Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Stained Glass Making interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Stained Glass Making Interview

Q 1. Describe your experience with different glass cutting techniques.

Glass cutting is fundamental to stained glass artistry. I’m proficient in several techniques, each offering unique advantages. The most common is using a glass cutter – a small, handheld tool with a hardened wheel that scores the glass. This score weakens the glass, allowing for a clean break when pressure is applied. I also utilize oil-fed cutters for smoother, more precise scoring, especially on intricate curves. For more complex shapes, I employ a grinding wheel, which allows for shaping and smoothing edges post-cutting. Finally, I use specialized nippers, which are essential for removing small pieces of glass or refining cuts made with a glass cutter. The choice of technique depends on the glass type, the design’s complexity, and the desired level of precision.

For instance, when working on a delicate floral design with many small petals, I’d rely heavily on nippers and potentially a grinding wheel for fine adjustments. In contrast, larger pieces for a more geometric window might primarily involve a glass cutter and perhaps only minimal grinding.

Q 2. Explain the process of creating a stained glass pattern from a design.

Translating a design into a workable stained glass pattern is a crucial step. It involves scaling the design to the final dimensions, considering the constraints of the available glass sheets. I usually start by creating a full-scale tracing of the design on paper. Next, I carefully break down the design into individual glass pieces. This includes defining the shape and size of each piece, paying close attention to how they fit together and maintain the integrity of the original design. This often involves creating a ‘pattern’ – a full-size template made of cardstock or other durable material, for each piece, ensuring accurate cutting and fitting.

Each pattern piece will then be used as a guide when cutting the corresponding glass pieces. Think of it like a jigsaw puzzle, but with glass! Creating an accurate and well-thought-out pattern is essential for a successful final product. A poorly planned pattern often leads to wasted glass and frustrated work. For complex designs, I utilize specialized computer software to assist in pattern creation and to optimize glass usage.

Q 3. What types of solder are used in stained glass work and what are their properties?

In stained glass work, we primarily use lead-based solder and tin-based solder. Lead solder, though increasingly less common due to safety concerns, is traditionally favored for its strength, ease of use, and its ability to create a strong, weather-resistant joint. It has a lower melting point, making it easier to work with. Tin solder, on the other hand, is a safer alternative and becoming more popular. It’s often used with a flux to help it flow smoothly, and is preferred for its lower toxicity. While it might require a slightly higher temperature to melt, the safety benefits often outweigh this minor inconvenience.

The choice of solder depends largely on personal preference and local regulations. I typically utilize tin-based solder in most of my projects, prioritizing safety while still maintaining high-quality results. The properties to consider include melting point, flow rate, strength, and toxicity, always weighing the trade-offs between ease of use and safety.

Q 4. How do you select the appropriate glass for a specific project?

Glass selection is paramount. It profoundly influences the final piece’s aesthetic and longevity. My choices depend on the project’s style, the light conditions, and the desired effect. For instance, I might use cathedral glass, known for its textured, translucent quality, for a traditional, religious window designed to diffuse light beautifully. Opalescent glass, with its milky translucence and vibrant colors, is perfect for more contemporary designs seeking a softer, less sharp glow. Antique glass, with its unique variations in color and texture, lends an old-world charm and adds character to a piece.

Beyond color, I carefully consider the glass’s thickness and stability. Thicker glass is more durable but requires more effort during cutting and soldering. The client’s budget also plays a significant role; antique glass, for example, tends to be more expensive than modern alternatives. Ultimately, it’s a balancing act between aesthetic vision, technical considerations, and practical limitations.

Q 5. Explain the process of foiling glass pieces.

Foiling is a technique used to create clean, precise lines between glass pieces, often providing a more modern look compared to traditional leaded glass. I typically use copper foil tape, a thin, self-adhesive tape, which is applied to the edges of the cut glass pieces. This foil acts as a barrier between the glass and the solder, ensuring a neat and professional finish. It also makes the soldering process simpler and more consistent.

