Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Tapping and Boring interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Tapping and Boring Interview

Q 1. Explain the difference between tapping and boring.

Tapping and boring are both machining processes used to create holes, but they differ significantly in their purpose and method. Tapping creates internal threads in a pre-drilled hole, essentially creating a mating surface for a screw or bolt. It uses a tap, a fluted tool resembling a screw. Boring, on the other hand, enlarges an existing hole to a precise diameter, improving its accuracy and surface finish. It employs a boring tool, typically a single-point cutting tool mounted on a lathe or boring machine. Think of it this way: tapping adds threads, while boring refines the size and shape of a hole.

Imagine you’re building a cabinet. You’d first drill pilot holes for the screws that hold the panels together. Then, you’d use a tap to create threads in those holes, allowing the screws to grip firmly. Later, you might need to bore a larger hole for a dowel or other fitting. The tapping creates the receiving surface for fasteners; boring creates the precisely sized hole itself.

Q 2. Describe the various types of taps used in machining.

Taps come in various types, categorized based on their flute design, material, and application. Here are some common types:

- Hand Taps: These are sets of three taps – taper, plug, and bottoming – used sequentially to create a complete thread. The taper tap starts the thread, the plug tap continues, and the bottoming tap finishes the thread at the bottom of the hole.

- Machine Taps: Designed for use in machine tapping heads, these are more robust and have longer life compared to hand taps. They are typically spiral pointed and are used in high-speed automated tapping operations.

- Spiral Point Taps: These taps have helical flutes that produce chips that are easily removed. This prevents chip buildup and reduces the risk of tap breakage, making them ideal for tough materials.

- Spiral Flute Taps: Similar to spiral point taps, these produce chips that easily escape the hole. They are better for through holes.

- Bottoming Taps: These taps have almost full-length flutes and are used to thread the entire depth of a blind hole. They are prone to breakage if not used correctly.

The choice of tap material (high-speed steel, carbide, or coated materials) depends on the material being tapped and the desired durability.

Q 3. What are the factors that influence tap selection?

Several factors influence tap selection. The most critical are:

- Material being tapped: Hard materials require taps made of harder materials (e.g., carbide) to prevent premature wear. Softer materials allow for the use of high-speed steel taps.

- Hole size and depth: Blind holes require bottoming taps, while through holes can use plug or spiral point taps. The hole depth influences the tap length needed.

- Thread type and size: The tap must match the thread specification (e.g., metric, UNC, UNF). Incorrect thread size will result in a poor fit or inability to cut the threads properly.

- Machining method: Hand tapping requires hand taps, while machine tapping requires machine taps designed for high speeds and automated systems.

- Desired surface finish: For high-quality finishes, spiral point or spiral flute taps are preferable due to their chip-clearing capabilities.

Choosing the wrong tap can lead to broken taps, damaged workpieces, and poor-quality threads. Careful consideration of these factors is essential.

Q 4. How do you determine the correct tap drill size?

Determining the correct tap drill size is crucial for achieving properly formed threads. This size is slightly smaller than the major diameter of the tap to allow for sufficient material to form the thread. Manufacturers provide tap drill size charts that specify the drill size required for each tap size and thread type. These charts take into account factors such as thread pitch and the type of tap used. Alternatively, you can use a tap drill size calculator. Failing to use the correct drill size will lead to weak threads or a tap that cannot form the correct thread profile. It’s always best to consult the manufacturer’s specifications to ensure accuracy.

For example, if you are tapping a 1/4-20 UNC thread (1/4 inch diameter, 20 threads per inch), the tap drill size chart might recommend a #7 drill bit. Using a larger drill would lead to weak threads, and using a smaller drill would likely break the tap.

Q 5. What are the common problems encountered during tapping and how are they resolved?

Common problems during tapping include:

- Tap breakage: This often results from excessive force, incorrect tap drill size, dull taps, or inappropriate cutting fluids.

- Poor thread quality: This can be caused by dull taps, incorrect tap drill size, inadequate cutting fluid, or excessive feed rate.

- Chip clogging: This is especially prevalent in blind holes and can cause tap breakage. Using spiral point taps and appropriate cutting fluid can mitigate this.

- Tap deflection: This can result in poorly formed threads and tap breakage. Ensuring proper clamping and rigidity of the workpiece is vital.

Resolutions include using the correct tap drill size, selecting appropriate taps for the material and application, using sufficient cutting fluid, maintaining proper speed and feed rates, ensuring rigid clamping of the workpiece, and regularly inspecting and sharpening taps.

