Cracking a skill-specific interview, like one for Turbine Insulation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Turbine Insulation Interview

Q 1. Explain the different types of turbine insulation materials and their applications.

Turbine insulation materials are chosen based on the operating temperature and the specific needs of the turbine. Several types exist, each with its strengths and weaknesses:

- Mineral wool: This is a common choice, offering excellent thermal insulation properties and good resistance to high temperatures. Different types exist, such as rock wool and ceramic fiber, each with varying temperature capabilities. Rock wool is often used for lower temperature applications, while ceramic fiber handles higher temperatures, but needs careful handling due to potential fiber inhalation.

- Calcium silicate: Known for its high-temperature resistance and excellent compressive strength, calcium silicate is often used in demanding applications. It’s less prone to shrinkage than some other materials. Think of it as the sturdy workhorse of turbine insulation.

- Insulating concrete: A spray-applied material, insulating concrete provides a monolithic layer with good thermal and acoustic insulation. It’s often used for larger areas or complex geometries. Imagine it like a protective shell, molded to the turbine’s shape.

- Aerogel: This cutting-edge material offers exceptional insulation properties due to its extremely low thermal conductivity. However, its higher cost and fragility limit its application to specialized high-temperature and demanding environments.

- Refractory bricks: These are used for lining furnace walls and other high-temperature components of the turbine system. They provide a barrier against extremely high temperatures and direct flame impingement.

The application of each material depends on factors like temperature, pressure, chemical exposure, and mechanical stress. For instance, a gas turbine operating at 1000°C might use ceramic fiber or calcium silicate, while a lower-temperature steam turbine could utilize mineral wool.

Q 2. Describe the process of installing turbine insulation, including safety precautions.

Installing turbine insulation is a specialized process requiring skilled technicians and adherence to strict safety protocols. Here’s a general overview:

- Preparation: This involves thoroughly cleaning the turbine surfaces to ensure proper adhesion of the insulation. All loose debris and contaminants must be removed.

- Insulation Installation: This depends on the chosen material. Mineral wool blankets might be wrapped and secured with wire or straps. Insulating concrete is sprayed onto the surface. Refractory bricks are carefully placed and mortared. Precise measurements and careful placement are critical to avoid gaps.

- Fastening and Securing: Insulation needs to be firmly secured to prevent movement or detachment during operation. Various methods, such as wire ties, clips, or adhesives, might be used depending on the material and the turbine’s design.

- Protective Covering: Often, a protective outer layer (e.g., sheet metal cladding) is installed to shield the insulation from damage and the environment. This layer also provides a neat and finished appearance.

Safety Precautions are Paramount:

- Respiratory Protection: Many insulation materials, especially ceramic fibers, can be harmful if inhaled. Respiratory protection, including respirators and appropriate ventilation, is mandatory.

- Heat Protection: Turbines and their insulation can be extremely hot. Appropriate heat-resistant clothing, gloves, and eye protection are essential.

- Fall Protection: Working at heights is common during insulation installation; appropriate fall protection equipment is a must.

- Lockout/Tagout Procedures: Ensure the turbine is completely shut down, depressurized, and locked out before commencing any work.

Proper training and adherence to all relevant safety standards are critical to prevent accidents and injuries during installation.

Q 3. What are the common causes of turbine insulation failure?

Turbine insulation failure can stem from several factors, often interacting to cause problems:

- High Temperatures: Exceeding the material’s design temperature limit leads to degradation, potentially causing shrinkage, cracking, or even melting.

- Mechanical Damage: Physical impacts, vibrations, and abrasion during operation or maintenance can damage the insulation.

- Moisture Ingress: Moisture can significantly reduce insulation’s effectiveness and promote corrosion, causing further deterioration.

- Chemical Attack: Exposure to aggressive chemicals in the turbine environment can degrade certain insulation materials.

- Poor Installation: Gaps, inadequate fastening, or incorrect material selection during installation can lead to premature failure.

- Thermal Cycling: Repeated heating and cooling cycles can cause thermal stress, leading to cracking and degradation.

For example, if a calcium silicate insulation is exposed to moisture, it can lose its strength and effectiveness. Similarly, using mineral wool in an environment with high chemical concentrations can lead to rapid degradation.

Q 4. How do you inspect and maintain turbine insulation systems?

