Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Tear-Off and Removal of Old Roofing interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Tear-Off and Removal of Old Roofing Interview

Q 1. Describe your experience with different roofing materials (e.g., asphalt shingles, tile, metal).

My experience encompasses a wide range of roofing materials, each requiring a unique approach to tear-off. Asphalt shingles, for instance, are relatively straightforward to remove, typically involving hand-stripping or using specialized tools. Tile roofs, however, demand more precision and care due to their weight and fragility. We often use specialized equipment and techniques to avoid damaging the underlying structure. Metal roofing presents its own set of challenges, often requiring specialized tools to cut and remove the panels safely, minimizing potential damage and ensuring the safety of the crew. I’ve worked on projects involving all three materials, and my experience allows me to tailor my approach to each specific material and its associated complexities.

- Asphalt Shingles: Often removed by hand, though power tools can speed up the process. Careful disposal is crucial to avoid damage to the underlying structure and the environment.

- Tile Roofs: Requires careful planning and execution due to weight and potential for breakage. We prioritize minimizing damage to the underlying structure and use appropriate tools like pry bars and hammers with extreme care.

- Metal Roofing: Can involve cutting panels with specialized tools to facilitate removal. Safety is paramount due to sharp edges and potential for injury. Proper disposal and recycling of metal roofing materials are essential.

Q 2. What safety protocols do you follow during a roof tear-off?

Safety is our top priority. We rigorously follow a comprehensive safety protocol that starts with a thorough job site assessment. This includes identifying potential hazards like power lines, unstable areas of the roof, and any signs of decay in the structure. Every team member uses appropriate personal protective equipment (PPE), including hard hats, safety harnesses, eye protection, and gloves. We also implement fall protection measures, such as setting up safety nets and ensuring the proper use of safety harnesses with anchored tie-off points. Before starting the tear-off, a detailed briefing is provided to all crew members, outlining the day’s specific tasks and emphasizing the importance of safety procedures. Regular safety check-ins are conducted throughout the day to ensure everyone remains vigilant and adheres to the established safety protocols.

Q 3. Explain the process of safely removing asbestos-containing roofing materials.

Removing asbestos-containing roofing materials is a highly specialized and regulated process. It requires a license and adherence to strict environmental and safety regulations. The first step is confirming the presence of asbestos through professional testing. If asbestos is present, we follow a strict protocol. This includes containing the work area with specialized materials, using only approved equipment, and ensuring proper disposal of waste in designated, EPA-approved facilities. Our team members receive specialized training on asbestos handling and all work is conducted under the supervision of a certified asbestos abatement professional. The process includes careful removal, double bagging, and labeling of materials for safe transportation and disposal.

Q 4. How do you identify and mitigate potential hazards during a roof tear-off?

Identifying and mitigating hazards is an integral part of our tear-off process. We conduct a thorough site inspection before work begins, looking for things such as damaged structural components, potential falling hazards, the presence of asbestos or other hazardous materials, overhead power lines, and any unstable or slippery areas on the roof. We develop a risk assessment plan to mitigate these hazards. This might involve reinforcing weak areas of the roof, using appropriate safety equipment, employing spotters, and utilizing specialized tools to safely remove hazardous materials. Regular communication within the team helps to proactively address emerging hazards during the tear-off process. We also have contingency plans in place to handle unexpected events and ensure the safety of the crew and the property.

Q 5. What are the common tools and equipment used in a roof tear-off?

The tools and equipment used in a roof tear-off vary depending on the roofing material, but typically include a combination of hand tools and power tools. Common hand tools include pry bars, hammers, shovels, and roofing nails. Power tools may include roofing nail removers, circular saws (for cutting metal roofing), and demolition hammers (for particularly stubborn materials). We also use safety equipment like harnesses, ropes, and scaffolding, depending on the project requirements. For larger jobs, we use dumpsters to manage waste effectively and maintain a clean work site. Proper disposal methods for various materials are also crucial.

Q 6. Describe your experience with different tear-off methods.

My experience encompasses various tear-off methods, chosen based on the specific roofing material, roof design, and overall project requirements. For example, on asphalt shingle roofs, we may use a combination of hand-stripping and the use of a power tool for faster removal. For tile roofs, a more delicate approach is needed, often involving manual removal of tiles one at a time to protect the underlayment. With metal roofing, specialized cutting tools are often needed to efficiently and safely remove the panels. We also adapt our methods to ensure minimum disruption to the surrounding environment and neighboring structures.

