Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Stockroom Maintenance interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Stockroom Maintenance Interview

Q 1. Describe your experience with inventory management systems.

My experience with inventory management systems spans over eight years, encompassing various platforms from simple spreadsheet-based systems to sophisticated enterprise resource planning (ERP) software like SAP and Oracle. I’ve worked with systems that track everything from raw materials to finished goods, managing everything from receiving and putaway to picking, packing, and shipping. I’m proficient in data entry, report generation, and using inventory management systems to optimize stock levels and minimize waste. For example, in my previous role at Acme Corp, we transitioned from a manual inventory system to an ERP system. This required significant training for the team, but the improvement in accuracy and efficiency was dramatic. We saw a 15% reduction in stockouts and a 10% decrease in inventory holding costs within six months.

My skills extend to utilizing inventory management systems for forecasting demand, analyzing sales trends, and identifying slow-moving items that need attention. I’m also comfortable with barcode and RFID technologies, which significantly enhance the speed and accuracy of inventory tracking.

Q 2. How do you ensure the accuracy of stockroom records?

Ensuring the accuracy of stockroom records is paramount. My approach involves a multi-pronged strategy that combines meticulous record-keeping with regular auditing. This includes:

- Regular Cycle Counting: Instead of a large annual physical inventory, I implement a cycle counting system. This involves counting a small portion of the inventory regularly, allowing for timely identification and correction of discrepancies.

- Verification upon Receiving: Every incoming shipment is meticulously checked against the purchase order and packing slip to ensure quantity and quality match. Any discrepancies are immediately documented and addressed with the supplier.

- Barcode/RFID Scanning: I leverage barcode or RFID technology wherever possible to eliminate manual data entry errors. This ensures quick and accurate updates to the inventory system.

- Proper Labeling and Organization: Clear labeling and a well-organized stockroom prevent misplacement and confusion, reducing the risk of errors. This includes using standardized location codes for easy retrieval.

- Regular Audits and Reconciliation: Conducting periodic full or partial inventory counts and comparing them to system records helps identify and correct any errors that may have slipped through the cracks.

Think of it like balancing your checkbook – small, regular checks prevent large surprises later on.

Q 3. Explain your process for receiving and inspecting incoming shipments.

My process for receiving and inspecting incoming shipments follows a standardized procedure to minimize errors and ensure quality control. The process begins with verifying the shipment against the purchase order and the accompanying packing slip. Next, I visually inspect the packaging for any signs of damage, and then, I carefully count and check each item against the documentation. If barcodes are present, I use a scanner to input the data directly into the system for immediate inventory updates. Any discrepancies in quantity or quality are immediately documented and reported to the supplier, with a copy retained for our records. I’ll also check the items’ expiration dates (if applicable) and verify that they meet the required quality standards outlined in the purchase order. Finally, items are correctly placed in their designated locations within the stockroom.

For example, if a shipment of 100 widgets arrives, but the count reveals only 98, I immediately document the shortage, notify the supplier, and initiate a return authorization if necessary. I ensure this entire process is documented, including photos of any damages.

Q 4. How do you handle discrepancies between physical inventory and system records?

Discrepancies between physical inventory and system records are investigated thoroughly to identify the root cause and prevent future occurrences. My approach involves:

- Reviewing Receiving Documents: I carefully review all receiving documents to check for errors in quantity, or identify potential mis-scanning or data entry errors.

- Locating the Physical Inventory: I physically locate the items in question to verify their existence and count. Items may be mis-shelved or overlooked.

- Investigating Potential Damage or Loss: I examine for damage or loss of stock due to theft, spoilage, or other factors.

- Adjusting Inventory Records: Once the discrepancies are identified and verified, I make the necessary adjustments in the inventory management system. The reasons for the discrepancies are documented and flagged for analysis.

- Implementing Corrective Actions: I work to identify and eliminate any processes or procedures that contributed to the discrepancy. This may include training, improved labeling, or changes to the inventory management system itself.

For instance, a regular review might show a consistent shortage in a particular item. This could indicate a problem with our receiving process, theft, or a possible inaccuracy in the purchasing process.

Q 5. What methods do you use to organize and maintain stockroom space?

