Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top TCLP and Hazardous Waste Management interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in TCLP and Hazardous Waste Management Interview

Q 1. Define TCLP and explain its purpose.

The Toxicity Characteristic Leaching Procedure (TCLP) is a standardized method used to determine the mobility of hazardous constituents from a variety of solid wastes. Its primary purpose is to predict the potential leaching of contaminants into the environment under specific conditions, helping determine whether a waste is hazardous according to US EPA regulations. Think of it as a worst-case scenario test that simulates how a waste might behave in a landfill or other disposal site.

Essentially, TCLP mimics the leaching process by exposing a waste sample to a specific extraction fluid under controlled conditions. The resulting leachate is then analyzed for the presence and concentration of various hazardous substances. If the concentration of any regulated constituent exceeds the established TCLP regulatory limit, the waste is classified as hazardous.

Q 2. Describe the TCLP procedure for a specific waste type (e.g., lead-based paint).

Let’s consider lead-based paint. The TCLP procedure for this waste involves several steps:

- Sample Preparation: A representative sample of the lead-based paint is prepared, ensuring homogeneity to avoid bias. This might involve crushing and mixing to obtain a uniform sample.

- Extraction: A precise weight of the prepared sample is mixed with a specific volume of extraction fluid (typically acetic acid). The mixture is then agitated for a defined period (usually 18 hours) under controlled conditions (e.g., temperature, rotation speed) to simulate leaching. The extraction fluid is designed to aggressively leach out potential contaminants.

- Separation: After the extraction period, the solid residue is separated from the liquid leachate through filtration. This leachate now contains the leached substances from the paint.

- Analysis: The leachate undergoes analysis to determine the concentration of lead using an appropriate method (e.g., Inductively Coupled Plasma Mass Spectrometry – ICP-MS or Atomic Absorption Spectroscopy – AAS).

- Comparison to Regulatory Limits: The measured lead concentration is compared to the EPA’s TCLP regulatory limit for lead. If the concentration surpasses the limit, the lead-based paint is classified as a hazardous waste.

It’s crucial to follow EPA Method 1311 meticulously during this process to ensure accuracy and reliability of the results.

Q 3. What are the key differences between TCLP and other extraction methods?

TCLP differs significantly from other extraction methods like the Toxicity Characteristic Leaching Procedure (TCLP) because of its highly specific and aggressive extraction conditions. Other methods, such as the Synthetic Precipitation Leaching Procedure (SPLP) or the American Society for Testing and Materials (ASTM) methods, use different extraction fluids, contact times, and pH levels, leading to varied results.

- Extraction Fluid: TCLP uses a dilute acetic acid solution, designed to mimic acidic conditions in a landfill. Other methods may utilize deionized water, or solutions with different pH levels.

- Contact Time: TCLP’s 18-hour extraction time is relatively short compared to some other methods, which might involve longer periods to simulate slower leaching processes.

- Solid-to-Liquid Ratio: TCLP uses a specific solid-to-liquid ratio; other methods might vary this parameter.

This difference in methodology leads to distinct results, with TCLP potentially yielding higher concentrations of leachable substances due to its aggressive nature, which is important for determining whether a waste meets the definition of hazardous.

Q 4. Explain the significance of the TCLP regulatory limits.

The TCLP regulatory limits are established by the EPA and represent the maximum concentration of a specific constituent allowed in the leachate to classify a waste as non-hazardous. These limits are based on risk assessment and ecological considerations, designed to protect human health and the environment. Exceeding a TCLP limit for a regulated constituent has significant consequences.

For example, if a waste sample exceeds the TCLP limit for lead, it’s classified as hazardous waste, requiring stringent management practices, including special transportation, storage, and disposal procedures. This impacts the cost and complexity of waste management, potentially adding significant financial burdens to the generators.

Q 5. How do you interpret TCLP results?

Interpreting TCLP results involves comparing the measured concentration of each regulated constituent in the leachate to its respective regulatory limit. If the concentration of any constituent exceeds its limit, the waste is classified as hazardous.

For example, if a sample shows 1.2 mg/L lead (and the TCLP limit is 5.0 mg/L), and 0.5 mg/L cadmium (and the TCLP limit is 1.0 mg/L), the waste is still considered hazardous because the cadmium level exceeds its limit, even though the lead is below it. It’s an all-or-nothing approach for classifying hazardous waste based on the TCLP test.