Q 6. Explain the concept of tap breakage and preventive measures.

Tap breakage is a common and frustrating issue in tapping operations. It usually stems from excessive force, improper tap selection, dull taps, or inadequate lubrication. In blind holes, chip clogging can contribute significantly to breakage.

Preventive measures include:

- Using the correct tap drill size: This provides sufficient material for thread formation and reduces stress on the tap.

- Selecting the appropriate tap for the material and application: Hard materials necessitate harder taps, and spiral point taps are superior for chip evacuation.

- Using sufficient cutting fluid: This lubricates and cools the tap, preventing excessive heat buildup and friction.

- Maintaining appropriate speed and feed rates: Too high a speed or feed rate can cause excessive stress and lead to breakage.

- Ensuring rigid clamping of the workpiece: This prevents tap deflection and ensures a consistent cutting action.

- Regularly inspecting and sharpening taps: Dull taps are more prone to breakage and produce poor-quality threads.

- Using tapping lubricant: Correct tapping lubricants help reduce friction and chip formation.

By implementing these preventive measures, you can significantly reduce the risk of tap breakage and improve the overall efficiency of your tapping operations.

Q 7. Describe different types of boring tools and their applications.

Boring tools are classified based on their design and application. Some common types include:

- Single-point boring tools: These consist of a single cutting edge and are used for precision boring operations. They are typically mounted on a lathe or boring mill and allow for precise control over the bore diameter.

- Boring bars: These hold single-point cutting tools and are used for boring deeper holes. They can be adjusted to achieve different bore diameters.

- Reaming tools: These tools slightly enlarge and improve the surface finish of an existing hole. They remove small amounts of material to achieve high accuracy and surface smoothness.

- BTA (Boring and Trepanning Association) boring tools: These are specialized tools used for creating deep, large-diameter holes, often in tough materials. They employ multiple cutting edges for improved efficiency.

- Multi-cutting edge boring heads: These tools have multiple cutting edges, enabling faster material removal compared to single-point tools, and are typically used for mass production.

The choice of boring tool depends on factors like the material being bored, the desired bore diameter and tolerance, the hole depth, and the production volume. For instance, a single-point boring tool is ideal for creating a precise bore diameter on a lathe, while a BTA tool is suitable for deep hole drilling in aerospace applications.

Q 8. What are the factors that affect boring accuracy?

Boring accuracy is paramount in machining, and several factors influence its precision. Think of it like baking a cake – if your measurements are off, the cake won’t turn out right. Similarly, inaccuracies in boring can lead to assembly issues or even part failure.

- Machine Rigidity: A stiff machine minimizes vibrations and deflections, ensuring the cutting tool stays on course. A flimsy machine, like using a wobbly table to hold your baking ingredients, will lead to inconsistencies.

- Tool Geometry and Wear: The sharpness and proper geometry of the boring bar are crucial. A dull or worn tool will produce inaccurate holes, much like a dull knife will produce uneven slices of bread.

- Workpiece Clamping and Stability: The workpiece needs secure clamping to prevent movement during cutting. If the workpiece shifts, the hole will be out of position.

- Cutting Parameters: Incorrect cutting speed, feed rate, and depth of cut can contribute to inaccuracy. Too much force (like trying to mix your batter too fast) can cause chatter and inaccuracy.

- Workpiece Material: Different materials behave differently under cutting stress; harder materials may require modifications to cutting parameters to avoid errors.

- Thermal Effects: Heat generated during boring can cause expansion and distortion, affecting the accuracy of the hole. Effective cooling prevents this problem.

Maintaining accuracy requires meticulous attention to each of these factors. Regular machine maintenance, sharp tools, precise setup, and optimized cutting parameters are essential for consistently accurate boring.

Q 9. How do you ensure proper coolant flow during tapping and boring operations?

Proper coolant flow is vital in both tapping and boring to manage heat and facilitate chip removal. Imagine trying to drill a hole without lubrication – the bit would quickly overheat and likely break. Coolant acts as both a lubricant and a heat sink.

- Sufficient Coolant Pressure and Volume: Adequate coolant pressure ensures it reaches the cutting zone effectively. Low pressure leads to insufficient cooling and lubrication. The flow volume should be sufficient to remove chips and prevent clogging.

- Coolant Delivery Method: Through-the-tool coolant delivery is most effective, delivering coolant directly to the cutting edge. Other methods include flood cooling and high-pressure nozzles.

- Nozzle Placement: The nozzles should be strategically placed to direct the coolant flow to the cutting zone. Consider the chip flow pattern during optimization of nozzle placement.

