Unlock your full potential by mastering the most common Tunnel Mucking Machine Operation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Tunnel Mucking Machine Operation Interview

Q 1. Describe your experience operating different types of tunnel mucking machines.

My experience encompasses a wide range of tunnel mucking machines, from smaller, crawler-mounted loaders used in smaller diameter tunnels to large, hydraulic excavators deployed in massive projects. I’ve operated machines with various loading mechanisms including front-end loaders, backhoes, and specialized muck handling systems integrated with conveyor belts. For example, I spent two years operating a Caterpillar 992K wheel loader in a hard rock tunnel project, focusing on efficient loading and minimizing downtime. Later, I transitioned to a Komatsu PC490 hydraulic excavator in a larger, soft-ground tunnel, where the focus shifted to precise maneuvering to avoid damaging the tunnel lining. This diverse experience has equipped me with a deep understanding of the strengths and limitations of different machine types and their applicability to varying geological conditions and project requirements.

Q 2. Explain the process of setting up a tunnel mucking machine for operation.

Setting up a tunnel mucking machine is a crucial step ensuring safe and efficient operation. It’s a multi-stage process that starts with a thorough site assessment. This involves checking the ground stability, identifying potential hazards like overhead obstructions and unstable rock faces, and ensuring the machine has sufficient access to the working area. Next, the machine’s stability is secured – this might involve using cribbing or outriggers depending on the ground conditions. We then conduct pre-operational checks, including verifying the hydraulic fluid levels, checking the braking system, and inspecting the condition of the bucket and other components. Finally, we test all operational systems, ensuring that all controls are responsive and the machine functions as expected before commencing operations. Imagine it like prepping a race car before a race – every detail matters for optimal performance and safety.

Q 3. How do you ensure the safety of yourself and others while operating a tunnel mucking machine?

Safety is paramount in tunnel mucking. My approach to safety involves a multi-layered strategy. Firstly, before starting any work, I always perform a comprehensive pre-operational inspection of the machine, including checking for leaks, worn parts, and proper functioning of all safety systems. Secondly, I strictly adhere to all site safety regulations and wear the appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, high-visibility clothing, and hearing protection. Thirdly, effective communication is key; I maintain constant communication with the tunnel foreman and other workers in the area, using hand signals and two-way radios. Finally, I’m vigilant about my surroundings, constantly assessing for potential hazards and taking proactive measures to mitigate them. For instance, I always ensure that the area around the machine is clear of personnel before starting the loading process and use spotters when visibility is limited.

Q 4. What are the common maintenance procedures for a tunnel mucking machine?

Regular maintenance is critical to prevent breakdowns and ensure machine longevity. This includes daily checks of fluid levels (hydraulic oil, engine oil, coolant), inspecting wear items like bucket teeth and tires, and lubricating moving parts. Weekly checks involve more thorough inspections of the hydraulic system, examining hoses and fittings for leaks or damage. Monthly maintenance includes more detailed inspections of the engine, checking filters and belts. Beyond this, a more comprehensive servicing is required based on the manufacturer’s recommendations or based on operating hours, this usually involves a detailed inspection of all major components and possibly the replacement of worn parts. Think of it as regular check-ups for your car – small consistent maintenance saves you from major problems down the line.

Q 5. How do you troubleshoot common malfunctions in a tunnel mucking machine?

Troubleshooting is a key skill for a tunnel mucking machine operator. Common problems might include hydraulic leaks, engine malfunctions, or electrical issues. My approach is systematic: I start by isolating the problem, determining which system is affected. For example, if the machine won’t start, I’d first check the battery, then the starter motor, and proceed to more complex components as needed. If a hydraulic leak is detected, I would pinpoint its source using visual inspection and then address the leak based on the severity, either by tightening a loose fitting or, more seriously, requiring a hose or component replacement. Using diagnostic codes, if the machine is equipped, can be a great help in narrowing down the problem area. Documenting the issue, resolution, and time taken is crucial for future reference and to aid in preventing similar problems.

Q 6. What are the different types of cutting heads used in tunnel boring machines?

