Are you ready to stand out in your next interview? Understanding and preparing for Street Light Installation and Maintenance interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Street Light Installation and Maintenance Interview

Q 1. What are the different types of street lights and their applications?

Street lights come in a variety of types, each suited for different applications. The choice depends on factors like cost, light output, energy efficiency, and the environment.

- High-Pressure Sodium (HPS): These were once very common due to their high efficacy (lumens per watt) and relatively low cost. However, they produce a yellowish light and are being phased out in many areas in favor of more energy-efficient and environmentally friendly options. Applications: Widely used in the past for general street lighting in residential, commercial, and industrial areas.

- Metal Halide (MH): These lamps offer better color rendering than HPS, producing a whiter light. They are more energy-efficient than HPS but have a shorter lifespan. Applications: Often used in areas requiring better color rendition, such as busy intersections or areas with signage.

- Light Emitting Diode (LED): LEDs are rapidly becoming the dominant technology in street lighting. They are highly energy-efficient, boast a long lifespan, and offer excellent color rendering options. They can be easily dimmed and controlled remotely. Applications: Widely used in new street lighting projects and are increasingly replacing older technologies in retrofits due to their long-term cost savings and environmental benefits. They are also ideal for smart city applications.

- Induction Lamps: These lamps use electromagnetic induction to generate light, offering a longer lifespan than HPS and MH lamps. However, they generally have a lower efficacy than LEDs. Applications: Less common, used in areas where long lifespan is paramount and energy efficiency isn’t the primary concern.

Choosing the right type of street light is crucial for ensuring effective illumination, safety, and cost-effectiveness. For instance, in residential areas, LEDs might be preferred for their energy efficiency and soft light, while busy intersections might benefit from the brighter, more color-accurate light of MH or high-lumen LEDs.

Q 2. Explain the process of installing a high-pressure sodium street light.

Installing a high-pressure sodium street light involves several steps, and safety is paramount throughout the process. Here’s a typical procedure:

- Site Preparation: This includes surveying the location, ensuring proper clearance from obstructions, and marking out the pole location. We need to consider things like underground utilities (cables, pipes) to avoid damage. We’d typically use a ground penetrating radar to confirm this.

- Pole Erection: The light pole is carefully erected using a crane or specialized equipment. The base is securely cemented into the ground. This is often done by a specialized crew.

- Wiring: The electrical wiring is connected to the pole, running from the nearest power source. This requires expertise to ensure proper grounding and safety. We use appropriate conduit and cabling to protect the wires.

- Fixture Installation: The HPS fixture is mounted on the pole and securely fastened. This involves aligning the fixture to ensure optimal light distribution.

- Ballast Connection: The ballast (which regulates the lamp’s electrical current) is connected to the fixture and the wiring. Specific ballast connections vary depending on the model, so it is vital to use the manufacturers instructions.

- Lamp Installation: The high-pressure sodium lamp is carefully installed in the fixture. It is important to handle these lamps with care, as they are fragile.

- Testing and Commissioning: The light is tested to ensure proper operation, correct light output and light direction. Any issues are rectified immediately.

Throughout this entire process, strict adherence to safety regulations and best practices is essential, as working with electricity and at heights presents significant risks.

Q 3. Describe the safety procedures you follow when working on street lights.

Safety is paramount in street light maintenance. Our team always follows a rigorous safety protocol. This includes:

- Lockout/Tagout Procedures: Before working on any electrical component, we always use lockout/tagout procedures to de-energize the circuit, preventing accidental electrocution. This ensures that the power cannot be accidentally turned back on while we’re working.

- Personal Protective Equipment (PPE): This includes wearing hard hats, safety glasses, high-visibility clothing, insulated gloves, and safety shoes. This protects us from falls, electrical shocks, and other potential hazards. Working at heights often requires harnesses and fall arrest systems.

- Elevated Work Safety: When working at heights, we use appropriate fall protection equipment, such as harnesses and lifelines, and follow strict procedures for setting up and using aerial lifts or bucket trucks. Detailed pre-job safety briefings are standard practice.

- Traffic Control: When working near roadways, we implement traffic control measures, such as cones, barricades, and flaggers, to ensure the safety of both our crew and the public.

