Cracking a skill-specific interview, like one for Steel Fabrication CAD/CAM, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Steel Fabrication CAD/CAM Interview

Q 1. Explain your experience with different CAD/CAM software packages used in steel fabrication.

Throughout my career, I’ve gained extensive experience with several leading CAD/CAM software packages commonly used in steel fabrication. My proficiency spans from industry-standard solutions like Tekla Structures, Autodesk Inventor CAM, and AutoCAD to specialized packages such as SolidWorks and its CAM add-ins. Each software has its strengths; for example, Tekla Structures excels in large-scale structural steel projects thanks to its powerful detailing capabilities and clash detection tools. Autodesk Inventor CAM shines when it comes to complex 3D modeling and machining simulations, while SolidWorks offers a versatile platform suitable for both design and CAM operations. My familiarity with these diverse platforms allows me to adapt quickly to any project’s specific requirements and choose the most appropriate tool for the job. For instance, on a recent high-rise building project, Tekla’s BIM capabilities were crucial in coordinating different trades. On smaller projects, the efficiency of SolidWorks proved advantageous.

Q 2. Describe your process for creating a fabrication drawing from a 3D model.

Creating fabrication drawings from a 3D model is a systematic process. It begins with verifying the accuracy and completeness of the 3D model, checking for any errors or inconsistencies. Next, I utilize the software’s features to generate detailed 2D drawings, including sections, elevations, and detailed parts lists. These drawings must adhere to industry standards and client-specific requirements. This typically involves creating different views of the model to showcase all necessary dimensions, tolerances, and material specifications. I always focus on clarity, making sure annotations are precise and unambiguous. For instance, if dealing with complex welds, I include detailed close-up views with weld symbols according to AWS standards. Finally, I perform a thorough review of the drawings before release, checking for any potential ambiguities or errors that could lead to fabrication issues. Think of it like creating a detailed instruction manual for the fabrication team – every step needs to be clear and precise to avoid costly mistakes.

Q 3. How do you handle clash detection and resolution in steel fabrication projects?

Clash detection is critical in steel fabrication, particularly in large and intricate projects where multiple components interact. I employ several strategies to address this. Firstly, I leverage the built-in clash detection features within the CAD software, like those found in Tekla Structures. These tools analyze the 3D model and highlight potential collisions between different elements – such as beams interfering with pipes or ductwork. Once a clash is identified, I systematically resolve it, often through iterative design adjustments and coordination with other disciplines (e.g., MEP engineers). This could involve re-routing pipes, slightly adjusting beam positions, or modifying component designs to create sufficient clearance. Furthermore, regular meetings and detailed communication with all stakeholders are essential for efficient clash resolution. I document all changes meticulously to ensure version control and clear traceability. Ignoring clashes can lead to costly on-site rework and project delays, so proactive clash detection and resolution is paramount.

Q 4. What are your preferred methods for optimizing nesting in sheet metal fabrication?

Optimizing nesting in sheet metal fabrication is crucial for minimizing material waste and maximizing cost-effectiveness. My preferred methods involve a combination of manual and automated techniques. I start by analyzing the shape and quantity of each part, then use the software’s automated nesting tools to generate initial layouts. These tools often employ algorithms to arrange parts efficiently, minimizing the overall sheet material usage. However, I rarely rely solely on automation. I manually refine the automated layouts, often finding further optimizations by strategically arranging parts and using my experience to identify better placement solutions. This often involves rotating parts, mirroring them, or carefully arranging smaller pieces in gaps to further reduce waste. Software often provides various nesting algorithms (e.g., ‘best-fit’, ‘first-fit’), and choosing the best one depends on factors like part complexity and sheet size. Furthermore, I regularly review the nesting results, comparing different layouts to ensure I’ve achieved the most economical solution.

Q 5. Explain your understanding of different steel grades and their properties in relation to fabrication.

