Unlock your full potential by mastering the most common Wastewater Regulations interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Wastewater Regulations Interview

Q 1. Explain the Clean Water Act and its relevance to wastewater treatment.

The Clean Water Act (CWA) of 1972 is the cornerstone of U.S. water pollution control. Its primary goal is to restore and maintain the chemical, physical, and biological integrity of the nation’s waters. For wastewater treatment, the CWA is incredibly relevant because it sets national goals for water quality and establishes a regulatory framework for discharging treated wastewater into waterways. This involves setting limits on the types and amounts of pollutants that can be discharged, requiring permits for discharges, and empowering the Environmental Protection Agency (EPA) and state agencies to enforce these regulations. Think of it as the rulebook for ensuring our rivers and lakes aren’t poisoned by wastewater.

The CWA mandates that wastewater treatment plants (WWTPs) obtain National Pollutant Discharge Elimination System (NPDES) permits. These permits specify the allowable limits for various pollutants in the treated effluent. Failure to comply can result in significant penalties, including fines and even plant shutdowns. Essentially, the CWA makes sure wastewater treatment plants operate responsibly and protect water quality.

Q 2. Describe the different types of wastewater treatment processes.

Wastewater treatment processes can be broadly categorized into several stages, often working in sequence to achieve progressively higher levels of treatment. These include:

- Preliminary Treatment: This initial step removes large debris like grit, rags, and plastics through screening and grit removal. Think of it as a pre-wash for your wastewater.

- Primary Treatment: This involves settling out heavier solids through sedimentation tanks. Imagine allowing sand to settle at the bottom of a glass of water – this removes a significant portion of the suspended solids.

- Secondary Treatment: This is where biological processes come into play, using microorganisms to break down organic matter. Common methods include activated sludge, trickling filters, and rotating biological contactors. These processes essentially use bacteria to ‘eat’ the pollutants.

- Tertiary Treatment: This advanced treatment stage further purifies the wastewater, removing remaining nutrients (nitrogen and phosphorus), pathogens, and other pollutants. Techniques might include filtration, disinfection (using chlorine, UV light, or ozone), and advanced oxidation processes. This stage is like giving the wastewater a final polish.

The specific treatment processes employed depend on factors such as the type of wastewater, the receiving water body’s quality standards, and regulatory requirements. Some plants may only perform primary and secondary treatment while others may incorporate advanced tertiary treatment.

Q 3. What are the key parameters monitored in wastewater effluent?

Effluent, the treated wastewater discharged from a WWTP, is rigorously monitored for a range of parameters to ensure compliance with permit limits and protect receiving water quality. Key parameters include:

- Biochemical Oxygen Demand (BOD): Measures the amount of oxygen consumed by microorganisms while decomposing organic matter. High BOD indicates a high concentration of organic pollutants.

- Chemical Oxygen Demand (COD): A broader measure of organic pollutants than BOD, including those not readily biodegradable.

- Suspended Solids (SS): Measures the amount of solid material suspended in the wastewater.

- Total Suspended Solids (TSS): Includes both settleable and non-settleable solids.

- Nutrients (Nitrogen and Phosphorus): Excessive nutrients can lead to eutrophication, causing algal blooms that deplete oxygen and harm aquatic life.

- pH: Measures the acidity or alkalinity of the effluent.

- Temperature: Excessive temperature can harm aquatic organisms.

- Pathogens (Bacteria, Viruses): Indicates the presence of disease-causing microorganisms.

Monitoring these parameters provides crucial information about treatment effectiveness and environmental impact, ensuring that the discharged wastewater meets regulatory requirements.

Q 4. How do you ensure compliance with discharge permits?

Ensuring compliance with discharge permits is a continuous process requiring diligent monitoring, record-keeping, and reporting. It involves:

- Regular Monitoring: Conducting frequent laboratory analyses of the effluent to measure key parameters.

- Accurate Record-Keeping: Maintaining detailed records of all monitoring data, treatment processes, and any operational issues.

- Reporting: Submitting regular reports to the regulatory agency, often on a monthly or quarterly basis, detailing the monitoring results and any deviations from permit limits.

- Process Optimization: Continuously evaluating and optimizing treatment processes to improve effluent quality and ensure compliance.

- Preventative Maintenance: Regular maintenance of treatment equipment to prevent malfunctions and ensure optimal operation.

- Emergency Response Plan: Having a plan in place to address any unexpected events that could affect effluent quality.

Failure to comply can lead to significant penalties, so proactive and meticulous attention to these steps is crucial. Think of it as constantly navigating a ship to stay within the designated channel; consistent monitoring and corrections are vital to avoid running aground.

Q 5. Explain the importance of sludge management in wastewater treatment.

Sludge management is a critical aspect of wastewater treatment, referring to the handling, processing, and disposal or beneficial reuse of the solids separated from the wastewater during various treatment stages. Sludge contains a significant amount of organic matter, nutrients, and potentially hazardous materials. Improper sludge management can lead to environmental contamination and public health risks. Effective sludge management involves:

- Thickening: Reducing the water content in the sludge to make it easier to handle and transport.

- Stabilization: Reducing the amount of putrescible organic matter through aerobic or anaerobic digestion. This reduces odors and pathogens.

- De-watering: Further reducing the water content to minimize disposal volume and costs.

- Disposal or Beneficial Reuse: Disposing of sludge in a safe and environmentally sound manner, such as in landfills designed for this purpose, or utilizing it beneficially as a soil amendment or in bioenergy production.

