The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Tensile and Tear Testing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Tensile and Tear Testing Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both crucial mechanical properties describing a material’s response to tensile stress, but they represent different points on its stress-strain curve. Tensile strength is the maximum stress a material can withstand before it fractures. Think of it as the ultimate breaking point. Yield strength, on the other hand, represents the stress at which the material begins to deform plastically – meaning the deformation becomes permanent, even after the stress is removed. It’s the point where the material starts to yield or permanently change shape. Imagine stretching a rubber band: the yield strength is where it starts to stretch permanently, and the tensile strength is when it finally breaks.

For example, a high-tensile-strength steel might withstand a large force before breaking, while its yield strength might indicate a lower stress at which permanent deformation begins. Knowing both values helps engineers choose materials suitable for specific applications where either high strength or ductility (ability to deform without breaking) is important.

Q 2. Describe the various types of tensile test specimens and their applications.

Various tensile test specimens are used, each designed to meet specific testing standards and material characteristics. Common types include:

- Round specimens: These are cylindrical and are simple to manufacture and test, suitable for homogeneous materials like metals.

- Rectangular specimens: Often used for sheet materials or composites, allowing for measurement of properties in different directions (e.g., along and across the rolling direction).

- Dogbone specimens: These have a narrow central section that ensures uniform stress and strain during testing. This reduces stress concentration at the grips and provides a more accurate measurement of material properties. They’re commonly used to avoid premature failure at the grips.

- Specialized specimens: These are tailored to the material being tested, like those with notches for fracture toughness testing or those shaped to represent real-world components.

The choice of specimen depends heavily on the material, the application, and the type of information required. For instance, a dogbone specimen is preferred for obtaining accurate stress-strain data, while a simpler round specimen might suffice for a quick strength assessment of a homogenous material.

Q 3. What are the common units used to express tensile strength and tear strength?

The common units for tensile strength are typically megapascals (MPa) or pounds per square inch (psi). Similarly, tear strength is often expressed in kN/m (kilonewtons per meter) or lb/in (pounds per inch). The choice depends on the standard and the reporting preferences.

It’s crucial to note that these units represent force per unit area for tensile strength (representing stress) and force per unit length for tear strength (representing the force required to propagate a tear). Therefore, while both are related to material strength, they measure different aspects of it.

Q 4. Explain the significance of the stress-strain curve in tensile testing.

The stress-strain curve is a graphical representation of a material’s response to applied tensile load. It’s a cornerstone of tensile testing, providing a wealth of information about the material’s mechanical behavior. The curve shows the relationship between stress (force per unit area) and strain (deformation per unit length). Key features include the elastic region (where deformation is reversible), the yield point (where plastic deformation begins), the ultimate tensile strength (maximum stress before fracture), and the fracture point.

By analyzing the stress-strain curve, we can determine critical properties such as yield strength, tensile strength, modulus of elasticity (Young’s modulus), ductility, and toughness. This information is vital for selecting the right material for a given application and predicting its behavior under load.

Q 5. How do you calculate Young’s modulus from a stress-strain curve?

Young’s modulus (E), also known as the modulus of elasticity, represents the stiffness of a material. It’s calculated from the elastic region of the stress-strain curve. Specifically, it is the slope of the linear portion of the curve, where stress is directly proportional to strain (Hooke’s Law). Mathematically:

E = Stress / Strain

To calculate it from a stress-strain curve, you’d select two points within the elastic region, calculate the change in stress (ΔStress) and the corresponding change in strain (ΔStrain), and then divide the former by the latter. The result represents Young’s modulus, often expressed in MPa or psi.

Q 6. What factors can affect the tensile strength of a material?

Many factors influence a material’s tensile strength. These can be broadly categorized into:

- Material Composition: The type and arrangement of atoms and molecules greatly influence the strength. For example, alloying elements in metals significantly affect their tensile strength.

- Processing Techniques: Manufacturing processes like heat treatment, cold working, and casting directly impact the material’s microstructure and thus its strength. Heat treatment can strengthen metals by altering their grain size and phase structure.

- Microstructure: Grain size, grain boundaries, and the presence of defects (e.g., voids, inclusions) can significantly affect the strength. Smaller grains generally lead to higher strength.