Q 6. What are the common challenges encountered during TCLP testing?

TCLP testing can present several challenges:

- Sample Heterogeneity: Ensuring a representative sample from a heterogeneous waste stream is crucial for accurate results. Inconsistent sampling can lead to misleading conclusions.

- Matrix Effects: The presence of certain components in the waste matrix can interfere with the analytical measurements, impacting accuracy. Method blanks and spiked samples help mitigate this, but careful sample preparation and quality control is essential.

- Analytical Variability: Even with meticulous procedures, analytical variability can occur. Implementing robust quality control measures and using certified reference materials can reduce this uncertainty.

- Regulatory Changes: Regulatory updates regarding listed constituents and their limits necessitate staying informed and adapting laboratory procedures.

Proper training, attention to detail, and adherence to strict quality control protocols can help minimize these challenges and ensure reliable results.

Q 7. Describe quality control measures implemented during TCLP analysis.

Rigorous quality control (QC) measures are crucial for ensuring the accuracy and reliability of TCLP results. These typically include:

- Method Blanks: These blanks are processed alongside the samples without any waste material to detect potential contamination during the extraction or analysis.

- Laboratory Control Samples (LCS): These are known samples with a defined concentration of target analytes. They’re processed similarly to the actual samples and serve to verify the accuracy and precision of the analytical method.

- Spiked Samples: These samples have known amounts of target analytes added before extraction, assessing the recovery efficiency of the analytical process.

- Duplicate Samples: Running duplicate samples helps evaluate the precision and reproducibility of the entire process.

- Use of Certified Reference Materials (CRMs): CRMs with known analyte concentrations are used to calibrate instruments and validate analytical results.

- Regular Instrument Calibration and Maintenance: Proper maintenance and regular calibration ensure the instruments’ accuracy and precision.

By implementing these QC checks, laboratories can ensure the reliability of TCLP data and confidently assess the hazardous nature of wastes.

Q 8. How do you handle non-detects in TCLP results?

Handling non-detects in TCLP (Toxicity Characteristic Leaching Procedure) results requires careful consideration. A non-detect doesn’t mean the analyte is absent; it simply means its concentration is below the method’s detection limit. We typically report non-detects as less than (<) the detection limit. For example, if the detection limit for lead is 0.5 mg/L and we don't detect lead, we report it as <0.5 mg/L. This is crucial for accurate data interpretation and regulatory compliance.

The handling of non-detects varies depending on the regulatory context and the specific analysis. Some regulations may allow the use of the detection limit itself in further calculations, while others might require more sophisticated statistical treatments, such as substitution with a value half the detection limit. This substitution method helps to minimize potential bias. Always refer to the specific regulatory requirements and the laboratory’s quality assurance/quality control (QA/QC) procedures.

In my experience, clear communication is key. Reporting non-detects accurately and transparently is critical to prevent misinterpretations. Always include the detection limit in the report alongside the non-detect result. For instance, if we’re evaluating the leachability of a waste sample for a permit application, we cannot simply ignore the non-detects. The regulatory agency will need a comprehensive understanding of our findings, including the limitations of the analytical methods.

Q 9. Explain the role of RCRA in hazardous waste management.

The Resource Conservation and Recovery Act (RCRA) is the cornerstone of hazardous waste management in the United States. It establishes a framework for the generation, transportation, treatment, storage, and disposal (TSD) of hazardous waste, aiming to protect human health and the environment. RCRA assigns clear responsibilities to generators, transporters, and TSD facilities, enforcing stringent regulations to prevent pollution.

RCRA’s role is multifaceted. It defines what constitutes hazardous waste, establishes permitting requirements for TSD facilities, monitors compliance, and provides mechanisms for enforcement. The act focuses on cradle-to-grave management, ensuring hazardous wastes are handled responsibly throughout their lifecycle. It also includes provisions for corrective actions should a release of hazardous waste occur.

Imagine a company generating hazardous waste. RCRA mandates that this company properly characterize its waste, obtain necessary permits if storing or treating it, and use a licensed transporter to move it to a permitted TSD facility. Failure to comply results in significant penalties and legal repercussions.

Q 10. What are the different hazardous waste classifications under RCRA?