- Coolant Condition: Clean and properly filtered coolant prevents clogging and ensures efficient performance. Regular coolant changes are important.

- Chip Management System: An efficient chip removal system prevents coolant contamination and overheating.

Regular inspection of the coolant system is crucial. A blocked nozzle or insufficient pressure can have significant impacts on both the quality of the finished part and the machine’s longevity.

Q 10. Explain the importance of surface finish in tapping and boring.

Surface finish is a key indicator of the quality of a tapped or bored hole. A smooth surface minimizes friction, improves fatigue resistance, and enhances the aesthetic appeal of the part. Think of it like the difference between a finely sanded piece of wood and a rough one – the smooth surface is more pleasing, durable and easier to work with.

- Improved Functionality: In applications requiring seals or close tolerances, a smooth surface is crucial for proper functionality. Leaking, poor sealing, and other defects are significantly less likely with smoother finishes.

- Reduced Wear: A superior surface finish reduces friction and wear, extending the life of components.

- Enhanced Appearance: For components with visible surfaces, a good surface finish contributes to overall quality and aesthetics.

- Improved Fatigue Strength: Smoother surfaces reduce stress concentrations, making the part less prone to fatigue failure.

Achieving a desired surface finish often requires careful selection of cutting tools, optimized cutting parameters, and the use of appropriate coolants. Post-processing methods such as honing or polishing might be necessary in some cases.

Q 11. Describe different methods of chip control during tapping and boring.

Chip control is essential in tapping and boring to prevent chip buildup, damage to the workpiece or tool, and to ensure efficient operation. Think of it as managing the mess when you’re cooking – you don’t want your ingredients spilling all over the place.

- Coolant Application: The right coolant, applied effectively, helps to break up chips and flush them away from the cutting zone.

- Chip Breakers: Special cutting tools with chip breakers are designed to create shorter, more manageable chips. This is like using a food processor to chop vegetables into smaller pieces.

- Cutting Parameters: Optimizing cutting speed and feed rate can influence chip formation. A slower speed and feed rate could create smaller, easier to handle chips.

- Workpiece Material: The material’s machinability affects chip formation; some materials generate longer, continuous chips requiring specialized chip management strategies.

- Chip Conveyors and Augers: Mechanical systems for removing chips from the machine help prevent blockages and ensure efficient operation.

The best chip control method depends on factors such as the machine, the workpiece material, and the cutting parameters. Often, a combination of techniques is necessary for optimal chip management.

Q 12. What are the safety precautions to be followed while performing tapping and boring?

Safety is paramount during tapping and boring operations. Always treat the machine and tools with respect, and observe all safety protocols.

- Machine Guarding: Ensure all guards are in place and functional before operating the machine. This is like wearing a helmet when riding a bike.

- Personal Protective Equipment (PPE): Wear safety glasses, hearing protection, and appropriate clothing to protect against flying chips and other hazards. This is the equivalent of wearing appropriate safety gear when performing any task.

- Tool Handling: Handle cutting tools with care to avoid injuries. Use caution when changing or adjusting tools.

- Workpiece Securing: Ensure the workpiece is properly clamped to prevent movement during cutting. A loose workpiece poses a high risk of injury.

- Emergency Stop Procedures: Know the location and operation of the emergency stop button. This is a critical safety precaution.

- Machine Maintenance: Regular maintenance ensures the machine is in good working order, minimizing the risk of accidents.

Safety should always be the top priority. A moment of carelessness can lead to severe injury. Follow all safety procedures diligently.

Q 13. How do you inspect the quality of a tapped or bored hole?

Inspecting the quality of a tapped or bored hole involves a multi-faceted approach, ensuring both dimensional accuracy and surface finish meet specifications.

- Dimensional Measurement: Use tools like calipers, micrometers, or coordinate measuring machines (CMMs) to verify the hole’s diameter, depth, and position. This ensures the hole is the correct size and in the correct location.

- Surface Finish Inspection: Visual inspection, along with surface roughness measurement tools, can determine the smoothness of the hole. A visual check often suffices for basic assessments. If high precision is required, use a surface roughness tester.

- Straightness and Roundness: Check for deviations from straightness and roundness using appropriate gauges or measuring instruments. A non-round hole is indicative of flaws in the process. A deviation from straightness indicates a problem with machine setup or tool wear.

- Thread Inspection (for tapped holes): Use thread gauges or a thread comparator to verify the thread profile, pitch, and fit. Ensuring the thread is properly formed is critical for function.