- Temperature: Tensile strength usually decreases at higher temperatures due to reduced atomic bonding strength.

- Environmental Factors: Exposure to aggressive environments (e.g., corrosive chemicals) can degrade the material and reduce its strength over time.

Understanding these factors is crucial for material selection and quality control. For example, knowing that cold working increases strength allows engineers to tailor material properties for specific applications.

Q 7. What are the different types of tear testing methods?

Several tear testing methods exist, each tailored to different materials and applications. The most common include:

- Elmendorf tear test: This uses a pendulum-type device to measure the force required to tear a specimen. It’s widely used for flexible materials like films and papers.

- Tongue tear test: This involves cutting a slit in the specimen and measuring the force needed to propagate the tear. It’s useful for evaluating the tear resistance of films and sheets, particularly when the slit starts in the middle of the specimen.

- Crescent tear test: This method uses a specimen with a crescent-shaped cut and measures the tear force. It is commonly used to characterize tear resistance in rubber and elastomers.

- Instron tear test: This utilizes a universal testing machine with grips that pull the sample apart. This method allows for a wider range of materials to be tested compared to the pendulum methods.

The selection of a specific tear testing method depends on the type of material, the shape of the specimen, and the desired accuracy. For example, the Elmendorf tear test is preferred for thin films due to its simplicity and standardization, while the Instron tear test offers more flexibility for different types of samples and data capture.

Q 8. Explain the principle behind the trouser tear test.

The trouser tear test, also known as the Elmendorf tear test, measures the force required to propagate a tear in a material. Imagine you’re trying to rip a piece of fabric – this test quantifies that ripping force. The principle is based on a pendulum-type apparatus where a pre-cut specimen is clamped, and a pendulum with a sharp blade is released to initiate a tear. The energy absorbed during the tear propagation is measured, directly related to the tear strength. The pendulum’s swing is directly proportional to the energy absorbed by the tear, hence the tear strength. It is particularly useful for testing relatively thin and flexible materials like textiles, films, and paper.

Q 9. How do you determine the tear strength from a tear test?

Tear strength from a tear test is not directly measured as a force but is calculated from the energy absorbed during tearing. The testing machine records the energy consumed by the tear propagation. This energy value is then converted into a tear strength value, usually expressed as grams-force per millimeter or Newtons per millimeter (gf/mm or N/mm). The formula used for calculation varies depending on the specific type of tear test (e.g., Elmendorf or trouser) and the machine’s calibration. The result represents the resistance of the material to tear propagation, indicating its toughness and durability. For example, a higher tear strength value indicates a more tear-resistant material.

Q 10. What are the limitations of tensile and tear testing?

Tensile and tear testing, while powerful techniques, have limitations. Tensile testing may not accurately reflect the real-world performance of materials under complex loading conditions, such as impact or fatigue. It primarily focuses on the material’s behavior under unidirectional tension. Furthermore, it might not be suitable for brittle materials prone to failure without significant elongation. Tear testing similarly only assesses the material’s resistance to tear propagation from an initiated tear; it doesn’t provide information about the material’s overall strength or its response to other types of stresses. Also, test results can be highly sensitive to factors such as sample preparation and environmental conditions. For instance, humidity can significantly affect the results of a tear test on a paper sample.

Q 11. Describe the importance of proper sample preparation in tensile and tear testing.

Proper sample preparation is crucial for obtaining reliable and repeatable results in both tensile and tear testing. Inconsistencies in sample dimensions, geometry, or surface condition can lead to significant errors. Samples must be carefully cut to the specified dimensions using sharp instruments to avoid introducing flaws. Any defects or imperfections should be noted and, if possible, avoided. For instance, for tensile testing, precisely measured dog bone specimens are required to accommodate the gripping mechanism of the machine. The conditioning of samples to a specific temperature and relative humidity is essential to minimize the effect of environmental factors on test results. Think of it like baking a cake – you need precise ingredients and preparation to achieve the expected outcome. Failing to properly prepare the samples invalidates the test results and misleads conclusions about the material’s properties.

Q 12. What are the different types of testing machines used for tensile and tear testing?