Regular inspection and maintenance are vital to ensure the long-term effectiveness and safety of turbine insulation. This involves:

- Visual Inspection: Regularly inspect for signs of damage, such as cracks, gaps, or loose insulation. Look for any signs of moisture or corrosion.

- Thermal Imaging: Infrared cameras can detect areas of heat loss, indicating potential insulation failure or weaknesses.

- Thickness Measurement: Periodically measure the thickness of the insulation to ensure it hasn’t thinned due to wear or degradation.

- Material Testing: In some cases, samples of the insulation might be tested in a laboratory to assess its remaining thermal conductivity and mechanical properties.

Maintenance may involve repairing minor damage, replacing deteriorated sections, or even a complete insulation overhaul depending on the findings of the inspection. A well-maintained insulation system extends the life of the turbine and improves its efficiency.

Q 5. What are the benefits of using high-temperature insulation in turbines?

High-temperature insulation in turbines provides numerous benefits:

- Improved Efficiency: By minimizing heat loss, high-temperature insulation allows the turbine to operate more efficiently, reducing fuel consumption and operational costs. Think of it like a well-insulated house—less energy is lost to the environment.

- Enhanced Safety: Reducing surface temperatures minimizes the risk of burns and other injuries to personnel during operation and maintenance.

- Extended Turbine Life: By protecting the turbine components from excessive heat, high-temperature insulation extends their lifespan, reducing the need for expensive repairs or replacements.

- Reduced Environmental Impact: Improved efficiency translates to lower emissions of greenhouse gases and other pollutants.

- Better Performance: Maintaining optimal operating temperatures ensures consistent and reliable turbine performance.

For example, in a power generation plant, improved efficiency through high-temperature insulation directly translates to cost savings and reduced carbon emissions.

Q 6. How do you determine the appropriate thickness of insulation for a given turbine?

Determining the appropriate insulation thickness is crucial for optimal performance and cost-effectiveness. Several factors influence this decision:

- Operating Temperature: Higher operating temperatures necessitate thicker insulation to minimize heat loss.

- Ambient Temperature: The difference between the operating temperature and the ambient temperature affects the required insulation thickness.

- Desired Heat Loss: The acceptable level of heat loss dictates the thickness. A stricter limit requires thicker insulation.

- Insulation Material: Each material has a different thermal conductivity, influencing the required thickness to achieve the same level of insulation.

- Economic Considerations: The cost of the insulation material and installation needs to be balanced against the benefits of improved efficiency and reduced heat loss.

Calculations involving thermal conductivity, temperature differences, and desired heat loss are used to determine the optimum thickness. Specialized software and engineering expertise are often employed for accurate calculations.

Q 7. Explain the importance of thermal conductivity in selecting insulation materials.

Thermal conductivity is a crucial material property when selecting turbine insulation. It represents a material’s ability to conduct heat. Lower thermal conductivity indicates better insulation performance. Think of it like this: a material with low thermal conductivity is like a good insulator in your home – it resists the flow of heat, keeping the inside warm in winter and cool in summer.

In selecting insulation, materials with low thermal conductivity are preferred. For example, aerogel boasts exceptionally low thermal conductivity, making it ideal for high-temperature applications where minimizing heat loss is paramount. However, other factors like cost, durability, and ease of installation need to be considered in conjunction with thermal conductivity. The final choice is a balance of performance, cost, and practicality.

Q 8. Describe different methods for measuring the effectiveness of turbine insulation.

Measuring the effectiveness of turbine insulation involves a multifaceted approach, combining both direct and indirect methods. Direct methods focus on measuring the temperature difference across the insulation layer. This can be done using thermocouples placed at various points on the turbine casing, both inside and outside the insulation. The smaller the temperature difference, the more effective the insulation. Infrared thermography is another powerful direct method, allowing for non-contact temperature measurement across the entire surface, quickly identifying ‘hot spots’ indicating insulation failure.

Indirect methods assess effectiveness by measuring the heat loss from the turbine. This might involve measuring the overall energy consumption of the turbine; higher energy efficiency suggests better insulation performance. We can also analyze the exhaust gas temperature, lower temperatures indicating reduced heat loss. Regular inspections, checking for physical damage or degradation of the insulation material, also provide vital indirect evidence of performance.

