Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Thermal Bridging Reduction Techniques interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Thermal Bridging Reduction Techniques Interview

Q 1. Explain the concept of thermal bridging and its impact on building energy performance.

Thermal bridging occurs when heat flows through a building element with higher thermal conductivity than the surrounding materials. Imagine a metal stud in a wall – it acts like a thermal bridge, conducting heat much faster than the insulation. This bypasses the insulation’s intended heat-blocking effect, leading to increased energy loss in winter and heat gain in summer. This directly impacts a building’s energy performance, raising heating and cooling bills and reducing overall energy efficiency. It can significantly decrease a building’s thermal performance, requiring more energy to maintain a comfortable indoor temperature.

For example, a poorly insulated building with many metal studs could lose up to 20% more heat than a similarly sized building with properly addressed thermal bridging.

Q 2. Describe different types of thermal bridges found in buildings.

Thermal bridges manifest in various forms within buildings. They aren’t always obvious; some are inherent in construction methods:

- Linear Thermal Bridges: These are continuous pathways of high conductivity, such as metal studs in walls, concrete beams, or window frames. They create a linear path for heat transfer.

- Planar Thermal Bridges: These occur in areas where there’s a discontinuity in the insulation layer, like where a wall meets a floor or roof. This creates a larger area of heat transfer.

- Point Thermal Bridges: These are localized points of high conductivity, often around fasteners or fittings. While small individually, their cumulative effect can be significant.

- Junction Thermal Bridges: Occur at the junctions of different building elements, such as the intersection of a wall and a window. The change in materials and geometry leads to increased heat loss.

Understanding the type of thermal bridge is crucial for selecting the most effective mitigation strategy.

Q 3. What are the common methods for reducing thermal bridging in walls?

Reducing thermal bridging in walls involves several strategies, focusing on either minimizing the conductivity of the bridge or interrupting the heat flow pathway. Common methods include:

- Insulation of Structural Members: Wrapping metal studs or timber frames with continuous insulation before installing the cladding significantly reduces heat flow through these elements.

- Use of Thermally Broken Components: Employing windows and doors with thermally broken frames (using materials with low thermal conductivity to separate the inner and outer frames) minimizes heat transfer through these crucial elements.

- Increasing the Insulation Depth: By increasing the insulation thickness on exterior walls, the impact of thermal bridges relative to the total wall insulation is reduced. A thicker layer of insulation makes the effect of individual thermal bridges less significant.

- Alternative Materials: Using materials with inherently lower thermal conductivity, such as wood framing instead of metal studs, helps naturally reduce thermal bridging.

- Insulated Concrete Forms (ICFs): ICFs provide excellent thermal performance by incorporating insulation within the structure’s core, minimizing thermal bridging associated with traditional concrete walls.

The best approach often combines several of these methods for optimal effectiveness.

Q 4. How do you assess the thermal performance of a building envelope considering thermal bridges?

Assessing a building envelope’s thermal performance considering thermal bridges requires a more nuanced approach than simply calculating U-values (overall heat transfer coefficient). We use specialized methods to account for these heat flow pathways:

- Thermal Simulation Software: Programs like WUFI, TRNSYS, or EnergyPlus allow for detailed 2D or 3D modeling of the building envelope, incorporating the geometry and material properties of thermal bridges. These simulations provide ψ-values (linear thermal transmittance) and χ-values (point thermal transmittance) which quantify the heat transfer through these elements.

- Ψ-Value and χ-Value Calculations: These values are used to quantify the thermal bridging contribution. The higher these values, the worse the thermal bridging effect.

- In-situ Measurements: Thermal cameras can detect temperature variations on the building’s surface, highlighting areas with significant heat loss due to thermal bridging. This provides valuable on-site verification of simulation results.

Combining these methods provides a comprehensive understanding of the building’s thermal performance, including the impact of thermal bridging.

Q 5. Explain the role of thermal bridging in condensation and mold growth.