Understanding steel grades and their properties is fundamental to successful steel fabrication. Different steel grades possess varying strength, weldability, formability, and machinability characteristics. For instance, A36 is a common structural steel grade suitable for many applications, offering a good balance of strength and weldability. Higher-strength steels like A992 are used where weight reduction is critical, but they might require specialized welding techniques and procedures. Stainless steel grades (e.g., 304, 316) are chosen for corrosion resistance, but they exhibit different machining characteristics compared to carbon steels. My knowledge encompasses not only the material properties but also how these properties impact the fabrication process. I choose the appropriate steel grade considering factors like the design load, environmental conditions, and the required fabrication methods. I meticulously specify the correct grade in all drawings and specifications to avoid errors and ensure that the final product meets the design requirements and relevant standards.

Q 6. How do you ensure accuracy and precision in your CAD/CAM work for steel fabrication?

Ensuring accuracy and precision is paramount in steel fabrication; even minor errors can lead to significant problems. My approach incorporates several measures: Firstly, I use precise modeling techniques in CAD, adhering to strict tolerances and incorporating constraints to maintain dimensional accuracy throughout the design process. Secondly, I regularly verify the model using automated checks and manual inspections to detect any discrepancies early on. Thirdly, I maintain detailed documentation, recording all design changes and decisions to ensure traceability and accountability. I employ units management diligently; always checking that units are consistent throughout the model to avoid costly mistakes. Finally, I incorporate quality control checks at every stage, from model creation to drawing generation and CAM programming. The adage ‘measure twice, cut once’ applies here – preventative measures are far more efficient than corrective actions.

Q 7. Describe your experience with CNC programming for steel cutting and machining.

I possess extensive experience in CNC programming for steel cutting and machining, primarily using G-code. My expertise encompasses various cutting methods, including plasma cutting, laser cutting, and oxy-fuel cutting, along with machining operations such as milling and drilling. I’m proficient in generating G-code using both CAM software and manual programming techniques. The choice depends on the project complexity and the available software tools. For example, complex 3D shapes are usually programmed through CAM software, while simple cuts can be programmed manually. I’m also adept at optimizing cutting paths to minimize cutting time and improve efficiency. This involves analyzing part geometry and selecting appropriate cutting speeds, feed rates, and tool paths to maximize productivity while ensuring precise and accurate results. Before implementing the code on the CNC machine, I always simulate the process within the CAM software to verify that the toolpaths are correct and avoid potential collisions. A thorough understanding of machine capabilities and limitations is crucial in this process; it allows for generating efficient and safe G-code.

Q 8. How do you manage revisions and updates to steel fabrication drawings?

Managing revisions and updates in steel fabrication drawings requires a robust system to ensure accuracy and prevent errors. We typically use a version control system, often integrated with our CAD software. Each revision is clearly numbered and dated, detailing the changes made. This might involve a simple change in a dimension, a modification to a connection detail, or a complete redesign of a component.

For example, imagine a change in the thickness of a steel plate. The original drawing (Revision A) specifies 10mm. A later revision (Revision B) changes this to 12mm due to a structural analysis update. The revision history clearly documents this change, indicating the date, author, and a description of the alteration. This allows traceability and accountability, crucial for error prevention and resolving potential discrepancies later in the fabrication process.

Revisions are communicated to all relevant parties – fabrication teams, engineers, and clients – through formal change orders. These orders might include impact assessments, explaining the consequences of the revision, and detailing any necessary adjustments to the project schedule or budget.

- Employing a version control system (like Autodesk Vault or similar)

- Implementing a clear revision numbering scheme (e.g., A, B, C, or 1.0, 1.1, 1.2)

- Maintaining a detailed revision log with descriptions and author information

- Distributing revisions via formal change orders

Q 9. Explain your familiarity with different welding processes and their impact on design.

My experience encompasses various welding processes, each with its own impact on design considerations. The choice of welding process depends heavily on factors such as material thickness, joint type, access limitations, and required weld quality.

- Shielded Metal Arc Welding (SMAW): Common and versatile, suitable for various materials and thicknesses, but prone to porosity and requires skilled welders for consistent results. Design considerations should allow for appropriate access for the welder.

