Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Understanding of OSHA and ANSI Standards interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Understanding of OSHA and ANSI Standards Interview

Q 1. Describe your experience with OSHA’s General Duty Clause.

OSHA’s General Duty Clause, found in Section 5(a)(1) of the Occupational Safety and Health Act, is the cornerstone of workplace safety. It’s a broad mandate requiring employers to furnish each employee with a workplace free from recognized hazards that are causing or are likely to cause death or serious physical harm. Think of it as the overarching principle that all other specific OSHA standards build upon. It’s not a specific regulation with detailed requirements, but rather a catch-all provision that applies whenever a hazard isn’t covered by a more specific OSHA standard.

In my experience, I’ve applied this clause in numerous scenarios, including addressing emerging hazards like new chemicals or unusual equipment malfunctions. For example, if a new piece of machinery lacks adequate safety guards, resulting in a potential for amputation, this would fall under the General Duty Clause even without a specific standard for that particular machine. The employer’s obligation is to identify the hazard, evaluate the risk, and implement appropriate controls to eliminate or mitigate the hazard.

Successfully invoking the General Duty Clause often involves demonstrating that the hazard was recognized, meaning the industry knows about it and its potential to cause harm, and that the employer failed to take reasonable steps to address it. This requires thorough investigations, detailed documentation, and a clear demonstration of the employer’s negligence.

Q 2. Explain the hierarchy of hazard controls according to OSHA.

OSHA promotes a hierarchy of hazard controls, a prioritized approach to minimizing workplace risks. This hierarchy prioritizes the most effective controls first, moving to less effective measures only if the more effective ones aren’t feasible.

- Elimination: This is the most effective control. It involves completely removing the hazard. For example, eliminating the need for workers to handle hazardous chemicals by using safer alternatives.

- Substitution: Replacing a hazardous substance or process with a less hazardous one. For example, substituting a highly flammable solvent with a less flammable alternative.

- Engineering Controls: Modifying the workplace to reduce exposure to hazards. This includes things like installing machine guards, implementing ventilation systems, or using enclosed systems to contain hazardous materials.

- Administrative Controls: Changing work practices to reduce exposure. Examples include implementing safety procedures, rotating workers through hazardous jobs, and using administrative controls like signage and safety procedures.

- Personal Protective Equipment (PPE): The least effective control, as it protects the worker rather than the hazard. This includes items like gloves, respirators, safety glasses, and hard hats. PPE should only be used as a last resort when other controls are infeasible.

This hierarchy is crucial because it ensures that employers implement the most effective safety measures possible, minimizing the risk to their workers. Following this hierarchy demonstrates a proactive and responsible approach to workplace safety.

Q 3. How familiar are you with OSHA Form 300?

OSHA Form 300, the Log of Work-Related Injuries and Illnesses, is a crucial document for tracking workplace injuries and illnesses. Employers with 11 or more employees must complete this form annually. It’s not just a record-keeping exercise; it’s a vital tool for identifying trends, preventing future incidents, and ensuring compliance with OSHA regulations.

My familiarity with OSHA Form 300 is extensive. I understand the specific information required, including the date of injury, the nature of the injury, and the affected body part. I also know the requirements for recording cases, the methods for summarizing data, and the specific timelines for posting and maintaining these records. I have experience analyzing the data from this form to identify areas needing improvement in safety protocols and training. For example, noticing a high number of back injuries might lead to an investigation of work practices and a review of ergonomic training.

Q 4. What are the key differences between OSHA and ANSI standards?

OSHA and ANSI standards are both important for workplace safety, but they serve different purposes and have different levels of enforceability. OSHA (Occupational Safety and Health Administration) standards are legally mandated by the U.S. government and are enforceable by law. Non-compliance can result in penalties and legal actions. ANSI (American National Standards Institute) standards, on the other hand, are voluntary consensus standards developed by various industry experts and stakeholders. They are not legally mandated, but they provide best practices and guidelines that many organizations choose to adopt.

Key differences include: OSHA standards are legally binding and enforceable, while ANSI standards are not. OSHA standards focus on worker safety and health, covering a wide range of hazards and industries, whereas ANSI standards address a broader range of topics related to various industries, including safety, but also covering aspects like product performance and quality. Many companies incorporate ANSI standards into their safety programs because adopting these standards demonstrates a commitment to safety beyond the minimum legal requirements and often leads to improved worker safety, reduced risk, and improved productivity.

Q 5. Explain the purpose and application of a lockout/tagout procedure.

Lockout/Tagout (LOTO) procedures are critically important for preventing accidental energization of equipment during maintenance or repair, safeguarding workers from serious injury or death. These procedures ensure that potentially hazardous energy sources, such as electrical, mechanical, hydraulic, pneumatic, chemical, or thermal energy, are isolated and rendered incapable of releasing stored energy during maintenance.

The process generally involves several steps:

- Preparation: Identify all energy sources connected to the equipment.

- Notification: Inform all personnel involved in the procedure.

- Lockout: Physically disconnect and secure the energy source using a lockout device.

- Tagout: Attach a tag to the lockout device clearly stating the reason for lockout and the authorized personnel.