- Leak Testing (where applicable): For holes intended for sealing, a pressure or leak test verifies the integrity of the surface finish and the hole’s ability to hold a seal.

The appropriate inspection methods depend on the specific application and required tolerances. Documentation of the inspection process is critical for quality control and traceability.

Q 14. Explain the relationship between cutting speed, feed rate, and depth of cut in boring.

In boring, the relationship between cutting speed (V), feed rate (f), and depth of cut (d) is complex but crucial for efficiency and surface finish. They’re interconnected factors influencing the overall machining process. Think of it like baking a cake; the temperature (speed), the amount of ingredients (feed), and the size of your pan (depth) all interact to determine the final product.

- Cutting Speed (V): This is the speed at which the cutting tool moves past the workpiece. Higher speed generally leads to a better surface finish but can generate more heat and potentially reduce tool life. It’s like the oven temperature – higher temperatures bake faster but risk burning the cake.

- Feed Rate (f): This refers to the rate at which the tool advances into the workpiece. A higher feed rate increases material removal rate but may lead to rougher surface finish and increased tool wear. Think of it as the amount of batter you put into the pan in each scoop – more batter, more cake, but may affect the consistency and appearance.

- Depth of Cut (d): This is the distance the tool penetrates into the workpiece with each pass. A deeper cut increases material removal rate but puts more stress on the tool and machine, potentially leading to vibrations and inaccurate results. A deeper cut is like using a larger cake pan – more cake, but requires more batter and a larger oven.

Finding the optimal balance among these parameters requires consideration of factors such as workpiece material, tool material, machine capabilities, and desired surface finish. Experience and experimentation often play a significant role in determining the optimal cutting parameters for specific applications.

Q 15. How do you troubleshoot a poorly tapped or bored hole?

Troubleshooting a poorly tapped or bored hole involves a systematic approach. First, we need to identify the specific problem: is the hole oversized, undersized, out of round, or damaged? The root cause could be several factors. Let’s explore some common issues and solutions:

Oversized Hole: This could be due to dull or worn tools, incorrect feed rate, excessive cutting speed, insufficient clamping, or improper tool setup (incorrect alignment or insufficient rigidity). The solution involves inspecting and replacing worn tools, adjusting machine parameters (speed and feed), ensuring secure workpiece clamping, and verifying proper tool setup. We might even need to check for machine vibration.

Undersized Hole: This often points to a tool that’s too small, a feed rate that’s too low, or a cutting speed that’s too high. The workpiece material’s hardness might also be a factor. The solution involves verifying the tool size, optimizing the machining parameters, and considering using a more suitable tool material for harder materials.

Out-of-Round Hole: This indicates issues like improper clamping (causing workpiece deflection), worn or damaged tooling (chipped cutting edges), or excessive cutting forces. The remedy includes improving workpiece clamping, replacing the cutting tool, and possibly reducing the depth of cut.

Damaged Hole (e.g., chipped or burred): This could stem from excessive cutting forces, improper chip evacuation, or a lack of coolant. Solutions include adjusting cutting parameters, optimizing chip control strategies, and ensuring adequate coolant supply.

In each case, a thorough inspection of the machine, tooling, and workpiece is crucial. Careful measurement of the hole using precision instruments like calipers or micrometers confirms the extent of the problem. Keeping a detailed log of machining parameters aids in identifying and rectifying recurring issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of boring machines?

Boring machines are classified into several types, each designed for specific applications and workpiece sizes. Here are a few examples:

Horizontal Boring Mills: These are large, heavy-duty machines capable of machining large workpieces. They feature a horizontal spindle that can move in multiple axes, providing excellent accessibility for complex operations.

Vertical Boring Mills: Similar to horizontal mills but with a vertical spindle, offering advantages for certain workpiece configurations and gravity-assisted chip removal. They are often used for machining large circular components.

Jig Borers: Known for high accuracy and precision, they’re used for precise location and machining of holes, often in jigs and fixtures. These machines typically employ very precise measuring systems.

CNC Boring Mills: These combine the power and versatility of boring mills with the precision and automation of Computer Numerical Control (CNC). This type allows for complex shapes and automated programming, leading to increased efficiency.

Turret Boring Machines: These utilize a turret head with multiple tools, enabling rapid tool changes and reducing cycle times. Especially beneficial for high-volume production.

The selection of a specific machine type depends on factors like workpiece size, required precision, production volume, and budget. In a large manufacturing facility, one may encounter a range of these machines depending on their specific needs.

Q 17. Explain the difference between through holes and blind holes.