Q 7. How do you ensure the structural integrity of the roof during the tear-off process?

Ensuring structural integrity is paramount throughout the tear-off process. We always begin with a careful assessment of the existing roof structure to identify potential weak points. We use caution and strategic methods to avoid unnecessary stress on the structure during the tear-off. We might use additional supports or shoring if needed to reinforce weak areas, preventing damage to the structure. We always work systematically, removing sections of the roofing material in a way that minimizes strain on the underlying structure. This systematic approach, combined with regular inspections, helps us prevent structural damage and guarantees a safe working environment for the crew.

Q 8. What is your experience with proper disposal of roofing waste?

Proper disposal of roofing waste is paramount for environmental responsibility and compliance. We meticulously separate materials – asphalt shingles, wood, metal, etc. – before disposal. Asphalt shingles, for instance, often go to designated recycling facilities that repurpose them into asphalt for roads or other construction materials. Other debris like wood or metal are taken to scrap yards or landfills depending on local regulations. Before starting any project, we obtain all necessary permits and follow all local, state, and federal guidelines regarding waste removal. We also maintain detailed records of the quantities and types of waste disposed of for traceability and accountability. For example, on a recent project involving a large commercial building, we diverted over 75% of the roofing waste from landfills through recycling efforts. This not only benefits the environment, but also minimizes the project’s overall cost.

Q 9. How do you handle unexpected issues during a roof tear-off project?

Unexpected issues are inherent in any construction project, especially roof tear-offs. We address these by having a proactive approach. This includes thorough pre-job site inspections to identify potential problems like hidden rot or unexpected structural issues. If something unforeseen arises, like discovering asbestos-containing materials during demolition, we immediately halt work. We then engage specialists, follow the proper protocols for handling hazardous materials, and revise the project timeline and budget accordingly. Clear communication with the client is crucial in these situations. We treat unexpected issues as opportunities to showcase our problem-solving skills and commitment to project success. Transparency and maintaining a safety-first approach are key.

Q 10. How do you manage a team during a roof tear-off operation?

Managing a roof tear-off team requires strong leadership, clear communication, and an emphasis on safety. Before the project begins, we hold a pre-job meeting to review safety procedures, work assignments, and the project plan. I utilize a hands-on approach, actively participating alongside my team, providing guidance and ensuring adherence to safety regulations. Regular communication, including frequent check-ins and daily briefings, keeps everyone informed and promotes teamwork. We celebrate successes, acknowledge challenges, and address concerns promptly. I foster a culture of respect, mutual support, and continuous improvement. This includes providing regular training on new techniques and safety best practices. For example, I recently implemented a new system for tool organization that improved efficiency and reduced the risk of accidents.

Q 11. Explain your knowledge of OSHA regulations concerning roofing safety.

OSHA (Occupational Safety and Health Administration) regulations are fundamental to our operations. We are well-versed in the requirements for fall protection, including the use of appropriate harnesses, lifelines, and anchor points. Our team undergoes regular safety training on fall protection procedures, hazard communication, and emergency response. We meticulously maintain our equipment and ensure that all safety gear is inspected and in optimal working condition. We also conduct regular safety meetings to address any safety concerns and enforce compliance with OSHA regulations. For example, we are meticulous about proper scaffold erection and usage. We ensure that everyone follows procedures for handling materials to prevent falls from heights, which is a leading cause of accidents in roofing work.

Q 12. How do you prepare a worksite for a roof tear-off?

Preparing the worksite is a critical first step. This involves securing necessary permits, protecting landscaping and surrounding structures with tarps or barriers, and establishing a designated area for waste disposal. We carefully mark off the perimeter to prevent unauthorized access. We ensure that access points for equipment and workers are clearly defined and safe. We also establish a clear communication system for coordinating work activities and ensuring everyone’s safety. For instance, we might use a two-way radio system to maintain constant communication between workers on the ground and those on the roof. A well-prepared worksite minimizes risks and maximizes efficiency.

Q 13. Describe your experience working at heights.

I have extensive experience working at heights. My experience spans over 15 years, encompassing diverse projects ranging from residential re-roofing to large-scale commercial projects. I am certified in various fall protection systems and have a deep understanding of safety protocols for working at heights. I’m comfortable using various types of fall protection equipment, including harnesses, lanyards, and anchor points. Furthermore, I’m adept at assessing the risks associated with working at different heights and implementing appropriate safety measures. Safety is never compromised; it’s the foundation of my approach to every job.