- First Aid and Emergency Response: We ensure that a trained first-aider is present on-site and that emergency response procedures are in place. Everyone on the crew is trained in basic first aid.

- Regular Safety Training: All our team members undergo regular safety training to keep their skills and knowledge up-to-date, and we continually look for ways to improve our safety procedures.

Failing to adhere to these safety procedures can result in serious injuries or fatalities. Safety isn’t just a policy—it’s our top priority.

Q 4. How do you troubleshoot a malfunctioning street light?

Troubleshooting a malfunctioning street light begins with a systematic approach. First, we need to determine if the problem is with the lamp, the ballast, the wiring, or something else entirely.

- Visual Inspection: We start with a visual inspection to check for obvious issues such as a damaged fixture, broken lamp, or loose wires. Often, a simple visual inspection solves the problem, such as replacing a damaged bulb or tightening a loose connection.

- Check the Power Supply: Next, we check the power supply at the pole and the circuit breaker in the nearby distribution panel. If there’s no power, it might be a simple blown fuse or tripped breaker. The cause of the power failure may need investigating beyond our immediate access.

- Test the Ballast: If power is present, we test the ballast. A faulty ballast will prevent the lamp from igniting or cause it to flicker. A multimeter is used to test the ballast according to manufacturer’s specifications.

- Test the Lamp: Once the ballast is deemed functional, we can test the lamp. A multimeter isn’t useful for this, and sometimes it is just visually obvious that the lamp is burned out or is broken. Lamp replacement is a frequent solution.

- Wiring Inspection: If the lamp and ballast are functional, it’s time to inspect the wiring for any breaks, shorts, or loose connections. This might involve using specialized equipment such as a cable fault locator.

Documentation is crucial. We always record our findings, the actions taken, and the outcome of the troubleshooting process. This helps in identifying trends and preventing future failures.

Q 5. What are the common causes of street light failures?

Street light failures stem from a variety of causes. Some are predictable, while others are less so.

- Lamp Failure: This is a common cause, especially with older technologies like HPS and MH lamps. The lifespan of a lamp is finite, and they eventually burn out.

- Ballast Failure: Ballasts regulate the electrical current to the lamp. Over time, they can overheat, fail, or become damaged by power surges. This is another very common cause of streetlight malfunction.

- Wiring Problems: Damage to wiring from accidents, rodents, or aging can cause outages or shorts. Poor quality installation can also create problems over time.

- Environmental Factors: Severe weather, such as storms, high winds, or lightning strikes, can damage fixtures, poles, or wiring.

- Vandalism: Intentional damage from vandalism can range from broken lamps to more serious damage to the fixtures or poles.

- Power Outages: Larger-scale power outages will obviously cause all streetlights to fail within the affected region. These power failures may be caused by a variety of things, and this would be handled by the power company, not our team.

Understanding these common causes enables proactive maintenance, such as regular lamp and ballast replacements, and helps in planning effective preventative measures.

Q 6. What are the different types of lighting controls used in street lighting systems?

Modern street lighting systems employ various control methods to optimize energy efficiency, enhance safety, and improve light quality.

- Astronomical Clocks: These simple timers switch lights on and off based on sunrise and sunset times. They are cost-effective but lack the flexibility of more advanced systems.

- Photocells: These sensors detect ambient light levels and switch lights on automatically when it gets dark and off when it gets light. They are more responsive than astronomical clocks but still relatively simple.

- Timers: Programmable timers allow for customized on/off schedules, enabling lights to be dimmed or switched off during periods of low traffic or occupancy.

- Central Management Systems (CMS): These systems allow remote monitoring and control of multiple streetlights, often using wireless communication (such as cellular or LoRaWAN). This level of control opens up the ability to dim lights or shut them off remotely based on traffic or other factors. They are crucial in creating ‘smart’ lighting systems.

- Smart Lighting Controls: These sophisticated systems integrate various sensors (e.g., motion detectors, traffic sensors, environmental sensors) to automatically adjust lighting levels based on real-time conditions. They enable advanced features such as adaptive dimming and remote diagnostics.