RCRA classifies hazardous wastes into several categories. The primary classifications are:

- Listed Wastes: These are wastes specifically listed by EPA as hazardous due to their known toxicity or potential for harm. These lists (F, K, P, and U) categorize wastes from various industrial processes and include specific substances, e.g., solvents, pesticides, and certain sludges.

- Characteristic Wastes: These wastes exhibit specific hazardous characteristics, regardless of their origin. The four characteristics are:

- Ignitability: Substances capable of readily catching fire.

- Corrosivity: Substances that can corrode metal containers.

- Reactivity: Substances that are unstable and react violently with water or air.

- Toxicity: Substances exhibiting toxicity as determined by the TCLP test.

- Mixed Wastes: Wastes containing both hazardous and radioactive components require additional handling and regulatory considerations.

Understanding these classifications is essential for proper waste management practices and compliance with RCRA. Misclassifying waste can lead to serious environmental damage and legal penalties.

Q 11. Describe the process of hazardous waste characterization.

Hazardous waste characterization is a critical process to determine if a waste is hazardous under RCRA. This involves a combination of procedures and analyses to identify the waste’s physical and chemical properties and match it to the appropriate RCRA classification.

The process generally begins with a thorough waste analysis plan. This plan defines the testing procedures, identifies the parameters to be measured, and outlines the quality assurance/quality control (QA/QC) measures to ensure the reliability and validity of the results. The plan should be tailored to the specific waste stream being analyzed. For example, a waste containing heavy metals would require metal analysis via TCLP and possibly other methods.

Subsequently, samples are collected according to specific protocols, ensuring representativeness. Lab analyses are then conducted to determine if the waste meets the criteria for listed wastes or exhibits any of the characteristic waste properties (ignitability, corrosivity, reactivity, toxicity). The results determine if the waste requires handling as hazardous waste.

Proper characterization is crucial for compliance. Inaccurate characterization can result in improper waste handling and potential environmental or human health risks. A comprehensive characterization study forms the basis for appropriate waste management decisions.

Q 12. Explain the concept of generator responsibility under RCRA.

Under RCRA, generators bear significant responsibility for the proper management of hazardous waste from the moment it’s generated until it’s properly disposed of. This includes accurate waste characterization, proper storage, appropriate labeling, and using licensed transporters and permitted facilities for treatment, storage, and disposal (TSD).

Generator responsibilities encompass several key areas:

- Accurate waste determination: Generators must determine if their waste is hazardous under RCRA guidelines.

- Proper labeling and record-keeping: Accurate documentation is vital, including manifest tracking, waste descriptions, and storage records.

- Storage requirements: Generators must store their waste in accordance with RCRA standards, preventing leaks and spills.

- Transportation using licensed haulers: Generators must employ only licensed and permitted transporters to transfer waste to a permitted TSD facility.

- Compliance with applicable regulations: Generators must remain updated on and compliant with all relevant RCRA regulations.

The generator’s responsibility extends beyond simple containment. It’s about ensuring the entire lifecycle of the hazardous waste is managed correctly and safely. Failure to meet these responsibilities can result in substantial fines and legal action.

Q 13. What are the different treatment, storage, and disposal (TSD) methods for hazardous waste?

Numerous treatment, storage, and disposal (TSD) methods exist for hazardous waste, each suited to specific waste characteristics and regulatory requirements. The selection of an appropriate TSD method depends on several factors, including the waste’s composition, volume, and toxicity.

Examples of TSD methods include:

- Incineration: High-temperature combustion to destroy organic hazardous wastes.

- Landfilling: Disposal in secure landfills designed to prevent leachate contamination.

- Chemical treatment: Neutralization, oxidation, or reduction to render the waste less hazardous.

- Biological treatment: Utilizing microorganisms to break down organic waste components.

- Solidification/Stabilization: Treating waste to reduce mobility and prevent leaching.

- Physical treatment: Methods such as filtration, evaporation, or extraction to separate and remove hazardous components.

The choice of method is crucial. For instance, incineration is effective for certain organic wastes but may not be suitable for some inorganic wastes. Landfilling requires robust containment measures to protect groundwater. Regulatory agencies approve and oversee these TSD methods, ensuring proper environmental protection.

Q 14. Describe your experience with hazardous waste manifest systems.