A range of testing machines are used for tensile and tear testing, with capabilities varying based on the material’s properties and the required precision. For tensile testing, universal testing machines are commonly used. These can apply tensile, compression, and bending forces. They are available in various load capacities, suitable for testing from delicate films to heavy-duty metals. For tear testing, specialized machines like the Elmendorf tear tester are employed. This pendulum-based instrument is designed specifically for measuring the energy required to propagate a tear. Other tear testers are available, using different mechanisms but similar principles, like the trouser tear tester. The choice of machine depends on the specific test standard being followed and the type of material being evaluated. High-precision load cells and extensometers are integrated into these machines for accuracy.

Q 13. Explain the calibration process for tensile and tear testing machines.

Calibration of tensile and tear testing machines is critical for ensuring accurate and reliable results. This is typically achieved using certified standard weights and/or calibrated extension devices. The calibration process involves applying known forces or extensions to the machine and comparing the machine’s readings to the known values. Any deviations are corrected by adjusting the machine’s settings. The frequency of calibration depends on usage and the machine’s specifications, but it is often done annually or more frequently for high-volume testing. Calibration certificates are essential for validating test results and maintaining the machine’s accuracy. Calibration ensures traceability to national and international standards, providing confidence in the reliability of the testing process. Using a non-calibrated machine could result in erroneous data, potentially leading to faulty decisions about material quality or suitability.

Q 14. How do you interpret the results of a tensile test report?

A tensile test report typically includes various parameters that provide a comprehensive understanding of the material’s mechanical properties. These include ultimate tensile strength (the maximum stress the material can withstand before failure), yield strength (the stress at which the material begins to deform permanently), elongation at break (the percentage increase in length before failure), and Young’s modulus (a measure of the material’s stiffness). Interpreting these results involves comparing them to the material’s specifications, industry standards, or previous test data to assess if the material meets the required standards. For instance, a lower than expected tensile strength might indicate a problem in material composition or manufacturing process. Similarly, a tear test report will include the tear strength, which indicates the material’s resistance to tear propagation. Comparing these values against required specifications or historical data allows for assessing the material’s quality and consistency. The report should also include details of the testing procedure, including the sample size, test conditions, and testing machine used, to ensure the results’ reproducibility and reliability.

Q 15. How do you identify and address anomalies in tensile and tear test data?

Anomalies in tensile and tear test data can stem from various sources, including specimen preparation errors, machine malfunction, or inherent material variability. Identifying these requires a systematic approach. First, I visually inspect the data for outliers – points significantly deviating from the general trend. Statistical analysis, like calculating the standard deviation and identifying data points falling outside a predefined confidence interval (e.g., 3 standard deviations), helps quantify these deviations.

Addressing these anomalies involves investigating the potential causes. For instance, if multiple data points are unusually low, this could indicate a problem with the testing machine’s calibration or a consistent flaw in specimen preparation (e.g., inconsistent thickness). If a single data point is an outlier, I would re-examine that specific test to rule out errors in sample handling or testing procedures. Thorough record-keeping, including detailed notes on the testing process and material properties, is critical in this troubleshooting process. Sometimes, repeating the test with a new specimen is necessary to confirm or rule out an anomaly. If the anomaly is related to the material itself and represents an inherent variation, then it would be documented and considered when determining overall material properties.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