- Verification: Verify that the equipment is de-energized and safe for maintenance.

- Maintenance: Perform the necessary maintenance.

- Tagout Removal: The authorized person removes the tag and unlocks the equipment after verifying its safe to do so.

- Energy Restoration: Restore power and check that all systems are functioning correctly.

In my experience, proper LOTO procedures are vital in preventing accidents in high-hazard environments, and non-compliance can lead to severe consequences. A robust LOTO program involves clear procedures, thorough training, regular audits, and rigorous enforcement.

Q 6. Describe your experience conducting safety inspections and audits.

I have extensive experience conducting safety inspections and audits, utilizing a variety of methods to ensure compliance with relevant standards and identify potential hazards. My approach involves a combination of planned inspections (following checklists and standards), random inspections (to catch unexpected issues), and audits (a more in-depth evaluation of the safety management system).

My inspections typically involve a thorough walkthrough of the facility, observing worker practices, checking equipment, and reviewing safety documentation. I use checklists tailored to the specific hazards present in the workplace and cross-reference them with relevant OSHA and ANSI standards. During audits, I would look at management systems like safety training programs, emergency response plans, and hazard communication programs to assess their effectiveness and compliance.

For example, in a manufacturing facility, I would look for things like proper machine guarding, adequate lighting, appropriate personal protective equipment usage, and the presence of emergency exits. Following an inspection or audit, I prepare a detailed report highlighting any identified hazards or violations, along with recommended corrective actions and timelines for implementation. I follow up to ensure these actions are taken and to monitor their effectiveness.

Q 7. How would you develop and implement a safety training program?

Developing and implementing a comprehensive safety training program is a crucial aspect of any effective safety management system. This program should be tailored to the specific hazards and risks of the workplace and should cover all employees, including management.

My approach includes the following steps:

- Needs Assessment: Identify the specific safety hazards and training needs through risk assessments and job hazard analyses. This will determine the content and focus of the training.

- Curriculum Development: Develop a training curriculum that is engaging, informative, and easy to understand. It should incorporate various methods of learning, such as lectures, demonstrations, hands-on practice, and interactive exercises. The training materials should be up-to-date and relevant to the workplace.

- Training Delivery: Deliver training using qualified instructors and appropriate methods. Training should be conducted regularly, especially for new hires and changes in processes or equipment.

- Evaluation: Evaluate the effectiveness of the training program through regular assessments, including pre- and post-training tests, observations, and feedback from employees. The training should be adjusted as needed based on these evaluations.

- Documentation: Maintain comprehensive records of training, including attendance sheets, evaluation results, and any corrective actions taken.

- Reinforcement: Regularly reinforce training through job-site observations, safety meetings, and refresher courses. Make safety a continuous process, not a one-time event.

A successful safety training program goes beyond simply imparting information; it cultivates a safety culture where employees feel empowered to identify and report hazards, and management is committed to providing a safe and healthy work environment.

Q 8. Explain your understanding of the OSHA recordkeeping requirements.

OSHA recordkeeping requirements are crucial for maintaining a safe workplace and demonstrating compliance. Essentially, OSHA requires employers to document workplace injuries and illnesses to track hazards and prevent future incidents. This involves maintaining a detailed log (OSHA Form 300), a summary of injuries and illnesses (OSHA Form 300A), and individual injury and illness reports (OSHA Form 301). The specific requirements depend on the size of the company; smaller companies may have simplified recordkeeping procedures.

For instance, if an employee suffers a laceration while operating a machine, the employer must document the injury on Form 301, including details like the date, time, nature of the injury, and the circumstances surrounding the event. This information is then summarized annually on Form 300A and kept on file for five years. Failure to properly maintain these records can result in significant penalties.

Understanding the nuances of OSHA recordkeeping is essential because it directly affects an organization’s safety culture and liability. It’s not just about filling out forms; it’s about proactively identifying and mitigating workplace hazards.

Q 9. How would you handle an OSHA inspection?

Handling an OSHA inspection requires a proactive and organized approach. First, I would ensure all employees are aware of the inspection and understand the importance of cooperating fully. This includes preparing them to answer questions truthfully and accurately. Second, I would gather all relevant safety documentation, including training records, safety manuals, inspection reports, and incident reports. These should be readily accessible to the compliance officer.

During the inspection, I would accompany the inspector, answer questions truthfully and directly, and point out any corrective actions already taken or planned. It’s vital to remain calm, professional, and respectful throughout the process. If there are areas of non-compliance, I would acknowledge them, explain the steps being taken to rectify the issues, and provide a timeline for completion. Following the inspection, I would carefully review the findings and promptly implement any necessary corrective actions, documenting these steps meticulously.

Think of it like this: An OSHA inspection is an opportunity to showcase your commitment to safety. Proper preparation and a professional demeanor can minimize negative consequences and highlight your company’s proactive safety culture.

Q 10. What are some common OSHA violations you’ve encountered?