Q 14. How do you estimate the time and materials required for a roof tear-off?

Estimating time and materials for a roof tear-off involves a thorough assessment of several factors. This includes the roof’s size and complexity, the type of roofing material, the condition of the existing roof (which impacts removal time), and the presence of any obstacles (like chimneys or skylights). We use specialized software and our experience to accurately determine the quantity of materials needed. This also includes considering potential waste generation during the tear-off process. We factor in potential delays caused by weather conditions and unforeseen circumstances. We develop a detailed breakdown of labor costs, material costs, and equipment rental costs to arrive at a comprehensive and accurate estimate for the client. We provide transparent pricing, ensuring the client understands each component of the total cost.

Q 15. What is your experience with different types of underlayment?

Understanding underlayment is crucial for a successful roofing project. Underlayment acts as a secondary water barrier, protecting the roof deck from moisture damage should the shingles fail. I’ve worked extensively with several types, each with its own strengths and weaknesses.

- Felt Underlayment: This is the traditional, asphalt-saturated felt. It’s inexpensive but less durable and susceptible to tears. I typically use it on simpler, less expensive projects where budget is a major concern.

- Synthetic Underlayment: These are becoming increasingly popular due to their superior strength, water resistance, and durability. They are less prone to tearing and offer better protection against wind uplift. Examples include polyethylene and polypropylene membranes. I prefer these for high-end projects or those in areas prone to severe weather. They offer a better long-term value.

- Rubberized Asphalt Underlayment: This offers a blend of affordability and enhanced protection, often being more durable than standard felt. I use this option when the client wants a balance between cost and quality.

Choosing the right underlayment depends heavily on the project’s specifics, including budget, climate, and the type of roofing material being used. For example, I’d choose synthetic underlayment for a steep-slope roof in a hurricane-prone area, but felt might suffice for a shed in a milder climate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper ventilation during a roof tear-off?

Proper ventilation is paramount to preventing moisture buildup, extending the roof’s lifespan, and preventing premature shingle failure. We achieve this through a combination of soffit vents (at the eaves) and ridge vents (at the peak). This creates a continuous airflow path that removes hot, moist air from the attic.

During a tear-off, it’s crucial to ensure these vents remain unobstructed. If the existing vents are damaged or insufficient, we replace or supplement them as needed. In some cases, we might even incorporate additional ventilation, such as gable vents or turbine vents, depending on the attic’s size and shape. Think of it like a house’s respiratory system; proper ventilation is vital for its health. I’ve seen firsthand how inadequate ventilation leads to mold, mildew, and even structural damage. We meticulously check and address any ventilation issues before installing the new roofing.

Q 17. Describe your experience with using different types of cutting tools.

Safety is my top priority when it comes to cutting tools. I’ve had experience using a variety of tools, each suited for different tasks.

- Circular Saw: Excellent for cutting through large areas of roofing material quickly. Always used with appropriate safety precautions, including eye protection and hearing protection.

- Reciprocating Saw: Versatile for cutting in tighter spaces, particularly useful when removing nails and fasteners near existing structures. Safety glasses are a must here as well.

- Utility Knife: Perfect for making precise cuts on felt underlayment or for trimming shingles. I always use a sharp blade to prevent accidental slips.

- Tin Snips: Very handy for cutting metal roofing materials. Again, safety glasses are non-negotiable.

Proper tool maintenance is essential, ensuring blades are sharp and equipment is in good working order prevents accidents and makes the job faster and more efficient.

Q 18. How do you manage waste disposal efficiently and cost-effectively?

Efficient and cost-effective waste disposal is a critical aspect of any tear-off project. We minimize costs by carefully sorting materials onsite.

- Shingles: Often recyclable in many areas, reducing landfill waste and saving disposal costs. We contact local recycling facilities to ensure proper disposal.

- Underlayment: Depending on the type, this can sometimes be recycled or disposed of via landfill.

- Nails and other debris: These are usually disposed of in regular dumpsters.

We work with reputable waste management companies who offer competitive pricing and ensure compliance with all environmental regulations. Pre-planning with the waste management company is key to ensure prompt and efficient removal of materials from the work site, which minimizes disruption and avoids additional costs due to delays.