Thermal bridging plays a significant role in condensation and mold growth. Cooler surface temperatures resulting from thermal bridging create ideal conditions for condensation, especially in areas where warm, moist indoor air encounters a cold surface. This condensation can lead to water accumulation and, subsequently, mold growth if the moisture isn’t effectively managed. The lower surface temperature near the thermal bridge is a cold spot that favors condensation, even with low relative humidity.

For example, condensation is frequently observed around window frames which are common thermal bridges. This is particularly true in areas with poor ventilation or high internal humidity.

Q 6. What software or tools do you use for thermal bridging analysis?

For thermal bridging analysis, I utilize several software tools depending on the complexity of the project and the level of detail required. These include:

- WUFI Plus: Excellent for detailed hygrothermal simulations, accounting for moisture transport and condensation risk in addition to heat transfer.

- TRNSYS: A powerful system simulation tool capable of modeling whole building energy performance, including the impact of thermal bridging.

- EnergyPlus: Another comprehensive whole-building energy modeler widely used for energy performance assessment and thermal bridge analysis.

- COMSOL Multiphysics: Offers greater flexibility in modeling complex geometries and material behaviors, but requires advanced knowledge of finite element analysis.

The choice of software depends on project requirements and the analyst’s expertise.

Q 7. How do you interpret thermal bridging results from a thermal simulation?

Interpreting thermal bridging results from a thermal simulation involves several steps:

- Examine ψ-values and χ-values: These values directly indicate the linear and point thermal transmittance, providing a quantitative measure of heat loss through thermal bridges. Higher values indicate greater heat loss.

- Identify Critical Areas: The simulation results will highlight specific locations within the building envelope where thermal bridging is most significant. These areas require prioritized attention for mitigation.

- Assess Surface Temperatures: The simulation often provides surface temperature distributions. Areas with significantly lower surface temperatures are more prone to condensation and mold growth.

- Compare Results with Acceptable Limits: National building codes or standards often provide guidance on acceptable levels of thermal bridging. Comparing the simulation results against these limits helps determine whether remedial action is needed.

- Sensitivity Analysis: Perform a sensitivity analysis to evaluate how changes in material properties or construction details impact the thermal performance of the building.

By systematically analyzing these aspects, we can develop effective strategies for reducing thermal bridging and improving the overall energy efficiency and durability of the building.

Q 8. Describe your experience with different insulation materials for reducing thermal bridging.

My experience spans a wide range of insulation materials used to combat thermal bridging. The choice depends heavily on the specific application, budget, and environmental impact considerations.

- Rigid Insulation Boards: Materials like extruded polystyrene (XPS), expanded polystyrene (EPS), and polyisocyanurate (PIR) are frequently used. XPS boasts high compressive strength, making it ideal for applications under slabs or in walls subject to high loads. EPS is a more cost-effective option, though less robust. PIR offers excellent thermal performance but can be more expensive. I’ve used these extensively in various projects, optimizing placement to minimize thermal bridging at critical junctions.

- Spray Foam Insulation: This offers superior air-sealing capabilities and can conform to complex geometries, minimizing gaps and reducing thermal bridging effectively. Open-cell spray foam is less expensive but offers slightly lower R-value compared to closed-cell, which is more durable and water-resistant. I’ve found spray foam invaluable in retrofit projects where intricate detailing is necessary.

- Mineral Wool Insulation: This sustainable option, including rock wool and glass wool, provides good thermal performance and excellent sound insulation. While its R-value is slightly lower compared to some foams, its breathability can improve indoor air quality. I often specify this in projects where sustainability and indoor environmental quality are paramount.

- Aerogel: This cutting-edge material offers exceptional thermal resistance within a minimal thickness. However, its high cost restricts its use to high-performance, often specialized, applications. I’ve utilized it in select instances where minimizing overall wall thickness was a primary constraint.

The selection process often involves a careful comparison of R-value, cost, durability, environmental impact, and ease of installation. A holistic approach ensures the most effective solution for each individual project.

Q 9. Explain the concept of Psi-values and U-values in relation to thermal bridges.