Throughout my career, I’ve encountered several recurring OSHA violations. One common issue is inadequate or improperly maintained lockout/tagout procedures for machinery. This often stems from a lack of thorough employee training or inconsistent enforcement of the procedures. Another frequent violation involves improper handling and disposal of hazardous materials, such as failure to provide proper personal protective equipment (PPE) or to follow appropriate spill response protocols.

I’ve also seen numerous instances of inadequate hazard communication, where safety data sheets (SDS) weren’t readily available or employees lacked sufficient training on the hazards associated with the chemicals they handle. Finally, violations related to fall protection, such as insufficient guardrails or lack of fall arrest systems in areas with significant fall hazards, are also common.

These violations highlight the importance of comprehensive training programs, robust safety procedures, and regular inspections to maintain a safe workplace. Each violation underscores the need for a proactive, rather than reactive, approach to safety.

Q 11. Describe your experience with PPE selection and use.

My experience with PPE selection and use encompasses a wide range of industries and hazards. The first step is to conduct a thorough hazard assessment to identify the specific risks employees face. This informs the selection of appropriate PPE, which must meet or exceed OSHA standards. For example, if employees are working with chemicals, selecting the right type of gloves, eye protection, and respiratory protection is crucial. For working at heights, this would involve using appropriate harnesses, lanyards, and safety helmets.

Beyond selection, proper training on the correct use, maintenance, and limitations of PPE is paramount. Employees need to understand when to use specific PPE, how to properly don and doff it, and how to inspect it for damage. Regular inspections and maintenance of PPE are also vital to ensure its effectiveness. For instance, a damaged hard hat offers little protection, and worn-out gloves offer reduced chemical resistance. This aspect of risk management is crucial.

Effective PPE selection and use is more than just providing equipment; it’s about creating a safety-conscious culture where employees understand the importance of protecting themselves and are empowered to report any deficiencies or concerns.

Q 12. How do you ensure compliance with ANSI standards in your work?

Ensuring compliance with ANSI standards requires a multi-faceted approach. First, it begins with understanding the relevant ANSI standards applicable to the specific tasks and equipment used. This often involves referring to ANSI standards documents and staying updated on any revisions or changes. For example, when working with electrical equipment, adhering to relevant ANSI/IEEE standards for electrical safety is crucial.

Next, selecting equipment and tools that meet or exceed the required ANSI standards is essential. This involves carefully reviewing manufacturer specifications and certifications. Finally, implementing a program of regular inspections and maintenance to ensure the continued compliance of equipment is vital. This prevents equipment degradation, which can compromise safety and ANSI compliance. Documentation of all inspections, maintenance, and training is critical for demonstrating compliance and accountability.

Essentially, compliance isn’t just a matter of purchasing compliant equipment; it’s about a culture of safety and continuous vigilance in maintaining equipment and processes that adhere to ANSI standards.

Q 13. Explain your understanding of hazard communication standards (OSHA 29 CFR 1910.1200).

OSHA’s Hazard Communication Standard (HCS), 29 CFR 1910.1200, aims to ensure employees are aware of the hazards associated with the chemicals they handle in the workplace. This is achieved through a comprehensive system of labels, safety data sheets (SDS), and employee training. Employers must ensure that all hazardous chemicals are properly labeled with clear and concise information about the hazards and necessary precautions.

SDSs provide detailed information about the chemical’s properties, hazards, and safe handling procedures. These sheets must be readily available to employees. Furthermore, employers are obligated to provide employees with training on the hazards of chemicals in their work area, the means of protecting themselves, and how to interpret SDSs. Training must be provided at the time of initial assignment and whenever new hazards are introduced.

Effective implementation of OSHA 29 CFR 1910.1200 is vital for preventing chemical-related accidents and illnesses. It’s about empowering employees with the knowledge to handle hazardous materials safely.

Q 14. What are the elements of an effective safety program?

An effective safety program is built upon several key elements. First, it must begin with a strong commitment from top management, ensuring that safety is prioritized at all levels of the organization. This commitment is manifested through resource allocation, establishing clear safety policies, and demonstrating visible support for safety initiatives.

Second, a thorough hazard identification and risk assessment process is necessary. This involves identifying potential hazards in the workplace and assessing the associated risks. This assessment guides the development of appropriate control measures. Third, a comprehensive training program is crucial. Employees must be properly trained on safe work practices, the use of PPE, and emergency procedures. Regular refresher training is essential to maintain knowledge and awareness.

Fourth, an effective communication system keeps employees informed about safety issues and ensures that concerns are addressed promptly. Finally, regular inspections and audits help identify potential hazards and ensure that safety procedures are being followed. This systematic approach to safety demonstrates a commitment to preventing accidents and creating a culture of safety.

In essence, a successful safety program is a holistic system, not just a collection of individual components. It’s an ongoing process of identification, prevention, and improvement, always aiming for continuous safety enhancement.

Q 15. How do you identify and assess workplace hazards?

Identifying and assessing workplace hazards is a systematic process crucial for maintaining a safe work environment. It involves a proactive approach, going beyond simply reacting to accidents. I employ a multi-pronged strategy, combining several key methods.