Proper sludge management is essential for environmental protection and public health, minimizing negative impacts associated with wastewater solids. It’s a crucial last step in the wastewater treatment process, often requiring specialized facilities and expertise.

Q 6. What are the common pollutants found in wastewater?

Wastewater contains a complex mixture of pollutants, varying depending on the source. Common pollutants include:

- Organic Matter: From food waste, human waste, and industrial discharges. This contributes to BOD and COD.

- Nutrients (Nitrogen and Phosphorus): From fertilizers, detergents, and human waste, leading to eutrophication.

- Suspended Solids: Sand, silt, clay, and other particulate matter.

- Pathogens: Bacteria, viruses, and parasites from human and animal waste.

- Heavy Metals: From industrial discharges and runoff.

- Pharmaceuticals and Personal Care Products (PPCPs): From household use, often resistant to conventional treatment processes.

- Oil and Grease: From various sources, including industrial discharges and restaurants.

- Toxic Organic Chemicals: From industrial discharges and spills.

Understanding the specific pollutant profile of a particular wastewater stream is essential for designing and operating an effective treatment system.

Q 7. Describe the role of biological processes in wastewater treatment.

Biological processes are the heart of secondary wastewater treatment, utilizing microorganisms to break down organic matter. These processes rely on the natural ability of bacteria and other microorganisms to consume and metabolize organic pollutants. In activated sludge, for example, a mixed culture of microorganisms is maintained in an aeration tank. Air is bubbled through the tank to provide the oxygen needed by the microorganisms for the aerobic digestion of organic matter. The microorganisms form flocs, which settle out in a clarifier, producing a clarified effluent and a concentrated sludge that is then treated further. Think of it as a microscopic army of cleaners, eating away at the pollutants.

Trickling filters use a bed of media over which wastewater is sprayed, providing a surface for biofilm growth. The biofilm, containing a diverse community of microorganisms, breaks down the organic matter. Other biological processes, like rotating biological contactors, offer slightly different approaches but all share the core principle of using microorganisms to accomplish efficient and cost-effective removal of organic pollutants.

Q 8. What are the different types of wastewater collection systems?

Wastewater collection systems are the crucial infrastructure responsible for gathering wastewater from various sources and transporting it to treatment plants. They can be broadly categorized into two main types:

- Sanitary Sewer Systems: These systems collect wastewater from homes, businesses, and institutions. Think of them as the veins of a city, carrying wastewater from sinks, toilets, showers, and other fixtures. They’re typically gravity-fed, meaning wastewater flows downhill to the treatment plant. However, in areas with flat topography, pumping stations are required to lift the wastewater to higher elevations. These systems often employ a network of pipes of varying diameters, manholes for access and inspection, and pumping stations to maintain flow.

- Storm Sewer Systems: These systems handle rainwater runoff and surface water. They are designed to quickly convey stormwater away from developed areas to prevent flooding. Ideally, they are completely separate from sanitary sewer systems to prevent contamination. However, combined sewer systems (CSS) exist in older cities, where stormwater and wastewater flow through the same pipes. This can lead to overflows during heavy rainfall events, posing significant environmental risks.

Understanding the differences between these systems is vital for effective wastewater management and preventing pollution. For example, proper separation of sanitary and storm sewers helps protect water quality by preventing untreated stormwater from entering treatment plants, thus lowering treatment costs and environmental impact.

Q 9. How do you address spills or leaks in a wastewater collection system?

Addressing spills or leaks in a wastewater collection system requires a swift and coordinated response. The process typically involves these steps:

- Immediate Action: First, isolate the area to prevent further spread. This could involve closing valves or diverting flow if possible. Safety is paramount; personnel should wear appropriate protective equipment like gloves, boots, and respirators.

- Assessment and Containment: Determine the source and extent of the spill or leak. This might require using specialized equipment like CCTV cameras to inspect pipes, or employing dye tracing techniques to identify the location of leaks. Containment measures might include deploying booms or absorbent materials to control the spread of the spill.

- Cleanup and Remediation: This involves removing spilled wastewater and contaminated materials, disinfecting the affected area, and repairing the damaged infrastructure. The specific methods used will depend on the nature of the spill and local regulations. For example, a spill of sewage requires different remediation strategies than a leak of rainwater.

- Reporting and Documentation: All incidents must be documented thoroughly, including the location, cause, volume of spillage, and remediation steps taken. This information is critical for future planning, improving system maintenance, and complying with regulatory requirements.

- Investigation and Prevention: Following the cleanup, a thorough investigation is conducted to identify the root cause of the spill or leak. This may involve reviewing maintenance records, assessing pipe condition, or upgrading infrastructure to prevent similar incidents in the future. Regular maintenance and inspections are key to preventing leaks and spills.

Q 10. Explain the concept of Total Maximum Daily Loads (TMDLs).

Total Maximum Daily Loads (TMDLs) are a cornerstone of the Clean Water Act in the United States. They represent the maximum amount of a pollutant that a water body can receive daily and still meet water quality standards. Think of it as a pollution budget for a specific water body. Each TMDL calculation considers the water body’s capacity to assimilate pollutants and the sources of pollution contributing to its impairment.

The process of establishing a TMDL typically includes:

- Identifying Impaired Water Bodies: This involves monitoring water quality to determine if it violates state water quality standards.

- Determining Pollutant Sources: Identifying the major sources of pollution contributing to the impairment, whether it’s from point sources (like industrial discharges) or non-point sources (like agricultural runoff).

- Calculating the Waste Load Allocation (WLA): Determining the amount of pollutant each source can discharge without exceeding the TMDL.

- Calculating the Total Maximum Daily Load (TMDL): This is the sum of all WLAs, plus a margin of safety to account for uncertainties and future changes.