Psi-values and U-values are crucial parameters in assessing thermal bridging. They’re often confused, but serve distinct purposes.

U-value represents the overall rate of heat transfer through a building element, considering both the insulation and the thermal bridges. A lower U-value indicates better insulation. Think of it as the overall energy efficiency of a wall section.

Psi-value, on the other hand, specifically quantifies the linear heat transfer through a thermal bridge, such as a steel stud in a wall. It’s expressed in W/mK and represents the heat flow per meter length of the bridge. It isolates the heat loss specifically caused by the thermal bridge, enabling accurate modeling of its impact.

Imagine a wall with steel studs. The U-value reflects the total heat loss, while the psi-value helps isolate the heat loss specifically attributed to the steel studs. By adding the psi-values of all thermal bridges and the U-value of the insulated sections we can get a precise estimation of the total heat loss.

Q 10. What are the limitations of different thermal bridging reduction techniques?

Each thermal bridging reduction technique has inherent limitations. For instance:

- Increased material costs: High-performance insulation materials or specialized detailing techniques can significantly increase the initial construction cost. This is particularly true for materials like aerogel.

- Complexity of installation: Implementing some solutions, like continuous insulation on the exterior, can lead to increased construction time and complexity, requiring specialized skills and potentially impacting the overall project schedule.

- Space constraints: Adding substantial insulation to existing structures can be difficult due to limited space. Retrofitting solutions might compromise interior space.

- Material limitations: Each material has its own limitations. For instance, some insulation materials are susceptible to moisture damage, requiring proper vapor barriers and careful installation.

- Durability concerns: Certain materials might degrade over time, reducing their thermal performance. Understanding material lifecycles and selecting appropriate solutions is critical.

Careful consideration of these limitations is crucial in choosing the best strategy for any project. A cost-benefit analysis is often essential to weigh the advantages against the potential drawbacks.

Q 11. How do you incorporate thermal bridging considerations into the design process?

Thermal bridging must be considered right from the initial design phase. I typically incorporate it using a multi-stage process:

- Early-stage modeling: Using thermal modeling software, we analyze the building design, identifying potential thermal bridges such as steel beams, concrete columns, and window frames. This allows for proactive design modifications.

- Material selection: We choose insulation materials and other building components based on their thermal performance and ability to minimize thermal bridging. This involves careful consideration of U-values and psi-values.

- Detailing: We pay meticulous attention to construction details, ensuring continuous insulation layers with minimal gaps and proper sealing around penetrations.

- Continuous insulation: We prioritize the use of continuous insulation systems on the exterior walls, foundation walls, and roofs to break the thermal bridges formed by structural elements.

- Thermal bridging mitigation strategies: We implement strategies like using thermal breaks in windows and doors, installing insulated concrete forms (ICFs), or employing other advanced techniques to minimize linear heat transfer.

This integrated approach minimizes thermal bridging from the outset, leading to a more energy-efficient building.

Q 12. Explain the impact of thermal bridging on the overall building energy consumption.

Thermal bridging significantly impacts a building’s energy consumption. Heat escapes readily through these conductive pathways, increasing the load on the heating system in winter and increasing cooling loads in summer. This results in:

- Higher energy bills: The increased heat loss and gain necessitate more energy to maintain comfortable indoor temperatures.

- Reduced thermal comfort: Cold spots along thermal bridges can create uncomfortable living conditions.

- Increased carbon footprint: Higher energy consumption translates into a larger carbon footprint, contributing to environmental concerns.

- Potential for condensation and mold growth: Temperature differences at thermal bridges can lead to condensation, fostering the growth of mold and mildew, impacting indoor air quality.

Effectively addressing thermal bridging is vital for minimizing energy consumption, reducing operating costs, and improving the overall sustainability of the building.

Q 13. How do you address thermal bridging in existing buildings?

Addressing thermal bridging in existing buildings presents greater challenges than in new constructions. However, various techniques can be employed:

- External wall insulation (EWI): This involves adding an insulating layer to the exterior of the building. It effectively covers thermal bridges, minimizing their impact. However, this can alter the building’s aesthetic appearance.