My experience with hazardous waste manifest systems spans several years, encompassing both practical application and regulatory compliance. I’ve been involved in the creation, tracking, and reconciliation of manifests for various hazardous waste streams, ensuring complete accountability from generation to disposal. These systems are critical for maintaining a comprehensive audit trail and ensuring compliance with RCRA’s cradle-to-grave tracking mandates.

I’m proficient in using both manual and electronic manifest systems. This includes understanding the requirements for accurately completing all fields on the manifest, ensuring that copies are properly distributed among generators, transporters, and TSD facilities, and maintaining thorough records for audits. I’ve successfully resolved discrepancies and managed delays in the manifest process, proactively identifying potential issues and working to correct them.

One significant project involved managing the manifests for a large industrial facility. This required close coordination with several different parties, including internal staff, transporters, and the receiving TSD facility. Through meticulous tracking and efficient communication, we successfully managed thousands of manifests without any significant compliance issues. This highlights the importance of accurate data entry, regular auditing, and consistent communication throughout the manifest system’s life cycle.

Q 15. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations, particularly those governing hazardous waste, requires a multi-faceted approach. It starts with a thorough understanding of all applicable federal, state, and local laws and regulations. This includes familiarity with the Resource Conservation and Recovery Act (RCRA), the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), and any specific regulations pertinent to the type of hazardous waste handled. For example, understanding TCLP (Toxicity Characteristic Leaching Procedure) limits is crucial for determining if a waste is hazardous based on its potential to leach contaminants.

Beyond understanding the regulations, compliance involves implementing robust waste management programs. These programs should encompass all aspects of hazardous waste management, from generation to disposal, including proper labeling, storage, transportation, and treatment. Regular internal audits, employee training, and meticulous record-keeping are essential components of a successful compliance program. Finally, proactive engagement with regulatory agencies through timely reporting and open communication is key to avoiding penalties and maintaining a strong compliance record.

For example, in a previous role, we implemented a new waste tracking system that automated many aspects of record keeping. This greatly reduced the risk of errors, simplified reporting to regulatory agencies, and significantly streamlined our compliance efforts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper hazardous waste labeling and packaging.

Proper hazardous waste labeling and packaging is paramount for worker safety and environmental protection. Think of it as the first line of defense in preventing accidents and spills. Accurate labeling ensures that everyone handling the waste understands the potential hazards associated with it. This includes identifying the specific hazardous components, the associated health risks (e.g., corrosive, flammable, toxic), and proper handling procedures.

Packaging must also meet stringent requirements to prevent leaks or spills during handling, storage, and transportation. The packaging material must be compatible with the waste’s chemical properties to avoid reactions or degradation. The packaging should be strong enough to withstand normal handling and transport conditions. For instance, using the wrong container for a corrosive waste could lead to container failure and a hazardous materials spill, potentially causing significant environmental damage and harm to personnel.

The failure to correctly label and package hazardous waste can lead to severe fines, legal liabilities, and potential harm to the environment and human health. Following established standards (e.g., DOT regulations for transportation) is critical.

Q 17. Describe your experience with hazardous waste emergency response plans.

My experience with hazardous waste emergency response plans involves developing, implementing, and regularly updating such plans for various facilities. A well-defined emergency response plan is crucial to minimize the impact of accidental releases of hazardous materials. It outlines procedures for detecting spills, controlling the spread of contamination, and providing immediate first aid and medical treatment.

A comprehensive plan includes detailed emergency contact information for regulatory agencies, emergency responders, and medical professionals. It also specifies roles and responsibilities for personnel during an emergency, outlining who is responsible for what task. For example, one plan I developed included detailed maps of the facility, showing the location of hazardous materials storage areas and emergency equipment such as spill kits and safety showers. Regular drills and training exercises are essential to ensure that personnel are familiar with and proficient in the procedures outlined in the plan.

Failure to have a well-defined and regularly practiced plan can result in significant consequences, including environmental damage, injuries, and substantial financial penalties.

Q 18. How do you manage hazardous waste spills and leaks?

Managing hazardous waste spills and leaks involves immediate action to contain the spill and prevent further contamination. The first step is always to ensure the safety of personnel involved by evacuating the area and implementing appropriate personal protective equipment (PPE).