Organizing and maintaining stockroom space is crucial for efficiency and safety. My methods include:

- Logical Layout: Items are organized logically by category, frequency of use, and size. Frequently used items are placed in easily accessible locations. Larger, less frequently used items are stored in more distant areas. I utilize a combination of shelving, racking, and binning systems to optimize space.

- Clear Labeling: Every shelf, bin, and location is clearly labeled with item numbers, descriptions, and quantity. This facilitates quick and accurate retrieval and reduces errors. We use a standardized labeling system to ensure consistency.

- Designated Areas: Specific zones are designated for incoming shipments, storage of various item types, and picking/packing areas to maintain order and streamline workflow.

- Regular Cleaning and Maintenance: The stockroom is regularly cleaned and organized to eliminate clutter and maintain a safe and efficient work environment. Regular inspections are also performed to ensure safety and avoid risks like fire hazards.

- Inventory Rotation (FIFO): A first-in, first-out (FIFO) system is implemented for perishable goods to minimize waste and maximize shelf life.

Visual aids, like color-coded labels for different categories of items, can further enhance organization and ease of navigation.

Q 6. Describe your experience with cycle counting procedures.

Cycle counting is a cornerstone of accurate inventory management, far superior to a full annual count. I’m experienced in implementing and managing cycle counting procedures, assigning specific items or areas for counting on a rotating schedule. This allows for regular verification of inventory quantities without halting operations for a complete physical inventory. I typically utilize a checklist or spreadsheet to document the counts, comparing them with system records. Any discrepancies are investigated and resolved promptly. This cycle counting data is analyzed to identify trends and areas needing improvement in our inventory procedures. This reduces the time spent on inventory taking while significantly improving accuracy.

For instance, if we find consistent discrepancies with a specific item or shelf location, we can identify and rectify the underlying problem — be it a labeling issue, an error in our inventory management system, or perhaps even theft. This continuous improvement is what sets a successful cycle counting system apart.

Q 7. How do you prioritize tasks in a fast-paced stockroom environment?

Prioritizing tasks in a fast-paced stockroom environment requires a structured approach. I use a combination of techniques:

- Urgent vs. Important: I employ an Eisenhower Matrix, categorizing tasks as urgent and important, important but not urgent, urgent but not important, and neither. This helps prioritize critical tasks, ensuring timely order fulfillment and preventing delays.

- Inventory Levels and Demand: Tasks are prioritized based on inventory levels and anticipated demand. Items with low stock and high demand are handled first. I use the inventory management system to identify these.

- Due Dates and Deadlines: Tasks with approaching deadlines or specific delivery requirements are given priority. I use a visual system – such as a Kanban board – to easily track progress and deadlines.

- Collaboration and Communication: Effective communication with the team and other departments helps coordinate tasks and anticipate potential bottlenecks. For example, communicating with receiving to expedite high-demand order processing ensures timely availability for picking and packing.

- Flexibility and Adaptability: Being flexible and ready to adjust priorities based on unexpected events or urgent requests is essential in a dynamic environment. This might mean putting aside a planned task to handle an urgent order fulfillment request.

Imagine a fire drill – everything else is paused while the immediate emergency is handled. Similarly, in a stockroom, urgent orders will take precedence over less pressing tasks.

Q 8. Explain your experience with using barcoding or RFID technology.

Barcoding and RFID (Radio-Frequency Identification) are crucial for efficient stockroom management. Barcoding uses laser scanners to read unique codes printed on labels, while RFID uses radio waves to identify tags attached to items. Both systems dramatically improve accuracy and speed in tracking inventory.

In my previous role, we implemented a barcode system for all incoming and outgoing items. This reduced manual data entry errors significantly, leading to a 20% decrease in discrepancies between physical inventory and our database. We used a handheld scanner to update our inventory management software in real-time, meaning we always had an accurate count of what was in stock. This was especially helpful during inventory audits. For high-value or frequently misplaced items, we integrated RFID tags, improving tracking capabilities and offering the advantage of tracking multiple items simultaneously without line-of-sight requirements. The data from both systems were integrated into a single database for comprehensive reporting and analysis.

Q 9. How do you handle damaged or obsolete inventory?

