

I possess significant experience with hydraulic calculations, which are fundamental to sprinkler system design and maintenance. I utilize industry-standard software and formulas to calculate friction loss, pressure drop, and flow rates. This ensures the system delivers the required water volume and pressure to each sprinkler head. A key aspect of my work involves verifying existing system calculations against actual field measurements. Discrepancies often indicate problems like pipe blockages or pump malfunctions. I can use this data to make necessary adjustments to ensure the system’s optimal performance. For example, I recently used hydraulic calculations to identify the cause of low pressure in a zone, which turned out to be a partially closed valve.

Q 26. Explain your understanding of different sprinkler head discharge patterns.

Sprinkler heads exhibit various discharge patterns, each designed to cover a specific area. Common patterns include:

- Full-circle: Provides 360-degree coverage.

- 180-degree: Covers a half-circle.

- 90-degree: Covers a quarter-circle.

- Side-discharge: Used for specific applications.

Understanding these patterns is crucial for proper system design and troubleshooting. An incorrectly positioned or malfunctioning head might not provide adequate coverage, creating fire safety risks. I’ve experienced situations where an improperly installed 90-degree head was causing dry spots within a protected area which was easily fixed by repositioning the head.

Q 27. How do you handle situations where a sprinkler head is leaking?

A leaking sprinkler head requires immediate attention. My first step involves identifying the source of the leak. This could range from a simple O-ring failure to a cracked body. Once the cause is determined, the appropriate repair or replacement is undertaken. Safety is always prioritized. Water is shut off to the affected zone before any repairs begin. I use the appropriate tools and replacement parts to ensure a watertight seal. After the repair, the system is thoroughly tested to confirm the leak has been fixed and the sprinkler’s proper function is restored. In many cases, a simple replacement of the O-ring or a worn-out gasket is sufficient. Documentation of the repair including the parts and labor used is crucial for my record-keeping.

Q 28. What is your experience with emergency repairs of sprinkler systems?

Emergency repairs require swift and decisive action. I’m well-versed in handling various emergency situations, from burst pipes to major leaks. My process starts with assessing the situation to determine the extent of the damage and the immediate risk. Then, I take the necessary steps to mitigate the damage, often involving the quick isolation of the affected area by turning off the water supply. Temporary repairs might be implemented to stop the immediate flow of water, followed by permanent repairs once the emergency is contained. In one instance, a burst pipe during a cold snap threatened significant water damage. I immediately shut off the main valve and, working with a plumber, patched the pipe to stop the leak before arranging for a full replacement of the affected section. Post-emergency procedures include a full system inspection to identify any other potential issues and prevent future occurrences.

Key Topics to Learn for Sprinkler Head Inspection and Repair Interview

- Understanding Sprinkler System Types: Familiarize yourself with various sprinkler system designs (wet pipe, dry pipe, pre-action, deluge) and their unique inspection requirements.

- Inspection Procedures and Documentation: Master the systematic approach to inspecting sprinkler heads, including visual checks, operational tests, and accurate record-keeping. Understand relevant codes and standards (e.g., NFPA).

- Identifying and Diagnosing Faults: Learn to recognize common sprinkler head malfunctions (clogged nozzles, damaged components, etc.) and troubleshoot effectively using appropriate tools and techniques.

- Repair and Replacement Techniques: Gain hands-on experience with replacing or repairing faulty sprinkler heads, ensuring proper alignment and functionality. Understand the importance of using correct replacement parts.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols related to working with sprinkler systems, including lockout/tagout procedures and hazard identification.

- Hydraulic Calculations (Basic): While not always deeply tested, a foundational understanding of water pressure, flow rates, and their impact on sprinkler performance is beneficial.

- Tools and Equipment: Be familiar with the various tools and equipment used in sprinkler head inspection and repair (pressure gauges, wrenches, testing devices, etc.).

- Problem-Solving and Decision-Making: Practice analyzing complex scenarios and making informed decisions regarding repair strategies, prioritizing safety and efficiency.