The difference between through holes and blind holes is straightforward: a through hole extends completely through the workpiece, while a blind hole only penetrates a portion of the workpiece’s thickness, leaving a bottom surface.

Imagine drilling a hole in a wooden block. If the drill bit goes all the way through, creating an opening on both sides, it’s a through hole. However, if the drill bit only goes partway through, leaving a flat base at the end of the hole, that’s a blind hole.

This distinction is crucial for tool selection and machining parameters. For through holes, chip evacuation is generally simpler. Blind holes require careful consideration to prevent tool breakage or poor surface finish at the bottom of the hole. The depth of a blind hole must be accurately controlled to avoid damaging the opposing surface.

Q 18. How do you calculate the cycle time for tapping and boring operations?

Calculating cycle time for tapping and boring operations requires considering several factors. It’s not a simple formula, but rather a summation of individual time components. These include:

Tool Approach and Retract Time: The time it takes for the tool to move to the workpiece and retract after the operation.

Cutting Time: The actual time spent machining the hole – this depends on hole depth, diameter, cutting speed, and feed rate.

Tool Change Time (if applicable): Time required to switch tools between boring and tapping if they are performed sequentially.

Workpiece Clamping and Unclamping Time: Time spent securing the workpiece in the machine.

Coolant On/Off Time: The time for coolant activation and deactivation.

Cycle time is typically expressed in seconds or minutes per part. Accurate estimation requires either time studies on the actual machine or careful analysis of the machining parameters and the specific machine’s characteristics. Experienced machinists can often estimate cycle time quite accurately based on their past experience. In many cases, software integrated into CNC machines provides cycle time estimates.

For instance: Cycle Time = Approach Time + Cutting Time + Retract Time + Tool Change Time + Clamping Time

Q 19. Describe the use of CNC in tapping and boring operations.

CNC (Computer Numerical Control) has revolutionized tapping and boring operations, providing significant improvements in precision, efficiency, and repeatability. CNC machines use computer programs to control the movements of the tools, allowing for complex geometries and automated processes.

Key benefits of CNC in tapping and boring include:

Increased Accuracy and Precision: CNC machines offer unparalleled precision, leading to tighter tolerances and better dimensional accuracy compared to manual operations. The programmed paths guarantee consistent hole positioning and size.

Improved Efficiency: Automation streamlines the process, reducing cycle times and increasing productivity. The machines can operate continuously without operator intervention for extended periods.

Enhanced Repeatability: CNC ensures that every hole is machined identically, eliminating variations that may occur in manual operations.

Complex Part Machining: CNC allows for the creation of intricate hole patterns and complex shapes that would be extremely difficult or impossible to achieve manually.

For example, a CNC machine can be programmed to bore a series of precisely located holes with varying diameters and depths in a complex component, a feat that would be very challenging to replicate using traditional methods.

Q 20. What is the role of tooling in achieving dimensional accuracy in tapping and boring?

Tooling plays a paramount role in achieving dimensional accuracy in tapping and boring. The selection and maintenance of appropriate tools directly impact the quality of the finished hole. Factors to consider include:

Tool Geometry: The cutting edges, rake angle, and other geometric features of the tool influence the cutting action and surface finish. Precisely ground tools are essential for accurate hole dimensions.

Tool Material: The tool material must be sufficiently hard and wear-resistant to withstand the cutting forces and maintain its shape throughout the operation. Materials like carbide and high-speed steel are frequently used.

Tool Condition: Dull or damaged tools will produce inaccurate and potentially damaged holes. Regular inspection and timely replacement or sharpening are crucial.

Tool Holding System: The tool holder must be rigid and precisely aligned to prevent tool deflection during cutting, ensuring accurate hole positioning.

Proper Tool Selection: Choosing the right tap and bore for the specific material and hole size is vital to minimizing errors.

For example, using a dull tap will result in a poorly formed thread, leading to inaccurate hole dimensions and potentially damaging the threads. Similarly, a worn bore will cause an oversized hole, compromising the intended fit or function of the component. Regular tool calibration and maintenance are essential for consistent results.

Q 21. How do you select the appropriate cutting tool material for tapping and boring?

Selecting the appropriate cutting tool material for tapping and boring depends primarily on the workpiece material and the desired machining parameters. The goal is to find a material combination that provides a balance between tool life and the required cutting performance.

Common materials include:

High-Speed Steel (HSS): A versatile material suitable for a wide range of materials, but with lower wear resistance than carbide.

Carbide: Offers superior hardness and wear resistance, especially beneficial for harder and tougher materials, resulting in longer tool life but may be more brittle.