Handling damaged or obsolete inventory requires a systematic approach to minimize losses and maintain a clean, organized stockroom. The first step is identification. We regularly conduct stock checks to identify damaged, expired, or obsolete items. For damaged goods, I assess the extent of the damage. Minor damage might allow for salvage or discount sales (with clear labeling). Severely damaged items are disposed of according to company policy, often involving proper recycling or environmentally friendly disposal methods. Obsolete inventory is treated similarly, taking into account any potential secondary markets or donation opportunities. Detailed records are always maintained for each disposal, including the reason, quantity, and disposal method. This documentation is crucial for inventory control and financial reporting. For instance, if we had a large batch of outdated electronics, we’d document the disposal process, possibly through a certified e-waste recycler, and update our inventory database accordingly.

Q 10. What safety procedures do you follow in the stockroom?

Safety is paramount in a stockroom environment. We adhere to strict safety procedures to prevent accidents and injuries. This includes regular safety training for all staff. Our protocols cover proper lifting techniques to prevent back injuries, using appropriate safety equipment like gloves and safety shoes (depending on the materials handled), and maintaining a clean and well-lit workspace to reduce trip hazards. We also implement a clear system for handling hazardous materials, including proper storage, labeling, and disposal according to regulations (SDS – Safety Data Sheets are always readily available). Furthermore, we have clearly marked aisles and walkways to ensure sufficient space for movement, and fire extinguishers and emergency exits are easily accessible and regularly inspected. A robust reporting system is in place for recording any accidents or near misses, enabling continuous improvement of our safety procedures.

Q 11. Describe your experience with stock rotation (FIFO/LIFO).

Stock rotation using FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) methods is essential for minimizing waste and ensuring product freshness. FIFO is ideal for perishable goods or items with expiration dates. For example, in a grocery stockroom, we’d place newer stock behind older stock, ensuring that older items are used or sold first. This prevents spoilage and reduces losses. LIFO, on the other hand, is suitable for non-perishable goods where the cost of goods sold is more relevant. For example, a lumber yard might use LIFO, as there’s less risk of obsolescence. We typically use FIFO for most items in our stockroom, carefully tracking expiration dates and rotating stock accordingly. We use a clear labeling system with dates to make it easy to identify and prioritize older items during stock replenishment.

Q 12. How do you handle stockroom equipment maintenance?

Regular equipment maintenance is crucial for a smooth-running stockroom. We establish a preventive maintenance schedule for all equipment, such as forklifts, pallet jacks, and shelving units. This schedule includes regular inspections, lubrication, and necessary repairs. We maintain detailed records of all maintenance activities. For example, we log the date of each forklift inspection, the service performed, and any parts replaced. This record-keeping is essential for compliance and helps to predict potential equipment failures. We also train staff on the proper operation and maintenance of equipment to prevent misuse and damage. In cases of equipment breakdown, we have a system for contacting repair technicians promptly to minimize downtime and ensure operational efficiency.

Q 13. How do you track and manage stockroom supplies?

Tracking and managing stockroom supplies is achieved through a combination of methods. We use an inventory management system (IMS) to track all supplies, from stationery to cleaning products. The IMS allows us to monitor stock levels, set re-order points, and generate purchase orders automatically when stock falls below a certain threshold. Regular physical inventory checks are conducted to verify the accuracy of the IMS data and to identify any discrepancies. We also use a designated area for storage of supplies, organized by category for easy access and retrieval. A well-defined system for requisitioning supplies ensures that staff can easily request items when needed. The IMS allows us to generate reports on supply consumption patterns, helping to optimize ordering quantities and minimize waste.

Q 14. What are your strategies for preventing stockroom theft or loss?

Preventing stockroom theft or loss requires a multi-layered approach. This starts with physical security measures: secure doors, locks, and surveillance cameras. Access control is paramount, limiting access to authorized personnel only. We implement a strict sign-in/sign-out system for all stock movements and regularly reconcile our inventory records. We encourage a culture of accountability by assigning responsibility for specific areas and items. Random inventory checks and regular audits help to deter theft and identify potential vulnerabilities in our system. Additionally, we carefully vet new employees and conduct background checks, as well as reinforcing the importance of ethical conduct and zero-tolerance for theft. A clear disciplinary policy deters theft and ensures appropriate action is taken if theft occurs.

Q 15. How familiar are you with various inventory management software?