Q 19. How do you maintain proper communication with clients and subcontractors during a tear-off?

Open and clear communication is fundamental to a successful project. We keep clients informed every step of the way.

- Daily Updates: We provide regular updates through photos or brief calls, describing progress and addressing any concerns.

- Scheduled Meetings: Formal meetings at key milestones (e.g., before starting the tear-off, during the process, and after completion) ensure clients are involved and understand the progress.

- Subcontractor Coordination: We maintain constant communication with all subcontractors to ensure everyone is on the same page regarding schedules, materials, and safety procedures.

We use various communication channels, including email, phone calls, and even video conferencing when necessary. Clear and concise communication prevents misunderstandings and fosters trust.

Q 20. What are your strategies for dealing with weather delays during a roof tear-off?

Weather can significantly impact a roofing tear-off. We have contingency plans in place to mitigate delays and potential damage.

- Weather Monitoring: We closely monitor weather forecasts and adjust schedules accordingly. If severe weather is anticipated, work is halted to prevent damage to materials and ensure worker safety.

- Protective Measures: In case of potential rain, we’ll use tarps to protect the exposed roof deck and other materials.

- Flexible Scheduling: We maintain flexibility in our scheduling to accommodate unexpected weather changes.

Open communication with the client is vital, keeping them informed of any weather-related delays and offering revised timelines. I’ve had projects where we’ve had to temporarily halt work due to heavy rain, but proactive measures and clear communication ensured minimal disruption.

Q 21. Describe your experience with different types of roof structures.

I’ve worked with a wide range of roof structures throughout my career.

- Gable Roofs: The classic A-frame, relatively straightforward to work with.

- Hip Roofs: Have sloping sides on all four sides, requiring more careful planning during the tear-off. The angles need to be managed very carefully.

- Gambrel Roofs: Have two slopes on each side, one steeper than the other, and often feature a more complex design.

- Mansard Roofs: Have a steep lower slope and a flatter upper slope.

- Flat Roofs: These often pose unique challenges due to their design and need for proper waterproofing.

Understanding the specific structural elements of each roof type is crucial to ensure a safe and efficient tear-off. Each roof structure requires a different approach and attention to detail to ensure proper removal and minimal damage. We always use the appropriate safety equipment and techniques for each roof design.

Q 22. How do you identify and resolve potential conflicts with neighbors during a roofing project?

Preventing neighborly conflicts during a roofing project starts long before the first shingle is removed. Proactive communication is key. We begin by scheduling a pre-project meeting with all directly affected neighbors. During this meeting, we explain the project scope, timeline, expected noise levels, and potential disruptions like dust or debris. We answer all their questions thoroughly and address any concerns they may have. We also provide them with contact information for a designated point person on our team to address any issues that might arise during the project. For example, if we anticipate significant noise during a particular phase of demolition, we provide advance notice so they can adjust their schedules. We always aim for transparency and clear communication to build trust and prevent misunderstandings.

Should any issues arise despite these precautions, we address them immediately and professionally. A simple act like promptly cleaning up any debris that drifts onto their property goes a long way. In the rare case of a serious disagreement, we’re prepared to mediate and find mutually acceptable solutions, perhaps by making adjustments to the work schedule or offering compensation for any inconveniences. Our goal is always to be good neighbors, ensuring that the project concludes peacefully and positively.

Q 23. What are your preferred methods for securing the perimeter during a tear-off?

Securing the perimeter during a tear-off is paramount for both worker and public safety. Our preferred methods involve a multi-layered approach. Firstly, we use heavy-duty construction fencing around the entire perimeter of the work area. This creates a physical barrier preventing accidental entry. Secondly, we strategically place caution tape, clearly marked with warnings like ‘Danger: Construction Zone’ and ‘Keep Out’. This adds visual reinforcement of the hazard zone. Thirdly, we might employ temporary barricades or traffic cones depending on the location and traffic conditions. In areas with higher pedestrian traffic, we might even arrange for temporary road closures or traffic control personnel for added safety. For instance, during a tear-off on a busy street, we always coordinate with local authorities to ensure pedestrian safety and traffic flow are properly managed. The entire perimeter is regularly inspected to ensure nothing is compromised.

Q 24. How do you handle damaged or deteriorated roofing components?