- Gas Metal Arc Welding (GMAW): High deposition rate, good for thick sections, and relatively easy to automate. Design should consider the need for shielding gas supply and potentially the use of wire feeders.

- Gas Tungsten Arc Welding (GTAW): Produces high-quality welds with excellent penetration and appearance, ideal for thin sections and critical applications. However, it’s slower and requires a skilled welder. Design should account for the precision required.

- Flux-Cored Arc Welding (FCAW): Offers good penetration and speed, suitable for outdoor use. Design aspects should ensure sufficient ventilation and consider the potential for spatter.

For example, when designing a complex structure with thin-walled members, GTAW might be specified to ensure high-quality welds with minimal distortion. Conversely, for a large, heavy-duty structure, GMAW or FCAW might be more efficient. The weld joint design itself is also heavily influenced by the chosen process; for instance, a fillet weld might be appropriate for SMAW, while a more complex groove weld might be used with GTAW.

Q 10. What is your experience with creating and managing bills of materials (BOMs)?

Creating and managing bills of materials (BOMs) is a critical aspect of steel fabrication, directly impacting cost, procurement, and fabrication time. I have extensive experience generating BOMs using both CAD software and dedicated BOM management systems. A well-structured BOM lists every individual component needed for a project, including material type, dimensions, quantity, and any necessary finishing or treatment specifications.

In my workflow, the BOM is often automatically generated from the CAD model. This ensures consistency between the design and the actual materials ordered. However, manual checks and adjustments are always performed to account for factors such as material wastage or special requirements. The BOM is then used for purchasing, inventory management, and cost estimation. It also serves as a crucial reference point for the fabrication team.

For example, a BOM for a simple steel frame might include entries such as: 5 x 200mm x 100mm x 10mm steel plates (Grade A36), 10 x 10mm diameter bolts (Grade 8.8), 10 x Washers (zinc-coated), 1 x Primer coat (grey). The details help procure all necessary materials efficiently.

Q 11. How do you ensure the manufacturability of your designs in steel fabrication?

Ensuring manufacturability is paramount in steel fabrication. It involves considering various aspects throughout the design process, from the initial concept to the final fabrication. Key considerations include:

- Material Selection: Choosing readily available materials that meet strength and other specifications, minimizing lead times and costs.

- Joint Design: Creating connections that are easily weldable or bolted, accessible for the fabrication team, and structurally sound.

- Component Sizes: Avoiding excessively large or complex components that are difficult to handle and fabricate. We aim for efficient workflow.

- Tolerances: Defining realistic tolerances to allow for slight variations during fabrication, and still maintaining accurate assembly.

- Fabrication Techniques: Considering the capabilities of the available machinery and the expertise of the fabrication team.

For example, if a component is designed with tight radii, this might be impossible or extremely expensive to fabricate using standard bending equipment. This would make the design unmanufacturable without adjustment. I constantly review designs with the fabrication team to catch these issues early.

Q 12. Describe your experience with different types of steel connections and their applications.

I have experience with a wide range of steel connections, each suited to specific applications and load conditions.

- Bolted Connections: Simple, readily adjustable, and suitable for various load types. Different bolt types and configurations (e.g., high-strength bolts, shear connectors) are selected based on strength and stiffness requirements.

- Welded Connections: Stronger and more efficient for some applications, but require skilled welders and careful design to avoid weld defects. Different weld types (e.g., fillet welds, groove welds) offer varying strength characteristics.

- Pinned Connections: Used in structures requiring precise alignment and articulation, like those with moving parts.

- Moment Connections: Designed to transmit both shear and bending moments, often used in more complex structural systems.

For example, a simple beam-column connection in a light-duty structure might use bolted connections for ease of assembly and adjustment. In contrast, a connection in a high-rise building would likely use more robust welded connections with careful consideration of stress concentrations and fatigue analysis. The selection is always a balance between structural performance, cost, and ease of fabrication.