My experience encompasses a wide range of inventory management software, from simple spreadsheet-based systems to sophisticated enterprise resource planning (ERP) solutions. I’m proficient in using software like Fishbowl Inventory, Cin7, Zoho Inventory, and NetSuite, among others. My familiarity extends beyond basic data entry; I understand how to configure these systems to optimize tracking, reporting, and forecasting. For example, in a previous role, we implemented Fishbowl Inventory to manage our stockroom, significantly reducing discrepancies and improving order fulfillment times. This involved customizing the software to reflect our specific product categories, location codes, and reporting needs. I also have experience integrating inventory management software with point-of-sale (POS) systems for real-time stock updates, ensuring accuracy across all sales channels.

I’m adept at utilizing the reporting features of these systems to identify slow-moving inventory, track stock levels, and predict future demand, helping us make informed purchasing decisions and minimize waste. My understanding extends to different inventory valuation methods like FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) and how to correctly apply them within the chosen software.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain a clean and organized stockroom?

Maintaining a clean and organized stockroom is crucial for efficiency and safety. My approach is systematic and involves several key steps. Firstly, I establish a clear organizational system, often using a combination of shelving, racking, and binning to categorize items based on their type, frequency of use, and size. Clear and consistent labeling is paramount, using both physical labels and a digital inventory management system. Regular cleaning is non-negotiable, involving sweeping, dusting, and mopping to prevent the buildup of dirt and debris. This prevents damage to stock and improves workplace safety.

I also implement a ‘5S’ methodology – Sort, Set in Order, Shine, Standardize, Sustain. This framework guides the entire process: Sorting involves removing unnecessary items; Setting in Order involves arranging remaining items logically; Shining ensures cleanliness; Standardizing creates consistent processes; and Sustaining keeps the system in place through continuous monitoring and improvement. For example, I implemented a color-coded system for our shelving units, with each color representing a different product category, making it instantly clear where to find specific items. Regular audits ensure the system stays up to date and prevents clutter from building up.

Q 17. Describe your experience with order fulfillment processes.

My experience with order fulfillment encompasses the entire process, from receiving orders to delivering them. I’m familiar with various order fulfillment methods, including manual picking and packing, and the utilization of barcode scanners and warehouse management systems (WMS) for more efficient processes. I understand the importance of accurate order picking to prevent errors and ensure customer satisfaction. My experience includes working in environments with diverse order volumes, ranging from small, individual orders to large-scale shipments.

I’m skilled at managing the entire fulfillment cycle, including receiving orders, verifying inventory availability, picking and packing the correct items, generating shipping labels, and coordinating with shipping carriers. In a previous role, I streamlined the order fulfillment process by implementing a pick-and-pack workflow, reducing processing times by 20%. This involved reorganizing our stockroom layout and optimizing our picking routes. I’m also proficient in managing returns and dealing with any discrepancies that may arise.

Q 18. How do you handle rush orders or unexpected demands?

Handling rush orders and unexpected demands requires a flexible and adaptable approach. My strategy involves prioritizing tasks effectively, utilizing available resources optimally, and communicating transparently with relevant stakeholders. When a rush order comes in, I immediately assess the required items and their availability. If items are in stock, I prioritize their picking and packing. If items are out of stock, I initiate immediate communication with purchasing and suppliers to expedite delivery. This often involves working overtime or collaborating with team members to ensure timely fulfillment.

For unexpected demands, I leverage real-time inventory data to quickly assess the situation. This helps me to identify any potential bottlenecks and proactively address them. For example, during a period of unexpectedly high demand, we reorganized the stockroom to optimize picking routes and increased our staffing levels temporarily to manage the increased workload. Communication is key throughout this process, keeping all departments informed of any potential delays or challenges. This ensures a coordinated response and prevents any negative impact on customer satisfaction.

Q 19. What is your experience with labeling and tagging inventory?

Labeling and tagging inventory is fundamental to efficient stockroom management. My approach focuses on clarity, consistency, and durability. I utilize a variety of labeling methods, including printed labels with barcodes, hand-written tags, and RFID tags for high-value or frequently moved items. The information included on each label is standardized to include item number, description, quantity, location, and date received. This consistency makes it easy for anyone to locate and identify items quickly.

I’m experienced with using barcode scanners and label printers to automate the labeling process, reducing manual effort and improving accuracy. I also ensure labels are affixed securely and are resistant to wear and tear, particularly in high-humidity or temperature environments. For example, in one role, we implemented an RFID system for tracking high-value equipment. This drastically improved accuracy in inventory counts and reduced time spent on manual inventory checks. Regular auditing and re-labeling ensure labels remain accurate and up-to-date.