The process involves carefully applying the foil tape, pressing it firmly to create a smooth, unbroken seal around the edges of the glass. Any excess foil is carefully trimmed using a sharp blade. Once all the pieces are foiled, they are assembled and soldered. The foil provides a clean, crisp line, and helps prevent the solder from seeping under the glass pieces, creating a much cleaner aesthetic.

Q 6. Describe your experience with different types of glass (e.g., cathedral, opalescent, antique).

My experience encompasses a wide array of glass types. Cathedral glass, with its distinctive textures and subtle color variations, allows for beautiful light diffusion and adds depth. Opalescent glass offers rich, luminous colors and a soft glow, perfect for modern or Art Nouveau styles. I frequently use antique glass, which gives a sense of history and authenticity due to its unique imperfections and aged patina. Each type has its own characteristics that affect how light interacts with it, and how it should be handled during the cutting and assembly process.

Beyond these, I work with stained glass, textured glass, streaky glass, and even fused glass, each with its own unique properties and application. The selection depends on the project’s requirements and artistic vision. I’ve worked on projects ranging from intricate Celtic knotwork using textured glass to vibrant floral arrangements using opalescent glass.

Q 7. What safety precautions do you take when working with glass and tools?

Safety is paramount. Working with glass and sharp tools requires vigilance. I always wear safety glasses to protect my eyes from flying glass shards or solder splatters. Gloves are essential to protect my hands from cuts and abrasions. I use a well-ventilated workspace to minimize exposure to fumes during soldering. Sharp tools are stored carefully, away from reach, when not in use. I always cut glass on a stable, padded surface to prevent the glass from slipping. Furthermore, I’m careful to maintain a clean and organized workspace to reduce the risk of accidental cuts or injuries.

I also regularly inspect my tools for damage and replace them as necessary. Safety isn’t just a set of rules; it’s a mindset I uphold throughout every stage of the process. It’s a continual commitment, not just an occasional consideration.

Q 8. How do you handle unexpected issues during a stained glass project?

Unexpected issues are part and parcel of stained glass work. Think of it like a complex puzzle where one wrong piece throws everything off. My approach is methodical. First, I carefully assess the problem. Is it a cracked piece of glass? A flawed lead line? A design error? Once identified, I determine the severity. Minor flaws might be addressed with careful repair; major ones may require redesigning a section or even the whole piece.

For example, if a piece of glass cracks during cutting, I evaluate if it’s salvageable. A small crack might be manageable, but a large one necessitates replacing the piece. I always have extra glass on hand in a variety of colors and textures to minimize downtime. My experience allows me to quickly adapt and find creative solutions, sometimes even turning a mistake into an unexpected design element!

- Assessment: Identify the problem’s nature and severity.

- Solution: Determine the best course of action – repair, replacement, or redesign.

- Adaptability: Flexibility is key; embrace unexpected opportunities.

Q 9. What software programs are you proficient in for stained glass design?

While many stained glass artists still rely on traditional drafting techniques, I’m proficient in several digital design programs. I use Adobe Illustrator extensively for creating precise vector-based designs. Its ability to manage intricate details and easily scale artwork is invaluable in stained glass. I also use CorelDRAW for similar reasons, offering a different workflow for those who prefer it. Additionally, I’m familiar with Photoshop for importing images and manipulating color palettes to get exactly the right shade and tone for a particular project. Finally, I utilize specialized glass design software, which helps with the exact calculations required for cutting and assembling.

For example, in Illustrator, I can create a detailed pattern, easily manipulate the scale for a specific window, and then export the design as a printable template for cutting my glass. This level of precision minimizes errors and saves significant time.

Q 10. Describe your experience with lead came and its installation.

Lead came is the quintessential material in traditional stained glass construction. It’s a thin, flexible strip of lead containing grooves that hold the glass pieces together. My experience encompasses all aspects of its use, from selecting the appropriate came profile (H-came, U-came, etc.) based on the project’s design and glass thickness, to the actual installation.