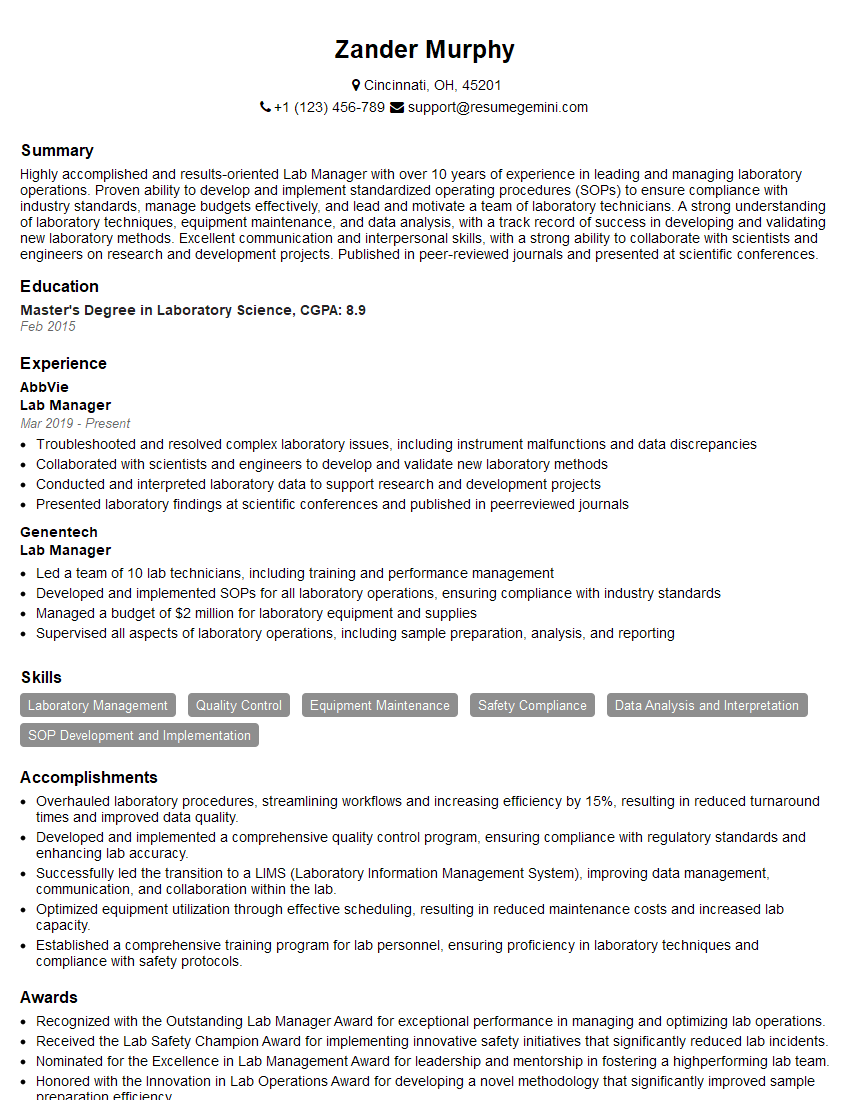

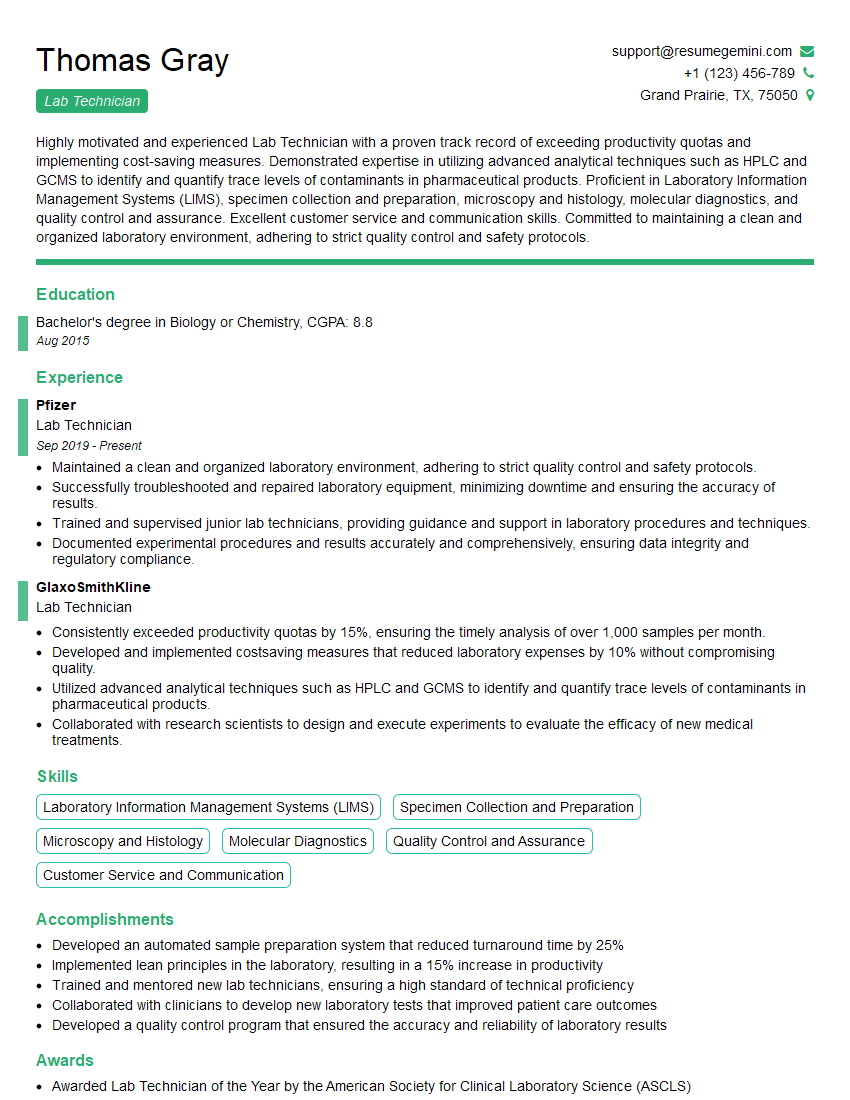

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the role of standard test methods (e.g., ASTM) in tensile and tear testing.

Standard test methods, such as those published by ASTM International, are crucial for ensuring consistency and comparability in tensile and tear testing. These standards define specific procedures, including specimen geometry, testing conditions (temperature, humidity), and data reporting requirements. Using standardized methods eliminates ambiguity and ensures that results obtained in different laboratories or by different operators are directly comparable. For example, ASTM D638 covers the standard test method for tensile properties of plastics, specifying the type of grips to use, the rate of extension, and the calculations to obtain tensile strength and elongation at break. Adherence to these standards is vital for quality control, product development, and legal compliance.

Without standardized methods, the results would be subjective, making it impossible to compare the properties of different materials or batches of the same material tested under varying conditions. The lack of standardization could lead to inconsistencies, unreliable conclusions, and difficulty in resolving disputes related to material performance.

Q 17. What are the safety precautions to be followed during tensile and tear testing?

Safety is paramount during tensile and tear testing. The primary concern is the potential for high-speed projectile motion should a specimen fail unexpectedly. Therefore, safety shields or barriers must always be in place around the testing machine. Eye protection is mandatory, as are gloves to prevent cuts from broken specimens. Proper training on the operation of the testing machine, including emergency shutdown procedures, is essential for all operators.