- Implementing and Monitoring: The development of TMDLs does not end with calculations. It also requires setting up monitoring programs to ensure compliance and effectiveness.

TMDLs provide a framework for reducing pollution in impaired water bodies, setting clear limits on pollutant discharge and guiding pollution control measures. They are a powerful tool for protecting and restoring water quality.

Q 11. What are the challenges associated with treating industrial wastewater?

Treating industrial wastewater presents unique challenges compared to domestic wastewater due to the wide variability in the types and concentrations of pollutants. Some key challenges include:

- High Pollutant Concentrations: Industrial wastewater can contain high concentrations of heavy metals, toxic organic compounds, and other pollutants that require specialized treatment methods.

- Variability in Wastewater Composition: The composition of industrial wastewater can fluctuate significantly depending on production processes. This makes it challenging to design a treatment system that consistently achieves the required effluent quality.

- Toxicity: Many industrial pollutants are toxic to microorganisms used in biological treatment processes, hindering the effectiveness of conventional treatment methods.

- High Treatment Costs: Treating industrial wastewater often requires more complex and expensive treatment technologies compared to domestic wastewater, adding to the overall cost.

- Regulatory Compliance: Strict regulations govern the discharge of industrial wastewater, requiring careful monitoring and adherence to specific effluent limits. This necessitates precise control and operation of treatment systems.

For example, a textile factory’s wastewater might contain high levels of dyes and heavy metals, demanding advanced treatment steps like adsorption or chemical precipitation, unlike the typical treatment of domestic wastewater.

Q 12. Describe different methods for removing nitrogen and phosphorus from wastewater.

Nitrogen and phosphorus are key nutrients that contribute to eutrophication, the excessive growth of algae and aquatic plants in water bodies, leading to oxygen depletion and harming aquatic life. Several methods are used to remove these nutrients from wastewater:

- Biological Nutrient Removal (BNR): This is a widely used method that utilizes microorganisms to remove nitrogen and phosphorus. It typically involves anoxic (low-oxygen) and anaerobic (no-oxygen) treatment processes to convert nitrogen into gaseous forms (nitrification and denitrification) and to encourage the uptake of phosphorus by microorganisms. The resulting biomass containing phosphorus is then removed via settling or filtration.

- Chemical Precipitation: This involves adding chemicals like ferric chloride or alum to the wastewater to form insoluble precipitates with phosphorus, which then settle out. This is particularly effective for removing phosphorus.

- Membrane Filtration: Membrane filtration processes, like ultrafiltration or microfiltration, can remove both nitrogen and phosphorus by physically separating them from the wastewater.

- Enhanced Biological Phosphorus Removal (EBPR): This is a specialized BNR process that uses specific types of microorganisms to enhance phosphorus removal efficiency.

- Struvite Crystallization: This process involves creating a crystalline precipitate of struvite (magnesium ammonium phosphate), which can be recovered as a fertilizer, thereby removing phosphorus and creating a valuable byproduct.

The choice of method depends on factors like wastewater characteristics, cost considerations, and required effluent quality. Often, a combination of methods is employed to achieve optimal nutrient removal.

Q 13. How do you perform a proper wastewater sample collection and analysis?

Proper wastewater sample collection and analysis are essential for monitoring water quality and ensuring compliance with regulations. The process involves several key steps:

- Sampling Location and Frequency: The location and frequency of sampling are crucial. Samples should be collected at representative points within the wastewater system (e.g., influent, effluent, various stages of treatment). The frequency depends on regulations and the specific needs of the monitoring program (daily, weekly, monthly etc.).

- Sampling Equipment and Procedures: Sterile containers are used for sample collection to avoid contamination. Samples should be collected using appropriate techniques, ensuring proper mixing and avoiding errors. The exact methods may differ depending on the parameters being analyzed.

- Sample Preservation and Handling: Samples must be preserved appropriately to prevent changes in the composition of the sample before analysis. This often involves refrigerating the samples or adding preservatives.

- Laboratory Analysis: Samples are sent to a certified laboratory for analysis. The parameters analyzed depend on the purpose of the monitoring, but typically include things like pH, BOD (Biological Oxygen Demand), COD (Chemical Oxygen Demand), nitrogen, phosphorus, heavy metals, and pathogens.

- Quality Control and Assurance: Quality control measures are essential to ensure the accuracy and reliability of the results. This involves using certified reference materials, performing blank analyses, and employing duplicate sampling.

Accurate and reliable wastewater analysis provides critical data for operational adjustments, regulatory compliance, and overall management of the wastewater system. Inaccurate data can lead to poor decision-making, treatment inefficiencies, and potentially environmental damage.

Q 14. What are the safety precautions associated with working in a wastewater treatment plant?

Working in a wastewater treatment plant presents several safety hazards, necessitating stringent safety precautions. Key hazards include:

- Exposure to Pathogens: Wastewater contains numerous pathogens that can cause diseases. Proper personal protective equipment (PPE), including gloves, boots, respirators, and eye protection, is crucial to minimize exposure risks.

- Exposure to Hazardous Chemicals: Many chemicals are used in wastewater treatment, some of which are corrosive, toxic, or flammable. Safe handling procedures, proper storage, and adequate ventilation are necessary.

- Confined Spaces: Wastewater treatment plants often have confined spaces (e.g., manholes, tanks) that pose risks of oxygen deficiency, hazardous atmospheres, and entrapment. Entry permits, gas monitoring, and rescue procedures are essential.