The installation process is painstaking and requires precision. I begin by carefully placing the cut glass pieces according to the design. Then, I use special came pliers to carefully shape and insert the lead came into the grooves, creating a strong, weatherproof seal. Experience helps me manage the lead consistently, ensuring even spacing and a neat, professional finish. This requires a steady hand, good eyesight, and a knack for detail. Poorly installed came can lead to leaks or structural instability, so proper technique is paramount.

For example, when working with intricate designs, I might use a thinner came for better detailing; for thicker glass, I’d use a more robust lead profile for strength.

Q 11. Explain the process of grouting and cleaning a finished stained glass piece.

Grouting and cleaning are crucial final steps that protect and enhance the stained glass piece. Grouting, using a cement-like material called grout, fills the spaces between the lead came, creating a weather-resistant seal and preventing drafts and water ingress. This is applied carefully with a specialized tool to ensure even distribution.

Cleaning requires gentle handling to avoid scratching the glass or damaging the lead. I use a soft cloth and a mild detergent solution or specialized glass cleaner. Avoiding harsh chemicals is vital. After cleaning, the piece should be carefully inspected for any remaining grout or debris.

For instance, after grouting, I allow ample time for it to fully cure before cleaning to prevent damaging the fresh grout. I then thoroughly clean the piece, paying special attention to the lead lines to remove any excess grout that might have hardened.

Q 12. How do you maintain and repair existing stained glass windows?

Maintaining and repairing existing stained glass windows requires a keen eye for detail and a delicate touch. Regular inspection is essential. Cracked or loose glass pieces are priority repairs. Lead came can degrade over time due to weathering, requiring replacement or reinforcement. The process involves carefully removing damaged pieces, cleaning the surrounding area, and installing new glass and came, matching the original style and technique as closely as possible.

For example, a common problem is loose or cracked came. I repair this by carefully removing the affected lead, cleaning the glass, and installing new came, ensuring a watertight seal. Sometimes, I need to replace entire panes, using historical techniques to match the original piece’s style, ensuring its longevity and aesthetic integrity.

Q 13. Describe your knowledge of different stained glass styles (e.g., Gothic, Art Nouveau).

My knowledge of stained glass styles spans centuries. Gothic style, prominent from the 12th to 16th centuries, is characterized by its vibrant colors, intricate tracery, and religious iconography. Think of the magnificent rose windows in cathedrals. Art Nouveau (late 19th and early 20th centuries) presents a contrasting style, featuring flowing organic lines, often incorporating nature-inspired motifs like flowers and leaves. The colors tend to be more muted and less intense compared to Gothic designs.

Beyond these, I am also familiar with other styles such as Arts and Crafts, emphasizing craftsmanship and simple, geometric patterns; and Tiffany style, known for its opalescent glass and highly detailed designs. Understanding these different styles is key to successfully restoring or creating authentic stained glass pieces.

Q 14. What is your experience with kiln-fired glass fusing?

Kiln-fired glass fusing is a completely different process than traditional lead came work. It involves layering different types of glass onto each other and then fusing them together in a kiln at high temperatures, resulting in a single piece of glass. This technique offers different creative possibilities, like creating textures and gradients that are impossible to achieve with traditional methods.

My experience with fusing is focused on creating decorative pieces, like small panels or jewelry. I’ve used both pre-cut glass and cut my own designs using specialized glass cutting tools. The process involves careful design planning, precise glass placement, and accurate kiln temperature control. Understanding different glass types and their behavior at high temperatures is crucial for successful fusing. It’s a complementary skill that adds to my overall stained glass capabilities.

Q 15. Explain the process of creating a stained glass lampshade.

Creating a stained glass lampshade involves a fascinating blend of artistry and technical skill. It begins with a design, which I usually collaborate on with the client. Then, I carefully select the glass pieces, considering color, texture, and the overall aesthetic. Each piece is cut to the exact dimensions using a glass cutter and then ground smooth to prevent sharp edges. Next, comes the foiling process; thin copper foil is applied to the edges of each glass piece, creating a strong and beautiful bond. After that, the pieces are carefully soldered together using a low-temperature lead-based solder and a soldering iron. This creates a strong and durable framework. Finally, after cleaning the solder and applying a patina for a more aged look (optional), the completed shade is fitted onto a suitable lamp base. The entire process requires precision, patience, and a keen eye for detail.