Handling damaged or deteriorated roofing components requires careful assessment and appropriate disposal. We thoroughly inspect the roof before the tear-off begins, identifying any components that pose a safety risk, such as weakened structural members or severely damaged flashing. These are handled with extra caution, often using specialized tools to safely dismantle them. For example, we might use a reciprocating saw to carefully cut through compromised lumber to avoid shattering it and causing potential injury. All damaged materials are segregated and disposed of responsibly according to local regulations. This might involve separating the damaged materials by type, such as asphalt shingles, wood, and metal, for proper recycling or landfill disposal. Detailed records are maintained to document the types and quantities of materials removed, ensuring compliance with environmental regulations. Safety remains a top priority throughout this process, and workers are trained on the proper techniques for handling hazardous materials.

Q 25. What are your methods for ensuring the safety of pedestrians and property during the tear-off?

Protecting pedestrians and property during a tear-off is a non-negotiable aspect of our work. Beyond perimeter security (as discussed earlier), we implement several additional measures. We establish clear pedestrian walkways, keeping them free from debris and construction materials. We regularly sweep and clean the work area to minimize dust and debris, preventing it from affecting neighboring properties. If there’s a risk of falling debris, we might erect scaffolding or netting to contain it. We also consistently communicate with pedestrians, directing them around the work area. For instance, during a residential tear-off, we often post signs and inform neighbors of temporary disruptions and ask for their cooperation in maintaining safe distances. Our crew undergoes rigorous safety training, emphasizing the importance of careful handling of materials and awareness of their surroundings. We continuously monitor the site for any potential hazards and take immediate corrective action if needed.

Q 26. How do you document the progress of a roof tear-off project?

Comprehensive documentation is crucial for the success and accountability of a tear-off project. We use a combination of methods to document progress. Daily reports are meticulously maintained, detailing the work completed, materials used, and any unforeseen issues encountered. These reports may include photographs or videos of the work area, documenting the progress and highlighting key stages of the tear-off. We also utilize digital project management software to keep track of all aspects of the project, from initial inspections to final cleanup. This software allows for easy access to project data, including photographs, safety reports, and any communication with clients or neighbors. Finally, upon completion, we provide a comprehensive final report which summarizes the work performed, materials removed and disposed of, and any noteworthy observations. This serves as a record for insurance, legal, and future maintenance purposes.

Q 27. What are your strategies for preventing job site accidents?

Preventing job site accidents starts with a robust safety program. This includes regular safety training for all crew members, covering topics such as fall protection, proper tool usage, material handling, and hazard identification. We enforce strict adherence to safety regulations and OSHA guidelines. All workers are required to wear appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and fall protection harnesses. Before any work commences, we conduct a thorough job site analysis, identifying potential hazards and implementing appropriate control measures. For example, before starting a tear-off, we might inspect the roof structure for weak points and implement measures like scaffolding to ensure worker safety. Regular tool inspections and maintenance are also crucial. We use a ‘toolbox talks’ approach, holding brief, regular meetings to discuss safety issues and lessons learned. We promote a culture of safety where reporting near-miss incidents is encouraged and seen as a valuable learning opportunity.

Q 28. Explain your experience with different types of fall protection equipment.

Our experience encompasses a wide range of fall protection equipment, selected based on the specific job requirements. We regularly use full-body harnesses, which are designed to distribute the force of a fall across the body, minimizing injury. These harnesses are often connected to anchor points on the roof using shock-absorbing lanyards to further reduce the impact of a fall. We also utilize safety nets where feasible, providing an extra layer of protection below the work area. Additionally, our team is proficient in the use of guardrails, when applicable, along roof edges to prevent falls. The choice of equipment is always dictated by job-site specifics and rigorous risk assessment. Regular inspections and maintenance of all fall protection equipment are performed to ensure optimal functionality and worker safety. Our team is trained on the proper use, inspection, and limitations of each piece of equipment. For example, we understand the difference between using a lanyard connected to an anchor point versus using a self-retracting lifeline and choose accordingly, based on the working height and potential fall distance.

Key Topics to Learn for Tear-Off and Removal of Old Roofing Interview

- Safety Procedures and Regulations: Understanding OSHA regulations, proper use of PPE (Personal Protective Equipment), and safe work practices for demolition and removal.

- Roofing Material Identification: Knowing how to identify different roofing materials (asphalt shingles, tile, slate, metal) and their specific removal techniques.

- Tear-Off Methods and Techniques: Mastering various tear-off methods, including manual removal, using power tools, and handling different roof pitches and complexities.