- Heavy Machinery and Equipment: Wastewater plants employ various heavy machinery and equipment. Lockout/tagout procedures to prevent accidental starts, appropriate training, and adherence to safety protocols are crucial.

- Slips, Trips, and Falls: Wet and slippery surfaces, uneven terrain, and elevated areas pose a high risk of slips, trips, and falls. Good housekeeping, appropriate footwear, and safety railings are essential.

- Electrical Hazards: Electrical equipment and wiring pose risks of electrocution and shock. Regular inspections and adherence to electrical safety regulations are crucial.

Regular safety training, emergency preparedness plans, and a strong safety culture are critical for maintaining a safe working environment in a wastewater treatment plant. It’s crucial to always follow established safety procedures and report any unsafe conditions immediately.

Q 15. What is the significance of the National Pollutant Discharge Elimination System (NPDES) permit?

The National Pollutant Discharge Elimination System (NPDES) permit is the cornerstone of the Clean Water Act’s regulatory framework. It’s essentially a legal document that allows facilities discharging pollutants into navigable waters to do so, but only under specific conditions. Think of it as a license to pollute, but with very strict rules attached. Without a permit, any discharge is illegal, regardless of the volume or the pollutant type. The significance lies in its power to protect water quality by setting limits on the types and amounts of pollutants released. This ensures that industrial and municipal wastewater treatment plants don’t overload waterways, harming aquatic life and potentially impacting human health.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of obtaining a wastewater discharge permit.

Obtaining a wastewater discharge permit is a multi-step process that can be quite involved. It typically begins with a thorough assessment of your facility’s wastewater streams to determine the types and quantities of pollutants generated. Next, you’ll need to submit a comprehensive permit application to the relevant regulatory agency (usually the Environmental Protection Agency (EPA) or a state equivalent). This application includes detailed information about your facility, wastewater treatment process, effluent characteristics, and proposed monitoring plan. The agency then reviews your application and may require additional information or site visits. If approved, you’ll receive a permit outlining the specific limits on pollutants you can discharge, monitoring requirements, and reporting deadlines. Failing to comply with these limits can result in significant penalties.

Imagine building a house – you need to submit detailed blueprints and get approval before construction begins. A wastewater permit application is similar, ensuring the proposed treatment methods will adequately protect water quality.

Q 17. How do you handle non-compliance issues with wastewater regulations?

Handling non-compliance issues requires a systematic approach, prioritizing prompt action and collaboration. First, we must identify the root cause of the non-compliance. Is it equipment malfunction, inadequate process control, or simply operator error? Once identified, corrective actions are immediately implemented to bring the discharge back into compliance. Detailed documentation of the non-compliance event, corrective actions taken, and preventive measures implemented is crucial. This information is then reported to the regulatory agency as required by the permit. Depending on the severity of the non-compliance, there might be additional penalties such as fines or enforcement actions. Proactive communication with the regulatory agency is essential throughout the process. We aim for transparency and demonstrate a commitment to environmental protection. For example, if a specific pollutant exceeds its limit, we might conduct additional testing, investigate the treatment process for issues, and potentially implement process improvements.

Q 18. What is your experience with wastewater treatment plant design and construction?

I have extensive experience in the design and construction of wastewater treatment plants, spanning various scales and technologies. My involvement has ranged from conceptual design and process selection to detailed engineering, procurement, and construction management. I’m familiar with a wide range of treatment processes, including activated sludge, membrane bioreactors, and constructed wetlands. For example, I recently led a project for the design and construction of a new wastewater treatment plant for a rapidly growing municipality. This involved collaborating with a multidisciplinary team to optimize plant design, select appropriate treatment technologies, and ensure compliance with all relevant regulations. We carefully considered factors like site constraints, projected population growth, and future expansion potential.

Q 19. How do you troubleshoot problems in a wastewater treatment process?

Troubleshooting problems in wastewater treatment is a critical aspect of my work. My approach involves a systematic investigation, starting with a review of operational data such as effluent quality parameters, flow rates, and energy consumption. I then examine the process parameters to pinpoint any deviations from the optimal operating conditions. For example, if effluent suspended solids are elevated, I would analyze parameters like mixed liquor suspended solids (MLSS), dissolved oxygen (DO), and sludge age to identify potential causes such as insufficient aeration, low sludge return rate, or problems with the clarifier. I use data analysis, process simulations, and often onsite inspections to diagnose and resolve the issue. The process resembles detective work, carefully piecing together clues to uncover the problem’s root cause.

Q 20. Describe your experience with wastewater modeling and simulation.

I have significant experience using wastewater modeling and simulation to optimize treatment processes, predict plant performance, and assess the impact of potential upgrades. This involves utilizing software packages like BioWin and SWMM to model various treatment scenarios and evaluate their effectiveness. For example, I used BioWin to model the impact of different aeration strategies on nitrogen removal in an activated sludge system. The simulation helped us optimize the aeration system to improve nitrogen removal efficiency and reduce energy consumption. Similarly, I’ve used SWMM to model the hydraulic performance of sewer networks, identifying areas prone to flooding or surcharge during heavy rainfall events.

Q 21. What software are you proficient in for wastewater management?

I’m proficient in several software packages commonly used in wastewater management. These include BioWin for biological process simulation, SWMM for hydraulic modeling of sewer systems, and various GIS software for data visualization and spatial analysis. I also have experience with SCADA systems for monitoring and controlling wastewater treatment plants. My proficiency extends to data analysis software such as R and Python, enabling me to conduct statistical analysis and develop custom tools for data interpretation. These tools are essential for optimizing treatment operations, predicting system behavior, and ensuring efficient resource utilization.