For example, I recently created a lampshade depicting a vibrant sunset over a cityscape. This required a complex layering of various shades of orange, yellow, pink, and blue glass to achieve the desired effect. The intricate detail of the buildings demanded meticulous cutting and soldering.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with different types of adhesives in stained glass work.

My experience with adhesives in stained glass encompasses various materials, each with its own strengths and weaknesses. Traditional lead cames, while classic and beautiful, require more experience. They need to be carefully sized and shaped to fit perfectly, ensuring good adhesion with the glass. I also use epoxy adhesives for certain projects, especially when working with unusual materials. Epoxies offer excellent strength and flexibility. However, they can be challenging to work with; clean up is essential. For smaller projects or repairs, I use specialized glass glues, which provide a quick and relatively clean solution, but typically aren’t as durable as lead or epoxy. Selecting the right adhesive is crucial for the longevity and integrity of the piece and must be chosen carefully based on project demands.

For instance, when working on a delicate Tiffany-style lamp, I’d choose epoxy for its flexibility and ability to fill small gaps without affecting the overall aesthetic, while a large window would benefit from the structural integrity of lead cames.

Q 17. How do you calculate the cost of a stained glass project?

Calculating the cost of a stained glass project is a multi-faceted process. It involves several key components: the cost of materials (glass, lead, solder, foil, etc.), the artist’s labor, and any additional expenses (like shipping or special tools). The pricing often includes the design consultation, the complexity and scale of the project, and the type of materials selected. For example, hand-blown art glass is substantially more expensive than standard sheet glass. Often, I provide a detailed breakdown for the client, outlining each cost component, to ensure transparency and mutual understanding.

For example, a small, simple panel might be priced based on a per-square-foot rate, while a large, complex window would involve a more detailed cost estimation, potentially including a project management fee to reflect the planning, coordination, and extensive time commitment.

Q 18. How do you handle client requests and revisions during a project?

Client communication is paramount. I maintain open and consistent communication throughout each stage of the project. Before starting, we have a detailed discussion about their vision and preferences. I create sketches and mock-ups to visualize the design. During the creation process, I provide regular updates, including photos or videos. I encourage client feedback at every stage and embrace revisions. My goal is to ensure the finished piece perfectly reflects their vision. I’m always open to discussion and modifications as long as they are feasible and do not fundamentally alter the project.

For example, one client initially wanted a traditional rose design but changed their mind during the design phase and opted for a more abstract representation of a blooming flower. It was a simple change that could be easily accommodated, and the result was something even more unique and meaningful to them.

Q 19. What are your strengths and weaknesses as a stained glass artist?

My strengths lie in my attention to detail, creative design skills, and my ability to translate a client’s vision into a tangible work of art. I am also adept at problem-solving, especially when faced with challenges during the creation process. I’m meticulous and strive for technical excellence in my work. My weakness, however, might be my perfectionism, which can sometimes extend project timelines. I’m working on improving my time management skills to balance quality with efficiency.

Q 20. How do you manage your time effectively during a stained glass project?

Effective time management is vital in stained glass work. I utilize project management tools like digital calendars and to-do lists to keep track of deadlines. I break down large projects into smaller, manageable tasks, which helps me stay focused and avoid feeling overwhelmed. I also dedicate specific time blocks for each task, which helps me maintain productivity. Prioritizing tasks based on their urgency and importance is critical. For example, cutting glass requires a dedicated period of concentrated effort. Similarly, soldering is best done in focused sessions.

Q 21. Describe your experience working independently versus collaboratively.