Next, the spill must be contained and cleaned up, utilizing the appropriate materials and methods for the specific hazardous waste involved. This may include using absorbent materials to soak up the spill, employing specialized cleaning equipment, or utilizing containment berms to prevent the spread. Proper disposal of the contaminated materials is critical – they cannot be disposed of in the regular waste stream.

Detailed documentation of the spill, cleanup procedures, and the quantities of waste involved is crucial for compliance and reporting purposes. This information is often reported to regulatory agencies, as mandated by law. A systematic approach, clear communication, and thorough documentation prevent further complications and ensure environmental protection.

Q 19. What are the key elements of a successful hazardous waste management program?

A successful hazardous waste management program hinges on several key elements: a strong commitment from leadership, thorough employee training, well-defined procedures, and robust record-keeping. It’s not simply about following rules; it’s about cultivating a safety-conscious culture throughout the organization.

- Comprehensive Waste Characterization: Accurately identifying the hazardous waste generated is fundamental. This involves laboratory analysis to determine the waste’s chemical composition and its hazard classification.

- Waste Minimization: Reducing waste at the source is environmentally preferable and economically advantageous. Implementing waste reduction strategies (e.g., process modifications, recycling) decreases both waste disposal costs and environmental liability.

- Proper Storage and Handling: Safe storage practices are paramount, requiring designated areas, appropriate containers, and regular inspections. Handling procedures must strictly adhere to safety guidelines to prevent accidents.

- Transportation and Disposal: Waste must be transported and disposed of by licensed haulers in accordance with all applicable regulations. Documentation is crucial here.

- Emergency Response Planning: A detailed plan is necessary to handle potential spills or leaks effectively and safely, limiting environmental impact and protecting personnel.

- Regular Audits and Compliance Monitoring: Ongoing internal audits and inspections ensure adherence to regulations and identify any potential weaknesses in the program.

Think of it like building a house – each element is crucial. A weak foundation (lack of leadership commitment) will ultimately compromise the entire structure, leading to compliance issues and potential risks.

Q 20. Describe your experience with hazardous waste audits and inspections.

My experience with hazardous waste audits and inspections involves both conducting internal audits and cooperating with external regulatory agency inspections. Internal audits assess compliance with our own program and identify areas for improvement. These are proactive measures aimed at maintaining compliance and preventing potential problems.

External inspections, often conducted by state or federal agencies like the EPA, are more formal and involve a comprehensive review of our waste management practices. They may involve review of our documentation, physical inspections of our facilities, and interviews with personnel. Preparation for these inspections is crucial, involving ensuring complete and accurate recordkeeping, preparing for questions, and demonstrating our commitment to compliance. These inspections can often highlight areas where we could further enhance our procedures.

Through both internal and external audits, we have identified areas of weakness and implemented improvements, leading to a more robust and efficient hazardous waste management system.

Q 21. Explain the concept of cradle-to-grave hazardous waste management.

Cradle-to-grave hazardous waste management refers to the entire lifecycle of a hazardous material, from its generation (cradle) to its final disposal (grave). It encompasses all aspects of managing the waste, ensuring its safe handling and disposal from the moment it’s created until it’s permanently disposed of in an environmentally sound manner.

This holistic approach emphasizes accountability throughout the entire process. It necessitates careful planning and execution at each stage, from the design of processes to minimize waste generation to the selection of appropriate disposal methods. Each stage requires careful consideration of environmental impacts and compliance with relevant regulations. This includes proper labeling and packaging, appropriate transportation, secure storage, and environmentally sound disposal. This comprehensive approach ensures that hazardous waste is managed responsibly and minimizes its potential impact on human health and the environment.

Consider a manufacturing plant using hazardous chemicals. Cradle-to-grave management would start with choosing less toxic alternatives whenever feasible and optimizing processes to minimize waste generation. It would include careful handling, storage, transportation, and finally, disposal of the waste at a permitted facility, adhering to stringent environmental regulations at every step.

Q 22. How do you address discrepancies between laboratory results and regulatory limits?

Discrepancies between TCLP (Toxicity Characteristic Leaching Procedure) results and regulatory limits are a common challenge in hazardous waste management. The first step is to meticulously review the data and the entire analytical process. This includes verifying the sample collection, handling, preparation, and laboratory analysis for any potential errors. Were the correct methods used? Were chain-of-custody procedures followed? Were there any anomalies in the laboratory data itself, such as unusually high or low values that deviate from the expected range?