Q 20. How do you communicate effectively with other departments regarding stockroom needs?

Effective communication with other departments is critical for efficient stockroom management. I utilize a multi-faceted approach, employing various communication channels tailored to the situation and audience. For routine updates, I use email or internal messaging systems to disseminate information about stock levels, upcoming deliveries, or any potential shortages. For more urgent or complex matters, I opt for direct phone calls or in-person meetings. I also utilize collaborative platforms like SharePoint or project management software to share documents and track progress on shared initiatives.

I focus on proactive communication, anticipating potential needs and providing timely updates. For example, I regularly communicate with purchasing regarding upcoming orders based on our stock levels and sales forecasts. I also maintain open communication with production and shipping departments, ensuring a smooth flow of materials and minimizing delays. This proactive communication builds strong relationships and ensures everyone is well-informed, leading to a more coordinated and efficient workflow.

Q 21. How do you manage stockroom space efficiently?

Efficient stockroom space management is crucial for productivity and cost savings. My approach involves a systematic evaluation of current space utilization, followed by strategic reorganization and implementation of space-saving strategies. This begins with a thorough inventory of all items, analyzing their frequency of use, size, and storage needs. Based on this analysis, I optimize the layout of the stockroom, prioritizing frequently accessed items for easy retrieval. I utilize vertical space effectively, employing shelving units and racking systems to maximize storage capacity and minimize floor space usage.

Regular stock rotation (FIFO) is implemented to minimize waste and prevent obsolescence. Regular audits help to identify and remove unnecessary items, freeing up valuable space. I employ different storage solutions such as bins, containers, and specialized racks depending on the items’ needs. For example, we optimized our stockroom by implementing a vertical shelving system, allowing us to store three times the amount of inventory in the same footprint, significantly reducing storage costs. Continuous monitoring and periodic reorganizations keep our space utilization at its peak efficiency.

Q 22. What metrics do you use to assess stockroom performance?

Assessing stockroom performance relies on a suite of key metrics, all aimed at optimizing efficiency and minimizing waste. I typically focus on these:

- Inventory Turnover Rate: This measures how quickly inventory is sold or used. A high turnover rate indicates efficient stock management, while a low rate suggests potential overstocking or slow-moving items. For example, a turnover rate of 6 means the entire stock is sold and replenished six times a year.

- Accuracy of Inventory Records: This is crucial for accurate forecasting and order management. I regularly perform cycle counts and full physical inventories to maintain a high degree of accuracy, aiming for less than 1% variance. Significant discrepancies trigger an immediate investigation to identify root causes.

- Order Fulfillment Rate: This metric tracks the percentage of orders fulfilled on time and completely. A high fulfillment rate showcases the effectiveness of stockroom processes and order picking efficiency. I continuously monitor this to identify bottlenecks in the process and improve response time.

- Storage Space Utilization: This evaluates how efficiently space is used. High utilization demonstrates effective organization and storage strategies. I regularly review space utilization to identify opportunities for improvement, such as implementing new shelving or optimizing product placement.

- Stockroom Expenses: Tracking storage costs, labor costs, and inventory loss helps to identify areas where cost savings can be achieved. For example, reducing damage to inventory or improving labor efficiency can significantly reduce expenses.

By tracking these metrics and analyzing trends, I can identify areas for improvement and implement data-driven solutions to optimize stockroom performance.

Q 23. Explain your experience with different types of storage equipment.

My experience encompasses a wide range of storage equipment, each suited for different needs and inventory types. I’m proficient with:

- Shelving Units: From basic static shelving to adjustable and heavy-duty options, I’ve used various shelving systems to optimize space and organize inventory based on size, weight, and frequency of access. I understand the importance of selecting appropriate shelving for the weight capacity needed to prevent accidents and damage.

- Pallet Racks: Ideal for bulk storage of palletized goods, I’ve managed the efficient placement and retrieval of pallets, ensuring safe access and minimizing damage. Understanding the safety requirements and regulations of using pallet racking is crucial.

- Drawer Cabinets: For small parts and tools, I’ve implemented drawer systems to maximize organization and prevent loss. Proper labeling and organization of drawers improves the ease of access and efficiency.