- Internal wall insulation (IWI): This involves installing insulation on the interior side of the walls. While less effective than EWI, it is often more practical for existing buildings. However, IWI can reduce the usable living space.

- Retrofit thermal breaks: In some cases, retrofitting thermal breaks into existing window frames or structural elements might be possible, though this is often more complex and costly.

- Air sealing: Improving the air tightness of the building envelope minimizes heat loss through air infiltration, effectively mitigating the overall impact of thermal bridging even if it isn’t directly addressed.

The best approach depends heavily on the building’s construction, its condition, and budget constraints. A thorough assessment is crucial to determine the most feasible and cost-effective solution.

Q 14. Discuss the cost-effectiveness of various thermal bridging mitigation strategies.

The cost-effectiveness of thermal bridging mitigation strategies varies considerably. A simple cost comparison is insufficient; the lifetime cost savings from reduced energy consumption must be considered.

Upfront costs: High-performance insulation materials like aerogel are expensive, while more conventional materials such as EPS are relatively affordable. Retrofitting techniques usually involve higher upfront costs than incorporating thermal bridging mitigation in new constructions.

Long-term savings: Reduced energy bills over the building’s lifetime often outweigh the higher initial investment. A comprehensive life-cycle cost analysis should be undertaken to accurately assess the economic viability of each strategy. The payback period, considering energy savings and reduced maintenance costs, will vary based on climate, energy prices, and chosen materials.

Non-monetary benefits: Besides cost, we need to consider the environmental and social benefits, such as reduced carbon emissions and improved indoor air quality. These intangible factors can significantly influence the overall value proposition.

Therefore, evaluating the cost-effectiveness requires a holistic approach, comparing initial costs with long-term savings and factoring in environmental and social benefits. Software tools and detailed modeling are often essential for performing accurate life-cycle cost analysis.

Q 15. What are the building codes and standards relevant to thermal bridging?

Building codes and standards regarding thermal bridging vary by location and are constantly evolving to meet stricter energy efficiency targets. However, many jurisdictions incorporate provisions from standards like the International Energy Conservation Code (IECC) and ASHRAE standards. These standards often set minimum insulation requirements and prescribe methods for calculating and mitigating heat loss through thermal bridges. For example, they might specify U-values (overall heat transfer coefficient) for building components and address thermal bridging specifically through requirements for continuous insulation, detailing around windows and doors, and the use of specific materials with lower thermal conductivity. Specific requirements are often found in local building codes, which will reference national standards and adapt them to regional climate conditions. It’s crucial for professionals to stay updated with the latest versions of these codes and standards in their area to ensure compliance.

For instance, a project might reference IECC’s prescriptive path for wall construction, dictating the minimum R-value for insulation and the required thermal break in window frames. Deviations from these standards often require engineering justification and approval from the building authorities.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure proper detailing and construction to minimize thermal bridging?

Minimizing thermal bridging requires meticulous detailing and precise construction. It starts with design, selecting materials with low thermal conductivity (like high-performance insulation and thermally broken framing systems) and carefully planning the building’s geometry to minimize points of discontinuity in the thermal envelope. During construction, continuous insulation is key – this means ensuring there are no gaps or breaks in the insulation layer, extending it around all penetrations and structural elements. Special attention must be paid to junctions like window and door frames, where thermal bridges are most common. This involves using thermally broken frames and ensuring a tight seal with high-performance sealant around the perimeter. Regular quality control checks, involving both visual inspections and thermal imaging, can help catch any errors in the construction process and address them before completion.

For example, a common error would be gaps between framing members and insulation in a wall cavity. Proper detailing would involve using foam sealant to completely fill those spaces. Similarly, carefully designed flashing details around windows prevent moisture ingress that could compromise insulation effectiveness and create thermal bridges.

Q 17. Explain the difference between linear and 2D thermal bridging.