If the discrepancy is significant, a thorough investigation is necessary. This might involve re-analyzing the original sample or collecting a new sample for testing at a different accredited laboratory. Depending on the severity, we may also need to explore alternative analytical methods to confirm the results. For example, if the initial TCLP test shows a result slightly above the regulatory limit for a specific hazardous constituent, a second test might be run, perhaps using a different extraction fluid. Documenting every step of this process is crucial for transparency and to support any decisions made.

Once the root cause of the discrepancy is identified and confirmed, appropriate corrective actions must be taken. This may involve modifying waste treatment processes to reduce the concentration of hazardous constituents, implementing more rigorous quality control measures in the sampling and analysis procedures, or even revising waste classification based on the confirmed data. In some cases, a consultation with the regulatory agency is needed to clarify the situation and obtain guidance on the most suitable course of action. This ensures compliance with all applicable regulations.

Q 23. What are your strategies for minimizing hazardous waste generation?

Minimizing hazardous waste generation is a cornerstone of responsible environmental management. My approach focuses on a multi-pronged strategy involving waste reduction, reuse, and recycling (the ‘3Rs’). This starts at the source, during the design phase of any process or project. For instance, we might use less hazardous materials or find substitutes that are less toxic. This proactive approach prevents hazardous waste from being created in the first place.

For existing processes, implementing process optimization techniques can significantly reduce waste. This could include improving efficiency through better equipment, modifying production techniques to lower by-product formation, or implementing better housekeeping practices to minimize spills and leaks. We might also explore material recovery, such as reclaiming valuable materials from waste streams for reuse, reducing the amount that needs disposal. This could be something as simple as recycling used solvents or as complex as recovering metals from manufacturing processes.

Another effective strategy is regular training for personnel. Proper training on waste handling, segregation, and best practices empowers employees to actively contribute to waste reduction. This reduces errors and leads to a more consistent and effective waste management program. Thorough record-keeping is essential to monitor progress, identify areas for improvement, and demonstrate compliance with environmental regulations.

Q 24. Describe your experience with environmental remediation techniques.

My experience in environmental remediation encompasses a range of techniques, tailored to the specific contaminants and site conditions. I’ve been involved in projects utilizing in-situ remediation techniques, such as bioremediation (using microorganisms to break down pollutants), pump and treat systems (extracting groundwater and treating it above ground), and soil vapor extraction (removing volatile organic compounds from the soil using vacuum systems).

I have also worked extensively on ex-situ remediation, which involves removing the contaminated material from the site and treating it elsewhere. This can include techniques like soil washing (using water or solvents to remove contaminants), thermal desorption (heating the soil to vaporize contaminants), and solidification/stabilization (treating the soil to reduce contaminant mobility). The choice of remediation technique depends on various factors, including the type and concentration of contaminants, the physical properties of the soil and groundwater, the site’s location, and regulatory requirements.

For example, I was involved in a project where bioremediation was successfully employed to treat soil contaminated with petroleum hydrocarbons. The strategy involved selecting specific microorganisms capable of degrading those hydrocarbons and providing suitable environmental conditions (e.g., moisture, nutrients, and oxygen) to optimize their growth and activity. Regular monitoring of contaminant concentrations was carried out to assess the effectiveness of the remediation process and ensure its compliance with the project goals and regulatory limits. Rigorous documentation and reporting were vital in the project’s success.

Q 25. Explain the role of risk assessment in hazardous waste management.

Risk assessment is fundamental to effective hazardous waste management. It involves identifying the hazards associated with the waste, evaluating the likelihood of those hazards causing harm, and determining the severity of the potential consequences. This structured approach ensures that resources are allocated to manage the most significant risks effectively. A thorough risk assessment helps prioritize actions, allowing for the most impactful and cost-efficient mitigation strategies.

The process often starts with characterizing the waste, identifying its hazardous constituents and their concentrations. Then, we consider the potential exposure pathways – how people and the environment could come into contact with the waste. This might include direct contact, inhalation, or groundwater contamination. Finally, we evaluate the potential health and environmental effects, based on the toxicity of the constituents and the likelihood of exposure. This might involve using models to predict contaminant transport or relying on existing toxicological data.