The choice of lighting control depends on the specific needs of the area, budget constraints, and desired level of automation and intelligence. Smart lighting systems, while more expensive upfront, offer significant cost savings and operational efficiencies in the long run.

Q 7. Explain the process of replacing a damaged street light fixture.

Replacing a damaged street light fixture requires careful planning and execution to ensure safety and correct functionality.

- Assessment and Safety Precautions: First, we assess the extent of the damage and the necessary safety precautions. This includes de-energizing the circuit using lockout/tagout procedures and implementing traffic control measures if necessary.

- Fixture Removal: Using appropriate tools and equipment (e.g., aerial lift or bucket truck), we carefully remove the damaged fixture from the pole, taking care not to damage the wiring or other components. The old fixture is lowered to the ground safely.

- Wiring Inspection: After removing the damaged fixture, we inspect the wiring for any damage. If needed, we repair or replace damaged wiring, ensuring that all connections are secure and properly grounded.

- New Fixture Installation: We carefully install the new fixture, aligning it correctly and ensuring it is securely fastened to the pole. Specific mounting instructions will be required for each type of fixture.

- Wiring Connection: We carefully connect the wiring to the new fixture, ensuring that all connections are correct and tightly secured. This will vary depending on the specific fixture and ballast type.

- Testing and Commissioning: Before leaving the site, we thoroughly test the new fixture to verify proper operation and light output. All safety measures are confirmed to be in place.

- Disposal of Old Fixture: The old fixture is disposed of properly according to local regulations and environmental guidelines. Hazardous components are handled carefully.

Replacing a damaged fixture is not just a matter of swapping parts. It requires detailed attention to safety, correct wiring procedures, and quality workmanship to ensure the longevity and effectiveness of the street lighting system.

Q 8. How do you test the electrical continuity of a street light circuit?

Testing the electrical continuity of a street light circuit is crucial for ensuring its safety and functionality. We use a multimeter, a device that measures voltage, current, and resistance. The process involves carefully de-energizing the circuit first – safety is paramount! Then, we connect the multimeter leads across the circuit’s various points, checking for a continuous path.

For instance, we’d test the continuity from the power source (e.g., transformer) to the light fixture itself. A reading of zero ohms (or very close to it) indicates a complete circuit, meaning electricity can flow freely. A high resistance reading or an infinite reading (OL) suggests a break in the circuit, possibly due to a damaged wire, faulty connection, or a blown fuse. We’ll methodically trace the circuit, testing each section until we pinpoint the fault. This systematic approach ensures efficiency and prevents unnecessary work.

Imagine it like testing a water pipe: if the water doesn’t flow, we need to find the blockage. Similarly, if electricity doesn’t reach the light, we use the multimeter to find the interruption in the flow.

Q 9. What are the regulations and standards you need to follow when working on street lights?

Working on street lights requires strict adherence to several regulations and standards. These vary by location but generally involve national and local electrical codes, occupational safety and health regulations (like OSHA in the US), and any specific guidelines from the utility company responsible for the street lighting system.

Key aspects include:

- Permitting: Obtaining the necessary permits before commencing any work.

- Lockout/Tagout (LOTO): Implementing LOTO procedures to de-energize the circuit completely, preventing accidental electrocution.

- Working at Heights: Utilizing appropriate safety harnesses, fall protection equipment, and following safe work practices when working on poles.

- Traffic Control: Implementing traffic control measures, such as cones and warning signs, to ensure pedestrian and vehicular safety during maintenance.

- Proper PPE: Wearing personal protective equipment (PPE), including safety glasses, gloves, hard hats, and high-visibility clothing.

Non-compliance can lead to severe penalties, injuries, or even fatalities. Safety is never compromised – it’s our top priority.

Q 10. How do you ensure the safety of pedestrians and traffic during street light maintenance?

Ensuring public safety during street light maintenance is critical. We utilize several strategies:

- Traffic Control: We employ cones, barricades, and warning signs to divert traffic away from the work area. In high-traffic areas, we might even require flaggers to guide vehicles safely.

- Pedestrian Control: We cordon off pedestrian walkways to prevent people from entering hazardous zones. Signage clearly indicates detours and restricted areas.