Furthermore, specimens should be handled carefully to avoid accidental cuts or injuries. For brittle materials that are prone to shattering, extra precautions may be necessary. Regular maintenance and calibration of the testing machine are critical to prevent malfunctions that could compromise safety. Finally, the testing area should be well-lit and free from obstructions to avoid tripping hazards.

Q 18. Describe your experience with different materials tested using tensile and tear methods.

My experience encompasses a wide range of materials, including various polymers (e.g., polyethylene, polypropylene, ABS), metals (e.g., aluminum alloys, steel), elastomers (e.g., rubber, silicone), and composites (e.g., fiber-reinforced polymers). I’ve worked extensively on characterizing the mechanical properties of these materials, employing both tensile and tear testing methods. For instance, in the automotive industry, I’ve tested the tensile strength and elongation of various plastic components to ensure they meet the required safety standards. In the textile industry, I’ve assessed the tear resistance of fabrics to determine their durability and suitability for clothing or industrial applications. Each material presents unique challenges and requires specialized test methods and specimen preparation techniques to obtain reliable results.

Q 19. How do you ensure the accuracy and precision of tensile and tear test results?

Accuracy and precision in tensile and tear testing are paramount. This starts with proper specimen preparation; ensuring consistent dimensions and avoiding defects. The testing machine itself must be meticulously calibrated and regularly maintained. Calibration involves verifying that the load cells and extensometers provide accurate measurements. Following the standardized test procedures (e.g., ASTM standards) is critical for consistency and reproducibility. This includes adhering to the prescribed crosshead speed, environmental conditions (temperature and humidity), and data acquisition techniques.