For example, during a recent project on a gas turbine, we used a combination of thermocouples and infrared thermography. The thermography revealed a localized area of higher temperature, indicating a small gap in the insulation. Further investigation revealed a minor installation flaw, which we were able to rectify, demonstrably improving the overall efficiency of the turbine.

Q 9. What are the environmental considerations related to turbine insulation materials?

Environmental considerations related to turbine insulation materials are paramount. Many traditional insulation materials contain harmful substances such as asbestos, which is highly carcinogenic and environmentally damaging. Modern regulations strictly prohibit the use of asbestos, necessitating the adoption of safer alternatives. The environmental impact is further assessed by considering the materials’ manufacturing processes, their lifecycle (including ease of recycling or disposal), and their potential for releasing harmful gases during operation or disposal. The carbon footprint associated with the production and transportation of the insulation materials should also be considered, alongside any potential for leaching of chemicals into soil or water.

For instance, the choice of calcium silicate insulation over fiberglass may be preferable due to its lower embodied energy and improved recyclability. The use of recycled content in the manufacturing of insulation materials also contributes positively towards environmental sustainability.

Q 10. How do you handle damaged or deteriorated turbine insulation?

Handling damaged or deteriorated turbine insulation requires a systematic approach, prioritizing safety and minimizing downtime. The first step involves a thorough visual inspection to identify the extent and nature of the damage. This includes checking for cracks, gaps, missing sections, and signs of degradation, such as discoloration or crumbling. Following a safety briefing and donning appropriate PPE (Personal Protective Equipment), the damaged insulation is carefully removed, paying close attention to avoid further damage to the underlying turbine components.

The removal process depends on the type of insulation; some materials can be easily peeled off, while others might require careful cutting or grinding. The area is then thoroughly cleaned to remove any loose debris. Once the area is prepared, the replacement insulation is installed using the same techniques as the original installation, ensuring proper sealing of all joints to prevent heat loss and potential damage to the equipment. A post-installation inspection confirms the effectiveness of the repair.

In one instance, we found significant deterioration in a ceramic fiber insulation around a steam turbine. After carefully removing the damaged material, we replaced it with a high-temperature resistant, reinforced ceramic composite, and then conducted thorough temperature monitoring to verify the repair’s efficacy.

Q 11. Explain the role of insulation in preventing turbine blade erosion.

Turbine blade erosion is a significant concern, often caused by the impingement of foreign particles or by high-velocity gas streams. Insulation plays a vital, albeit indirect, role in minimizing this erosion. By maintaining a consistent and even temperature distribution around the turbine casing, insulation helps to prevent thermal stresses and uneven expansion, which can lead to cracks and other structural weaknesses. This enhanced structural integrity reduces the likelihood of particles dislodging from the casing and impacting the turbine blades. Moreover, a well-insulated turbine operates more efficiently, reducing the speed and intensity of the gas stream which can contribute to erosion.

Think of it like this: insulation acts as a protective buffer, preserving the structural integrity of the turbine casing and ensuring that the turbine operates within its designed parameters. This indirectly helps to minimize the risk of blade erosion.

Q 12. What are the safety risks associated with working with turbine insulation materials?

Safety risks associated with working with turbine insulation materials vary greatly depending on the specific material. Some materials, like older asbestos-containing insulation, pose significant health risks, including lung cancer and asbestosis. Even modern materials can present hazards. Many insulation materials are fibrous and can irritate the lungs if inhaled; some are also highly flammable or can release toxic fumes when heated. Working at heights, during installation or repair, adds further risk. The potential for falls or burns from contact with hot surfaces are major concerns.

To mitigate these risks, rigorous safety protocols are essential. These include comprehensive risk assessments, the use of appropriate PPE (respiratory protection, eye protection, gloves, etc.), strict adherence to lockout/tagout procedures, and thorough training for all personnel involved in handling insulation materials. Regular health checks are also crucial for workers exposed to potentially harmful materials.

Q 13. How do you ensure the proper sealing of insulation joints?

Proper sealing of insulation joints is critical for preventing heat loss and ensuring the effectiveness of the insulation system. The method of sealing depends on the type of insulation and the specific application. Common methods include the use of high-temperature sealants, specialized tapes, or mastics. These sealants are chosen based on their compatibility with the insulation material, their ability to withstand high temperatures, and their resistance to degradation over time. For some high-temperature applications, a combination of sealant and a metal retaining band might be used to provide additional reinforcement and a secure seal.