The outcomes of the risk assessment guide the development of a waste management plan. It dictates the choice of treatment methods, the level of containment needed, and the monitoring program. For example, a high-risk waste stream may require more stringent treatment and more frequent monitoring compared to a lower-risk one. Risk assessment is an iterative process; it’s regularly reviewed and updated to reflect new information or changes in the circumstances.

Q 26. How do you stay updated on changes in environmental regulations?

Staying abreast of changes in environmental regulations is crucial in this field. I utilize a multi-faceted approach. I subscribe to relevant professional journals and newsletters, such as those published by EPA and other regulatory agencies. I actively participate in professional organizations and attend conferences and workshops to network with colleagues and learn about the latest developments in the field. This networking offers valuable opportunities to gain insights from experts and discuss emerging challenges.

I also use online resources, including government agency websites and legal databases, to access up-to-date information on regulatory changes. Staying informed through these channels enables proactive compliance and provides the opportunity to adapt strategies in anticipation of regulatory shifts. Regular internal training sessions for our team keep everyone on the same page regarding regulatory updates and ensures that our procedures reflect the latest requirements.

Furthermore, I engage in direct communication with regulatory agencies. This involves attending public hearings, participating in consultations, and establishing relationships with regulatory personnel. This direct engagement clarifies any uncertainties and helps navigate complex regulatory landscapes effectively.

Q 27. Describe your experience working with different stakeholders in hazardous waste management (e.g., regulators, clients).

Effective hazardous waste management demands collaboration with diverse stakeholders. My experience includes working extensively with regulatory agencies, clients, contractors, and the local community. Communication and transparency are key to building trust and achieving successful outcomes. I have found that clear and concise communication, focusing on mutual goals, is crucial. For example, when working with clients, I take the time to explain complex technical concepts in a way that is easy to understand, ensuring they are fully informed about the process and potential risks.

When dealing with regulatory agencies, building a positive relationship through open and honest communication is paramount. This means proactively addressing any concerns, providing clear and accurate documentation, and maintaining consistent communication throughout the project lifecycle. With contractors, clear contracts outlining responsibilities, timelines, and quality standards are crucial for effective project execution. This involves robust oversight and regular monitoring of their performance.

Community engagement is also critical. I’ve participated in public meetings to address community concerns and provide information about hazardous waste management projects, ensuring that the community feels involved and informed. This involves actively listening to community feedback and incorporating those concerns into project planning. This collaborative approach builds trust and fosters a sense of shared responsibility for environmental protection.

Q 28. How do you handle conflicting requirements from different regulatory agencies?

Conflicting requirements from different regulatory agencies can be a significant challenge. My approach centers around identifying the specific points of conflict and documenting them precisely. This means carefully reviewing each agency’s regulations and identifying any inconsistencies or overlaps. It’s crucial to understand the rationale behind each requirement and explore potential avenues for reconciliation.

Then, I engage in direct communication with each agency to clarify their expectations and explore potential compromises. This frequently involves providing detailed technical justifications and demonstrating how our approach will meet the spirit of the regulations, even if it doesn’t perfectly align with the letter of every rule. Sometimes, it’s necessary to seek a legal opinion to interpret ambiguous regulations or to negotiate a mutually agreeable solution.

Maintaining comprehensive documentation throughout this process is vital. This includes documenting all communications with regulatory agencies, justifications for our actions, and any agreed-upon solutions. This documentation serves as a valuable record of the process and provides evidence of compliance, should any disputes arise. In essence, the goal is to navigate the complexities through a combination of careful analysis, proactive communication, and thorough documentation, all while prioritizing environmental protection and regulatory compliance.

Key Topics to Learn for TCLP and Hazardous Waste Management Interview

- Regulatory Framework: Understanding RCRA, its Subtitle C and D regulations, and their implications for hazardous waste management.

- TCLP Procedure: Mastering the TCLP (Toxicity Characteristic Leaching Procedure) methodology, including sample preparation, extraction, and analysis techniques.

- Hazardous Waste Characterization: Familiarize yourself with different methods of identifying hazardous waste, including listed and characteristic wastes.

- Waste Minimization and Treatment Technologies: Explore various methods for reducing waste generation and treating hazardous waste, such as incineration, biological treatment, and solidification/stabilization.