Q 22. Explain your understanding of advanced oxidation processes (AOPs) in wastewater treatment.

Advanced Oxidation Processes (AOPs) are a suite of chemical treatment techniques used in wastewater treatment to remove recalcitrant pollutants that resist conventional biological treatment. These pollutants can include pharmaceuticals, personal care products, pesticides, and other emerging contaminants. AOPs work by generating highly reactive species, primarily hydroxyl radicals (•OH), which are powerful oxidizing agents capable of breaking down complex organic molecules into less harmful substances.

Several AOPs exist, each utilizing different methods to generate these hydroxyl radicals. Common examples include:

- UV/H2O2: Ultraviolet (UV) light is used to decompose hydrogen peroxide (H2O2), producing •OH radicals. This is a relatively simple and effective method.

- O3/H2O2: Ozone (O3) reacts with H2O2 to generate even more •OH radicals, leading to enhanced degradation.

- Fenton process: Involves the reaction of ferrous ions (Fe2+) with H2O2 to produce •OH radicals. This process is cost-effective but requires careful pH control.

- Photocatalysis (TiO2): Uses titanium dioxide (TiO2) nanoparticles as a catalyst in the presence of UV light to generate •OH radicals. This approach offers potential for long-term use due to the catalyst’s reusability but can require specialized reactor designs.

In practice, the choice of AOP depends on factors like the specific pollutants present, the desired treatment level, energy consumption considerations, and operational costs. For example, a municipality struggling with micropollutant removal might choose UV/H2O2 for its relative simplicity and effectiveness, while a facility dealing with high concentrations of persistent organic pollutants might opt for a more powerful combination like O3/H2O2 or photocatalysis.

Q 23. How do you ensure the safety and security of wastewater treatment facilities?

Ensuring the safety and security of wastewater treatment facilities is paramount, involving a multi-faceted approach encompassing physical security, process safety, and cybersecurity. Physical security measures include perimeter fencing, access control systems (e.g., card readers, security cameras), and regular patrols to prevent unauthorized entry and vandalism. Process safety focuses on preventing accidents and minimizing risks associated with hazardous materials handling, such as chlorine storage and handling procedures, ensuring proper ventilation, and maintaining equipment in optimal condition. Regular inspections and maintenance are critical.

Cybersecurity is increasingly crucial, as modern wastewater treatment plants rely heavily on sophisticated control systems. Protecting these systems from cyberattacks is vital to prevent disruptions in operations. This involves measures like network segmentation, intrusion detection systems, regular software updates, and employee training on cybersecurity best practices. A robust emergency response plan, regularly tested and updated, is also crucial; it should cover scenarios like equipment failure, chemical spills, and cyberattacks. For example, in a facility I worked with, a detailed emergency response plan included regular drills involving local emergency services, ensuring preparedness for various potential hazards.

Q 24. What are your strategies for managing and minimizing energy consumption in wastewater treatment?

Minimizing energy consumption in wastewater treatment is a key priority, both economically and environmentally. Strategies for achieving this include optimizing aeration processes (a significant energy consumer) through techniques like optimizing dissolved oxygen control, implementing innovative aeration systems (e.g., fine-bubble diffusers, membrane aerators), and utilizing advanced process control strategies. Energy-efficient pumps and motors are also crucial; implementing variable frequency drives (VFDs) can significantly reduce energy consumption by adjusting pump speeds based on demand. Additionally, using renewable energy sources like solar power to supply electricity to the facility reduces reliance on the grid and can decrease carbon footprint.

Further optimization can be achieved through heat recovery systems. Heat generated during certain processes can be captured and reused for other purposes, such as preheating incoming wastewater or powering digesters. Waste sludge management also presents an opportunity for energy reduction; anaerobic digestion of sludge produces biogas, which can be used to generate electricity or heat, thereby reducing the need for external energy sources. A practical example from my experience involved implementing a VFD on the main aeration blower, which resulted in a 20% reduction in energy consumption without impacting treatment efficiency.

Q 25. Explain your knowledge of different disinfection methods for wastewater.

Disinfection is a crucial final step in wastewater treatment to eliminate harmful pathogens before effluent discharge. Several methods exist, each with advantages and disadvantages:

- Chlorination: The most common method, using chlorine gas or hypochlorite solutions to kill bacteria and viruses. It is effective and relatively inexpensive but can produce disinfection byproducts (DBPs) like trihalomethanes (THMs), which are potentially carcinogenic. Careful control of chlorine dosage is vital.

- UV Disinfection: Uses ultraviolet light to damage the DNA of microorganisms, rendering them incapable of reproduction. It’s effective, environmentally friendly (no DBPs), and requires minimal operator supervision but is less effective against some resistant microorganisms and requires regular lamp replacement.

- Ozone Disinfection: Employs ozone gas (O3) as a powerful oxidant that disrupts cellular processes in microorganisms. It’s effective, leaves no harmful byproducts, and is particularly effective against viruses but requires specialized equipment and is more energy-intensive than chlorination.

- Chloramine Disinfection: Using chloramines (e.g., monochloramine) offers a compromise between chlorination and other methods. It reduces the formation of DBPs compared to free chlorine but still requires careful monitoring of residual levels.

The choice of disinfection method depends on various factors, including effluent quality, regulatory requirements, cost considerations, and the presence of specific pathogens of concern. For instance, a coastal wastewater treatment plant might favor UV disinfection to avoid the risk of DBPs impacting marine life.

Q 26. Describe your experience with conducting wastewater audits and inspections.