Careful attention should be paid to surface preparation before sealing. Any gaps or irregularities in the insulation should be filled before applying the sealant. A consistent and even application of the sealant is essential to ensure a strong and durable seal. After applying the sealant, adequate curing time must be allowed before the turbine is restarted to allow the sealant to fully set.

In one project, we used a specialized ceramic fiber blanket insulation and secured the joints with high-temperature metallic tapes, followed by a secondary application of a high-temperature sealant. This ensured a completely air-tight and durable seal, maintaining the integrity of the insulation over extended periods.

Q 14. Describe your experience with different insulation installation techniques (e.g., spray, blanket, etc.).

My experience encompasses a wide range of insulation installation techniques. Spray-applied insulation, typically using refractory materials like calcium silicate or ceramic fiber, is ideal for complex shapes and provides a seamless, uniform coating. This method requires specialized equipment and skilled technicians to achieve consistent thickness and prevent voids. Blanket insulation, consisting of pre-formed mats or rolls of various materials, is simpler to install and offers good thermal performance. It’s suited for applications where access is easier and a more straightforward installation is preferred. Loose-fill insulation, such as mineral wool or perlite, is used in less demanding applications, often as a fill within cavities or around pipes.

The choice of technique depends on factors such as the shape and size of the turbine, the operating temperature, the access available for installation, and the budget. For example, in a recent project involving a large industrial gas turbine, we used a combination of spray-applied insulation in difficult-to-reach areas and pre-formed blanket insulation in more accessible locations. Careful planning and execution were key to optimizing both the thermal performance and the overall installation time.

Q 15. How do you address challenges in accessing difficult-to-reach areas for insulation?

Accessing hard-to-reach areas during turbine insulation is a common challenge. We tackle this using a multi-pronged approach. First, thorough pre-planning is crucial. This involves detailed 3D modeling of the turbine to identify all access points and potential obstacles. Second, we employ specialized equipment like articulated robotic arms with insulation-application tools, allowing for precise placement in tight spaces. For exceptionally difficult areas, we might utilize flexible insulation blankets or specialized spray-on foam insulation, minimizing the need for extensive disassembly. Finally, our team undergoes rigorous safety training in confined space entry and working at heights, ensuring both project completion and worker safety. For instance, on a recent project involving a large gas turbine, we used a robotic arm with a custom-designed nozzle to apply ceramic fiber insulation to the internal components of the combustion chamber, a task previously deemed almost impossible without extensive disassembly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What software or tools are you familiar with for designing or analyzing turbine insulation systems?

My experience encompasses various software and tools used in turbine insulation design and analysis. For 3D modeling and visualization, I’m proficient in AutoCAD and SolidWorks, using them to create detailed models of turbine components and insulation systems. For thermal analysis, I frequently use ANSYS and COMSOL Multiphysics to simulate heat transfer within the turbine and optimize insulation design for minimal heat loss. These simulations help predict temperature gradients and identify potential hotspots. We also use specialized software for calculating insulation material thickness based on operating temperature and heat flux. For example, in a recent steam turbine project, we used ANSYS to model the insulation system and optimize the thickness of different insulation layers to reduce thermal stress and maintain efficiency within the budget.

Q 17. Explain your understanding of relevant industry codes and standards for turbine insulation.

Understanding and adhering to industry codes and standards is paramount in turbine insulation. We routinely work with standards like ASME (American Society of Mechanical Engineers) codes, specifically those related to pressure vessels and piping systems, as many turbines fall under these regulations. Additionally, we comply with API (American Petroleum Institute) standards for related oil and gas applications and relevant OSHA (Occupational Safety and Health Administration) guidelines for worker safety and environmental regulations. These standards dictate material selection criteria, insulation thickness requirements, inspection procedures, and safety protocols. For instance, the selection of insulation materials must consider the operating temperature, chemical compatibility, and fire resistance, as detailed in relevant ASME and API standards. Regular inspections, in accordance with these standards, are crucial for the long-term performance and safety of the insulation system.

Q 18. How do you manage insulation projects within budget and schedule constraints?