Next Steps

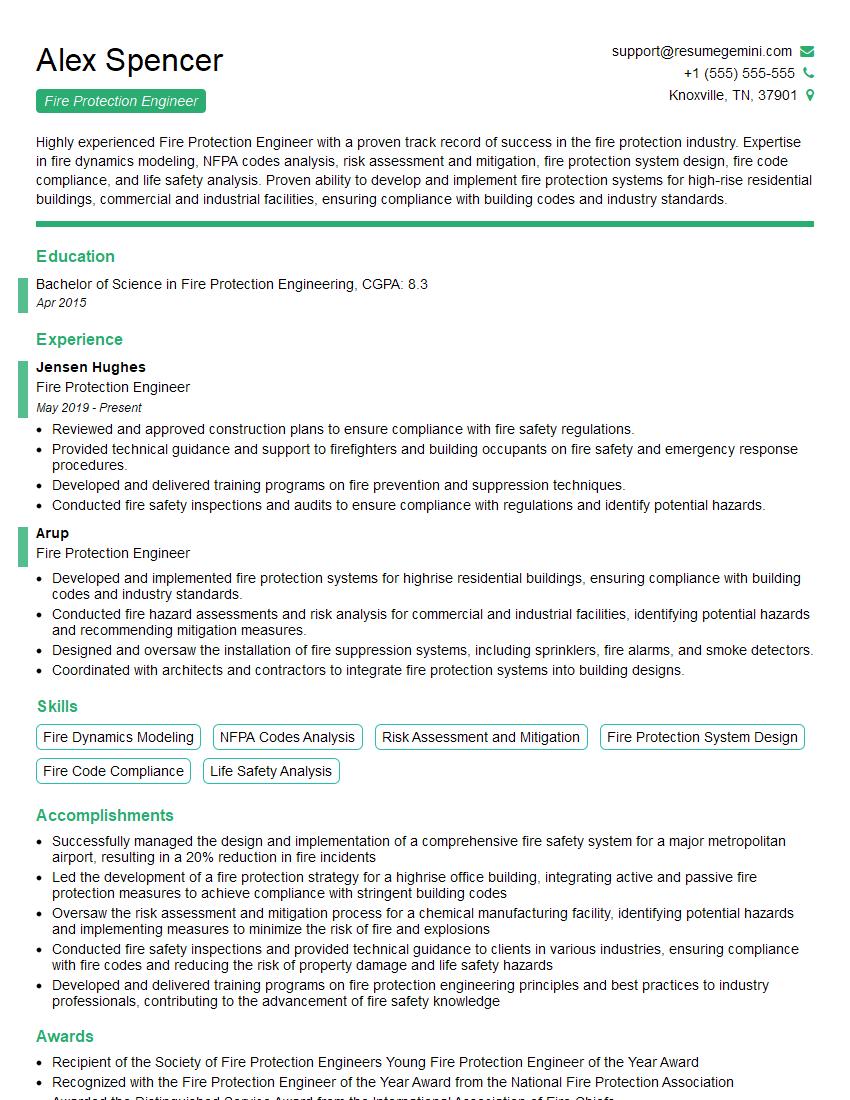

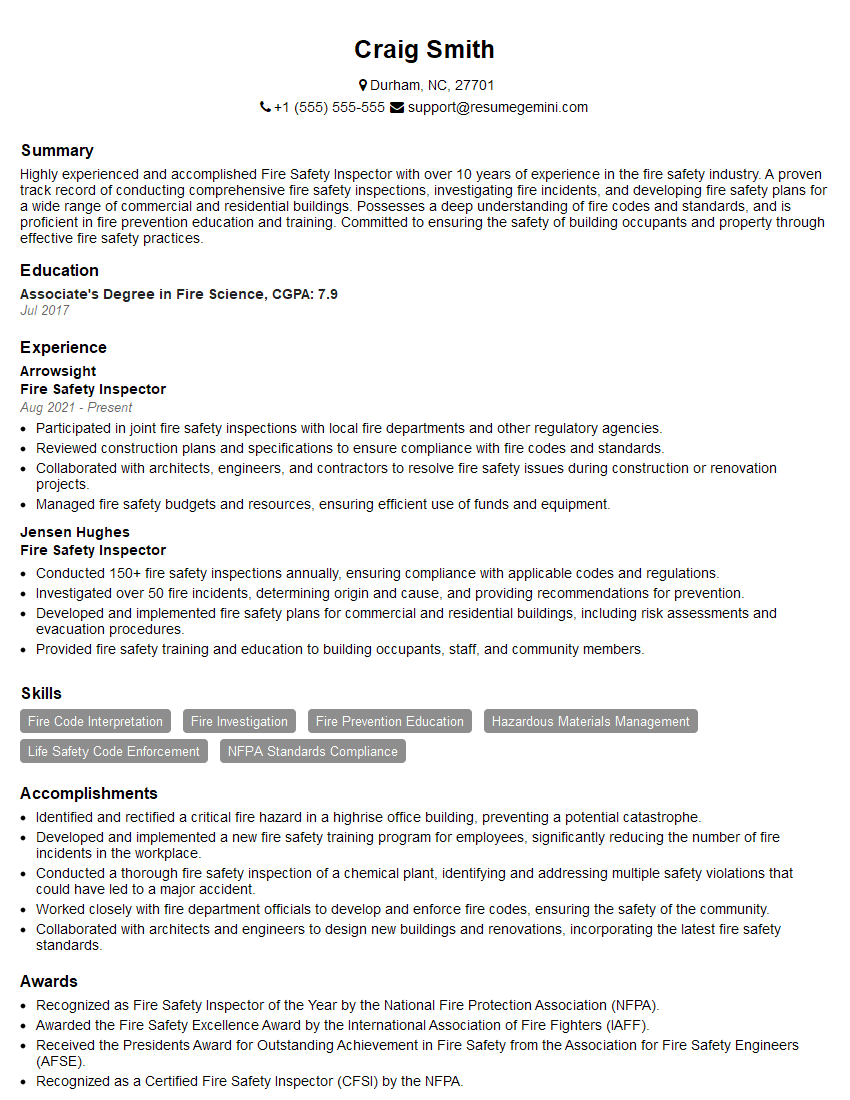

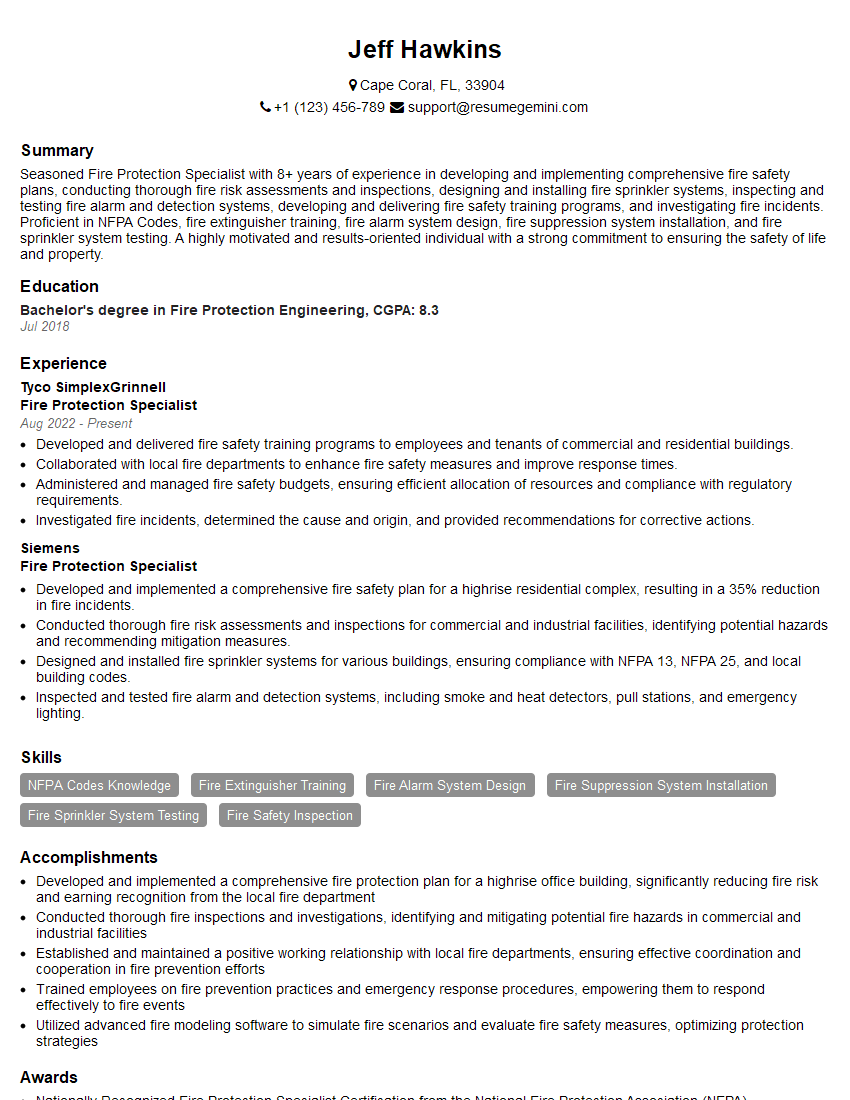

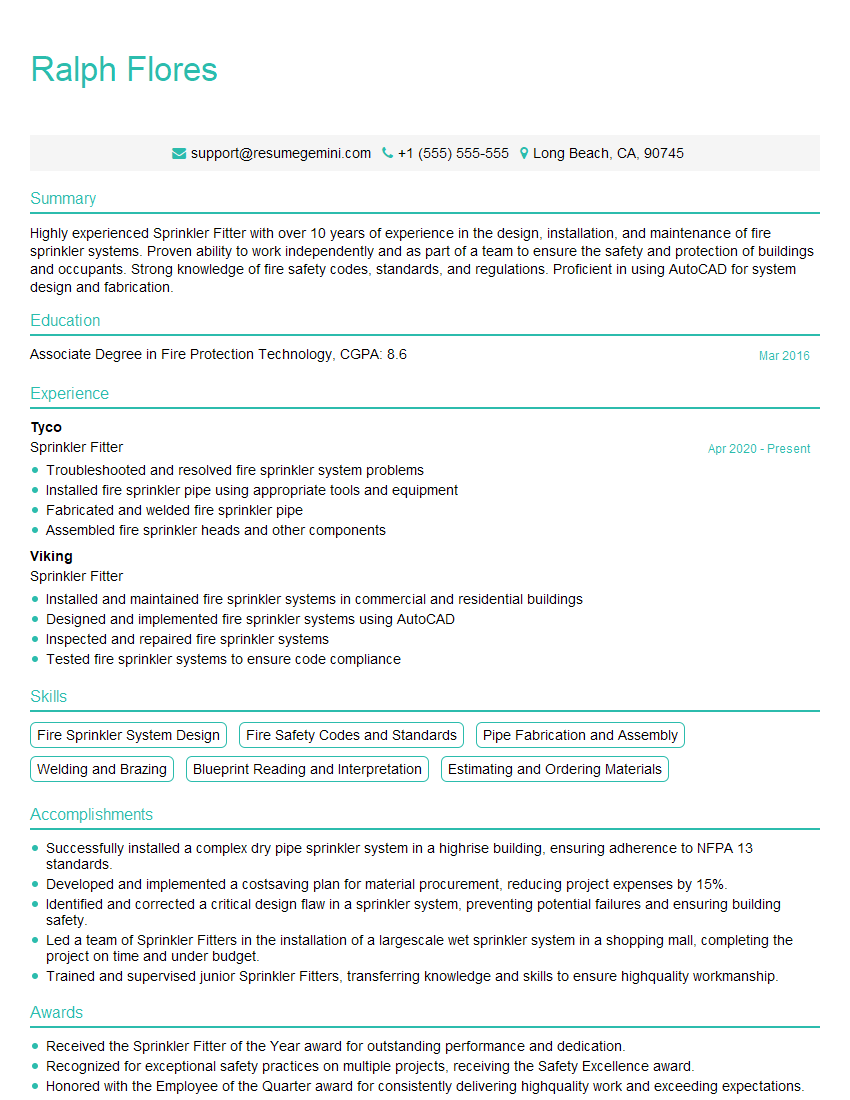

Mastering sprinkler head inspection and repair opens doors to rewarding and stable career opportunities within the fire protection industry. To stand out, create a compelling resume that showcases your skills and experience effectively. An ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise. Examples of resumes tailored to Sprinkler Head Inspection and Repair are available to guide you through the process. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.