- Vertical Lift Modules (VLMs): For high-density storage, I have experience with VLMs, understanding the optimal configuration for specific items and their retrieval process. This helps improve space efficiency and optimize access times for items that are frequently used.

- Bin shelving: Used for smaller items, bins allow for easy organization and inventory management. Different bin sizes allow for flexible storage of a wider range of items.

Selecting the appropriate equipment depends on the specific inventory, available space, and operational requirements. My experience allows me to evaluate different systems and recommend the most effective solution for any given situation.

Q 24. Describe your experience with physical inventory counts.

Physical inventory counts are crucial for maintaining accurate inventory records. My experience involves both cycle counting and full physical inventories.

- Cycle Counting: This involves counting a small portion of the inventory regularly, rather than counting everything at once. This approach reduces downtime and improves accuracy over time. I employ a systematic approach, perhaps counting a specific section each day or week, ensuring all inventory is verified within a set timeframe. For example, a rotating schedule based on usage frequency of the items.

- Full Physical Inventories: These are comprehensive counts of all inventory items. I typically lead these, ensuring all team members are trained and follow a clear, structured process. This includes assigning team members to specific areas, using standardized counting procedures, double-checking counts, and documenting any discrepancies. A post-inventory reconciliation is done to identify discrepancies and make the appropriate adjustments. The full inventory will be scheduled during periods of low activity to minimize business impact.

Regardless of the method, I emphasize accuracy, thorough documentation, and timely reconciliation. Any discrepancies are investigated thoroughly to identify and correct the root cause, preventing future errors. I use barcoding and scanning technology whenever possible to improve speed and accuracy.

Q 25. How do you identify and address areas for improvement in stockroom operations?

Identifying areas for improvement is an ongoing process that involves a combination of data analysis and observation.

- Data Analysis: I analyze the performance metrics discussed earlier (turnover rate, fulfillment rate, etc.) to pinpoint areas with underperformance. Trends and patterns in the data often reveal inefficiencies.

- Observation and Feedback: I regularly observe stockroom operations, paying attention to workflows, storage efficiency, and employee processes. I also solicit feedback from stockroom personnel to identify challenges or areas for improvement from their perspectives. This ensures an inclusive approach to problem-solving.

- Waste Audits: Conducting regular waste audits helps to identify and quantify waste in various areas, such as damaged goods, expired items, or inefficient processes. This provides actionable data to implement changes.

- Benchmarking: Comparing our stockroom operations against industry best practices or similar organizations helps identify areas where we can improve. This involves researching effective methods and strategies utilized by other organizations.

Once areas for improvement are identified, I develop and implement solutions, tracking their impact on performance metrics to ensure effectiveness. This iterative process of improvement is crucial for maintaining a high-performing stockroom.

Q 26. What are your strengths in stockroom management?

My strengths in stockroom management include:

- Organizational Skills: I excel at creating and maintaining organized systems for inventory storage and retrieval. This includes clear labeling, logical product placement, and efficient use of space.

- Process Improvement: I’m adept at identifying inefficiencies and implementing solutions to improve workflows and streamline operations. I have a history of successfully implementing lean principles to improve efficiency.

- Teamwork and Leadership: I’m a collaborative team player who motivates and empowers staff to perform their best. I effectively delegate tasks and provide clear instructions.

- Problem-Solving: I am able to analyze issues, identify root causes, and develop practical solutions to resolve various challenges that may arise in the stockroom.

- Technical Proficiency: My experience with inventory management software and barcode scanning technologies enhances accuracy and efficiency. I am comfortable learning and utilizing new technologies.

These strengths allow me to manage the stockroom efficiently, ensuring smooth operations and high performance.

Q 27. What are your weaknesses in stockroom management?

While I possess strong skills in stockroom management, one area I continually strive to improve is my delegation skills in complex projects. While I’m effective at assigning individual tasks, sometimes I find myself overly involved in the details of intricate projects, delaying their completion. To address this, I’m actively working on improving my ability to clearly define project scopes, delegate responsibilities more effectively, and trust my team to execute those tasks without excessive oversight. I am actively seeking training and mentorship opportunities to enhance my delegation skills.

Q 28. How do you handle conflicts or disagreements in the stockroom?

Handling conflicts in the stockroom requires a fair and effective approach. I prioritize open communication and active listening.

- Open Dialogue: I encourage individuals to express their concerns and perspectives in a respectful manner. I create a safe space for open discussions.