Managing insulation projects within budget and schedule demands a meticulous approach. We begin with detailed project planning, including a thorough scope of work, material cost estimations, and a realistic schedule. We leverage our experience to choose cost-effective insulation materials without compromising quality. Regular progress monitoring and communication with the client are key to identifying and addressing potential issues proactively. We implement value engineering techniques to explore alternative solutions that meet project goals within budget constraints. For instance, on a recent project, we substituted a more expensive high-temperature insulation material with a cost-effective alternative, after careful thermal analysis, ensuring that performance remained within acceptable limits, and achieving significant cost savings.

Q 19. Describe your experience working with different types of turbines (gas, steam, etc.).

My experience spans various turbine types, including gas turbines, steam turbines, and combined cycle power plants. Each turbine type presents unique insulation challenges due to differences in operating temperatures, pressure levels, and geometries. Gas turbines, for example, operate at extremely high temperatures, requiring specialized high-temperature insulation materials. Steam turbines, while generally operating at lower temperatures, still necessitate insulation to prevent condensation and maintain efficiency. Combined cycle plants present a blend of both high- and low-temperature environments, requiring a combination of insulation materials and strategies. This diversity in experience allows for a comprehensive understanding of the specific insulation needs of each type.

Q 20. How do you troubleshoot problems related to heat loss or uneven insulation coverage?

Troubleshooting heat loss or uneven insulation coverage starts with a thorough inspection of the insulated system. Infrared thermography is an invaluable tool, allowing us to identify hot spots indicating areas of insufficient or damaged insulation. We analyze operational data, comparing actual performance to design specifications to pinpoint any anomalies. We then use systematic troubleshooting steps to determine the root cause, which may involve investigating material degradation, improper installation, or design flaws. The solution might include replacing damaged insulation, addressing design flaws, or implementing improved installation techniques. For example, discovering inconsistent insulation thickness using infrared scans led us to identify a faulty application process and adjust accordingly, resolving significant heat loss in a gas turbine project.

Q 21. How do you ensure the compatibility of different insulation materials in a system?

Ensuring material compatibility in a turbine insulation system is critical to prevent chemical reactions, degradation, and performance issues. We meticulously review material compatibility charts and manufacturers’ data sheets to verify the compatibility of different insulation materials in contact with each other and with the turbine components. Factors like temperature, moisture content, and chemical exposure are carefully considered. We avoid using materials that might react negatively, leading to reduced insulation effectiveness or damage to the turbine. For instance, we avoid placing certain types of fibrous insulation next to metallic components without appropriate barrier layers to prevent corrosion. This careful selection and strategic layering ensure the long-term reliability and performance of the entire insulation system.

Q 22. Explain your understanding of the impact of vibration on turbine insulation.

Vibration significantly impacts turbine insulation’s lifespan and effectiveness. Constant vibrations, especially in high-speed turbines, can cause insulation materials to degrade faster. This degradation can manifest as cracking, settling, and loosening of the insulation, leading to reduced thermal performance and potential damage to the turbine components. The severity depends on the frequency, amplitude, and duration of the vibration. For instance, resonant frequencies can cause significant damage, even with relatively low-amplitude vibrations. Think of it like constantly shaking a sandcastle – eventually, it will crumble. We mitigate this by selecting vibration-resistant materials, employing proper installation techniques (e.g., using flexible supports and minimizing gaps), and implementing vibration damping solutions where necessary.

Q 23. How do you identify and mitigate the risks of moisture ingress into turbine insulation?

Moisture ingress is a critical threat to turbine insulation as it reduces its thermal efficiency and can lead to corrosion of underlying components. We identify potential risks through regular visual inspections, checking for signs of water staining, condensation, or rust. We also use infrared thermography to detect temperature anomalies that might indicate moisture penetration. Moisture ingress mitigation strategies include:

- Implementing proper sealing and weatherproofing measures around the turbine housing.

- Using hydrophobic insulation materials with excellent water-repellent properties.

- Ensuring proper drainage around the turbine to prevent water accumulation.

- Installing moisture barriers within the insulation system.

- Employing regular maintenance and inspections, potentially including moisture meters, to detect early signs of problems.

For example, in one project, we discovered a minor leak in a pipe near the turbine, causing moisture to slowly penetrate the insulation. By promptly addressing the leak and applying a hydrophobic sealant, we prevented significant damage and costly repairs.

Q 24. Describe your experience with non-destructive testing methods used for evaluating turbine insulation.

My experience encompasses various non-destructive testing (NDT) methods for evaluating turbine insulation. These methods allow us to assess the condition of the insulation without causing damage. Some common techniques I’ve utilized include:

- Infrared thermography: Detects temperature differences, indicating areas of insulation degradation or moisture penetration.