Linear thermal bridging occurs along continuous elements extending through the building envelope, such as steel studs or concrete columns. These elements conduct heat more readily than surrounding insulation, creating paths for heat transfer. Imagine a metal stud running from the inside to the outside of a wall – this is a linear thermal bridge.

2D thermal bridging, on the other hand, occurs at junctions or intersections of building components where different materials meet, like where a window frame meets a wall. These junctions often have complex geometric shapes and create significant heat loss. Think of the corner of a building exterior where multiple walls meet. Here, the heat flow is two dimensional, as it’s affected by multiple components simultaneously.

The difference lies in the dimensionality of the heat flow: linear is primarily one-dimensional, while 2D is more complex and involves multiple dimensions. Both types of bridging contribute significantly to energy loss and require different mitigation strategies.

Q 18. Describe your experience with thermal imaging for identifying thermal bridges.

Thermal imaging is an invaluable tool for identifying thermal bridges. I’ve used infrared cameras extensively throughout my career to both detect existing thermal bridges and to evaluate the effectiveness of mitigation strategies in new construction and retrofit projects. The process usually involves scanning the building’s exterior and interior surfaces under controlled conditions (often at night or in stable weather) to capture the temperature differences. Areas showing warmer temperatures on the exterior (indicating heat loss) highlight potential thermal bridges. These images are then analyzed to pinpoint the location and severity of the problem.

For example, a recent project involved identifying significant heat loss through poorly insulated window frames in a historic building. The thermal images clearly revealed these cold spots, which led to targeted interventions focusing on improving the insulation and air sealing around the window frames.

The results of thermal imaging are crucial for quantifying heat loss and validating the effectiveness of mitigation strategies. It provides visual evidence of the problem which is very compelling for clients and stakeholders.

Q 19. How do you communicate the importance of thermal bridging mitigation to non-technical stakeholders?

Communicating the importance of thermal bridging mitigation to non-technical stakeholders requires translating technical concepts into relatable language. I usually start by emphasizing the direct impact on comfort and energy bills. Instead of discussing U-values, I focus on the consequences – cooler or drafty areas in the building, increased heating and cooling costs, and potential for moisture problems.

I often use analogies to make complex ideas simpler. For example, I compare a building’s insulation to a winter coat: gaps and breaks in the insulation are like holes in the coat, letting heat (and money) escape. Visual aids such as thermal images or simplified diagrams also enhance understanding. Presenting cost-benefit analysis – comparing the initial investment in mitigation strategies with the long-term savings on energy bills – is usually very persuasive.

Finally, highlighting the environmental benefits – reduced carbon footprint and reliance on fossil fuels – strengthens the case for investing in thermal bridging solutions. For instance, showing how improved insulation saves the equivalent of X tons of CO2 per year is more impactful than just quoting R-values.

Q 20. Explain the role of air sealing in reducing thermal bridging effects.

Air sealing plays a crucial role in reducing thermal bridging effects. While insulation reduces conductive heat transfer, air leakage can negate these efforts. Air infiltration and exfiltration through gaps and cracks around windows, doors, and other building penetrations create thermal bridges by allowing warm indoor air to escape and cold outdoor air to infiltrate, bypassing the insulation. This creates drafts and discomfort, and significantly increases energy consumption.

By effectively sealing these gaps and cracks with appropriate sealants, caulk, weatherstripping, and other air-sealing measures, we minimize air leakage and reduce the bypass pathways for heat transfer. This enhances the overall performance of the building envelope and significantly improves the effectiveness of the insulation, reducing the impact of thermal bridging.

For example, addressing air leakage around window frames with high-quality sealant can reduce draftiness and improve indoor comfort. A comprehensive air sealing strategy implemented alongside insulation significantly enhances the efficiency of energy use and improves overall building performance.

Q 21. Describe the impact of thermal bridging on indoor comfort.

Thermal bridging has a significant impact on indoor comfort. It creates uneven temperature distribution within the building, resulting in cold spots near windows, exterior walls, and other points of thermal discontinuity. These cold spots can cause discomfort, particularly near windows or in poorly insulated areas, leading to drafts and discomfort. This can be especially problematic in areas prone to colder climates.