While the question mentions tunnel *mucking* machines, it’s important to note that cutting heads are primarily associated with Tunnel Boring Machines (TBMs). TBMs use various cutting heads depending on the ground conditions. These include:

- Disc Cutters: Used in soft to medium-hard ground conditions.

- Roller Cutters: Effective in a wide range of ground conditions, from soft clays to hard rocks.

- Pick Cutters: Best suited for very hard rock formations.

- Combination Cutters: These integrate different types of cutters for optimal performance in varied geological conditions.

Q 7. Explain the importance of proper lubrication in tunnel mucking machine maintenance.

Proper lubrication is vital for maintaining the health and efficiency of a tunnel mucking machine. Lubrication reduces friction between moving parts, preventing wear and tear, overheating, and potential failures. It’s essentially a preventative measure reducing maintenance costs and downtime. Without sufficient lubrication, components can seize up, leading to expensive repairs or even complete machine failure. This is particularly crucial in the harsh environment of a tunnel, where dust and debris can contaminate lubricants. Regular lubrication schedules, using the correct type and grade of lubricant as specified by the manufacturer, are essential for maximizing machine lifespan and operational reliability. Think of it like oiling the hinges on a door – it ensures smooth operation and prevents damage over time.

Q 8. How do you monitor the machine’s performance during operation?

Monitoring a tunnel boring machine’s (TBM) performance is crucial for efficiency and safety. It’s a multifaceted process involving several key parameters. Think of it like monitoring the vital signs of a patient – you need a holistic view.

Penetration Rate: We constantly track the machine’s advance rate (meters per hour). A sudden drop might indicate a change in ground conditions (e.g., encountering harder rock) or a mechanical issue.

Torque and Thrust: These readings reflect the machine’s effort in cutting through the ground. High torque coupled with low penetration rate suggests the cutterhead is encountering unusually hard material, potentially requiring adjustments to the cutting parameters or even a tool change. Low torque may indicate a problem with the drive system.

Cutting Tool Wear: Regular monitoring of cutterhead wear is essential. We use various methods such as visual inspections via cameras and sensors that measure tool wear. Excessive wear implies that the cutting parameters need adjusting or replacement is needed, reducing efficiency and increasing the risk of cutter failure.

Power Consumption: Unexpected spikes or drops in power consumption can signal problems with the main drive motors, hydraulic systems or even indicate unexpected ground conditions that require adjustment of parameters and monitoring of system status.

Muck Removal Efficiency: We closely monitor the rate at which muck (excavated material) is being removed from the tunnel face. Bottlenecks in the muck disposal system can significantly affect the overall TBM performance.

Ground Water Inflow: We use sensors to detect any increases in ground water entering the tunnel. A sudden increase may necessitate adjustments to the machine’s operation or installation of additional ground support systems.

All this data is typically displayed on a central control panel and logged for later analysis. We use this data to optimize the machine’s performance, identify potential problems early, and ensure safe and efficient tunneling.

Q 9. Describe your experience with different types of ground conditions and their impact on machine operation.

Ground conditions dramatically influence TBM operation. It’s like trying to drive a car on different terrains – a smooth highway is vastly different from a muddy off-road trail.

Competent Rock: Hard, strong rock (like granite) requires higher torque and thrust, potentially leading to increased wear on the cutterhead. We might need to adjust cutting parameters to avoid excessive stress on the machine.

Weak Rock: Soft, weathered rock (like shale) can cause instability and cave-ins. We often employ advanced ground support systems, such as rock bolting and shotcrete, to prevent collapses. We might also reduce the cutting parameters to avoid overstressing the surrounding ground.

Clay and Silt: These materials can be highly abrasive and prone to swelling when exposed to water. Special cutterheads and careful ground water management are crucial. We might employ additives to stabilize the ground, or select a TBM better suited for these conditions.

Fractured Rock: This poses significant risk of unexpected collapses. Frequent geological surveys and careful monitoring of ground movement using instruments like inclinometers are necessary. We may need to adopt a more cautious advance rate and strengthen the ground support systems to reduce risks.

My experience encompasses working across a diverse range of ground conditions and the operational adjustments needed in each case; this has improved my ability to assess risk and adapt TBM parameters for optimal performance and safety.

Q 10. What safety protocols do you follow when working in confined spaces?