Regularly checking the machine’s performance using certified reference materials helps ensure that the results are reliable and traceable to national standards. Blind testing – where the operator doesn’t know the material being tested – helps eliminate bias. Finally, meticulous data analysis, including outlier detection and proper statistical analysis, ensures the accuracy and precision of the reported values. Documentation of every step of the process, from sample preparation to data analysis, is essential to maintain the traceability and integrity of the results.

Q 20. Explain the concept of Poisson’s ratio and its significance in tensile testing.

Poisson’s ratio is the ratio of transverse strain to axial strain in a material subjected to uniaxial stress. In simpler terms, it describes how much a material deforms in the direction perpendicular to the applied force relative to its deformation in the direction of the force. For instance, if you stretch a rubber band, it gets thinner in the middle. Poisson’s ratio quantifies this thinning effect. A positive Poisson’s ratio indicates that the material contracts laterally when stretched (typical for most materials), while a negative Poisson’s ratio means the material expands laterally when stretched (auxetic materials).

In tensile testing, Poisson’s ratio is significant because it provides additional information about the material’s elastic properties. It is used in conjunction with Young’s modulus to characterize the material’s response to stress. Understanding Poisson’s ratio is crucial in various engineering applications, like designing structures or predicting how materials will behave under stress. For example, in designing a bridge, engineers need to consider the Poisson effect to ensure the structure can withstand lateral stresses. It is also helpful in material selection processes, where knowing the Poisson’s ratio can help predict how a material will deform under load.

Q 21. Describe different types of failure observed in tensile testing.

Tensile testing can reveal different failure modes depending on the material’s properties and the loading conditions. Common failure modes include:

- Ductile Fracture: This is characterized by significant plastic deformation before failure. The specimen necks down before it eventually breaks. This is common in ductile metals like mild steel.

- Brittle Fracture: This occurs with little or no plastic deformation. The specimen breaks suddenly without significant elongation. This is typical for brittle materials like ceramics or some polymers.

- Fatigue Failure: This happens when a material is subjected to repeated cyclic loading, eventually leading to failure at a stress level lower than its ultimate tensile strength. This type of failure often involves crack propagation.

- Creep Rupture: This is the slow deformation and eventual failure of a material under sustained stress at elevated temperatures.

Identifying the failure mode is crucial in understanding the material’s behavior and designing appropriate safety factors in engineering applications. For instance, if a material fails due to fatigue, appropriate modifications to the design or material selection could increase its service life. Understanding these modes of failure allows material scientists and engineers to make informed decisions for choosing appropriate materials for specific applications.

Q 22. How does temperature affect tensile and tear strength?

Temperature significantly impacts both tensile and tear strength. Generally, an increase in temperature leads to a decrease in tensile strength and an increase in ductility (ability to deform before breaking). Conversely, a decrease in temperature often results in increased tensile strength and decreased ductility, making materials more brittle. This is because higher temperatures provide more energy to the material’s molecular chains, allowing them to move more freely and resulting in easier deformation. At lower temperatures, these chains become more rigid, resisting deformation and leading to a higher breaking point.

For example, polymers like plastics show a dramatic change in tensile properties with temperature. A plastic that’s flexible at room temperature might become brittle and shatter at very low temperatures. Conversely, some metals demonstrate increased ductility at higher temperatures, making them easier to form or shape. The exact relationship between temperature and material strength is material-specific and can be described using sophisticated material models, often requiring experimental data at various temperatures.

Understanding this temperature dependency is crucial in material selection and design. For instance, designing a component for outdoor use in a cold climate requires a material with high tensile strength at low temperatures, while a component operating at high temperatures needs a material that retains its structural integrity despite reduced strength.

Q 23. How do you handle non-standard samples for tensile and tear testing?

Handling non-standard samples in tensile and tear testing requires careful consideration and adaptation of test methods. ASTM and ISO standards provide guidelines for standard specimen geometries, but real-world applications often present us with parts of irregular shapes or sizes.

Our approach involves several steps:

- Careful Sample Preparation: We might need to carefully cut or machine the non-standard sample to create a region with dimensions suitable for gripping in the testing machine. This ensures consistent stress distribution to achieve reliable results. Any imperfections introduced by cutting must be carefully considered and documented.