Q 13. How do you handle tolerances and dimensional control in steel fabrication?

Tolerance control is crucial for accurate assembly and proper structural performance. We adhere to industry standards and client specifications to manage tolerances throughout the fabrication process.

During the design phase, tolerances are explicitly defined for all dimensions and angles. These are carefully considered in relation to fabrication methods and the capabilities of the machinery. Overly tight tolerances can increase costs and fabrication time, while overly loose tolerances can compromise the structural integrity. We utilize GD&T (Geometric Dimensioning and Tolerancing) to clearly communicate dimensional and geometric requirements.

For example, a tolerance might be specified as +/- 1mm on a linear dimension and +/- 0.5 degrees on an angle. This ensures that all components will fit within defined limits and that the assembled structure meets the required specifications. Regular quality checks, including dimensional inspections during and after fabrication, ensure adherence to these tolerances.

Q 14. What are your methods for quality control and inspection in steel fabrication?

Quality control and inspection in steel fabrication is a multi-stage process, starting from material selection and continuing through every step of fabrication and assembly. A robust quality control system comprises several key elements:

- Material Inspection: Checking the quality of incoming steel, verifying compliance with specified grades and dimensions.

- Process Control: Monitoring the fabrication processes, ensuring adherence to procedures and standards.

- Dimensional Inspection: Regularly checking the dimensions of components throughout fabrication, using tools such as calipers, measuring tapes, and coordinate measuring machines (CMMs).

- Welding Inspection: Employing visual inspection, non-destructive testing (NDT) methods like radiography or ultrasonic testing, and sometimes destructive testing to verify the quality of welds.

- Final Inspection: A thorough inspection of the completed structure, verifying compliance with the design and specifications before delivery.

Documentation is essential at each stage, creating a verifiable audit trail. Regular training and adherence to industry best practices help to maintain a high level of quality in our projects.

Q 15. Explain your understanding of different steel fabrication techniques (e.g., welding, cutting, bending).

Steel fabrication relies on several key techniques to transform raw steel into finished components. Let’s explore three fundamental processes: welding, cutting, and bending.

- Welding: This is a joining process that fuses two or more pieces of steel together using heat and sometimes filler material. Different welding methods exist, each suited for specific applications and material thicknesses. For example, MIG (Metal Inert Gas) welding is commonly used for its speed and ease of use in many fabrication shops, while TIG (Tungsten Inert Gas) welding offers superior precision and quality for more intricate work. The selection of the welding process significantly impacts the strength and quality of the final product. Incorrect welding parameters can lead to defects like porosity or lack of fusion.

- Cutting: This involves severing steel using various methods. Common techniques include plasma cutting (using a high-velocity jet of plasma), laser cutting (using a highly focused laser beam), and oxy-fuel cutting (using a combination of oxygen and fuel gases). Each method offers unique advantages. For instance, laser cutting is known for its precision and ability to cut intricate shapes, while plasma cutting is more cost-effective for thicker materials. The choice of cutting method depends on factors like material thickness, desired accuracy, and budget.

- Bending: This technique shapes steel into desired angles or curves. This can be achieved through various means, such as press brakes (using hydraulic pressure to bend sheets of metal) or roll forming (using rollers to bend longer lengths of steel into continuous shapes). Precise bending is crucial for ensuring the structural integrity and dimensional accuracy of the final component. Bending involves considerations of material properties, bending radius, and the prevention of material cracking or buckling.

Understanding these techniques and their limitations is essential for effective steel fabrication design and process planning. The selection of the appropriate technique is often determined by factors such as material thickness, desired precision, production volume, and cost.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you utilize simulation tools to verify the accuracy and feasibility of your designs?