- Proper Lighting and Warning Devices: We use warning lights, such as flashing beacons, on our vehicles and equipment to alert drivers and pedestrians to our presence.

- Communication: Clear communication with traffic control personnel and the public is essential. This can involve informing local authorities about planned outages or maintenance activities.

- Timely Completion: Efficient work practices minimize the duration of disruptions to traffic and pedestrian flow.

Our goal is to complete the work quickly and safely, minimizing any inconvenience to the public.

Q 11. What tools and equipment are commonly used in street light installation and maintenance?

Street light installation and maintenance require a range of specialized tools and equipment:

- Bucket Truck/Aerial Lift: Essential for reaching high poles safely.

- Multimeter: For testing electrical continuity and voltage.

- Voltage Tester: To verify the absence of voltage before working on circuits.

- Lineman’s Pliers/Tools: For working with wires and connectors.

- Screwdrivers (various sizes): For tightening screws and bolts.

- Wrenches (various sizes): For tightening nuts and bolts.

- Safety Harness and Fall Protection Equipment: For working at heights.

- Digging Tools (shovels, spades): For underground cable work (if applicable).

- Ladders and Scaffolding (if applicable): For shorter poles or ground-level work.

- Protective Gear (gloves, safety glasses, hard hat, high-visibility clothing): Essential for safety.

The specific tools needed vary depending on the task at hand, but safety equipment is always a priority.

Q 12. Describe your experience with different types of lighting poles.

I have extensive experience with various lighting pole types, including:

- Steel Poles: These are the most common, offering good strength and durability. Different designs (e.g., tapered, straight) are chosen based on aesthetic preferences and wind load considerations. I’ve worked on various sizes and heights.

- Aluminum Poles: Lighter than steel, offering better corrosion resistance, but potentially less robust. I’ve worked on installations where aesthetics and lower maintenance costs are prioritized.

- Concrete Poles: Heavier and more durable but less versatile in terms of design. They are used in specific situations, often in areas with high wind speeds or extreme conditions.

- Wood Poles: Traditional, but increasingly less common due to maintenance requirements and longevity. I’ve encountered these in older installations, primarily needing repairs or replacements.

Each type requires specific installation techniques, and understanding their strengths and weaknesses is crucial for making informed decisions about their application and maintenance.

Q 13. How do you handle emergency street light repairs?

Emergency street light repairs require immediate attention to ensure public safety and restore lighting. Our response protocol involves:

- Immediate Assessment: Assessing the situation to determine the extent of the damage and any immediate safety hazards.

- Prioritization: Prioritizing repairs based on the severity of the issue and the impact on public safety (e.g., a light out on a busy intersection needs quicker attention than one in a less-trafficked area).

- Safety Measures: Implementing all necessary safety measures, including traffic control and LOTO procedures.

- Temporary Repairs: If a complete repair isn’t possible immediately, we might implement a temporary fix to restore some level of lighting until a permanent solution can be implemented.

- Coordination: Close coordination with local authorities and other relevant parties to ensure a smooth and effective repair process.

- Documentation: Thoroughly documenting the incident, repair process, and any associated costs.

Speed and efficiency are critical, but safety always comes first.

Q 14. What are the benefits of LED street lights compared to traditional street lights?

LED street lights offer significant advantages over traditional high-pressure sodium (HPS) or mercury vapor lights:

- Energy Efficiency: LEDs consume significantly less energy for the same amount of light output, leading to substantial cost savings.

- Longevity: LEDs have a much longer lifespan than traditional lamps, reducing replacement costs and maintenance efforts.

- Brightness and Color Rendering: LEDs offer better color rendering, improving visibility and safety. They can also provide higher brightness levels, enhancing illumination in targeted areas.

- Environmental Friendliness: LEDs don’t contain mercury or other harmful substances, making them more environmentally friendly.

- Directional Lighting: LEDs can be designed to direct light more precisely, minimizing light pollution and maximizing illumination where needed.

- Dimming Capabilities: LED lights can be dimmed based on time of day or traffic conditions, further optimizing energy use.