I enjoy both independent and collaborative work. Independent work allows for complete creative control and deep immersion in the artistic process. Collaborating with others, whether clients or fellow artists, provides diverse perspectives and enhances the creative process. Working with a team can be a great way to tackle larger projects. For instance, I’ve collaborated on large-scale architectural projects, dividing tasks according to individual strengths. This allows for a more efficient and comprehensive output. My approach is to utilize both methods depending on project demands.

Q 22. What techniques do you use to prevent glass breakage?

Preventing glass breakage in stained glass is paramount. It involves careful handling throughout the entire process, from selecting the right glass to the final installation. Think of it like building a delicate, beautiful puzzle – each piece needs respect.

Careful Glass Selection: Choosing high-quality, consistently thick glass minimizes the risk of shattering. Avoid glass with imperfections or stress marks.

Proper Cutting Techniques: Using sharp scoring tools and employing the correct scoring pressure ensures clean breaks and reduces chipping. I always emphasize a steady hand and precise movements.

Secure Foiling and Soldering: Properly applied foil creates a strong bond between glass pieces, distributing stress evenly. Likewise, consistent and thorough soldering strengthens the structure and seals the foil, preventing moisture ingress which could lead to cracking.

Safe Handling and Transportation: Protecting the finished piece during transport is vital. This often involves custom-made crates with cushioning materials to prevent impacts and vibrations.

Appropriate Installation: The stained glass must be correctly installed, whether in a window or other setting. This includes using appropriate supports and ensuring the structure is properly secured to prevent movement and stress.

Q 23. How do you maintain the quality and consistency of your work?

Maintaining quality and consistency in my work relies on a combination of meticulous planning, precise execution, and continuous self-assessment. Think of it like a skilled chef maintaining high standards in their kitchen – attention to detail is essential.

Standardized Procedures: I follow established processes for cutting, foiling, soldering, and finishing, ensuring uniformity across projects. This includes using calibrated tools and maintaining consistent working conditions.

Quality Control Checks: At each stage, I inspect my work for imperfections—checking for even foil application, consistent solder lines, and the absence of chips or cracks. This is a constant cycle of review and refinement.

Material Consistency: I source my materials from reputable suppliers, ensuring consistent quality in the glass and other components. This includes careful storage to protect against damage.

Continuous Learning: I regularly review my techniques and seek feedback to identify areas for improvement. This might involve experimenting with new tools or techniques or attending workshops to stay updated on best practices.

Q 24. Describe your process for troubleshooting common stained glass problems.

Troubleshooting in stained glass often involves a methodical approach, similar to diagnosing a mechanical problem. Experience plays a huge role here; I’ve encountered a vast range of issues.

Cracked Glass: This often points to improper handling, poor soldering, or stress from the structure. I would carefully examine the cracks to determine the cause and may need to replace the affected glass.

Uneven Solder Lines: This could indicate inconsistent heat application or improper flux application. Sometimes re-soldering is necessary, or if more serious, I’ll re-foil the area.

Loose Glass Pieces: This typically means insufficient foil or poor soldering. Reinforcing the solder joints or re-foiling the area usually resolves the problem.

Discoloration: This might be due to environmental factors, improper cleaning, or the use of incompatible materials. I’d determine the cause and take appropriate corrective actions, which may involve cleaning or material replacement.

In every case, careful observation and methodical analysis are key to successful troubleshooting. Sometimes, a magnifying glass and good lighting are my best tools!

Q 25. How do you stay current with trends and advancements in the field of stained glass?

Staying current in stained glass involves a multifaceted approach, much like any creative field. It’s a constant evolution, embracing new techniques and designs.

Industry Publications and Websites: I regularly read specialist magazines and online resources to keep abreast of new techniques, materials, and artistic trends.

Workshops and Conferences: Attending workshops and conferences allows me to learn from other artists, network, and explore new ideas firsthand.

Museum Visits and Gallery Exhibitions: Studying historical and contemporary stained glass work in person provides immense inspiration and expands my knowledge of different styles and techniques.

Online Communities and Forums: Participating in online communities and forums allows me to connect with other stained-glass artists, share knowledge, and seek advice.

Q 26. What is your understanding of color theory and its application to stained glass design?