- Risk Assessment and Management: Understand the principles of risk assessment related to hazardous waste and how to implement effective risk management strategies.

- Site Remediation: Learn about the process of cleaning up contaminated sites, including investigation, remediation methods, and regulatory compliance.

- Waste Transportation and Disposal: Familiarize yourself with the regulations and procedures for safely transporting and disposing of hazardous waste.

- Emergency Response Planning: Understand the importance of developing and implementing emergency response plans for hazardous waste incidents.

- Data Management and Reporting: Know how to accurately collect, manage, and report data related to hazardous waste management activities.

- Practical Application: Consider case studies and real-world examples to illustrate your understanding of the theoretical concepts.

- Problem-Solving: Practice analyzing scenarios and proposing solutions to common challenges encountered in hazardous waste management.

Next Steps

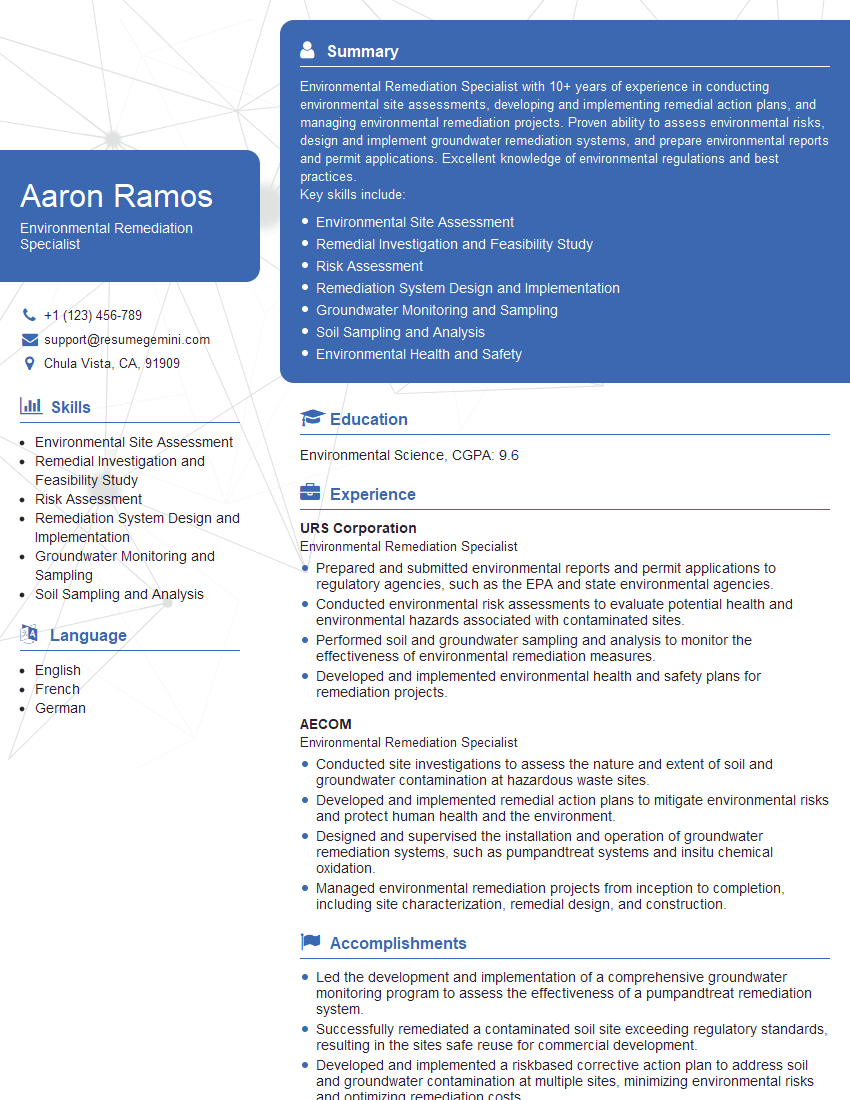

Mastering TCLP and Hazardous Waste Management opens doors to exciting and impactful careers in environmental consulting, industrial safety, and regulatory compliance. A strong understanding of these principles significantly enhances your job prospects. To maximize your chances of landing your dream role, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of TCLP and Hazardous Waste Management positions. Examples of resumes tailored to this field are provided to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.