The initial investment in LED technology might be higher, but the long-term cost savings and environmental benefits make them a highly attractive option for modern street lighting.

Q 15. How do you perform preventative maintenance on street lights?

Preventative maintenance on streetlights is crucial for ensuring longevity, safety, and efficient operation. It’s about proactively identifying and addressing potential issues before they lead to costly repairs or outages. My approach involves a multi-pronged strategy focusing on regular inspections, cleaning, and component checks.

Regular Inspections: I schedule routine inspections, typically quarterly, covering all aspects of the streetlight. This includes checking for loose connections, damaged luminaires (the light fixture itself), corroded wiring, and signs of vandalism or physical damage. I use checklists to ensure thoroughness and maintain records of each inspection.

Cleaning: Accumulated dirt and grime significantly reduce light output. I regularly clean luminaires and lenses, using appropriate cleaning agents to avoid damage. This process can significantly improve light efficiency.

Component Checks: This involves checking the photocell (light sensor) for proper operation, ensuring the ballast (which regulates the current to the lamp) functions correctly, and inspecting the lamp itself for any signs of failure. I replace components as needed, prioritizing energy-efficient replacements whenever possible.

Lubrication: Moving parts, like hinges on covers or poles, benefit from regular lubrication to prevent seizing and ensure smooth operation. This extends the lifespan of the equipment.

By implementing this preventative maintenance program, we can minimize unexpected outages, extend the lifespan of equipment, and improve overall system efficiency, saving both money and resources in the long run. For instance, during a recent inspection, I noticed a corroded connection on several lights in a high-traffic area. Addressing this prevented a potential fire hazard and ensured consistent lighting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with working at heights.

Working at heights is an integral part of my job, and safety is my paramount concern. I’ve received extensive training in fall protection techniques, including proper harness use, anchor point selection, and rescue procedures. I’m certified to operate various types of aerial lifts, such as bucket trucks and articulating booms, and I always adhere to strict safety protocols.

My experience includes working on a wide range of heights, from replacing lamps on standard poles to more complex tasks on high-mast lighting structures. I am comfortable assessing risk, implementing necessary safety measures, and always prioritizing safe working practices. I regularly review and update my knowledge on the latest safety standards and regulations to remain proficient and compliant.

For instance, during a recent project involving high-mast lighting, I meticulously planned the lift operation, selecting the appropriate equipment and anchor points. I conducted thorough pre-lift inspections and ensured all crew members followed safety procedures rigorously. This resulted in the completion of the project without any incidents.

Q 17. How do you read and interpret electrical schematics for street lighting systems?

Reading and interpreting electrical schematics is fundamental to my work. These diagrams provide a visual representation of the electrical pathways within the street lighting system. I understand single-line diagrams showing the power flow, as well as more detailed schematics illustrating specific components and connections.

I can identify key components such as transformers, circuit breakers, photocells, and luminaires on a schematic. I understand how these components interact with each other to deliver power to the lights. For example, I can trace the path of power from the main feed to an individual streetlight, identify potential voltage drops, and understand how different control systems operate. This skill allows me to troubleshoot problems, design new installations, and plan preventative maintenance effectively.

A recent example involved troubleshooting a street light outage. By examining the schematic, I quickly identified a faulty section of the circuit and pinpointed the location of the problem, significantly reducing repair time. My understanding of schematics is crucial for ensuring efficient and safe operation of the lighting systems.

Q 18. Explain the process of grounding a street light.

Grounding a street light is a critical safety measure to protect against electrical shocks and prevent damage to equipment. It provides a low-resistance path for fault currents to flow to the earth, preventing dangerous voltage buildup. The process generally involves connecting the metal parts of the light pole and fixture to a grounding electrode, usually driven deep into the earth. This connection is typically made using a grounding wire, often copper, of sufficient gauge to handle the anticipated current.

The grounding electrode may be a separate ground rod or connected to the existing building or underground power system’s grounding grid. Connections must be tight and corrosion-resistant, often using specialized connectors and clamps. Regular inspection of these connections is vital to ensure continued effectiveness. A poorly grounded street light poses a significant risk to both personnel and the equipment itself.