- Waste Management and Disposal: Understanding proper disposal procedures for roofing materials, including recycling and environmentally responsible practices.

- Tools and Equipment: Familiarity with various hand tools, power tools, and specialized equipment used in tear-off and removal (e.g., roofing nails pullers, demolition hammers, safety harnesses).

- Problem-Solving and Troubleshooting: Developing the ability to identify and resolve on-site issues, such as unexpected structural problems or material challenges during tear-off.

- Worksite Organization and Cleanup: Maintaining a clean and organized worksite throughout the tear-off process to ensure safety and efficiency.

- Estimating and Planning: Understanding how to estimate material quantities, labor hours, and project timelines for tear-off projects.

Next Steps

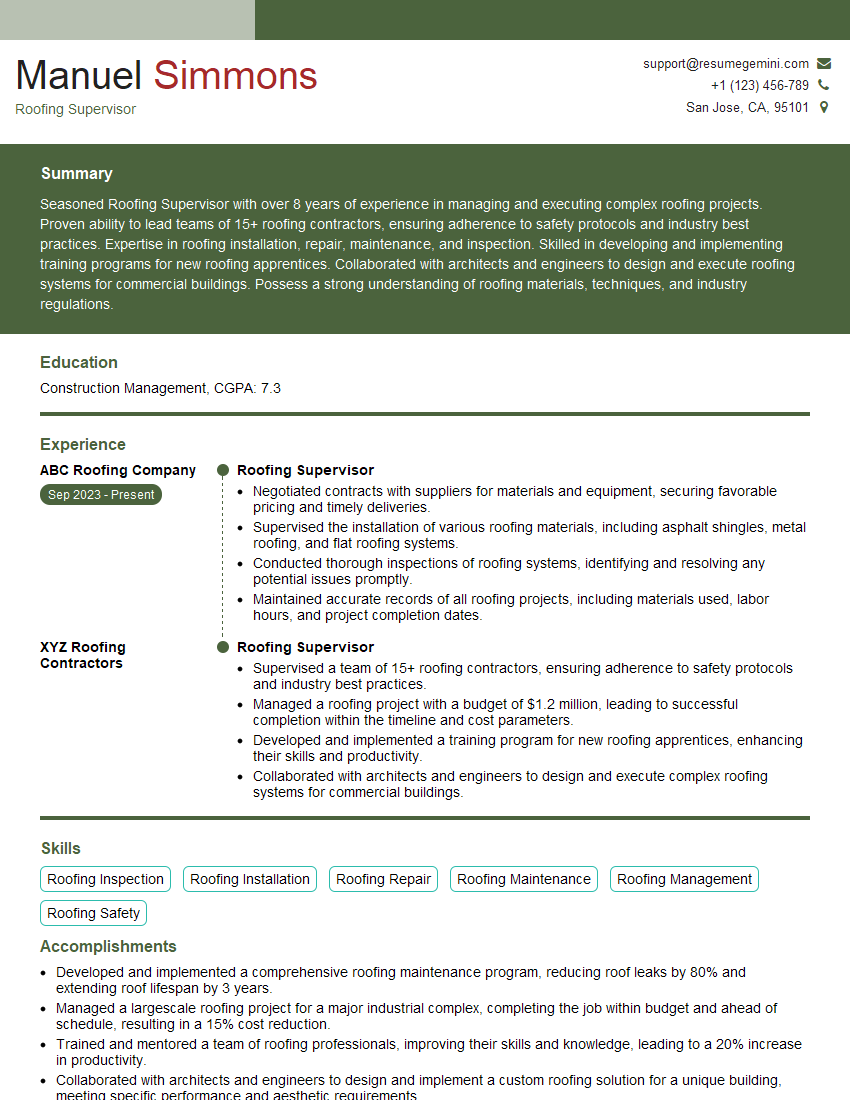

Mastering tear-off and removal of old roofing is crucial for career advancement in the construction industry. This skillset demonstrates a strong work ethic, attention to detail, and proficiency in handling demanding physical tasks. To increase your job prospects, creating a professional, ATS-friendly resume is essential. ResumeGemini can significantly enhance your resume-building experience, helping you showcase your skills and experience effectively. We provide examples of resumes tailored to Tear-Off and Removal of Old Roofing to help you build a compelling application. Invest time in crafting a strong resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.