- Focus on Solutions: Instead of dwelling on the problem, I direct the conversation towards finding mutually agreeable solutions. I facilitate collaborative problem-solving by encouraging brainstorming and identifying common ground.

- Fairness and Objectivity: I strive to remain impartial and objective, addressing the issue based on facts rather than personal feelings. I follow company policies and procedures for conflict resolution.

- Documentation: I maintain records of any conflicts or disagreements, including the resolution reached, to track patterns and prevent future occurrences.

If I’m unable to resolve the conflict independently, I escalate it to the appropriate supervisor or management to seek their guidance and support. My goal is always to create a positive and productive work environment where disagreements are handled professionally and constructively.

Key Topics to Learn for Stockroom Maintenance Interview

- Inventory Management: Understanding and applying various inventory control methods (FIFO, LIFO, etc.), cycle counting procedures, and utilizing inventory management software.

- Organization and Space Optimization: Designing efficient stockroom layouts, implementing effective storage solutions (shelving, racking, etc.), and maximizing space utilization to improve workflow and accessibility.

- Safety and Compliance: Adhering to safety regulations (OSHA, etc.), proper handling of hazardous materials, maintaining a clean and organized workspace to prevent accidents and ensure compliance.

- Equipment Maintenance: Understanding the basic operation and maintenance of stockroom equipment (forklifts, pallet jacks, etc.), performing routine checks, and identifying when repairs are needed.

- Receiving and Shipping Procedures: Efficiently processing incoming and outgoing shipments, verifying quantities and condition of goods, and accurately documenting transactions.

- Record Keeping and Reporting: Maintaining accurate inventory records, generating reports on stock levels, usage, and discrepancies, and utilizing data to improve stockroom efficiency.

- Problem-Solving and Troubleshooting: Identifying and resolving issues related to inventory discrepancies, equipment malfunctions, or space constraints; implementing solutions to prevent recurring problems.

- Technology Proficiency: Familiarity with common stockroom software and technologies (barcoding, scanning, databases) used for inventory tracking and management.