Ceramics: Excellent for machining hard materials at high speeds but require careful handling due to brittleness.

Cubic Boron Nitride (CBN): The hardest material used in cutting tools, suited for extremely hard materials like hardened steel, but is more expensive.

Polycrystalline Diamond (PCD): Extremely hard and wear-resistant; ideal for machining non-ferrous materials and some plastics.

The selection process often involves consulting material property charts and tool manufacturer recommendations. Factors like cutting speed, feed rate, and coolant usage should also be considered. In some cases, cost-benefit analyses may be conducted to determine the optimal tool material based on overall machining cost, including tool replacement frequency.

For instance, machining aluminum might use HSS tools, while machining hardened steel may require carbide or even CBN tools. The choice is never arbitrary but driven by a careful consideration of all relevant factors.

Q 22. What is the importance of proper machine setup in tapping and boring?

Proper machine setup is paramount in tapping and boring for achieving high precision and preventing tool damage. Think of it like baking a cake – if your oven isn’t preheated correctly or your ingredients aren’t measured precisely, the final product won’t be as good. In tapping and boring, this translates to accurate hole location, size, and thread quality.

- Spindle Alignment: A misaligned spindle can lead to inaccurate hole positions and even tool breakage. Regular checks using precision instruments are essential.

- Workpiece Clamping: Secure clamping prevents workpiece movement during operation, crucial for maintaining hole accuracy and preventing chatter. The clamping force must be sufficient to prevent movement but not so strong that it distorts the workpiece.

- Tool Selection and Adjustment: Selecting the right tap or boring tool for the material and desired hole size is critical. Proper adjustment of tool height and alignment minimizes errors and maximizes tool life.

- Cutting Fluid Delivery: The correct type and flow rate of cutting fluid is crucial for lubrication, cooling, and chip evacuation. Inadequate cooling can lead to tool wear and heat damage to the workpiece.

For example, during a recent project involving precision boring of a large aluminum component, meticulous attention to spindle alignment ensured the final bore diameter was within 0.001mm of the specification. This level of accuracy wouldn’t have been possible without careful machine setup.

Q 23. Describe different types of cutting fluids used in tapping and boring.

The choice of cutting fluid in tapping and boring is crucial for optimal performance and tool life. It acts as a lubricant, coolant, and chip remover. Different fluids cater to various materials and applications.

- Mineral Oils: These are common and relatively inexpensive, offering good lubrication and some cooling. They are suitable for many general applications but may not be ideal for high-temperature operations or when superior cooling is needed.

- Synthetic Fluids: These offer superior performance compared to mineral oils, providing better lubrication, cooling, and chip evacuation. They’re often preferred for challenging materials or high-speed operations.

- Water-Miscible Fluids: These are blends of water and oil-based components, providing both good lubrication and excellent cooling. They’re environmentally friendly compared to straight oils, but can be more susceptible to bacterial growth if not managed carefully.

- Soluble Oils: Similar to water-miscible fluids, but usually with a higher oil concentration, providing better lubrication for heavy-duty applications.

For instance, when working with stainless steel, I would usually opt for a synthetic fluid to combat the material’s tendency to work-harden. Conversely, for a low-speed tapping operation in mild steel, a mineral oil would suffice.

Q 24. How do you maintain and care for tapping and boring tools?

Maintaining and caring for tapping and boring tools is essential for extending their lifespan and ensuring consistent performance. This involves proper cleaning, storage, and sharpening.

- Cleaning: After each use, tools should be thoroughly cleaned to remove chips and cutting fluid. Compressed air is effective for removing loose chips, while a solvent can be used to clean the flutes.

- Inspection: Regular inspection for signs of wear, such as chipping, cracking, or excessive wear on cutting edges, is crucial. Damaged tools should be replaced or sharpened immediately.

- Storage: Tools should be stored in a clean, dry environment, ideally in a designated tool box or cabinet to prevent damage or corrosion. Lubricating the tools can also help prevent rust.

- Sharpening: Dull taps and boring tools produce poor quality holes, reduced cutting efficiency, and increased tool wear. Regular sharpening maintains optimal performance. Specialized equipment and expertise are often required for effective sharpening.

I always make sure to clean and inspect my tools after each job, even if it’s just a quick visual check. Regular maintenance ensures that the tools remain in peak condition, contributing directly to the quality and efficiency of my work. For example, a worn tap can lead to cross-threading, which is time-consuming and expensive to correct.

Q 25. Explain the concept of tolerance and its importance in tapping and boring.