Conducting wastewater audits and inspections involves a systematic evaluation of a wastewater treatment facility’s operational efficiency, compliance with regulations, and environmental performance. My experience involves a detailed review of facility operations, reviewing process control data, conducting visual inspections of equipment, analyzing laboratory data, and reviewing compliance records. I utilize a standardized checklist to ensure consistent evaluation across different facilities. The audits assess various aspects, such as:

- Process efficiency: Evaluating the effectiveness of various treatment units, identifying areas for optimization, and assessing energy consumption patterns.

- Compliance: Verifying adherence to local, state, and federal regulations regarding effluent discharge limits, reporting requirements, and safety protocols.

- Maintenance and Operation: Assessing the effectiveness of maintenance programs, training practices, and staff competency.

- Safety: Evaluating the facility’s adherence to safety standards and procedures to prevent accidents and ensure worker protection.

Following an audit, I prepare a comprehensive report outlining findings, recommendations for improvements, and corrective actions. I’ve successfully identified operational inefficiencies resulting in cost savings and compliance improvements in multiple facilities, leading to improved environmental outcomes. For example, one audit revealed an issue with sludge dewatering equipment, causing higher operating costs and potential compliance violations. My recommendations on preventative maintenance and equipment upgrades resulted in significant cost savings and improved sludge handling.

Q 27. What are the emerging trends and technologies in wastewater treatment?

The wastewater treatment field is constantly evolving, with several emerging trends and technologies shaping its future:

- Advanced oxidation processes (AOPs): As discussed earlier, AOPs are crucial for removing micropollutants.

- Membrane bioreactors (MBRs): Combining biological treatment with membrane filtration provides high-quality effluent, ideal for water reuse applications.

- Artificial intelligence (AI) and machine learning (ML): These technologies are increasingly used for process optimization, predictive maintenance, and real-time monitoring, enhancing operational efficiency and reducing costs.

- Resource recovery: Focusing on recovering valuable resources from wastewater, such as energy (biogas), nutrients (strvite), and water, fostering a circular economy approach.

- Smart sensors and automation: These technologies are revolutionizing monitoring and control systems, enabling better data collection and more efficient operations.

- Microbial fuel cells (MFCs): These generate electricity from the breakdown of organic matter in wastewater, offering a sustainable energy source for the treatment plant itself.

These technologies are not only improving treatment efficiency but also creating opportunities for resource recovery and environmental sustainability. The integration of these advances will shape the future of wastewater treatment, leading to more sustainable and efficient systems.

Key Topics to Learn for Wastewater Regulations Interview

- Discharge Permits and Compliance: Understanding the NPDES permit process, monitoring requirements, and reporting procedures. Practical application includes analyzing permit limitations and ensuring compliance.

- Wastewater Treatment Processes: Familiarize yourself with various treatment methods (e.g., primary, secondary, tertiary) and their effectiveness in removing pollutants. Practical application involves troubleshooting treatment plant malfunctions and optimizing operational efficiency.

- Water Quality Parameters and Monitoring: Mastering the significance of key water quality indicators (BOD, COD, TSS, nutrients) and their regulatory limits. Practical application involves interpreting lab results and identifying potential pollution sources.

- Sludge Management and Disposal: Understanding regulations and best practices related to sludge handling, processing, and disposal. Practical application involves evaluating different sludge management strategies and ensuring compliance with environmental regulations.

- Industrial Wastewater Pretreatment: Knowledge of regulations and procedures for managing industrial wastewater discharges to municipal systems. Practical application includes reviewing pretreatment programs and ensuring compliance by industrial dischargers.

- Regulatory Agencies and Enforcement: Familiarity with relevant federal, state, and local agencies and their enforcement procedures. Practical application involves understanding permit conditions and responding to regulatory inspections.

- Emerging Contaminants and Regulations: Understanding the challenges posed by emerging contaminants (e.g., pharmaceuticals, microplastics) and the evolving regulatory landscape. Practical application involves researching best practices for managing these contaminants.