- Modified Fixture Design: For samples with odd shapes, custom gripping fixtures might be needed to securely hold the material during testing. We’d work with our engineering team to design fixtures that provide uniform stress distribution without damaging the sample.

- Alternative Test Methods: In some instances, traditional tensile and tear tests may not be suitable. We might need to use alternative methods like micro-tensile testing for very small samples or consider a different testing paradigm altogether to assess the mechanical properties relevant to the application.

- Data Correction and Analysis: Data obtained from non-standard samples requires careful analysis to account for the effects of the irregular geometry. Software can sometimes assist in compensating for variations in cross-sectional areas, and we must carefully document all deviations from standard testing procedures.

Each step should be thoroughly documented to ensure the integrity and traceability of the results. Proper documentation is crucial if the results are to be used in a regulatory or quality assurance context.

Q 24. What software and data analysis techniques are you familiar with for tensile and tear testing?

My experience encompasses a wide range of software and data analysis techniques for tensile and tear testing. I am proficient in using industry-standard software packages like Instron’s Bluehill, Zwick/Roell’s testXpert, and similar software from MTS Systems Corporation.

These software packages allow for automated data acquisition, real-time data visualization, and comprehensive analysis. I utilize various techniques such as:

- Curve Fitting: To determine material properties like Young’s modulus, yield strength, ultimate tensile strength, and elongation at break.

- Statistical Analysis: To evaluate the variability in material properties and calculate confidence intervals. This is especially crucial when analyzing multiple samples to ensure data reliability.

- Data Transformation and Normalization: Sometimes data needs transformation or normalization to compensate for factors like sample thickness variations or non-linear responses.

- Fracture Mechanics Analysis: To characterize crack initiation and propagation behavior in tear testing.

Beyond these software tools, I also have experience with programming languages like Python and MATLAB for custom data processing and analysis. This enables me to create custom scripts for automating repetitive tasks or developing specialized analysis techniques tailored to specific material behaviors.

Q 25. Explain your experience with troubleshooting tensile and tear testing equipment.

Troubleshooting tensile and tear testing equipment is a regular part of my work. My approach follows a systematic procedure:

- Initial Inspection: I always start with a visual inspection of the entire system, checking for obvious issues like loose connections, damaged components, or signs of wear and tear.

- Calibration Verification: I verify that the machine is properly calibrated and that its calibration certificates are up-to-date and valid. A poorly calibrated machine can lead to significant inaccuracies in the measurements.

- Sensor Check: I test the load cell and extensometer to ensure they are functioning correctly. I might use a known weight for the load cell and a calibrated gauge for the extensometer. Faulty sensors are a common cause of measurement errors.

- Software Diagnostics: I utilize the software’s diagnostic tools to detect and address any software-related issues. Problems with data acquisition or communication between the different components can be diagnosed through these diagnostics.

- Hydraulic or Pneumatic System Check: For hydraulic or pneumatic systems, I examine the fluid levels, pressure, and any leaks in the system. These systems need regular maintenance to prevent errors and ensure smooth operation.

- Component Replacement: If necessary, I replace faulty components according to the manufacturer’s instructions. This step often requires proper safety measures and may necessitate temporary shutdown of the equipment.

Keeping detailed records of maintenance, calibration, and troubleshooting activities is critical for ensuring the equipment’s reliability and the accuracy of the test results.

Q 26. Describe a situation where you had to solve a problem related to inaccurate tensile or tear test data.

I once encountered a situation where the tensile strength data for a batch of polymer films consistently fell outside the expected range. Initially, the data indicated lower-than-expected strength. After carefully reviewing the testing procedure and equipment, we discovered that the grips were not properly aligned, resulting in uneven stress distribution across the samples. This misalignment caused premature failure in some samples, leading to inaccurate readings.

Our solution involved:

- Careful Re-alignment of Grips: We meticulously realigned the grips using a precise alignment tool, ensuring that the clamping force was distributed evenly across the sample’s width.

- Retesting Samples: We retested a new set of samples with the properly aligned grips.

- Statistical Analysis: We performed rigorous statistical analysis on both the original and the retested data sets to compare results and assess the significance of the error.