Safety in confined spaces like tunnels is paramount. It’s about meticulous adherence to procedures and a constant awareness of potential hazards. We treat it like a mission-critical protocol.

Permit-to-Work System: Before entering a confined space, we always obtain a permit outlining potential hazards and necessary precautions. This ensures everyone is aware of the risks and their respective roles.

Atmospheric Monitoring: We routinely monitor the air quality for oxygen levels, combustible gases (methane), and toxic gases (hydrogen sulfide). Gas detectors are critical safety equipment.

Emergency Evacuation Plan: We have detailed evacuation plans for different scenarios, ensuring swift and efficient escape routes are clearly marked and understood.

Personal Protective Equipment (PPE): Hard hats, safety glasses, respiratory protection, and high-visibility clothing are mandatory. The type and level of PPE is determined by the specific hazards present.

Communication Systems: Robust communication systems are critical to enable immediate communication between personnel inside and outside the tunnel. This allows for quick alerts and direction.

Rescue Procedures: Regular training in rescue techniques ensures we are well-prepared to handle emergencies, such as trapped personnel.

Our safety procedures aren’t just a checklist; they’re ingrained into our operational culture and constantly reviewed and updated.

Q 11. How do you handle unexpected situations or emergencies during operation?

Unexpected situations, whether mechanical failures or geological surprises, require swift and decisive action. My approach is based on a structured, methodical response.

Assess the Situation: Quickly determine the nature and severity of the emergency. This involves immediate communication with the team to gather information.

Implement Emergency Procedures: Based on the assessment, initiate appropriate emergency procedures – this may include shutting down the TBM, evacuating personnel, or contacting emergency services.

Problem Solving: Once the immediate danger is mitigated, we move to identifying the root cause of the issue and devising solutions. This may involve troubleshooting mechanical problems or adapting the operational plan to account for unexpected geological conditions. This often involves consulting with geologists and engineers.

Documentation: Meticulous documentation of the event, including the cause, response, and outcome, is essential for learning from mistakes and preventing future occurrences.

For example, I once encountered a sudden influx of groundwater. We immediately shut down the machine, evacuated personnel, and implemented our emergency procedures. After analyzing the situation, we worked with the geological team to implement additional ground support and revised our ground water management plan. This involved installing additional pumps and drainage systems.

Q 12. Explain your understanding of ground support systems in tunnel construction.

Ground support systems are critical for maintaining tunnel stability and preventing collapses. Think of them as the skeleton and muscles supporting the tunnel structure.

Rock Bolts: These are steel rods inserted into the rock mass to reinforce weak areas and improve the overall stability. They transfer loads from the surrounding rock, preventing failure.

Shotcrete: A sprayed concrete layer that provides immediate support to the tunnel walls and prevents rock falls. It is especially effective in weak or fractured rock.

Steel Sets or Ribs: These are prefabricated steel structures that provide additional support to the tunnel lining. They are used in areas of high stress or where the rock quality is poor. They’re like a reinforced cage within the tunnel.

Mesh and Fiber Reinforced Polymers (FRP): These provide additional reinforcement to the shotcrete and prevent cracking. They improve the overall strength and durability of the support system.

Drainage Systems: Effective drainage systems are crucial to manage groundwater inflow, preventing swelling pressures and instability. They include systems like sumps and drains.

The selection of appropriate ground support systems depends on the specific geological conditions and design requirements. This involves a detailed geotechnical investigation and careful analysis of the rock mass parameters before the actual selection of the system takes place.

Q 13. What is your experience with different types of muck disposal systems?

Muck disposal systems vary significantly depending on the project scale and site conditions. It’s like choosing the right transportation method – you need a different approach for carrying a small package versus transporting large quantities of freight.

Belt Conveyors: These are used for large-scale projects where the muck is transported long distances. They are efficient and provide a continuous flow of muck to the disposal site.

Truck Haulage: This is commonly used in smaller projects or where access to the disposal site is limited. Trucks are relatively simple, but transportation becomes a bottleneck for large volume operations.

Hydraulic Mucking Systems: These systems use water or slurry to transport muck, particularly effective for fine-grained materials. They’re particularly efficient and are suitable for environments with limited space. However, they have environmental considerations for water management and disposal.