Simulation tools are invaluable for verifying the accuracy and feasibility of steel fabrication designs before actual production. Software packages like Autodesk Robot Structural Analysis Professional or Abaqus allow us to model the structure, apply loads (dead loads, live loads, wind loads, etc.), and analyze stress and strain distributions. This predictive analysis helps identify potential weak points, structural deficiencies, or areas requiring design adjustments. For example, we can simulate welding distortion to predict how the parts might warp during welding and compensate in the design. Finite Element Analysis (FEA) simulations help us understand how components will behave under various loading conditions, preventing costly failures in the real world. Before committing to expensive steel cutting and welding, we can refine the design until we’re confident it meets all structural and performance requirements.

Beyond structural analysis, we also use simulation for other aspects, like nesting (optimizing material usage to minimize waste), robotic path planning (to determine the most efficient robotic welding sequences), and even predicting the heat flow during welding to minimize distortion. This allows for a more efficient and cost-effective fabrication process.

Q 17. How do you stay updated on the latest advancements in steel fabrication CAD/CAM technology?

Staying current in the rapidly evolving field of steel fabrication CAD/CAM requires a multi-pronged approach. I actively participate in industry conferences and workshops like those hosted by organizations focusing on steel construction and manufacturing. These events provide opportunities to network with other professionals and learn about the latest advancements firsthand.

Furthermore, I subscribe to relevant industry publications and online journals, and regularly follow thought leaders and experts on platforms like LinkedIn. This keeps me abreast of new software releases, emerging technologies (such as additive manufacturing for steel), and innovative design methodologies.

Continuous learning is a priority. I actively seek out online courses and tutorials to improve my skills in specific software packages, and I participate in training programs offered by software vendors to enhance my proficiency in new features and functionalities. This constant pursuit of knowledge ensures I’m at the forefront of the industry.

Q 18. Describe a time you had to troubleshoot a problem in a steel fabrication project.

In one project involving a complex steel frame for a high-rise building, we encountered significant challenges during the fabrication of a crucial node connecting several beams. Initial simulations predicted acceptable stress levels, but during assembly, we observed significant warping and distortion near the weld joints. This affected the overall dimensional accuracy and threatened to compromise the structural integrity.

Our troubleshooting process began with a thorough review of the welding procedures and parameters. We discovered that the heat input during welding was higher than anticipated, leading to excessive warping. We then used a combination of techniques to mitigate the problem. First, we implemented pre-heating of the steel components to reduce thermal gradients during welding. Second, we adjusted the welding sequence to minimize distortion. Finally, we utilized precision machining to correct minor dimensional discrepancies. Through careful analysis, adjustments, and meticulous execution, we successfully resolved the issue and delivered a structurally sound and dimensionally accurate component, avoiding delays and costly rework.

Q 19. How do you collaborate effectively with other team members in a steel fabrication environment?

Effective collaboration is paramount in steel fabrication. I actively participate in regular team meetings and design reviews to ensure clear communication and alignment on project goals and timelines. We employ project management software (such as Microsoft Project or similar) to track progress, identify potential bottlenecks, and maintain transparency throughout the process.

I believe in open communication. I actively listen to team members’ ideas, perspectives, and concerns. I am comfortable sharing my expertise and knowledge, while also readily seeking input from others. This collaborative approach ensures that all perspectives are considered, leading to better solutions and more robust designs. When disagreements arise, we prioritize constructive dialogue and focus on finding mutually agreeable solutions. I always prioritize maintaining a professional and respectful working environment.

Q 20. What are your experience with different file formats used in steel fabrication (e.g., DXF, DWG, DSTV)?

I possess extensive experience working with various file formats commonly used in steel fabrication. These include:

- DXF (Drawing Exchange Format): A widely used vector graphics format that is compatible with many CAD software applications. It’s commonly used for exchanging 2D drawings between different systems.

- DWG (Drawing): Autodesk’s proprietary format for storing CAD drawings. It supports 2D and 3D models and contains rich design information. It’s the industry standard for many engineering and design firms.

- DSTV (Data Standard for Steel Construction): A standardized format specifically designed for exchanging structural steel data between different software applications and manufacturing processes. It contains detailed information about the steel members, connections, and fabrication details. It is crucial for streamlining the workflow between design and fabrication.