- Ultrasonic testing: Measures the speed of sound waves through the insulation, revealing density variations or the presence of voids.

- Moisture meters: Directly measure moisture content within the insulation material.

- Visual inspection: A fundamental step, identifying obvious signs of damage like cracks, deterioration, or displacement.

For instance, during a recent inspection, infrared thermography revealed a localized area of heat loss, indicating compromised insulation in that section. Further investigation using ultrasonic testing confirmed the presence of voids within the insulation, prompting targeted repairs.

Q 25. What are the key performance indicators (KPIs) you use to assess the effectiveness of turbine insulation?

Key performance indicators (KPIs) for evaluating turbine insulation effectiveness include:

- Heat loss reduction: Measured by comparing the heat loss before and after insulation installation or maintenance.

- Surface temperature: Monitoring the turbine’s surface temperature to ensure it’s within acceptable limits.

- Insulation thickness: Checking for consistent thickness to ensure uniform thermal protection.

- Operational efficiency: Analyzing fuel consumption and turbine performance to evaluate the impact of the insulation on overall efficiency. This is often measured as a percentage improvement compared to a baseline.

- Mean time between failures (MTBF): Tracking the intervals between maintenance activities or failures to assess insulation longevity.

We typically use data loggers and monitoring systems to collect these data points, allowing for continuous evaluation and optimization.

Q 26. How do you communicate technical information effectively to non-technical personnel?

Communicating technical information to non-technical personnel requires clear, concise language and avoiding jargon. I utilize several strategies:

- Analogies and metaphors: Explaining complex concepts using relatable examples. For instance, I might compare heat loss to water leaking from a bucket.

- Visual aids: Using diagrams, charts, and pictures to illustrate key points.

- Simplified language: Avoiding technical terms whenever possible or providing clear definitions when necessary.

- Focus on impact: Highlighting the practical consequences of the technical information, such as cost savings or improved safety.

- Active listening and feedback: Ensuring understanding by actively listening to the audience’s questions and addressing any concerns.

I always aim to make the information understandable and relevant to the audience’s needs and level of understanding.

Q 27. Explain your experience with different types of insulation removal techniques.

My experience involves various insulation removal techniques, each chosen based on the specific material and condition. These include:

- Manual removal: Using hand tools like chisels and scrapers for delicate or localized removal.

- Mechanical removal: Employing specialized equipment like wire brushes, demolition hammers, or robotic systems for larger-scale removal. This approach is generally faster and better suited for thicker layers.

- Chemical removal: Using solvents or specialized cleaning agents to dissolve or loosen the insulation, particularly effective for certain adhesive materials. This requires careful consideration of environmental impact and worker safety.

- High-pressure water jetting: A method that uses high-pressure water streams to remove insulation, often combined with other techniques.

Safety is paramount during removal. Proper personal protective equipment (PPE) is always mandatory, and we follow strict procedures to prevent damage to underlying components and environmental contamination.

Q 28. Describe your experience with the procurement and specification of turbine insulation materials.

My role in procurement and specification of turbine insulation materials involves a rigorous process. This starts with understanding the specific needs of the turbine, including operating temperature, pressure, and environmental conditions. Next, we create a detailed specification document, clearly defining the required properties, such as:

- Thermal conductivity: The material’s ability to conduct heat.

- Density: Affecting the insulation’s thickness and thermal performance.

- Moisture resistance: Crucial to prevent degradation and corrosion.

- Durability and lifespan: Ensuring the insulation can withstand operational stresses and environmental exposure.

- Fire resistance: A critical safety aspect.

We then evaluate different materials from reputable suppliers, comparing their technical specifications, pricing, and lead times. The selection process often involves testing samples to verify compliance with the specifications. Finally, we ensure proper documentation and traceability throughout the entire procurement chain to maintain quality control.

Key Topics to Learn for Turbine Insulation Interview

- Material Science of Insulation: Understanding the properties of various insulation materials (e.g., ceramic fiber, calcium silicate) and their suitability for different turbine applications. This includes thermal conductivity, compressive strength, and chemical resistance.

- Installation Techniques: Familiarize yourself with best practices for installing turbine insulation, including proper techniques for minimizing heat loss and ensuring structural integrity. Consider different installation methods and their impact on efficiency and longevity.