Slurry Systems: Similar to hydraulic systems, these systems mix muck with water to create a pumpable slurry. The slurry is then transported to a settling pond where the water is separated and the solids are disposed of.

My experience includes working with all these systems, selecting and optimizing the best method for specific projects while considering factors such as project size, available infrastructure, environmental impact and cost-effectiveness.

Q 14. Describe your experience with pre-shift and post-shift inspections.

Pre-shift and post-shift inspections are fundamental for ensuring the safe and efficient operation of the TBM. It’s like a pre-flight checklist for an airplane – you need to make sure everything is functioning as designed.

Pre-shift Inspection: This involves a thorough examination of the TBM and its surrounding environment before starting operation. This checklist includes checking for any visible damage, ensuring all safety systems are functioning correctly, verifying the availability of necessary tools and equipment, and checking for any hazardous conditions.

Post-shift Inspection: This inspection happens after the shift ends. It includes documenting any issues that were encountered during the shift, checking for any damage or wear and tear, recording the machine’s performance parameters, and preparing the machine for the next shift. This is essential for maintenance scheduling and problem prevention.

These inspections are crucial for early detection of potential problems, preventing accidents, and maintaining the TBM’s optimal performance. The data collected is analyzed to inform proactive maintenance and improve operational efficiency. This meticulous approach helps to ensure the longevity and effective operation of the TBM in a safe environment.

Q 15. How do you ensure the machine is operating within its specified parameters?

Ensuring a tunnel mucking machine operates within its specified parameters involves a multi-faceted approach combining preventative maintenance, real-time monitoring, and operator skill. Think of it like a finely tuned sports car – you need to understand its limits and operate within them for optimal performance and longevity.

- Regular Inspections: Before each shift, a thorough pre-operational inspection is crucial. This involves checking fluid levels (hydraulic oil, engine coolant), tire pressure, wear on cutting tools, and the overall structural integrity of the machine. Any anomalies are immediately addressed.

- Operational Data Monitoring: Modern machines are equipped with sophisticated monitoring systems that track engine RPM, hydraulic pressure, cutting force, and other key parameters. We constantly monitor these readings against pre-set limits, displayed on a dashboard. If a parameter exceeds its limit, it triggers an alert, allowing for immediate corrective action.

- Adherence to Manufacturer Guidelines: Operating manuals provide detailed instructions on safe operating procedures, load limits, and maintenance schedules. Strict adherence to these guidelines is paramount. For example, overloading the machine can lead to premature wear and tear, or even catastrophic failure.

- Operator Training: Experienced operators understand the machine’s capabilities and limitations. This includes anticipating potential issues and adapting the operation accordingly based on ground conditions and material properties. Regular training keeps operators updated on best practices and new technologies.

For example, if the hydraulic pressure consistently drops below a safe threshold, it indicates a potential leak requiring immediate attention before it escalates into a major breakdown. Similarly, exceeding the recommended RPM can lead to engine overheating.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the signs of impending machine failure, and how do you respond?

Recognizing the signs of impending machine failure requires a keen eye and understanding of the machine’s behavior. It’s like listening to your car – unusual noises or vibrations are warning signs.

- Unusual Noises: Grinding, squealing, or unusual banging noises indicate potential issues with bearings, gears, or the cutting mechanism.

- Excessive Vibrations: Strong vibrations throughout the machine can signify imbalance, worn parts, or structural damage.

- Hydraulic Leaks: Leaks in the hydraulic system are serious and require immediate attention to prevent catastrophic failure. Look for dripping oil, low hydraulic pressure readings, and unusual noises from the hydraulic pump.

- Overheating: Engine overheating, evident through high temperature readings and steam, indicates a problem with the cooling system or potential engine failure.

- Erratic Sensor Readings: Inconsistent or fluctuating readings from sensors monitoring engine parameters, hydraulic pressure, or cutting force signal potential malfunctions.

Response: The response to any of these signs is immediate shutdown, safety assessment, and reporting to the supervisor. Depending on the severity, this could involve minor repairs, major component replacement, or a full machine inspection by a qualified technician.