My proficiency in these formats enables seamless data exchange with colleagues, clients, and fabrication shops, minimizing errors and ensuring accuracy throughout the design and construction process. I understand the strengths and limitations of each format and choose the most appropriate one depending on the context and the needs of the project.

Q 21. Explain your familiarity with different types of steel structural members (e.g., beams, columns, plates).

My understanding of steel structural members is comprehensive. I am familiar with a wide range of components, including:

- Beams: Horizontal structural members designed to carry loads primarily along their length. These can be I-beams, wide-flange beams, channels, or other shapes, each with unique strength and stiffness characteristics. I understand how to select appropriate beams based on load requirements and span lengths, considering factors such as bending moment, shear force, and deflection.

- Columns: Vertical structural members designed to carry compressive loads. Similar to beams, columns come in various shapes and sizes, and their selection depends on load capacity, slenderness ratio, and buckling considerations. I am proficient in column design calculations according to relevant building codes.

- Plates: Flat steel members used for various purposes, such as base plates for columns, connection plates, and shear plates. The selection of plate thickness and dimensions is critical for ensuring adequate strength and stability under expected loads.

In addition to these, I am also familiar with other structural members such as angles, tees, and other custom shapes, often used in connection details. My experience extends to understanding the material properties of various steel grades, their strengths, and their limitations, ensuring the design meets all safety and performance requirements.

Q 22. How do you address changes in project scope or requirements during the steel fabrication process?

Addressing scope changes in steel fabrication requires a structured approach. Think of it like building with LEGOs – a change in the blueprint means you might need to rebuild sections. First, I’d meticulously review the change request, quantifying the impact on materials, labor, and timelines. This involves careful analysis of the existing CAD models and drawings to understand the ripple effect. Then, I’d use the CAD software to model the proposed changes, generating updated drawings and material lists. Communication is crucial; I’d update stakeholders—project managers, engineers, and fabricators—on the revised plan, including any cost or schedule implications. This transparent approach minimizes disruptions and maintains project integrity. For example, if a beam needs to be lengthened, I’d update the model, generate new CNC cutting instructions, and check for interference with other components. The updated design would be reviewed and approved before proceeding to fabrication.

Q 23. What is your experience with creating and interpreting fabrication shop drawings?

I have extensive experience in creating and interpreting fabrication shop drawings, a critical aspect of steel fabrication projects. My process starts with understanding the structural engineer’s design intent. This involves detailed review of architectural plans and structural calculations. Then, I utilize CAD software like Tekla Structures or AutoCAD to create detailed fabrication drawings, including dimensions, material specifications (grade, thickness), weld symbols, and cut lists. These drawings serve as blueprints for the fabrication shop. I incorporate annotations and notes to ensure clarity, minimizing room for error in the shop floor. Interpreting existing drawings involves verifying dimensions, checking for inconsistencies, and ensuring compliance with codes and standards. I often use redlining techniques to highlight changes or potential issues found during the review process. For instance, I once identified a conflict in a drawing that could have caused misalignment of two critical structural members – early identification saved substantial time and cost.

Q 24. Describe your understanding of safety regulations and procedures relevant to steel fabrication.

Safety is paramount in steel fabrication. My understanding encompasses OSHA regulations, specifically those related to fall protection, lockout/tagout procedures, personal protective equipment (PPE) use (hard hats, safety glasses, steel-toed boots), and safe handling of materials. I’m familiar with the hazards associated with machinery like CNC cutting machines, welding equipment, and cranes. Pre-job hazard analysis is essential, and I actively participate in site safety meetings and toolbox talks. I enforce the use of appropriate PPE and ensure machines are properly maintained and guarded. Furthermore, I’m trained in emergency response procedures, including recognizing and reacting to fire hazards, and knowing how to properly use fire extinguishers. We follow strict procedures for material handling, ensuring loads are properly secured to prevent accidents. Imagine it like a conductor of an orchestra, ensuring every instrument (worker and machine) plays safely and in harmony.