Walkthrough Inspections: Regularly walking through the workplace, observing work practices, and identifying potential hazards visually. This includes paying close attention to housekeeping, equipment condition, and employee behavior.

Job Hazard Analysis (JHA): This involves a detailed breakdown of each job task, identifying potential hazards associated with each step. This method is particularly useful for high-risk tasks and allows for preventative measures to be implemented before incidents occur. For example, in a construction site, a JHA for operating a crane would identify hazards like load instability, electrical hazards, and fall risks.

Employee Input: Encouraging open communication with workers is paramount. They often have the most direct experience and can identify hazards that management might overlook. Regular safety meetings, suggestion boxes, and anonymous reporting systems help facilitate this.

OSHA and ANSI Standards Review: Regularly reviewing applicable OSHA and ANSI standards ensures that the workplace complies with all relevant regulations and best practices. This ensures we’re not just addressing immediate concerns, but also proactively preventing hazards that might not be immediately apparent.

Near Miss Reporting and Analysis: Analyzing ‘near misses’ – incidents that almost resulted in an accident – helps identify underlying systemic issues and potential hazards before they lead to injuries or damage.

The assessment phase involves prioritizing hazards based on their severity and likelihood of occurrence, using a risk matrix to determine appropriate control measures. This may include engineering controls (e.g., guarding machinery), administrative controls (e.g., establishing safe work procedures), and personal protective equipment (PPE).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with incident investigation and root cause analysis.

Incident investigation and root cause analysis are crucial for learning from past events and preventing future occurrences. My approach follows a structured methodology, often employing techniques like the ‘5 Whys’ and fault tree analysis.

Step-by-step process:

Secure the scene: The immediate priority is to ensure the safety of personnel and preserve evidence.

Gather information: This includes interviewing witnesses, reviewing documentation (e.g., incident reports, maintenance logs), taking photographs, and creating sketches.

Identify contributing factors: This phase moves beyond immediate causes to understand the underlying reasons that led to the incident. The ‘5 Whys’ technique helps to drill down to the root causes by repeatedly asking ‘why’ until the fundamental issue is identified.

Develop corrective actions: Based on the root cause analysis, specific corrective actions are developed to eliminate the hazard and prevent recurrence. These actions are often documented in a formal report.

Implement and monitor corrective actions: Following implementation, the effectiveness of these actions is monitored to ensure they are successful in preventing similar incidents.

For instance, in an investigation of a fall from height, initial analysis might identify a lack of fall protection as the immediate cause. However, further investigation using the ‘5 Whys’ might reveal underlying causes such as inadequate training, lack of management oversight, or insufficient resources for safety equipment.

Q 17. How do you ensure the effectiveness of your safety training programs?

Effective safety training programs are crucial for creating a safety-conscious culture. I ensure effectiveness through several key strategies:

Needs Assessment: Identifying specific training needs based on job roles, hazards, and regulatory requirements is essential. This allows the training to be targeted and relevant.

Interactive Training Methods: Using a variety of methods, such as interactive simulations, hands-on training, and group discussions, to cater to different learning styles.

Practical Application: Focusing on practical application of safety procedures through scenario-based training and real-world examples. This reinforces learning and prepares employees for real-life situations.

Regular Refreshers: Providing refresher training regularly, especially for high-risk activities, ensures knowledge remains current and relevant.

Assessment and Feedback: Regular assessments, such as written tests, practical demonstrations, and observations, are used to measure employee understanding and identify areas for improvement.

Documentation: Maintaining detailed records of training provided, attendance, and assessment results, to demonstrate compliance and track employee progress.

For example, for forklift operators, training would include classroom instruction on safe operating procedures, followed by hands-on training in a controlled environment, and regular skill assessments to ensure proficiency.

Q 18. Describe your experience with developing and implementing emergency response plans.

Developing and implementing emergency response plans requires a thorough understanding of potential hazards and a structured approach. My experience includes:

Hazard Identification: Identifying all potential emergencies, such as fires, chemical spills, natural disasters, and medical emergencies.

Plan Development: Creating detailed plans outlining procedures for each type of emergency, including evacuation routes, assembly points, communication protocols, and roles and responsibilities for personnel.

Training and Drills: Conducting regular training and drills to familiarize employees with emergency procedures and ensure their effectiveness. These drills should be realistic and incorporate feedback mechanisms.

Communication Systems: Establishing reliable communication systems to facilitate efficient response during emergencies. This might involve alarm systems, two-way radios, or emergency notification systems.

Regular Review and Updates: Regularly reviewing and updating the plans to reflect changes in the workplace, regulatory requirements, or lessons learned from previous incidents.

A comprehensive plan would include specific procedures for each emergency, designated roles for personnel (e.g., emergency response team, first aid responders), and clear communication channels to ensure efficient coordination during an emergency.

Q 19. What is your understanding of ergonomics and its application in the workplace?

Ergonomics is the science of designing workplaces, tasks, and tools to fit the physical capabilities and limitations of people. It focuses on reducing risks of musculoskeletal disorders (MSDs) by optimizing the work environment. My understanding involves applying ergonomic principles to prevent injuries and improve productivity.