For instance, a sudden hydraulic leak might require immediate shutdown to prevent further damage and potential injury. Similarly, consistent high-temperature readings necessitate immediate attention to prevent engine seizure.

Q 17. Explain your understanding of hydraulic systems in tunnel mucking machines.

Hydraulic systems are the lifeblood of a tunnel mucking machine, powering the cutting head, conveyor belt, and other critical components. Think of it as the circulatory system of the machine. It’s a closed system using high-pressure oil to transfer power from the hydraulic pump to actuators – cylinders or motors that convert hydraulic energy into mechanical work.

- Hydraulic Pump: The heart of the system, providing the high-pressure oil.

- Hydraulic Valves: These control the flow and direction of oil, regulating the movement of the actuators.

- Hydraulic Cylinders: These convert hydraulic pressure into linear motion, used for things like raising and lowering the cutting head.

- Hydraulic Motors: These convert hydraulic pressure into rotary motion, powering components like the conveyor belt.

- Hydraulic Reservoirs: These store hydraulic fluid, ensuring a continuous supply.

Maintaining the hydraulic system is crucial, requiring regular checks of fluid levels, cleanliness, and pressure. Leaks, contamination, and wear in components can severely impact the machine’s performance and safety. Regular oil changes and filtration are vital to prevent costly repairs.

For example, a malfunctioning hydraulic valve can prevent the cutting head from operating correctly, resulting in decreased productivity or even a complete halt in operations. Similarly, contaminated hydraulic fluid can damage the pump and other sensitive components.

Q 18. How do you manage material handling and logistics in a tunnel environment?

Material handling and logistics in a tunnel environment are significantly more challenging than in open areas due to confined spaces and limited access. It’s like working on a tightrope – precision and planning are vital.

- Efficient Mucking Cycles: Optimizing the loading and unloading cycles of the machine is critical. This involves proper positioning of the machine to minimize travel time and maximize loading capacity.

- Transportation Systems: Efficient transportation of excavated material from the tunnel face to the surface depends on a well-planned system of conveyors, trucks, or rail systems. This includes ensuring smooth material flow and minimizing bottlenecks.

- Storage and Disposal: Planning for the storage and disposal of excavated materials is critical. This involves arranging for appropriate storage areas, waste management protocols, and environmental compliance.

- Safety Procedures: Safety is paramount. This includes strict adherence to procedures for handling heavy materials, proper ventilation to prevent dust inhalation, and implementation of fall prevention measures.

- Real-time Monitoring: Using technology to monitor material flow, inventory, and equipment status can aid in optimizing logistics and preventing delays.

For instance, a poorly designed conveyor system can lead to backups and delays. Similarly, inadequate storage planning can lead to congestion and safety hazards. A well-planned logistics system, coupled with effective communication among teams, can streamline operations significantly.

Q 19. What are the different types of sensors used in modern tunnel mucking machines?

Modern tunnel mucking machines utilize a range of sensors to monitor various parameters crucial for efficient and safe operation. These sensors act like the machine’s senses, providing valuable feedback.

- Pressure Sensors: Monitor hydraulic pressure, tire pressure, and air pressure in various systems.

- Temperature Sensors: Track engine temperature, hydraulic oil temperature, and bearing temperatures to detect overheating.

- Flow Sensors: Measure hydraulic fluid flow rates to detect leaks or blockages.

- Position Sensors: Monitor the position of various components such as the cutting head, conveyor belt, and boom.

- Vibration Sensors: Detect unusual vibrations that could indicate wear or damage to components.

- Proximity Sensors: Detect obstacles or personnel in the vicinity of the machine for safety.

- Load Cells: Measure the weight of excavated material loaded into the machine.

The data collected by these sensors feed into the machine’s control system, providing real-time information to the operator and the monitoring system.

Q 20. How do you interpret sensor data to optimize machine performance?

Interpreting sensor data is crucial for optimizing machine performance and preventing failures. It’s like understanding a patient’s vital signs – subtle changes can reveal underlying issues.

- Real-time Monitoring: Continuously monitoring sensor readings allows for early detection of anomalies, enabling proactive intervention before they escalate into problems.