Furthermore, thermal bridging can exacerbate moisture problems. Cold spots in the building envelope can lead to condensation and the formation of mold and mildew, negatively affecting the indoor air quality and creating health concerns. In extreme cases, this can lead to structural damage. Reducing thermal bridging ensures more consistent temperatures across the building’s interior resulting in increased comfort and improved indoor air quality. Therefore, a building with effective thermal bridging mitigation is significantly more comfortable and healthier to live in.

Q 22. How does the orientation of a building influence thermal bridging effects?

A building’s orientation significantly impacts thermal bridging because it dictates the exposure of thermal bridges to solar radiation and prevailing winds. Imagine a building with a large north-facing window and a poorly insulated concrete frame – the cold north winds will directly impact this bridge, leading to increased heat loss. Conversely, a south-facing wall with a thermal bridge might experience more solar gain, partially offsetting the heat loss. The angles of the sun throughout the day and year also affect the heat gain/loss through thermal bridges. East and west-facing walls experience varying solar radiation based on the time of day and season. Therefore, careful consideration of building orientation is crucial for minimizing the impact of thermal bridging, including optimizing window placement and insulation strategies based on prevailing weather conditions.

Q 23. What are some innovative techniques for reducing thermal bridging?

Innovative thermal bridging reduction techniques go beyond traditional insulation. For example, we’re seeing increased use of:

- Advanced Thermal Break Materials: High-performance materials like polyamide, fiberglass reinforced polymer, and even advanced composites are designed to offer superior insulation compared to traditional materials. Their high thermal resistance drastically reduces heat flow.

- Insulated Concrete Forms (ICFs): ICFs create a highly insulated building envelope from the start, minimizing thermal bridging opportunities inherent in traditional concrete construction. The foam core acts as a built-in thermal break.

- Vacuum Insulated Panels (VIPs): VIPs offer exceptionally high thermal resistance in a thin form factor, making them ideal for retrofitting or integrating into existing structures with thermal bridges. Their thin profile allows for minimal impact on the overall building design.

- Computational Fluid Dynamics (CFD) Modeling: This advanced simulation technique allows us to accurately predict the thermal performance of a building design and identify areas most susceptible to thermal bridging before construction, enabling proactive solutions.

- Thermochromic Paints and Coatings: These paints change their thermal properties based on temperature, thus reducing heat transfer across a thermal bridge. Though still in development, they offer promising future possibilities for dynamic thermal management.

Q 24. What are your preferred methods for quantifying thermal bridge heat loss?

Quantifying thermal bridge heat loss requires precise methods. My preferred approaches include:

- Finite Element Analysis (FEA): FEA software, such as ANSYS or COMSOL, allows for detailed modeling of heat flow through complex building geometries, including thermal bridges. It provides accurate results considering the material properties, dimensions, and boundary conditions.

- Ψ-Values (Psi-Values): These values represent the linear thermal transmittance of a thermal bridge, providing a standardized way to quantify heat loss per unit length. Using established Ψ-values, from reliable sources, aids in quick yet effective assessment.

- Thermal Imaging: Infrared thermography provides a visual representation of heat loss, allowing us to easily identify thermal bridges on existing buildings. It’s a powerful tool for both investigation and verification purposes.

The combination of FEA and Ψ-values often provides the most comprehensive and reliable quantification.

Q 25. How do you validate your thermal bridge analysis results?

Validating thermal bridge analysis is critical. I employ several techniques:

- Comparison with Measured Data: If working on an existing building, comparing the predicted heat loss with actual measurements (e.g., using thermal cameras or energy monitoring systems) is vital for validation. Discrepancies highlight areas needing improvement in modeling assumptions.

- Peer Review: Having other experienced engineers review the models and methodologies ensures accuracy and identifies potential errors or biases in the analysis. A second set of eyes is crucial for complex projects.