During a recent installation, I ensured proper grounding by carefully selecting the grounding wire size based on the system’s amperage rating. I used corrosion-resistant connectors and verified the continuity of the ground path using a multimeter to ensure the ground connection provided adequate protection.

Q 19. What is your experience with different types of photocells?

I have experience with various types of photocells, which are light sensors that control when street lights turn on and off. These sensors typically use cadmium sulfide (CdS) or other photoconductive materials. Their sensitivity to light varies, affecting the lighting’s response to changing ambient light levels. Some photocells are designed for specific applications, like those with increased sensitivity for dusk-to-dawn operation, or those integrated with smart lighting controls.

I’m familiar with the differences between various photocell technologies, including their sensitivity ranges, response times, and reliability. This knowledge allows me to choose the most appropriate photocell for a given installation, considering factors such as ambient light conditions, desired lighting schedules, and budget constraints. For example, in areas with significant ambient light pollution, a photocell with higher sensitivity is needed for reliable operation.

In one instance, I replaced an older, less reliable photocell with a more modern, energy-efficient model. This resulted in improved energy savings and more consistent lighting operation, showcasing the importance of selecting the right photocell.

Q 20. How do you determine the appropriate lighting level for a particular area?

Determining the appropriate lighting level for a particular area requires a careful consideration of several factors. The goal is to provide sufficient illumination for safety and visibility while minimizing light pollution and energy consumption. Factors to consider include:

Functional Requirements: What activities take place in the area? Highways require different illumination than residential streets.

Safety Concerns: Are there pedestrian crossings, high-traffic areas, or potential hazards needing special attention?

Environmental Impact: Light pollution can disrupt wildlife and astronomy; minimizing unnecessary lighting is crucial.

Energy Efficiency: Using energy-efficient lamps and luminaires can significantly reduce operational costs.

Aesthetics: The lighting should complement the surrounding environment.

I use lighting design software and calculations to determine the appropriate illuminance levels (measured in lux) needed to meet the specific requirements of the area. This process involves considering factors like the lamp type, pole height, spacing between lights, and the reflectivity of the surrounding surfaces. I also consider relevant lighting standards and guidelines to ensure compliance and best practice.

A recent project involved designing a lighting scheme for a new park. Through careful analysis, I created a lighting plan that provided sufficient illumination for safety while minimizing light spill into the surrounding residential areas.

Q 21. What is your experience with smart street lighting systems?

I have experience with smart street lighting systems, which offer advanced control and monitoring capabilities beyond traditional systems. These systems typically use networked sensors, communication technologies (like cellular or LoRaWAN), and intelligent control systems to optimize lighting performance and energy efficiency. They often integrate with other smart city initiatives.

My experience includes the installation, configuration, and maintenance of smart street lighting networks. This involves working with various communication protocols, data analysis software, and cloud-based platforms. The ability to remotely monitor and control individual lights allows for predictive maintenance and targeted adjustments based on real-time data. For example, we can dim lights in areas with low traffic or automatically adjust light levels based on weather conditions or occupancy sensors.

I recently participated in the implementation of a smart lighting system for a municipality. This involved integrating sensors into existing streetlights and configuring the control system to adjust light levels based on real-time traffic patterns and pedestrian activity. The result was a significant reduction in energy consumption without compromising safety or visibility.

Q 22. How do you manage your time and prioritize tasks when working on multiple street light projects?

Managing multiple street light projects requires a robust system. I utilize project management software to track deadlines, budgets, and resources. I prioritize tasks based on urgency and impact, using a combination of methods like the Eisenhower Matrix (urgent/important) and critical path analysis. For example, if several projects are underway, I might prioritize completing the urgent repairs that affect public safety before moving onto scheduled maintenance on a less critical route. This proactive approach ensures that all projects are completed efficiently and effectively, while maintaining a focus on the most pressing needs.

I also hold regular team meetings to coordinate efforts and address any emerging issues. Open communication is key to staying on schedule and within budget. We discuss progress, identify potential roadblocks, and adjust the plan as needed. This collaborative approach prevents bottlenecks and ensures everyone is aligned on priorities.

Q 23. Describe your experience with working in various weather conditions.