- Data Analysis: Analyzing sensor data over time helps identify trends and patterns that might reveal potential issues, even if they don’t trigger immediate alerts. For example, a gradual increase in hydraulic oil temperature over several shifts might indicate a developing problem.

- Predictive Maintenance: By analyzing sensor data, we can predict potential failures and schedule maintenance accordingly, minimizing downtime and increasing efficiency. This is akin to preventive health checks.

- Performance Optimization: Analyzing sensor data like cutting force and RPM can help optimize machine parameters for optimal performance while minimizing wear and tear.

For example, a sudden drop in hydraulic pressure might indicate a leak, while consistently high vibration readings could signify the need for bearing replacement. By analyzing these data points, we can make informed decisions about maintenance and operation to maximize the machine’s efficiency and longevity.

Q 21. Describe your experience with remote control operation of tunnel mucking machines.

Remote control operation of tunnel mucking machines offers significant advantages, particularly in hazardous environments. It’s like piloting a plane from a control tower – you have a safe distance but complete control.

- Enhanced Safety: Operators can control the machine from a safe distance, minimizing exposure to hazardous conditions like falling rocks, dust, or confined spaces.

- Improved Efficiency: Remote control can enhance efficiency by allowing for continuous operation without the need for constant operator repositioning.

- Precise Control: Remote controls often provide finer control over the machine’s movements, allowing for more precise excavation and material handling.

- Real-time Monitoring: Remote control systems typically integrate with sensor data, providing real-time feedback to the operator.

- Emergency Shutdowns: Remote control systems allow for immediate emergency shutdowns if necessary.

My experience includes using several different remote control systems, all of which require extensive training and adherence to safety protocols. For example, I’ve used systems with joystick controls, touchscreens, and even augmented reality overlays for improved situational awareness. The key is to master the control interface and understand the system’s limitations to ensure safe and efficient operation.

Q 22. How do you ensure the machine complies with all relevant safety regulations?

Safety is paramount in tunnel mucking machine operation. We adhere to a multi-layered approach, starting with rigorous pre-shift inspections. This includes checking all safety systems – emergency stops, braking mechanisms, lighting, and the structural integrity of the machine itself. We meticulously review the site-specific safety plan, which details potential hazards like unstable ground conditions, gas leaks, and proximity to high-voltage lines. Throughout the operation, we maintain constant vigilance, adhering to speed limits, and ensuring that all personnel follow prescribed safety protocols including wearing appropriate PPE (Personal Protective Equipment) such as hard hats, safety glasses, and high-visibility clothing. Regular training and competency assessments are key to maintaining safety standards. For example, we conduct regular drills on emergency shutdown procedures and the use of rescue equipment. Finally, detailed post-shift reports are filed, documenting any incidents, near misses, or required maintenance, contributing to continuous improvement in our safety performance.

Q 23. What are the environmental considerations when operating a tunnel mucking machine?

Environmental considerations are integral to responsible tunnel mucking. Minimizing dust generation is crucial. This involves utilizing effective dust suppression techniques, such as water sprays and dust collection systems, directly at the cutting face. We also carefully manage the disposal of excavated material. Spoil (excavated rock and debris) is often transported to designated disposal sites, minimizing environmental impact. Noise pollution is another concern; we employ noise-reducing techniques like mufflers and scheduling work to avoid sensitive times. The potential for water contamination is also mitigated by using appropriate containment measures to prevent runoff from carrying pollutants. Furthermore, we strive to minimize fuel consumption by optimizing machine performance and adhering to best practices for engine operation. Regular monitoring and environmental impact assessments ensure compliance with all relevant regulations and contribute to responsible operation.

Q 24. Describe your experience with different types of rock and their impact on cutting tools.

My experience encompasses working with a variety of rock types, each requiring a different approach. Hard, abrasive rocks like granite necessitate the use of robust, carbide-tipped cutting tools that can withstand high wear and tear. Softer rocks, such as shale or sandstone, may require tools with different geometries and cutting edges to avoid excessive breakage or chipping. I’ve also encountered highly fractured or jointed rocks, requiring modifications to the cutting strategy and potentially the use of specialized tools to prevent unpredictable behavior and ensure worker safety. The impact on cutting tools is significant; harder rocks lead to faster wear and increased tool replacement frequency, impacting both cost and operational efficiency. For example, working in a tunnel with extremely hard basalt required more frequent tool changes than a project where the primary rock was a softer limestone. This highlights the importance of proper tool selection and regular monitoring of tool wear.