Application in the workplace:

Job Design: Analyzing job tasks to identify movements and postures that place strain on the body. This could involve adjusting work heights, providing proper seating, or redesigning tools to reduce awkward postures and repetitive movements.

Workplace Layout: Optimizing the layout of the workplace to minimize unnecessary movements and walking distances. This might involve reorganizing workstations or installing material handling equipment.

Equipment Selection: Choosing tools and equipment that are ergonomically designed, considering factors like weight, grip size, and control placement.

Personal Protective Equipment (PPE): Providing appropriate PPE, such as back supports or gloves, to protect employees from ergonomic hazards.

Training and Education: Educating employees on proper lifting techniques, workstation setup, and body mechanics to prevent injuries. This training is critical to ensure workers can implement the ergonomic adjustments properly.

For instance, in an office setting, ergonomic principles might involve providing adjustable chairs, monitor stands, and keyboard trays, and educating employees about proper posture and workstation setup.

Q 20. How would you address employee resistance to safety procedures?

Addressing employee resistance to safety procedures requires a proactive and empathetic approach. It’s crucial to understand the reasons behind the resistance, which can stem from various factors, including lack of understanding, inconvenience, or perceived unnecessary restrictions.

Strategies for addressing resistance:

Communication and Education: Clearly communicating the importance of safety procedures and the potential consequences of non-compliance. This should include clear explanations of the benefits of following procedures, including injury prevention and improved productivity.

Involve Employees: Involving employees in the development and implementation of safety procedures fosters a sense of ownership and increases buy-in. This can involve seeking feedback on existing procedures or having employees participate in safety committees.

Positive Reinforcement: Recognizing and rewarding employees for their commitment to safety. This might involve safety awards, incentives, or public acknowledgment.

Address Concerns: Actively listening to employees’ concerns and addressing them in a constructive manner. If procedures are truly cumbersome or impractical, consider revising them to be more effective and less burdensome.

Lead by Example: Management and supervisors must set a positive example by consistently following safety procedures themselves. This demonstrates commitment and helps to build trust among employees.

For example, if employees resist wearing safety glasses, addressing their concerns about comfort or vision impairment and offering various styles of glasses could increase compliance.

Q 21. Describe your experience with conducting job hazard analyses.

Conducting Job Hazard Analyses (JHAs) is a crucial step in proactively identifying and controlling workplace hazards. It’s a systematic process of breaking down a job into its individual steps and identifying potential hazards at each stage.

My approach involves:

Selecting the Job: Identifying the specific job or task to be analyzed, prioritizing high-risk jobs or those with a history of incidents.

Breaking Down the Job: Dividing the job into smaller, sequential steps. Each step should be clearly defined and easily understood.

Identifying Hazards: For each step, identify potential hazards, including physical, chemical, biological, and ergonomic hazards. Consider various scenarios and potential errors.

Evaluating Risks: Assessing the risk associated with each hazard by considering its severity and likelihood of occurrence. This helps prioritize control measures.

Recommending Control Measures: Developing control measures to eliminate or mitigate the identified hazards. This might include engineering controls, administrative controls, or PPE.

Documenting the JHA: Creating a written document outlining the job steps, identified hazards, risk assessments, and control measures. This document should be reviewed and updated regularly.

For example, a JHA for a cleaning job might identify hazards such as exposure to cleaning chemicals, slips and falls, and repetitive motions. Control measures could include providing appropriate PPE (gloves, eye protection), implementing safe cleaning procedures, and providing ergonomic tools to reduce strain.

Q 22. What is your understanding of OSHA’s regulations on confined spaces?

OSHA’s confined space regulations are designed to protect workers from the hazards associated with entering and working in confined spaces. These spaces are defined as areas that have limited openings for entry and exit, are not designed for continuous occupancy, and may contain hazardous atmospheres or other dangers. The regulations outline a comprehensive permit-required confined space program, which includes:

- Identification and Evaluation: Thoroughly identifying all confined spaces in the workplace and assessing potential hazards like oxygen deficiency, flammable gases, toxic substances, and engulfment.

- Permit System: Establishing a formal permit system authorizing entry only after hazards have been controlled. Permits detail the hazards, control measures, and emergency procedures.

- Atmospheric Monitoring: Regular monitoring of the atmosphere within the confined space before, during, and after entry to ensure it’s safe for workers. This often involves using gas detection instruments.

- Ventilation: Implementing adequate ventilation to remove or dilute hazardous atmospheres.

- Entry Procedures: Establishing safe entry and exit procedures, including the use of harnesses, lifelines, and attendants.

- Emergency Procedures: Developing and practicing emergency rescue plans in case of accidents or emergencies.

- Training: Providing comprehensive training to all workers involved in confined space entry, including authorized entrants, attendants, and supervisors.

For example, in a grain silo, before entry, atmospheric testing is crucial to detect oxygen deficiency and the presence of flammable gases. A permit would be required, and a rescue plan including a harness and retrieval system would be essential. Failure to follow these regulations can lead to serious injury or death.

Q 23. Explain your experience with fall protection systems and their compliance standards.