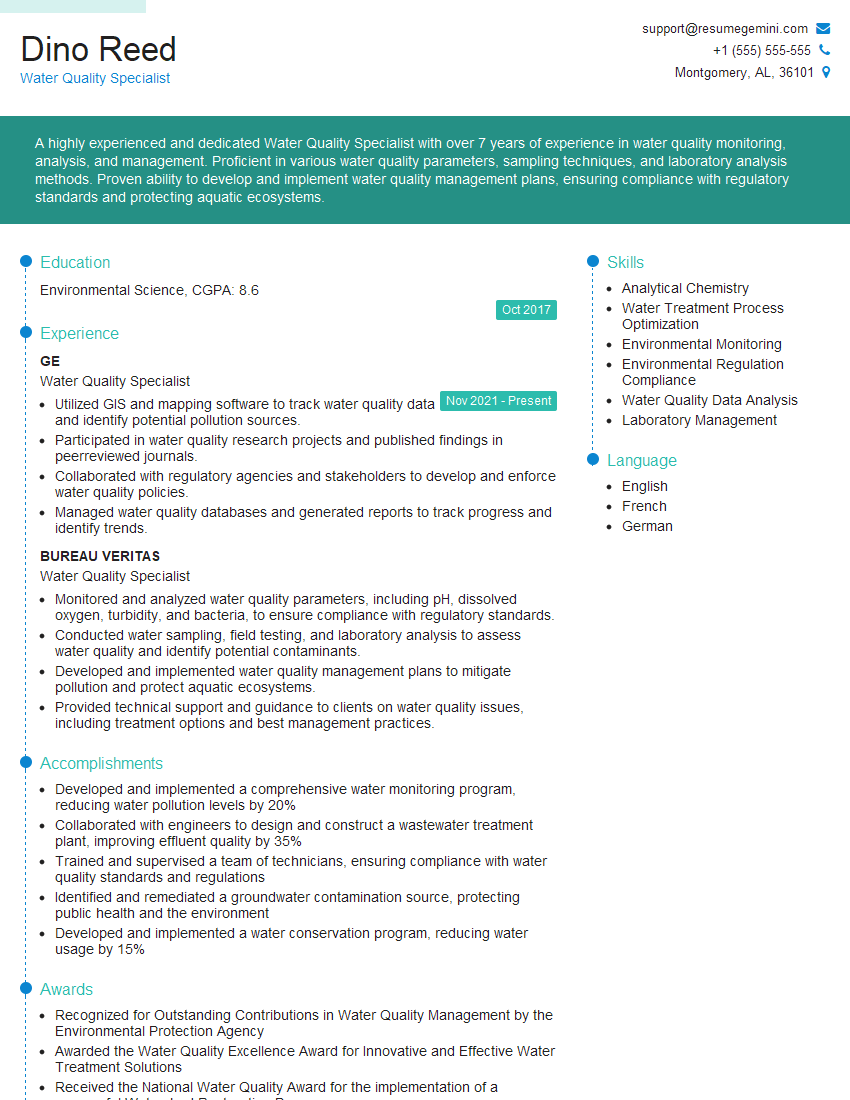

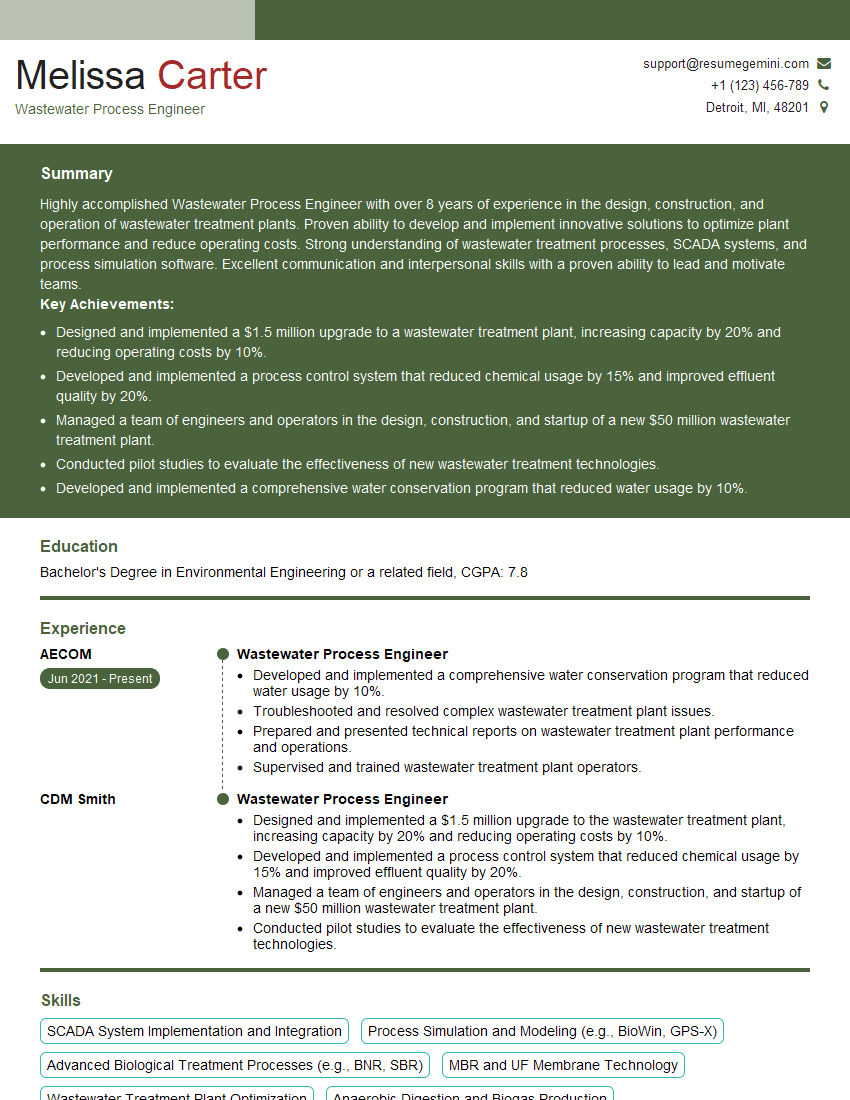

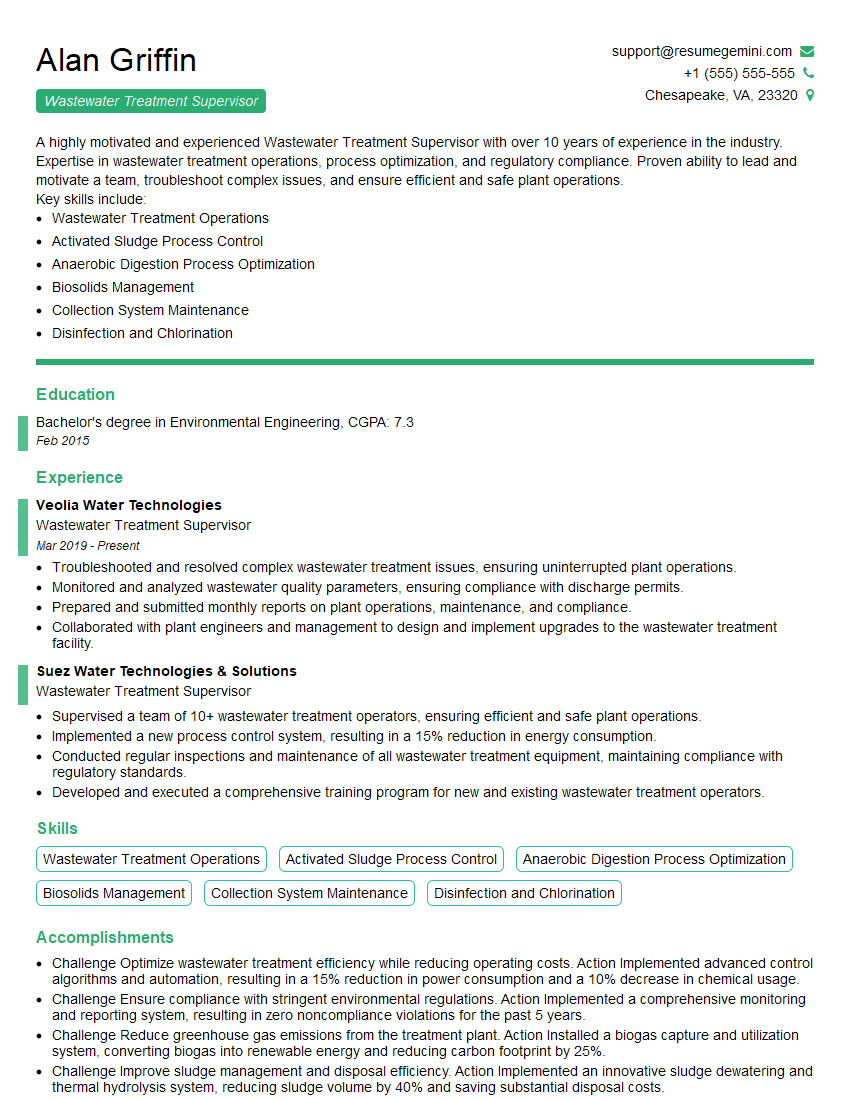

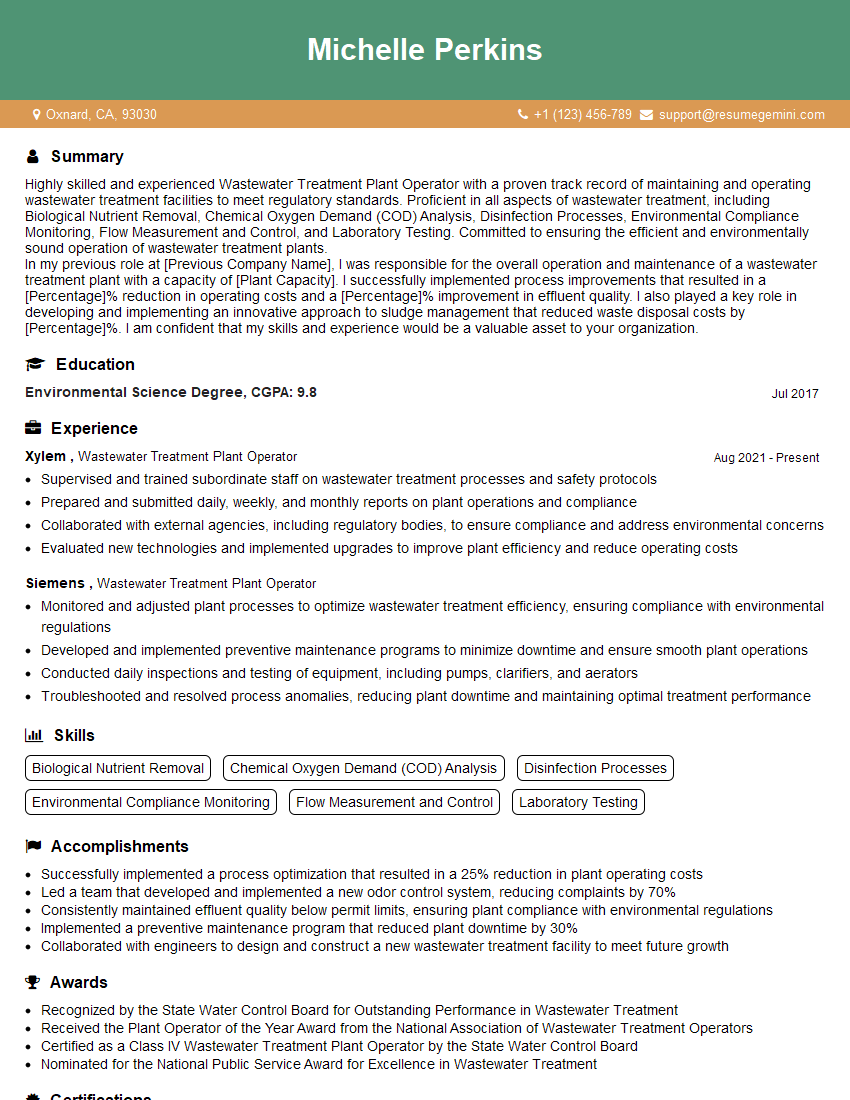

Next Steps

Mastering Wastewater Regulations is crucial for career advancement in the environmental sector, opening doors to specialized roles and increased earning potential. A strong, ATS-friendly resume is your key to unlocking these opportunities. To make your application stand out, leverage ResumeGemini to create a professional and impactful resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to Wastewater Regulations to help you build a compelling application. Take the next step toward your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.