Working outdoors in varied weather conditions is a fundamental aspect of this job. I have extensive experience working in extreme heat, torrential rain, snow, and icy conditions. Safety is paramount, so I always adhere to strict safety protocols and use appropriate personal protective equipment (PPE) like high-visibility clothing, waterproof jackets, and insulated boots. Weather also influences scheduling. For instance, during a blizzard, we prioritize emergency repairs rather than routine maintenance. We also adjust our work schedule to avoid the most severe weather periods whenever possible. Planning ahead and being flexible are crucial for effectively managing operations across varying weather conditions.

I’ve learned to adapt my work methods based on the conditions. For example, using specialized equipment for working in icy conditions, or adjusting the timing of our operations to prevent working in extreme heat during the midday sun. We also always have contingency plans in place to handle unexpected weather events effectively. This includes backup equipment, alternate work locations, and clear communication protocols to keep teams safe and informed.

Q 24. How do you handle conflicts or disagreements with colleagues or supervisors?

Conflicts are inevitable in any team environment. My approach is always based on open and respectful communication. I try to understand the other person’s perspective before stating my own. I believe in finding mutually agreeable solutions through collaborative discussion. For example, if there is a disagreement about the best approach to a specific repair, I’ll facilitate a discussion among team members, weighing different opinions and technical expertise to reach the most efficient and effective solution. If I can’t resolve the issue directly, I’ll involve a supervisor, keeping the communication professional and factual.

I believe in focusing on the problem, not the person. This collaborative approach respects individual contributions and ultimately leads to better outcomes for the entire team. Maintaining a professional and respectful demeanor, even in challenging situations, fosters a positive work environment and leads to more productive conflict resolution.

Q 25. What are your salary expectations?

My salary expectations are in line with the market rate for a Street Light Installation and Maintenance professional with my experience and qualifications. I am open to discussing this further based on the specifics of the role and benefits package offered.

Q 26. What are your strengths and weaknesses?

My strengths include my problem-solving skills, my ability to work independently and as part of a team, and my attention to detail. I am efficient, organized, and adept at managing multiple tasks simultaneously. For example, I recently managed the installation of 100 new streetlights within a tight deadline, coordinating with various teams and navigating unforeseen challenges effectively. I pride myself on my ability to think critically and troubleshoot complex issues, drawing from my extensive experience to find optimal solutions.

One area I am continuously working on is delegation. While I’m comfortable taking ownership of tasks, I recognize the value of effective delegation to increase team efficiency. I’m actively learning to delegate tasks more effectively while providing adequate support to my team members.

Q 27. Why are you interested in this position?

I am highly interested in this position because of my passion for infrastructure maintenance and my commitment to enhancing public safety. Your company’s reputation for quality and innovation aligns perfectly with my professional values. The opportunity to contribute to a team dedicated to providing reliable and efficient street lighting services is particularly appealing. The specific projects outlined in the job description resonate with my skills and experience, and I am confident I can make a significant contribution.

Q 28. Where do you see yourself in five years?

In five years, I see myself as a valuable asset to your organization, possibly in a supervisory or leadership role. I am keen to expand my knowledge and expertise in areas such as smart lighting technologies and energy-efficient solutions. I am also eager to mentor and train new team members, sharing my experience and contributing to the overall growth of the team. I am committed to continuous learning and professional development, ensuring I remain at the forefront of the field.

Key Topics to Learn for Street Light Installation and Maintenance Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA standards, permit requirements, and working safely at heights.

- Electrical Wiring and Connections: Knowledge of different wiring types, proper grounding techniques, and troubleshooting electrical faults in street lighting systems.

- Pole Climbing and Equipment Handling: Safe and efficient techniques for climbing utility poles, using specialized equipment, and maintaining proper balance and safety.

- Street Light Components and Functionality: Familiarity with various street light fixtures, ballasts, photocells, and control systems; understanding their functions and interdependencies.

- Preventive Maintenance and Inspection: Performing regular inspections, identifying potential issues, and carrying out preventative maintenance tasks to extend the lifespan of street lighting systems.