My experience with fall protection encompasses various systems and their respective compliance standards, including those defined by OSHA and ANSI. I’ve worked with systems such as guardrails, safety nets, personal fall arrest systems (PFAS), and fall restraint systems. Understanding the differences is key. PFAS stop a fall, while fall restraint systems prevent a fall from happening in the first place.

Compliance demands careful consideration of several factors:

- Anchor Point Selection: Anchor points must be structurally sound and capable of supporting at least 5,000 lbs per worker. Improper anchor points are a leading cause of fall protection system failures.

- Equipment Inspection: Regular inspections are vital to identify and address any damage or wear to harnesses, lanyards, and other components. We use documented checklists and regular training to reinforce this.

- Training: All workers required to use fall protection equipment must receive thorough training on proper usage, inspection, and limitations. This ensures a proper understanding of the equipment and its safe application.

- Proper Selection: Choosing the appropriate system for the specific task and work environment is critical. A system that works well on a flat roof might be unsuitable for working around equipment or in confined spaces.

For instance, working at heights on a construction site requires a carefully selected and regularly inspected PFAS, with a strong anchor point, and regular training for workers to ensure that they are not only using the proper equipment, but are also trained to anticipate hazards and how to react.

Q 24. How do you measure the effectiveness of a safety program?

Measuring the effectiveness of a safety program involves a multi-faceted approach that goes beyond simply looking at accident rates. Key indicators include:

- Incident Rates: Tracking the number and severity of accidents, injuries, and near misses. A reduction in these rates signifies improved safety.

- Training Completion Rates: Monitoring the participation and successful completion of safety training programs. Higher completion rates indicate better engagement and knowledge.

- Observation Data: Conducting regular safety observations to identify unsafe behaviors and conditions. This proactive approach can prevent accidents before they occur.

- Employee Feedback: Gathering feedback from employees through surveys or meetings to understand their perceptions of safety and identify areas for improvement. Employees are often the first line of defense.

- Compliance Audits: Performing regular audits to ensure adherence to safety regulations and company policies. This ensures consistency and identifies any gaps in the safety program.

- Safety Culture Survey: Gauge the overall commitment to safety from employees, management and contractors. A strong safety culture is often a key differentiator between successful and unsuccessful safety programs.

By combining quantitative data (like incident rates) with qualitative data (like employee feedback), a comprehensive picture of safety program effectiveness emerges. For example, a decrease in near misses coupled with positive employee feedback on safety training suggests a program that is creating a proactive safety culture.

Q 25. Explain your understanding of OSHA’s requirements for respiratory protection.

OSHA’s respiratory protection standards (29 CFR 1910.134) aim to protect workers from inhaling hazardous airborne substances. The key aspects include:

- Hazard Assessment: Determining if respiratory hazards exist in the workplace and identifying the specific types of hazards. This includes identifying the type and concentration of harmful substances in the air.

- Respiratory Protection Program: Developing a comprehensive written program that outlines procedures for selecting, fitting, using, and maintaining respiratory protection equipment.

- Medical Evaluation: Requiring medical evaluations for workers to ensure they are physically capable of using respiratory protection.

- Selector Guidelines: Using OSHA’s guidance to select appropriate respirators based on the identified hazards. This involves selecting the proper respirator type (e.g., air-purifying respirator or supplied-air respirator) and protection factor.

- Fit Testing: Conducting proper fit testing to ensure that the chosen respirator provides an adequate seal. This step is crucial and must be conducted with every new respirator and periodically as required.

- Training and Use: Providing thorough training to workers on the proper use, maintenance, and limitations of respiratory protection equipment.

For example, workers in a paint-spraying booth would require appropriate respirators selected based on the specific chemicals used, with fit-testing and regular training to ensure compliance with OSHA’s stringent regulations. Inadequate respiratory protection can have severe consequences, leading to lung damage, and other respiratory illnesses.

Q 26. How would you handle a workplace accident or injury?

Handling a workplace accident or injury requires a systematic and prompt response. My approach follows these steps:

- Emergency Response: Prioritize immediate first aid and call for emergency medical services (EMS) as needed. This is the most crucial step.

- Secure the Scene: Isolate the area to prevent further injuries and preserve evidence. This ensures the safety of others involved and preserves any necessary evidence.

- Incident Investigation: Conduct a thorough investigation to determine the root cause of the accident. This involves interviews with witnesses, reviewing safety records, and analyzing the accident scene. This step is often overlooked, but crucial for preventing future incidents.

- Reporting: Report the accident to OSHA (as required) and company management according to established procedures. Accurate reporting and documentation are critical.

- Corrective Actions: Implement corrective actions to prevent similar accidents from happening in the future. These actions might include modifying procedures, improving equipment, or providing additional training.

- Follow-up: Follow up with the injured worker and provide support for their recovery. This shows a genuine concern for the employee’s well-being.

For example, if a worker falls from a scaffold, I would immediately call for emergency services, secure the scene, interview witnesses, review the scaffold’s inspection records, and report the incident to OSHA. Corrective actions might involve improving scaffold safety procedures or providing additional training.

Q 27. Describe your experience with implementing and monitoring safety performance indicators.