Tolerance in tapping and boring refers to the allowable variation in the size and position of a hole. It’s the difference between the maximum and minimum acceptable dimensions. Think of it as a range of acceptable values. The importance of tolerance stems from the need to ensure the hole fits correctly with other parts of a machine or assembly. Too tight and the parts won’t assemble, too loose and the assembly might be weak or inaccurate.

- Hole Diameter Tolerance: Specifies the permissible variation in the diameter of a bored or tapped hole.

- Positional Tolerance: Determines the allowable deviation of a hole’s location from its specified position.

- Thread Tolerance: For tapped holes, this covers variations in thread pitch diameter, major diameter and minor diameter.

The level of tolerance required depends on the application. A high-precision component requires much tighter tolerances than a less critical part. For example, in aerospace applications, tolerances can be extremely tight – measured in microns – to ensure proper functioning and safety. In contrast, a simple bracket might have much looser tolerances.

Q 26. How does workholding affect the accuracy of tapping and boring?

Workholding is the method used to secure the workpiece during tapping and boring. Its impact on accuracy is substantial. If the workpiece isn’t held securely, it can move during the operation, resulting in inaccurate hole location, size, or thread form. This is similar to trying to draw a straight line with a shaky hand – the result won’t be precise.

- Rigidity: The workholding system needs to be rigid enough to prevent any movement or vibration during machining. A flexible setup will introduce inaccuracies.

- Alignment: The workpiece should be accurately aligned with the machine spindle to ensure that the hole is drilled in the correct location and orientation.

- Clamping Force: The clamping force must be sufficient to hold the workpiece securely but not so strong as to deform it.

In my experience, I’ve seen projects significantly hampered by poor workholding. On one occasion, insufficient clamping resulted in workpiece movement during a deep boring operation, leading to a scrapped part and significant rework. We corrected the problem by using a more robust workholding system and increasing the clamping force, after which the accuracy improved dramatically.

Q 27. Describe your experience with different types of tapping machines.

My experience encompasses several types of tapping machines, each with its strengths and weaknesses:

- Hand Taps: For small-scale work and manual operation, hand taps are useful, but require skill and care to avoid cross-threading and breakage. They’re mostly used for low volume work or intricate situations where a machine may not be practical.

- Tapping Machines (Automatic): These machines automate the tapping process, resulting in higher speed and consistency. They range from small benchtop units to large, CNC-controlled machines for high-volume production.

- CNC Machines (with tapping capability): Many modern CNC machining centers offer integrated tapping cycles, enhancing precision and control over the entire machining process. This allows for complex tapping operations to be programmed and executed automatically.

I’ve extensively used automatic tapping machines in high-volume production settings, finding them invaluable for their speed and accuracy. The consistency they provide is a major advantage, reducing the chance of human error and ensuring a consistently high-quality output. CNC machines with tapping functionality are my preference for complex, high-precision applications, allowing programmed operations and a high degree of flexibility.

Q 28. Describe your experience with different types of boring machines and their capabilities.

My experience with boring machines covers a range of types, each suited for different applications and capabilities:

- Vertical Boring Mills: These are large machines ideal for boring large-diameter holes in heavy workpieces. Their vertical orientation is convenient for large and awkward parts.

- Horizontal Boring Mills: These are better suited for workpieces that are difficult to position vertically. They allow for extensive tooling access and flexibility.

- Jig Borers: These high-precision machines are designed for highly accurate hole location, commonly used in tooling and gauge manufacturing.

- CNC Boring Machines: CNC-controlled boring machines offer precision, automation, and the ability to execute complex boring operations with high repeatability. They’re versatile and efficient.

I’ve worked extensively with CNC boring machines in a precision manufacturing environment, finding their repeatability and accuracy invaluable. For example, during the production of a complex hydraulic cylinder, the CNC boring machine ensured that the internal bore diameter remained consistently within the required tolerance. I also had experience working with jig borers during the manufacture of jigs and fixtures, where extreme accuracy is essential for precise part positioning and machining.

Key Topics to Learn for Tapping and Boring Interview

- Machine Selection and Setup: Understanding the different types of tapping and boring machines, their capabilities, and the process of selecting the appropriate machine for a given task. This includes considerations for material type, size, and precision requirements.

- Tooling and Cutting Parameters: Knowledge of various taps and boring tools, including their geometry, materials, and coatings. Understanding how to select optimal cutting speeds, feeds, and depths of cut to achieve desired surface finish and dimensional accuracy. This also includes recognizing and preventing tool wear.