Q 25. How familiar are you with robotic welding systems and their programming?

I possess a strong understanding of robotic welding systems and their programming. My experience includes using various robotic welding brands, including Fanuc and ABB. This involves programming the robots using specialized software like RoboGuide or similar platforms. Programming entails defining weld paths, parameters (speed, voltage, amperage), and joint types, often based on data extracted from CAD models. I’m also skilled in troubleshooting and maintaining robotic welding systems. I understand the importance of proper calibration and preventative maintenance to ensure optimal performance and efficiency. For example, I once programmed a robotic system to automate the welding of a complex frame structure, significantly reducing production time and improving consistency compared to manual welding. Working with robotic systems allows for precise and repeatable welds, resulting in higher quality and reduced waste.

Q 26. What are your experience with lean manufacturing principles in steel fabrication?

I’m experienced in applying lean manufacturing principles to steel fabrication. Lean methodologies focus on eliminating waste and improving efficiency. In the context of steel fabrication, this means optimizing workflow, reducing lead times, minimizing inventory, and improving quality. This includes using techniques like 5S (sort, set in order, shine, standardize, sustain) for shop floor organization, value stream mapping to identify bottlenecks, and implementing Kanban systems to manage inventory flow. For example, I helped implement a Kanban system in a previous role which reduced lead times by 20% and lowered material waste. Lean principles are all about continuous improvement – constantly seeking ways to make the process faster, cheaper, and better. It’s a mindset that permeates every decision, not just a set of processes.

Q 27. Explain your proficiency with using automated nesting software.

I’m proficient in using automated nesting software, such as AutoNest or SigmaNEST. These software packages optimize the placement of parts on a sheet of material to minimize waste. The process begins by importing the part geometry from the CAD model. The software then uses algorithms to automatically arrange the parts on the sheet, considering factors like material size, part orientation, and cutting tolerances. The output is a detailed nesting plan showing the optimized layout and cutting paths. This significantly reduces material waste, leading to cost savings. For example, I’ve reduced material waste by up to 15% by efficiently using automated nesting software. My experience extends to adjusting nesting parameters to account for different materials, part geometries, and cutting processes.

Q 28. How do you ensure your designs adhere to relevant building codes and standards?

Adherence to building codes and standards is non-negotiable. I ensure my designs comply with relevant codes such as AISC (American Institute of Steel Construction) standards, local building codes, and any specific project requirements. This involves using design software with integrated code checking features. I also use reference manuals and resources to confirm design parameters and calculations. Detailed reviews and checks are part of the process, verifying that structural members meet the required strength and stability criteria. For example, during design, I verify that connection details comply with AISC requirements for weld sizes and bolt patterns. Any deviations from the codes must be justified and documented, often requiring consultation with structural engineers. Thorough documentation and a rigorous design review process guarantee that all designs meet the necessary safety and performance standards.

Key Topics to Learn for Steel Fabrication CAD/CAM Interview

- CAD Software Proficiency: Mastering software like AutoCAD, Tekla Structures, or similar platforms. Understand the nuances of 2D drafting and 3D modeling within the context of steel fabrication.

- CAM Programming & CNC Machining: Grasp the principles of generating CNC machine code from CAD models. Familiarize yourself with different machining processes (e.g., cutting, drilling, welding) and their implications for programming.

- Material Selection & Properties: Demonstrate a thorough understanding of different steel grades, their properties (strength, weldability, etc.), and how these factors influence design and fabrication choices.

- Fabrication Processes: Be prepared to discuss various steel fabrication techniques, including cutting, bending, welding, and assembly. Understand the limitations and advantages of each process.

- Blueprint Reading & Interpretation: Showcase your ability to accurately interpret complex engineering drawings and translate them into workable CAD models.

- Tolerance & Dimensioning: Explain your understanding of GD&T (Geometric Dimensioning and Tolerancing) and its importance in ensuring precision and quality in steel fabrication.