Implementing and monitoring safety performance indicators (KPIs) is a crucial part of any effective safety program. My experience involves selecting relevant KPIs, establishing baselines, tracking progress, and using data to drive improvements.

Here’s how I approach this:

- KPI Selection: Selecting KPIs aligned with the organization’s safety goals. This might include incident rates, near miss reports, training completion rates, and safety observation scores. These should be measurable and relevant.

- Data Collection: Establishing systems for collecting and recording safety data accurately and consistently. This is crucial for accurate reporting and analysis.

- Data Analysis: Analyzing the collected data to identify trends, patterns, and areas for improvement. This analysis allows for effective prioritization of efforts and resources.

- Reporting and Communication: Regularly reporting KPIs to management and employees to keep everyone informed of progress and any issues. Open communication is essential for achieving buy-in from everyone involved.

- Action Planning: Developing and implementing action plans based on the data analysis to address identified issues and improve safety performance. Effective action planning ensures that the insights gained from the data are translated into effective changes.

For example, if the data shows a rise in near misses related to a specific piece of equipment, I would analyze the root cause, potentially implement additional safety measures, and then re-evaluate the KPI in a defined period to determine the effectiveness of the improvement plan.

Q 28. How familiar are you with the latest updates and changes to OSHA and ANSI standards?

I maintain awareness of the latest updates and changes to OSHA and ANSI standards through several methods:

- Regularly reviewing OSHA’s website: OSHA’s website is the primary source for the latest standards, interpretations, and enforcement guidelines. This ensures up to date knowledge.

- Professional Development: Participating in industry conferences, webinars, and training courses to stay informed about new developments and best practices. This keeps my knowledge relevant and current.

- Industry Publications: Reading industry publications and journals that cover occupational safety and health. This is an important supplement to formal training.

- Networking: Networking with other safety professionals to share knowledge and learn about new trends and challenges. Staying connected with the broader community aids knowledge sharing.

Staying current on these changes is essential to ensure that our safety programs and practices remain compliant and effective. This proactive approach helps avoid potential penalties and, more importantly, helps protect worker safety and well-being.

Key Topics to Learn for Understanding of OSHA and ANSI Standards Interview

- OSHA Regulations: Understanding the fundamental principles of OSHA, including its mission, structure, and key acts. Focus on how these regulations impact workplace safety and your role in ensuring compliance.

- ANSI Standards: Familiarize yourself with the role of ANSI in developing voluntary consensus standards. Learn how these standards relate to OSHA regulations and best practices in various industries.

- Hazard Identification and Risk Assessment: Master the process of identifying potential hazards in a workplace setting, conducting thorough risk assessments, and implementing effective control measures.

- Personal Protective Equipment (PPE): Learn about different types of PPE, their proper selection, use, and limitations. Understand the regulations surrounding PPE usage and training.

- Emergency Response and Preparedness: Familiarize yourself with emergency procedures, including evacuation plans, first aid, and reporting procedures. Be prepared to discuss your role in emergency response and prevention.

- Recordkeeping and Reporting: Understand the importance of accurate recordkeeping and reporting requirements under OSHA. Know how to maintain logs and reports and comply with reporting deadlines.

- Inspections and Audits: Prepare for potential interview questions about conducting safety inspections and audits, identifying non-compliances, and implementing corrective actions.

- Specific Industry Standards: Research the OSHA and ANSI standards relevant to your target industry. This demonstrates specialized knowledge and dedication.

- Practical Application: Consider real-world scenarios and how you would apply your knowledge of OSHA and ANSI standards to solve workplace safety problems. Prepare examples from your experience.