- Workholding and Fixturing: Mastering techniques for securely holding and aligning workpieces during tapping and boring operations. This includes selecting appropriate workholding devices (e.g., chucks, vises, fixtures) and ensuring workpiece stability to prevent vibrations and inaccuracies.

- Programming and CNC Operation (if applicable): For CNC machines, understanding the programming process, including G-code or other relevant programming languages, and the ability to operate and troubleshoot CNC tapping and boring machines. This includes interpreting machine error messages and implementing corrective actions.

- Quality Control and Inspection: Knowing how to inspect tapped and bored holes for accuracy, surface finish, and compliance with specifications. Understanding various inspection methods and tools. This includes identifying and addressing potential sources of error.

- Safety Procedures and Best Practices: Familiarity with relevant safety regulations and procedures for operating tapping and boring machines. This includes proper use of personal protective equipment (PPE) and understanding the potential hazards associated with the process.

- Troubleshooting and Problem Solving: Ability to diagnose and resolve common problems encountered during tapping and boring operations, such as broken tools, inaccurate dimensions, or machine malfunctions. This includes a systematic approach to troubleshooting.

Next Steps

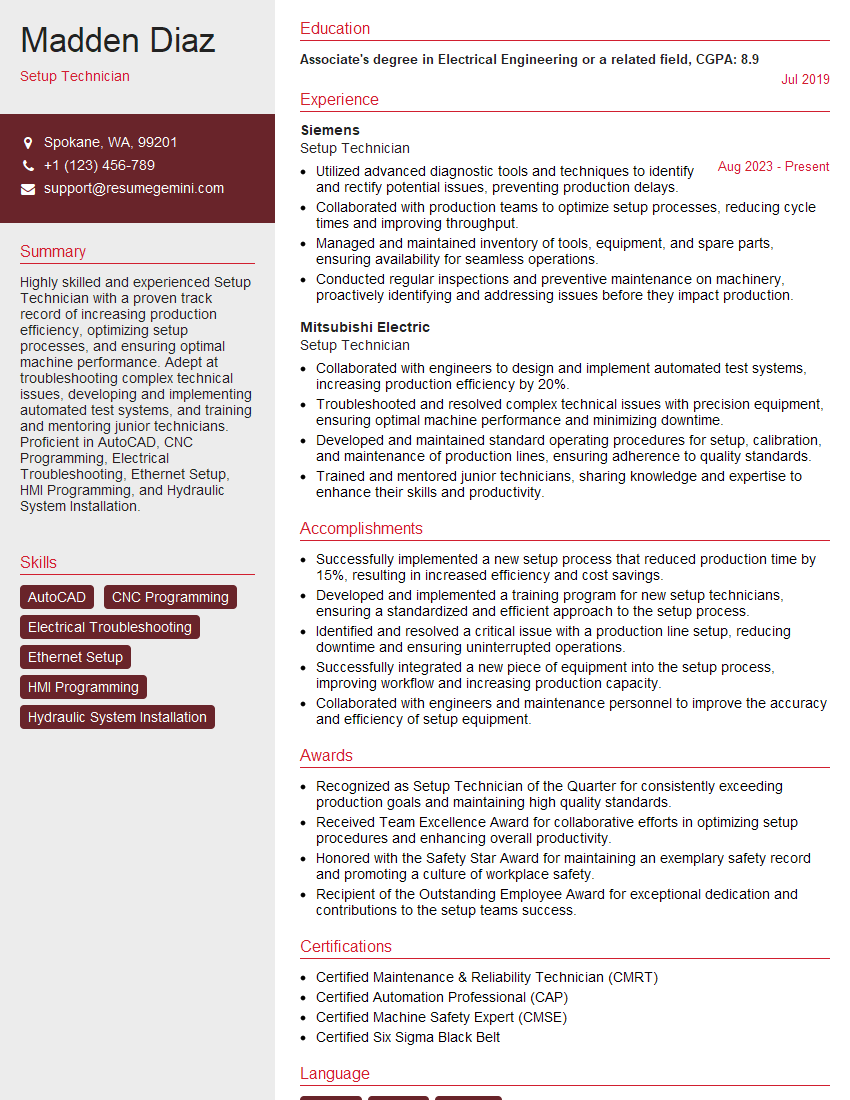

Mastering tapping and boring techniques is crucial for a successful career in manufacturing and machining. A strong understanding of these processes demonstrates valuable skills to potential employers, leading to increased job opportunities and career advancement. To maximize your chances of landing your dream role, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to the Tapping and Boring field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.