- Procedure Refinement: We revised our standard operating procedure to incorporate a pre-test grip alignment check as a preventative measure to avoid similar issues in the future. We improved our alignment process and added explicit instructions to our SOP to prevent this error.

This experience emphasized the importance of meticulous attention to detail throughout the testing process, from sample preparation to equipment calibration and data analysis.

Q 27. How would you explain the concept of tensile and tear testing to a non-technical audience?

Imagine you need to know how strong a material is, like a rubber band or a piece of metal. Tensile and tear testing is like a strength test for materials. Tensile testing pulls the material until it breaks, measuring how much force it takes to stretch it and how much it stretches before breaking. Think of it like stretching a rubber band—how far can it stretch before it snaps?

Tear testing checks how easily a material tears. It’s like ripping a piece of paper—some paper rips easily, while others are more resistant. These tests help determine if a material is suitable for its intended purpose. For example, a seatbelt needs to be strong (high tensile strength) and resist tearing, while a plastic bag needs to be flexible and easy to tear open. These tests help engineers and manufacturers choose the right material for their products and make sure they are safe and reliable.

Q 28. What are your future goals related to tensile and tear testing?

My future goals in tensile and tear testing involve several key areas:

- Advanced Materials Characterization: I aim to expand my expertise in characterizing the mechanical properties of advanced materials such as composites, biomaterials, and nanomaterials. These materials present unique challenges in terms of testing and analysis.

- Automation and AI Integration: I am particularly interested in exploring the potential of automation and artificial intelligence in tensile and tear testing to improve efficiency, accuracy, and data interpretation. Automated analysis and predictive modeling could transform our current capabilities.

- Development of Novel Testing Methods: I want to contribute to the development of new and improved testing methods that address the limitations of existing techniques. This could involve innovative sample preparation methods, advanced sensor technologies, or the creation of specialized test fixtures.

- Collaborative Research: I see value in collaborating with researchers and engineers in other disciplines to apply tensile and tear testing to solve problems in diverse fields such as bioengineering, aerospace, and civil engineering.

Ultimately, I strive to contribute to the advancement of knowledge and practical application of tensile and tear testing, enhancing the reliability and safety of products used in various industries.

Key Topics to Learn for Tensile and Tear Testing Interview

- Stress-Strain Curves: Understanding the relationship between stress and strain, including elastic region, yield point, ultimate tensile strength, and fracture point. Knowing how to interpret and analyze these curves is crucial.

- Material Properties: Familiarize yourself with key material properties derived from tensile and tear testing, such as Young’s modulus, tensile strength, elongation at break, and tear strength. Understand the implications of these properties for different materials.

- Testing Standards and Procedures: Become proficient in common testing standards (e.g., ASTM, ISO) for tensile and tear testing. Understand the importance of proper sample preparation and testing procedures to ensure accurate and reliable results.

- Types of Testing Machines: Gain familiarity with various types of tensile and tear testing machines, including their capabilities and limitations. Be prepared to discuss the principles behind their operation.

- Data Analysis and Interpretation: Develop skills in analyzing test data, identifying anomalies, and drawing meaningful conclusions. Practice interpreting results in the context of material selection and quality control.

- Failure Analysis: Understand common failure mechanisms in materials, such as ductile fracture, brittle fracture, and fatigue failure. Be able to relate these failures to the results obtained from tensile and tear testing.

- Practical Applications: Explore the diverse applications of tensile and tear testing across various industries, including aerospace, automotive, biomedical, and manufacturing. Be ready to discuss specific examples.

- Problem-Solving: Prepare to discuss troubleshooting common issues encountered during tensile and tear testing, such as machine calibration, sample preparation inconsistencies, and data interpretation challenges.

Next Steps

Mastering tensile and tear testing significantly enhances your prospects in materials science, engineering, and quality control roles. A strong understanding of these techniques demonstrates valuable technical expertise and problem-solving abilities. To increase your chances of landing your dream job, creating a well-structured, ATS-friendly resume is paramount. ResumeGemini offers a powerful tool to help you build a compelling resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to Tensile and Tear Testing professionals – making the process easier and more efficient. Invest in your future and build a resume that gets noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.