- Sensitivity Analysis: I test the model’s robustness by adjusting input parameters (like material properties or boundary conditions) to understand their effect on the results. This assesses the uncertainty in the predictions.

- Calibration and Verification: For complex FEA models, calibration against known data is crucial. After that, verification steps are taken to confirm that the model accurately reflects the physical phenomenon.

Q 26. Discuss your experience with different types of thermal break materials.

My experience encompasses a range of thermal break materials. Each has its strengths and weaknesses:

- Polyamide (Nylon): A common and cost-effective choice, particularly in window frames. However, its thermal performance might be less impressive than other high-performance materials.

- Fiberglass Reinforced Polymer (FRP): Offers excellent strength and thermal insulation, often utilized in larger structural elements. Its cost is usually higher than polyamide.

- High-Density Polyurethane Foam: This is often used in wall sections, providing good thermal resistance, but needs careful consideration due to potential moisture absorption issues.

- Aerogel: An emerging material providing extremely high thermal insulation, but often at a high cost and with limitations in practicality.

Material selection depends on various factors, including cost, thermal performance requirements, structural demands, and durability considerations. For instance, a high-rise building might require high-strength FRP, while a residential project might find polyamide sufficient.

Q 27. What is your understanding of dynamic thermal bridging effects?

Dynamic thermal bridging refers to the time-dependent heat flow through a thermal bridge. Unlike steady-state analysis, which assumes constant conditions, dynamic analysis considers fluctuating temperatures and solar radiation throughout the day and year. This is crucial because the amount of heat transfer through a thermal bridge changes significantly over time, affecting indoor comfort and energy consumption. For example, a cold winter night will cause significantly more heat loss than a mild evening. A dynamic model incorporates these changes and predicts the temperature fluctuations more accurately.

Accounting for dynamic effects requires sophisticated simulation tools capable of handling time-dependent boundary conditions and thermal properties.

Q 28. How do you handle thermal bridges in complex building geometries?

Handling thermal bridges in complex geometries is challenging but achievable. My approach involves:

- Detailed 3D Modeling: Using advanced FEA software to create a highly accurate 3D model of the building, including all the complex geometrical features. This is essential for capturing the nuanced heat flow patterns.

- Mesh Refinement: Focusing mesh refinement (the process of subdividing the model into smaller elements for computation) on areas with complex geometry and high thermal gradients, to provide a more accurate solution.

- Localized Thermal Break Strategies: Implementing tailored thermal break solutions in specific areas of the building envelope where thermal bridging is most pronounced. This might involve strategic placement of insulation, thermal break strips, or other materials.

- Iterative Design Optimization: Using the FEA results to iteratively refine the design, adjusting the location and size of insulation and thermal breaks to achieve optimal thermal performance. This allows for exploration of diverse design solutions.

The complexity of the geometry necessitates a thorough understanding of FEA and a detailed design process.

Key Topics to Learn for Thermal Bridging Reduction Techniques Interview

- Understanding Thermal Bridges: Defining thermal bridges, their impact on building energy efficiency, and identifying common locations within building structures.

- Insulation Strategies: Exploring various insulation materials and techniques for minimizing thermal bridging, including continuous insulation, insulating concrete forms (ICFs), and advanced insulation systems.

- Material Selection: Analyzing the thermal properties of different building materials and their role in reducing thermal bridging. This includes understanding U-values, R-values, and thermal conductivity.

- Design & Construction Practices: Examining building design principles that minimize thermal bridging, such as detailing around windows and doors, and understanding the implications of different construction methods.

- Computational Fluid Dynamics (CFD) and Thermal Modeling: Understanding the application of software tools for simulating heat transfer and analyzing the effectiveness of thermal bridging reduction strategies. This includes interpreting simulation results and using them to inform design decisions.

- Building Codes and Regulations: Familiarity with relevant building codes and regulations related to thermal performance and thermal bridging reduction in different regions.

- Case Studies and Best Practices: Reviewing successful case studies of thermal bridging reduction projects and understanding best practices for implementation.