Next Steps

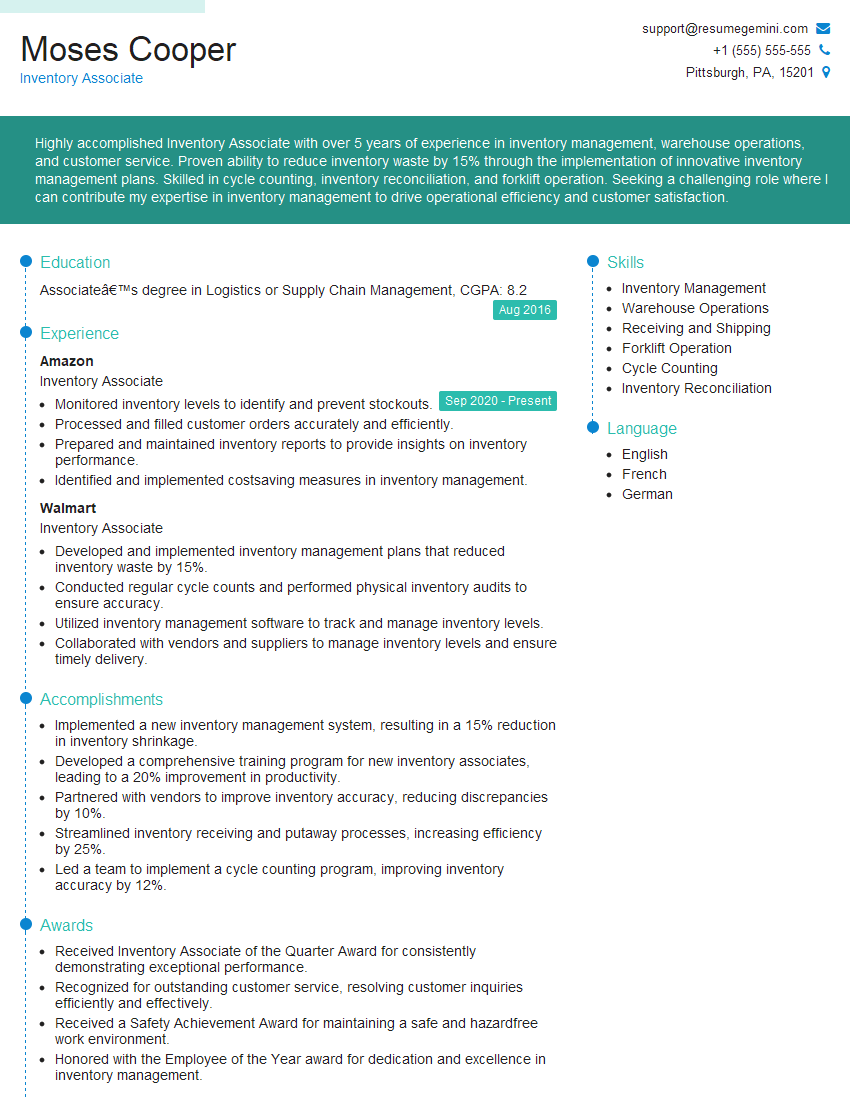

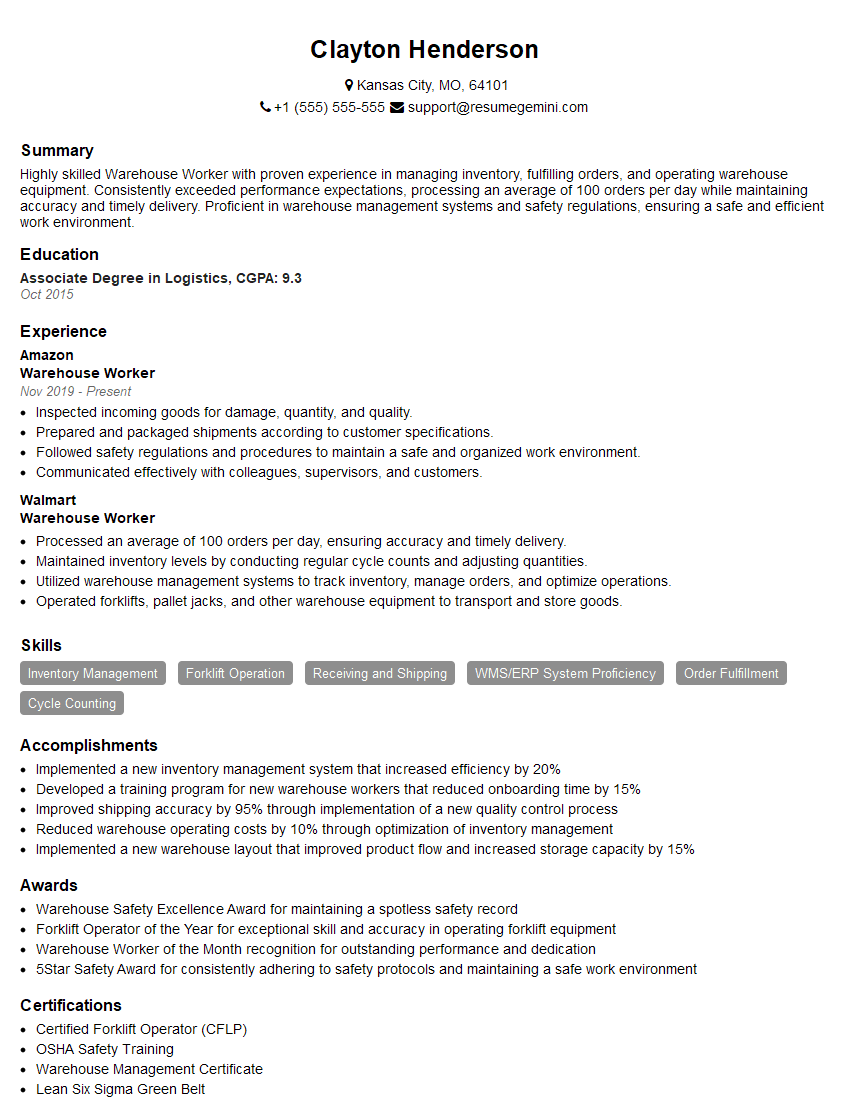

Mastering Stockroom Maintenance opens doors to diverse career paths within logistics, warehousing, and operations management. Demonstrating proficiency in these areas significantly enhances your job prospects. To stand out to potential employers, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and compelling resume tailored to your specific experience. Examples of resumes tailored to Stockroom Maintenance are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.