- Troubleshooting and Repair: Diagnosing and repairing common street light malfunctions, including replacing components, fixing wiring issues, and addressing lighting deficiencies.

- Documentation and Reporting: Maintaining accurate records of maintenance activities, inspections, and repairs; creating clear and concise reports.

- Different Lighting Technologies: Understanding the advantages and disadvantages of various lighting technologies (e.g., LED, High-Pressure Sodium, Metal Halide) and their applications.

- Use of Diagnostic Tools: Proficiency in using testing equipment like multimeters, voltage testers, and other specialized tools for fault diagnosis.

- Problem-solving and Critical Thinking: Applying logical reasoning and problem-solving skills to address unexpected challenges and complex issues on the job.

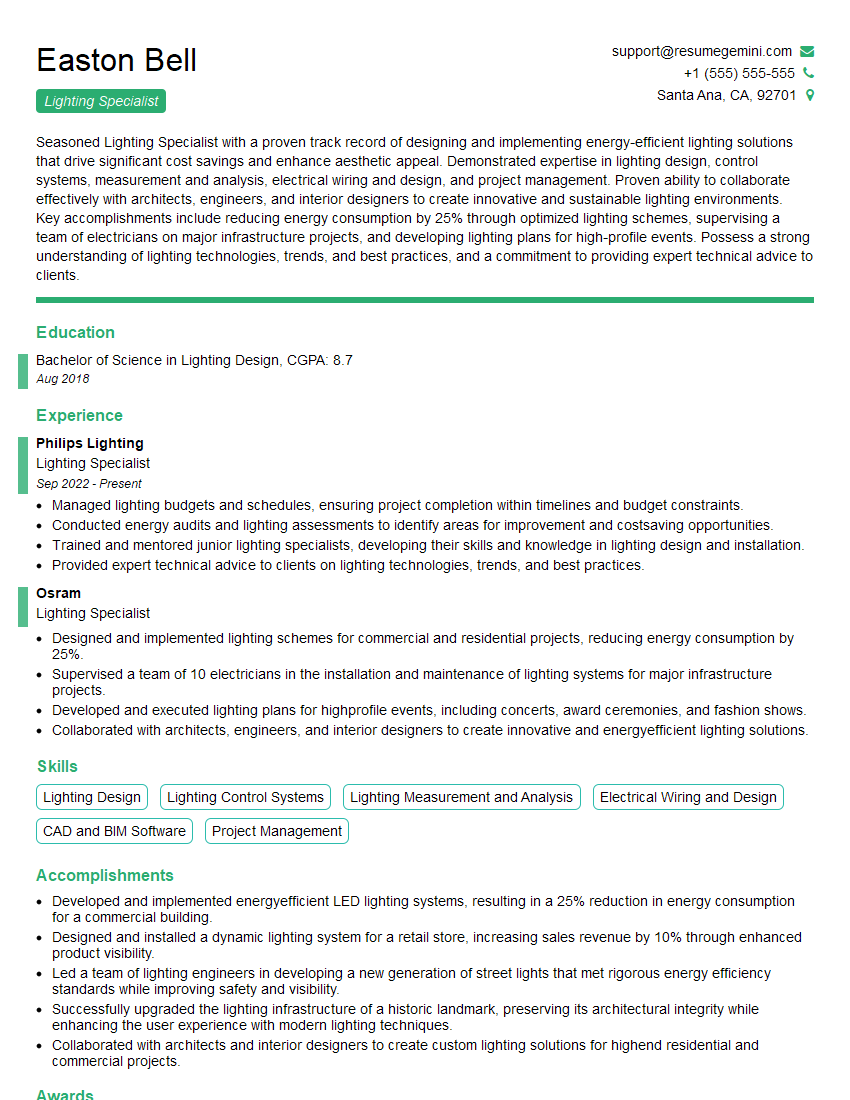

Next Steps

Mastering Street Light Installation and Maintenance opens doors to a stable and rewarding career with opportunities for advancement. A strong understanding of these key areas will significantly improve your interview performance and increase your chances of landing your dream job. To further enhance your job prospects, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored specifically to the Street Light Installation and Maintenance field to help guide you in creating a compelling application that showcases your unique qualifications.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.