- Structural Analysis & Design: Demonstrate basic knowledge of structural principles and how they relate to the design and fabrication of steel structures. This might include understanding load calculations and stress analysis.

- Problem-Solving & Troubleshooting: Be ready to discuss your approach to identifying and resolving issues that arise during the design or fabrication process. Highlight your ability to think critically and find solutions efficiently.

- Production Planning & Optimization: Show understanding of how to optimize the fabrication process for efficiency, minimizing material waste and maximizing productivity.

- Safety Procedures & Regulations: Demonstrate awareness of safety protocols and industry regulations related to steel fabrication and CNC machining.

Next Steps

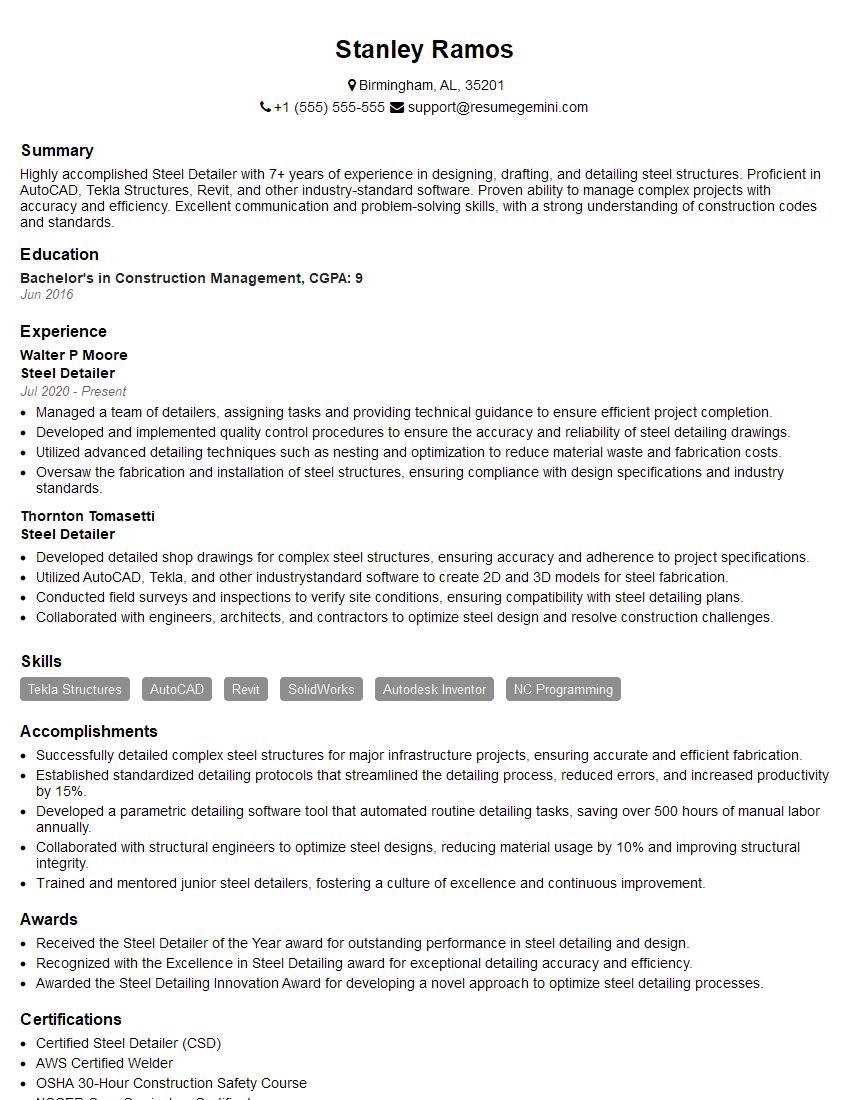

Mastering Steel Fabrication CAD/CAM opens doors to exciting career opportunities in a high-demand field. To stand out, a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you create a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Steel Fabrication CAD/CAM to help guide you in crafting yours. Take this opportunity to showcase your abilities and secure your ideal position.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.