Color theory is fundamental to stained glass design. It’s about understanding how colors interact with each other, affecting the overall mood and visual impact of the piece. It’s like painting with light!

Color Harmonies: I often use color harmonies—such as analogous (colors next to each other on the color wheel) or complementary (colors opposite each other)—to create balanced and pleasing compositions.

Light and Shadow: Understanding how light affects the perception of color is critical. The same color will appear different in different lighting conditions. I consider this throughout the design process.

Warm and Cool Colors: I use warm colors (reds, oranges, yellows) to create a sense of warmth and energy, and cool colors (blues, greens, purples) for calmness and serenity. The interplay of these colors is vital in creating a desired atmosphere.

Value and Saturation: Controlling the value (lightness or darkness) and saturation (intensity) of colors helps to create depth and visual interest. This involves careful selection of glass and the arrangement of pieces.

Q 27. Explain the importance of proper lighting in showcasing stained glass work.

Proper lighting is crucial for showcasing stained glass. Think of it as the final, vital touch, bringing the artwork to life. Without it, the beauty and detail are lost.

Natural Light: Natural light, especially diffused sunlight, is ideal. It allows the colors to shimmer and reveal their full brilliance.

Artificial Light: When natural light is insufficient, carefully selected artificial lighting is necessary. LEDs are a good option as they offer high color rendering and minimal heat output, reducing the risk of damage.

Lighting Placement: The position of light sources is critical. Overhead lighting or side lighting can drastically change the appearance of the glass, emphasizing different details and color interactions. I often consider the position of the sun at different times of the day.

The goal is to enhance the vibrant colors and intricate details of the piece and allow the viewer to fully appreciate its beauty.

Q 28. Describe your experience with restoration and conservation of antique stained glass.

Restoring and conserving antique stained glass requires specialized knowledge and a meticulous approach. It’s like restoring a historical artifact – respect for the past is vital.

Assessment and Documentation: The initial step involves a thorough assessment of the glass’ condition, documenting existing damage and degradation. Photography and detailed notes are crucial.

Careful Cleaning: Gentle cleaning techniques are used to remove dirt and grime without damaging the fragile glass. This often involves specialized cleaning solutions and soft brushes.

Repair and Consolidation: Damaged areas are carefully repaired using traditional methods and materials, ensuring the structural integrity is maintained. This might involve lead replacement or the careful patching of cracks.

Re-leading: If extensive lead repairs are needed, I use traditional techniques to ensure a historically appropriate aesthetic, matching the style and age of the original work.

Protective Measures: Once the restoration is complete, I would put measures in place to protect the glass from further deterioration, such as UV protection or specialized coatings.

In every restoration, my priority is to preserve the historical integrity of the artwork while ensuring its longevity.

Key Topics to Learn for Your Stained Glass Making Interview

- Glass Selection and Properties: Understanding different types of glass (e.g., float, antique, textured), their optical properties (translucency, color saturation), and appropriate applications for various projects. Practical application: Explaining your choices of glass for a specific project based on its aesthetic and structural requirements.

- Cutting and Grinding Techniques: Mastering safe and precise glass cutting methods (e.g., oil-fed glass cutter, scoring, snapping), and techniques for grinding and smoothing edges for a clean, professional finish. Practical application: Demonstrating your skill in cutting intricate shapes and achieving precise dimensions.

- Foil and Solder Techniques: Proficiency in applying copper foil to glass pieces accurately and consistently, and expertise in soldering techniques for creating strong, durable joints. Practical application: Explaining different soldering methods and their suitability for different projects, highlighting your ability to troubleshoot solder issues.

- Pattern Design and Transfer: Understanding and applying different methods for transferring patterns onto glass, including full-scale drawings, tracing, and projecting images. Practical application: Describing your process for creating and transferring complex designs accurately onto glass.

- Lead Came Construction: Knowledge of traditional lead came techniques, including lead selection, came fitting, and soldering. Practical application: Explaining the challenges of working with lead came and your solutions for achieving straight lines and strong joints.