- Maintenance and Repair: Learn about common issues related to turbine insulation, such as degradation, damage, and repair procedures. Understanding preventative maintenance is crucial.

- Thermal Modeling and Analysis: Gain a basic understanding of how thermal models are used to predict heat transfer and optimize insulation design. This might involve familiarity with software or methodologies used in the field.

- Safety Regulations and Standards: Be prepared to discuss relevant safety regulations and industry standards related to working with high-temperature insulation materials and equipment. This is essential for demonstrating your commitment to workplace safety.

- Economic Considerations: Understand the cost implications of different insulation materials and installation techniques. Demonstrating an understanding of balancing cost and performance will be beneficial.

- Environmental Impact: Familiarize yourself with the environmental implications of different insulation materials and disposal methods. Highlighting environmentally conscious practices is increasingly important.

Next Steps

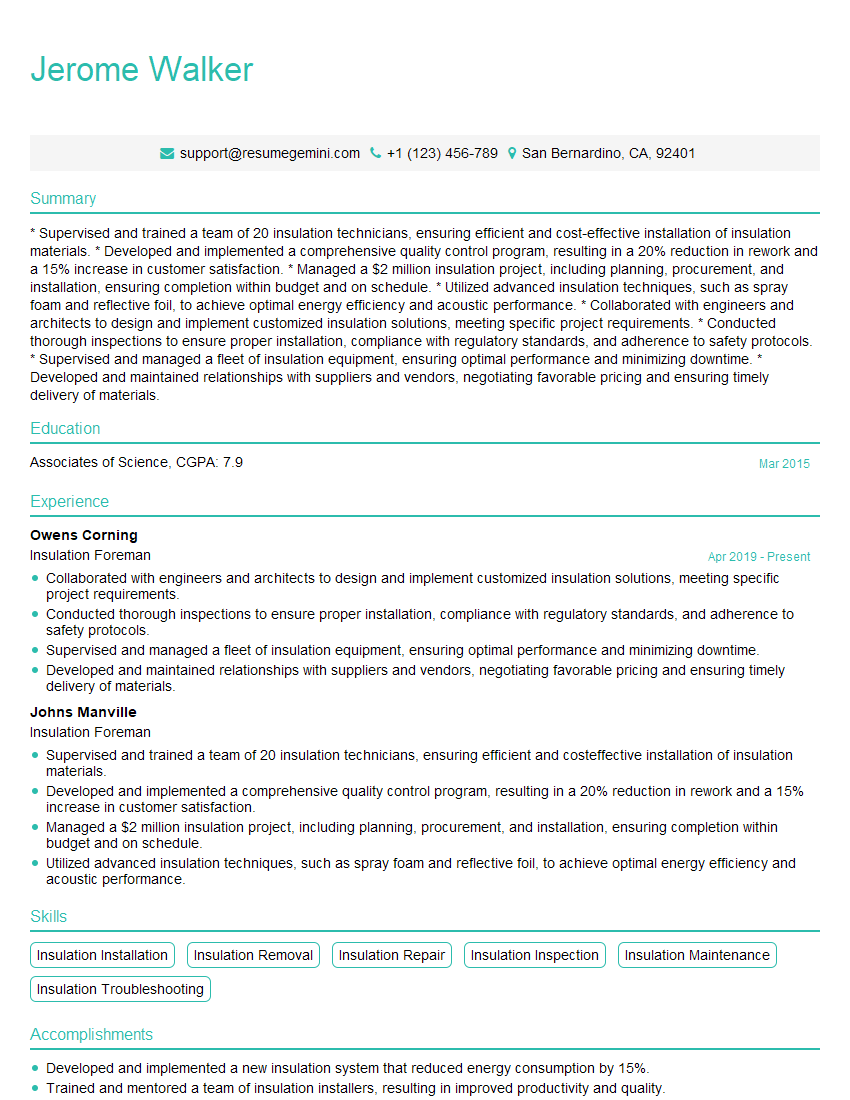

Mastering turbine insulation knowledge opens doors to exciting career opportunities in a high-demand field, offering excellent growth potential and competitive compensation. To maximize your chances of landing your dream role, creating a strong, ATS-friendly resume is paramount. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to highlight your skills and experience in turbine insulation. Examples of resumes specifically designed for the Turbine Insulation industry are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.