Next Steps

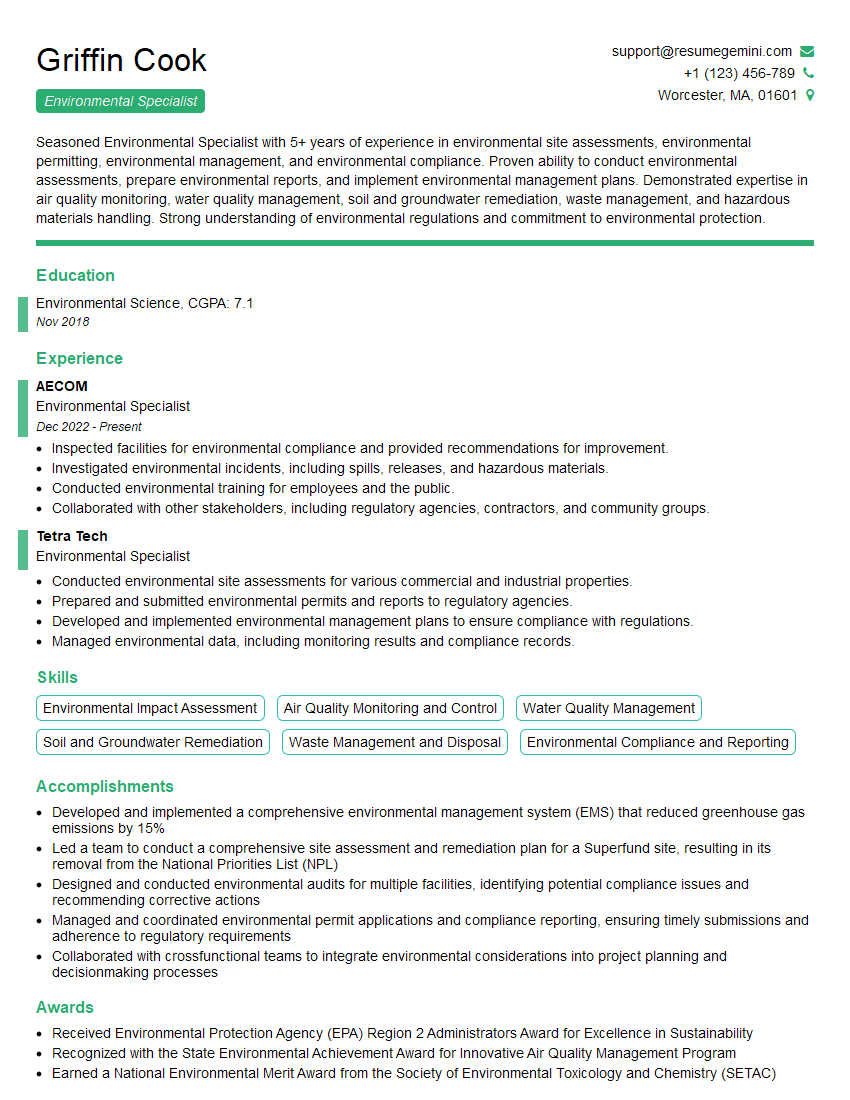

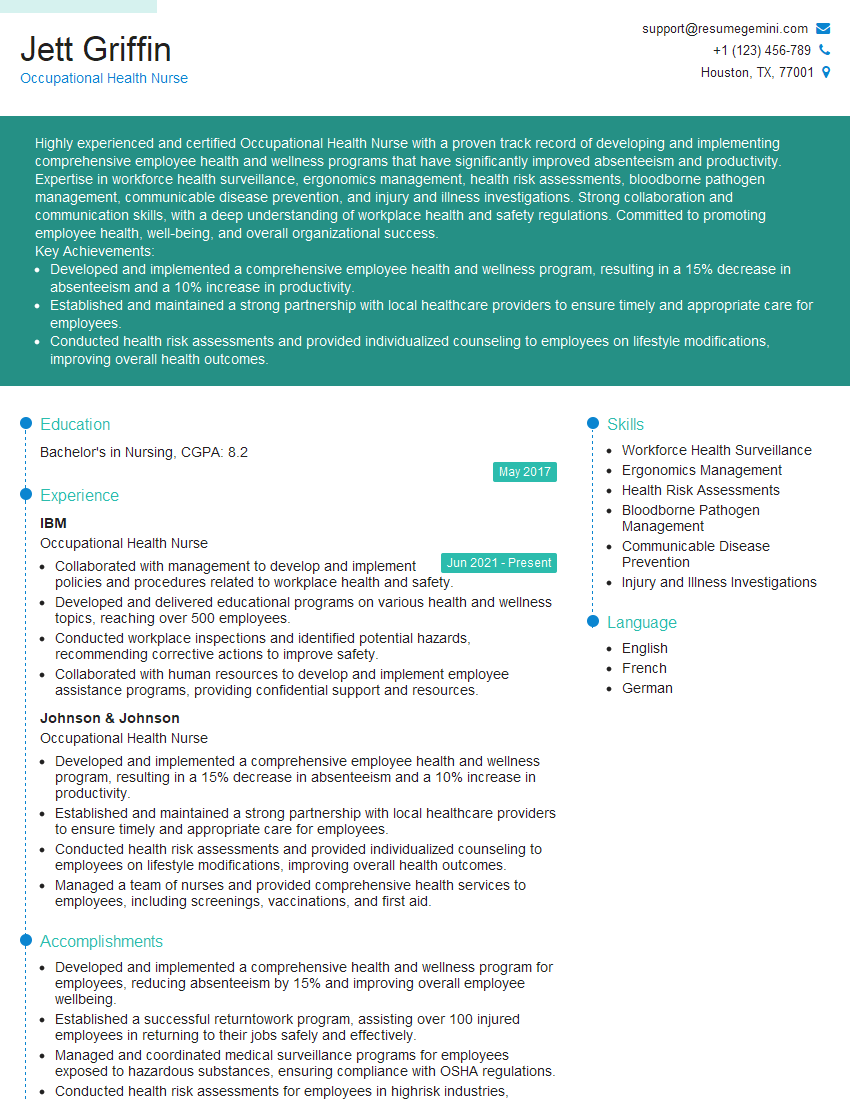

Mastering OSHA and ANSI standards is crucial for career advancement in many safety-sensitive industries. It demonstrates a commitment to workplace safety and a deep understanding of legal requirements. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that catch the attention of recruiters. We provide examples of resumes tailored to professionals with expertise in Understanding of OSHA and ANSI Standards to help you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.