- Grouting and Finishing: Understanding the importance of proper grouting techniques to create a watertight and aesthetically pleasing finish. Practical application: Describing your approach to cleaning and finishing a piece for optimal durability and visual appeal.

- Safety Procedures and Studio Practices: Demonstrating knowledge of safe glass handling practices, appropriate personal protective equipment (PPE), and studio organization for efficiency and safety. Practical application: Describing your approach to maintaining a safe and organized work environment.

- Project Planning and Management: Ability to estimate time and materials needed for a project, manage budgets, and meet deadlines. Practical application: Describing your approach to planning and executing complex stained glass projects.

Next Steps

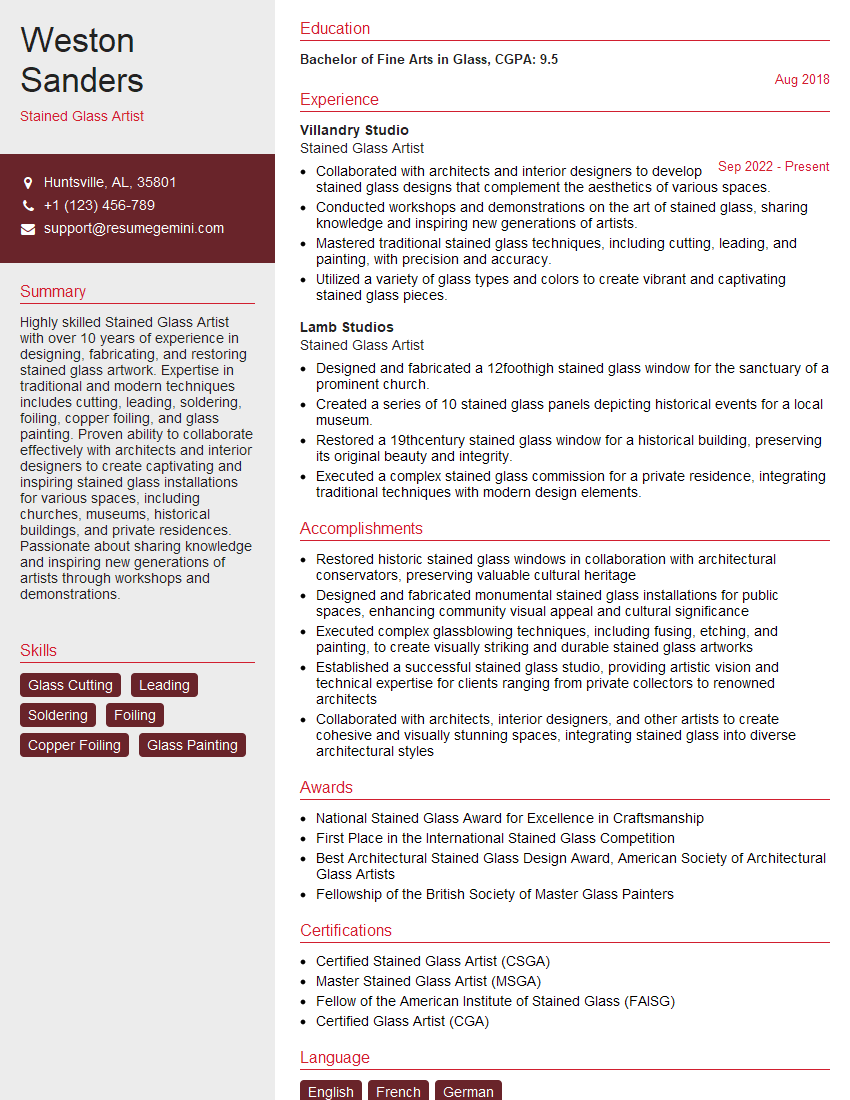

Mastering stained glass making opens doors to a fulfilling and creative career, offering opportunities in artistic expression, restoration, and even commercial projects. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They even provide examples of resumes tailored specifically to the stained glass making field to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.