- Cost-Benefit Analysis: Evaluating the economic feasibility of various thermal bridging reduction techniques, considering both initial investment and long-term energy savings.

- Practical Problem Solving: Applying theoretical knowledge to solve real-world scenarios related to thermal bridging reduction in different building types and climates.

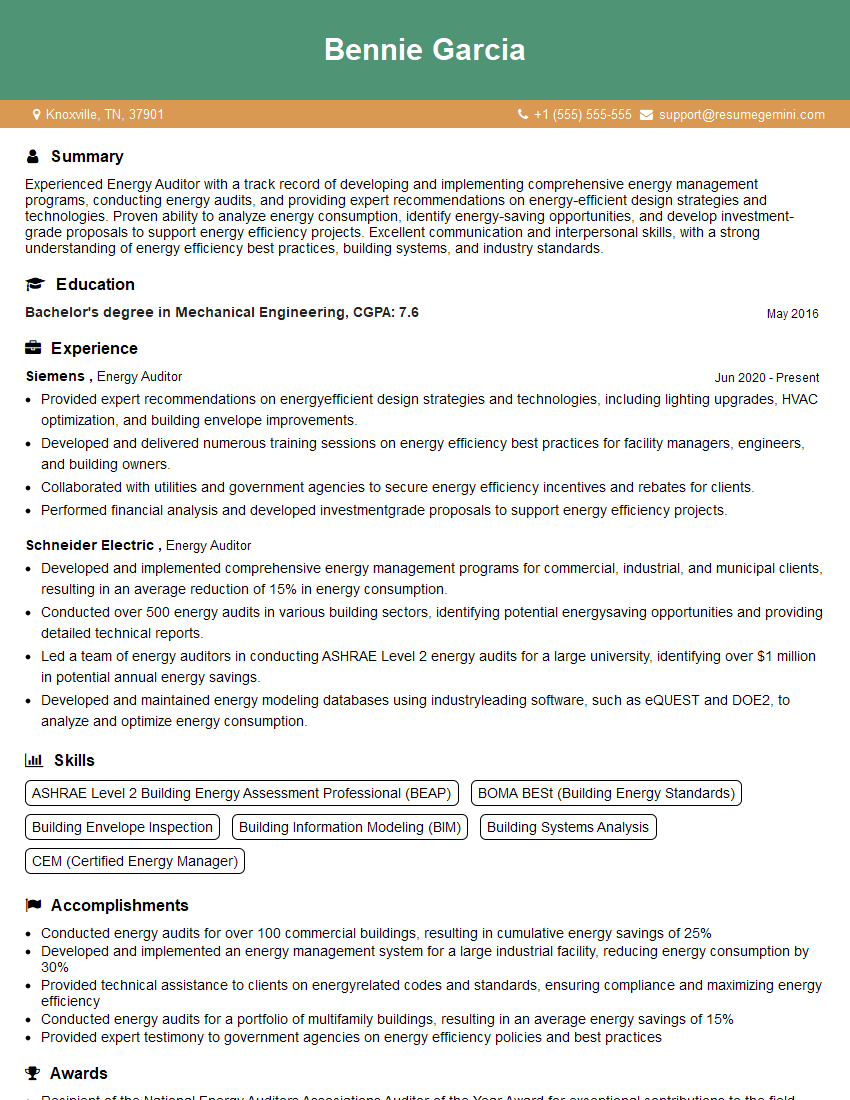

Next Steps

Mastering Thermal Bridging Reduction Techniques is crucial for career advancement in the building science and sustainable construction sectors. Demonstrating expertise in this area will significantly enhance your job prospects and open doors to exciting opportunities. To maximize your chances of securing your dream role, it’s vital to present your skills and experience effectively. Creating an ATS-friendly resume is key to getting noticed by recruiters. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume tailored to highlight your expertise in Thermal Bridging Reduction Techniques. Examples of resumes tailored to this specific field are available to provide inspiration and guidance. Invest in your future – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.