Q 25. How do you manage dust and air quality during tunnel excavation?

Managing dust and maintaining good air quality are crucial for both worker health and environmental protection. Our primary strategy involves using high-pressure water sprays at the cutting face to suppress dust generation at its source. We also employ powerful ventilation systems that draw air out of the tunnel, minimizing the accumulation of dust particles. In addition to these measures, we use specialized filtration systems on the machine itself, further reducing the amount of dust in the immediate working environment. Air quality is continuously monitored using sensors that provide real-time data on particulate matter levels. If readings exceed acceptable limits, we immediately implement additional control measures, such as increasing water spray intensity or deploying supplementary ventilation. Regular cleaning of the machine and work area also contributes to maintaining good air quality. We also use respiratory protection for personnel as an additional safety layer.

Q 26. Explain your understanding of the different types of cutting tools and their applications.

Tunnel mucking machines employ a variety of cutting tools, each suited to different rock conditions. Pick tools, with sharp points, are effective for breaking up hard and brittle rocks. Disc cutters, featuring rotating abrasive discs, are ideal for softer or more abrasive materials. Roller cutters, with numerous small cutting elements, provide efficient cutting in moderately hard rocks. The selection depends on rock hardness, abrasiveness, and the desired excavation rate. For instance, in a project involving hard granite, we would employ robust pick tools and reinforced disc cutters. In contrast, softer sedimentary rock might benefit from the use of roller cutters and perhaps less aggressive pick tools. Proper tool selection directly impacts productivity, wear rates, and the overall efficiency of the operation.

Q 27. How do you maintain accurate records of machine operation and maintenance?

Accurate record-keeping is critical for operational efficiency and legal compliance. We maintain detailed logs of each shift, documenting parameters such as machine operating hours, material excavated, tool changes, fuel consumption, and any maintenance performed. These logs are usually digital, stored on secure cloud-based systems and readily accessible. We also meticulously track maintenance activities, including scheduled preventative maintenance and any unscheduled repairs. This includes recording the type of repair, parts used, and the time taken to complete the work. This data is essential for analyzing machine performance, predicting potential issues, and planning for future maintenance. The data is also used for cost analysis and reporting to project stakeholders. This detailed approach ensures transparency, facilitates effective maintenance planning, and allows for thorough analysis of operational costs and efficiency.

Q 28. Describe a challenging situation you faced while operating a tunnel mucking machine and how you resolved it.

During a project in mountainous terrain, we encountered an unexpected geological formation – a large, heavily fractured rock mass that was significantly more unstable than anticipated. Initial attempts to excavate resulted in several near-misses due to falling rocks. The solution required a multi-pronged approach. First, we halted excavation and implemented enhanced safety measures, including additional shoring and improved worker positioning. Secondly, we conducted a thorough geological assessment to determine the best strategy for removing the unstable section. This involved using a combination of controlled blasting techniques (with proper safety precautions in place) and more careful, smaller-scale excavation using hand tools and specialized smaller equipment in the immediate vicinity of the unstable area. Careful planning and communication were vital for overcoming this challenge safely and efficiently. This experience underscored the importance of thorough site investigation and flexibility in adapting to unforeseen geological conditions. It also demonstrated the value of teamwork and proactive safety measures in high-risk environments.

Key Topics to Learn for Tunnel Mucking Machine Operation Interview

- Machine Mechanics & Hydraulics: Understanding the intricate workings of the TBM, including cutterhead mechanisms, conveyor systems, and the role of hydraulics in operation and maintenance.

- Operational Procedures & Safety Protocols: Practical application of safety regulations, emergency procedures, and adherence to strict operational guidelines for efficient and safe tunneling.

- Geological Considerations & Ground Conditions: Analyzing geological reports to predict potential challenges during excavation and adapting operational strategies accordingly. This includes understanding the impact of different soil types and rock formations on machine performance.

- Data Acquisition & Monitoring: Interpreting data from sensors and monitoring systems to identify potential issues, optimize performance, and ensure the machine’s overall health.

- Troubleshooting & Maintenance: Diagnosing and resolving common mechanical and hydraulic issues, performing routine maintenance tasks, and understanding preventative maintenance schedules.

- Excavation Techniques & Strategies: Applying different excavation techniques based on geological conditions, optimizing cutting parameters for efficiency and minimizing wear and tear on the machine.

- Advanced Control Systems & Automation: Familiarity with advanced control systems and automation technologies used in modern TBMs, including GPS guidance and remote monitoring.

Next Steps

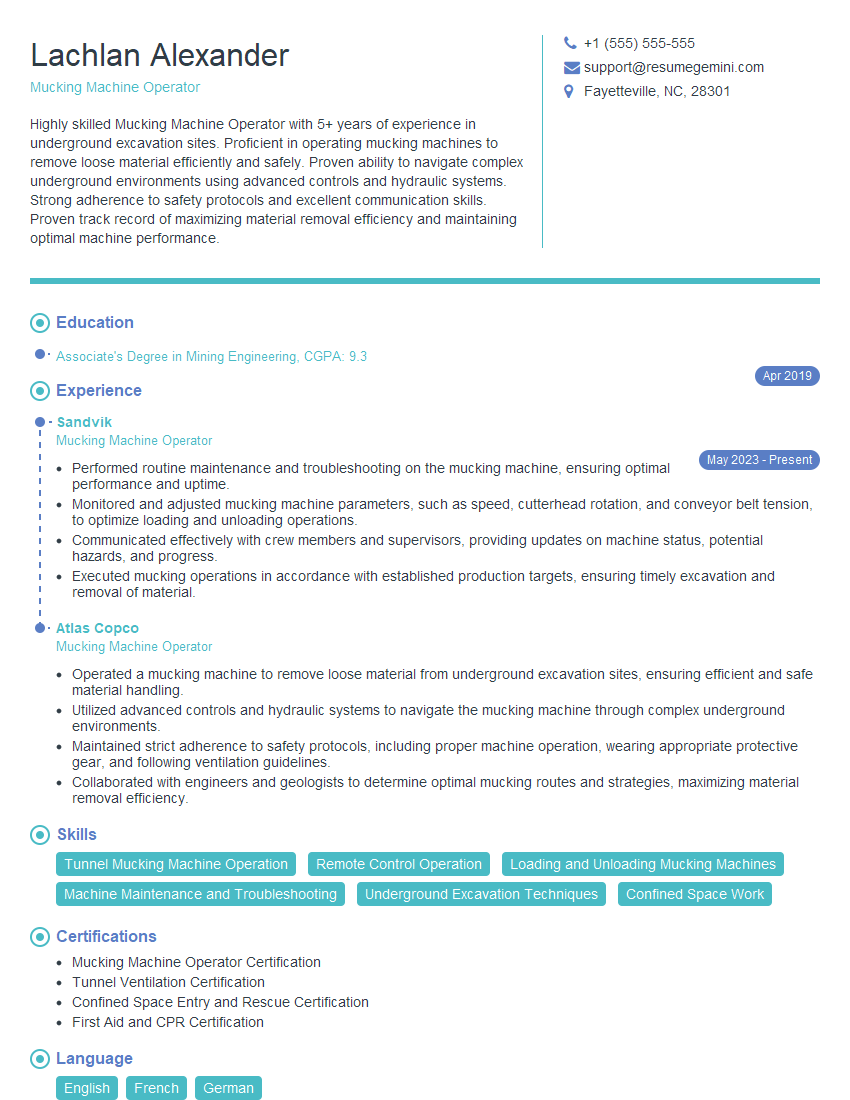

Mastering Tunnel Mucking Machine Operation opens doors to exciting career opportunities in large-scale infrastructure projects worldwide. This specialized skillset is highly valued, offering excellent earning potential and the chance to contribute to significant engineering feats. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting noticed by recruiters. ResumeGemini can help you craft a compelling and impactful resume that highlights your expertise in Tunnel Mucking Machine Operation. We offer examples of resumes tailored to this specific field to help guide you. Take the next step towards your dream career – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.