Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Wastewater Troubleshooting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Wastewater Troubleshooting Interview

Q 1. Explain the process of activated sludge treatment.

Activated sludge treatment is a crucial biological wastewater treatment process that uses microorganisms to break down organic matter. Imagine a tiny, bustling city of bacteria and other microbes working tirelessly to clean up the wastewater. The process begins with the wastewater entering an aeration tank, where it’s mixed with a population of microorganisms called ‘activated sludge’. These microbes consume the organic pollutants in the wastewater, essentially ‘eating’ the pollution. This process requires oxygen, which is provided by aerators (think of them as the lungs of the system). The aeration tank allows these beneficial microbes to thrive, efficiently removing pollutants. After the aeration process, the mixture flows into a clarifier, a large settling tank. Here, the heavier activated sludge settles to the bottom, while the treated wastewater flows out from the top. A portion of the settled sludge is recycled back to the aeration tank to maintain a healthy microbial population, ensuring continuous treatment. The remaining sludge is sent for further processing, often anaerobic digestion, which further breaks down the organic matter, producing biogas (a renewable energy source!) and a smaller volume of stabilized sludge for disposal.

Think of it like composting on a large scale. We’re using nature’s own cleanup crew to break down organic materials into less harmful substances. The continuous recycling of sludge ensures that the system maintains its efficiency. The final effluent is then disinfected before being safely discharged into the environment.

Q 2. Describe different types of wastewater treatment processes.

Wastewater treatment processes vary widely based on the wastewater characteristics and desired treatment level. Here are a few key types:

- Primary Treatment: This involves physical processes like screening, grit removal, and sedimentation to remove larger solids and settleable particles. Imagine a simple strainer removing large debris from your sink drain—that’s the basic principle.

- Secondary Treatment: This primarily utilizes biological processes, such as the activated sludge process (explained above), trickling filters, and rotating biological contactors, to remove dissolved and suspended organic matter. This step focuses on removing the ‘invisible’ pollutants.

- Tertiary Treatment (Advanced Treatment): This goes beyond secondary treatment to remove specific pollutants like nutrients (nitrogen and phosphorus) and pathogens. Techniques include filtration, disinfection (chlorination, UV, ozonation), and chemical precipitation. This is like giving the wastewater a deep clean, ensuring only pure water is released.

- Anaerobic Digestion: This process breaks down organic matter in the absence of oxygen. It’s used for sludge stabilization, producing biogas as a byproduct. Think of it as a natural way of decomposing organic waste, similar to how things break down in a compost heap.

The specific processes used in a particular plant depend on factors such as the type of wastewater, environmental regulations, and available budget. For example, a plant treating industrial wastewater with high concentrations of specific chemicals might require a tailored treatment process, potentially including specialized chemical treatments or advanced oxidation.

Q 3. How do you troubleshoot a malfunctioning clarifier?

Troubleshooting a malfunctioning clarifier requires a systematic approach. First, we visually inspect the clarifier for obvious issues: is the sludge blanket too high or too low? Are there any signs of poor settling or bulking sludge? Then, we check the operational parameters. Are the flow rates and solids retention times within the design parameters? Is the clarifier properly raked or scraped? We would also analyze the influent and effluent samples to assess the quality of the wastewater entering and leaving the clarifier. High suspended solids in the effluent are a clear indication of a problem. Let’s say we find excessive solids in the effluent. We might then investigate potential causes, such as inadequate mixing in the aeration tank, leading to poor floc formation, or mechanical issues with the clarifier itself (e.g., a malfunctioning rake). We might also test for the presence of filamentous bacteria, which can cause sludge bulking.

Troubleshooting a clarifier is a bit like detective work. We systematically gather clues to identify the root cause of the problem. Once identified, we can implement the appropriate corrective actions—repairing equipment, adjusting operational parameters, or addressing the biological issues contributing to poor settling.

Q 4. What are the common causes of high ammonia levels in wastewater?

High ammonia levels in wastewater are usually due to inadequate biological nitrification. Nitrification is a crucial step in wastewater treatment, where specialized bacteria convert ammonia (NH3) into nitrite (NO2-) and then nitrate (NO3-). This process requires specific environmental conditions, including sufficient dissolved oxygen and a suitable pH range. If these conditions are not met, the nitrifying bacteria will struggle to perform their job, leading to elevated ammonia levels. Other causes include influent wastewater with a high ammonia concentration (perhaps from industrial discharges or faulty pretreatment), insufficient aeration, or low temperatures, which inhibit bacterial activity. Essentially, the ‘cleanup crew’ isn’t doing its job effectively because of some environmental obstacle.

To solve this, we need to identify the root cause. If it’s due to insufficient aeration, we increase the oxygen supply. If the problem is low temperatures, we might need to improve process temperature control. If the issue is a lack of nitrifying bacteria, we might need to seed the system with a culture of these bacteria.

Q 5. How do you identify and address issues related to biological nutrient removal?

Biological nutrient removal (BNR) focuses on removing nitrogen and phosphorus, which can cause eutrophication (excessive algae growth) in receiving waters. Issues in BNR often manifest as high effluent nutrient concentrations. We diagnose problems by analyzing effluent samples for nitrogen and phosphorus levels and also examining the sludge for characteristics indicative of poor nutrient removal. For example, poor phosphorus removal might be due to inadequate anaerobic conditions in the process, while ineffective nitrogen removal could be due to insufficient nitrification or denitrification.

Addressing these issues often involves adjusting operational parameters like dissolved oxygen levels, solids retention time, and the carbon-to-nitrogen ratio. We might also investigate the microbial community in the system and take steps to improve the abundance of the specific bacteria responsible for nutrient removal. For example, we might adjust the sludge age or the carbon source to optimize the growth of these essential microorganisms. It’s all about creating the ideal conditions for the beneficial bacteria to efficiently remove nutrients.

Q 6. What are the key indicators of proper disinfection in a wastewater treatment plant?

Proper disinfection in a wastewater treatment plant is essential to protect public health. Key indicators of effective disinfection include achieving a specific level of pathogen inactivation, as measured by fecal coliform or E. coli counts. We monitor the effluent for these indicators, ensuring that the counts are below regulatory limits. We also monitor the disinfectant concentration (chlorine, UV dose, etc.) and the contact time between the disinfectant and the wastewater. Adequate contact time is crucial to ensure effective disinfection. Regular maintenance and calibration of disinfection equipment are essential, as are checks for residual disinfectant in the effluent to confirm the process effectiveness.

Think of disinfection as the final safety check before discharging the treated water. Monitoring these parameters guarantees that the treated wastewater is safe and won’t pose a threat to public health or the environment.

Q 7. Explain the importance of proper sludge management.

Proper sludge management is critical for several reasons. First, it minimizes environmental risks associated with sludge disposal. Untreated sludge can release pathogens and pollutants, potentially contaminating soil and water. Second, effective sludge management reduces operational costs. Efficient sludge dewatering reduces transportation and disposal costs. Furthermore, sludge can be a valuable resource. Anaerobic digestion, as mentioned before, can produce biogas, a renewable energy source, and digestate, a valuable soil amendment. Proper sludge management involves a combination of processes, such as thickening, dewatering, and digestion, to reduce sludge volume, stabilize it, and ultimately safely dispose of or reuse it.

Efficient sludge management is not only environmentally sound but also economically advantageous. It transforms what was once a waste product into a valuable resource, closing the loop and creating a more sustainable system.

Q 8. How do you diagnose and solve problems related to pump failures?

Diagnosing pump failures starts with a systematic approach. First, I’d check the most obvious: is the pump even receiving power? A simple voltage check at the motor terminals is crucial. If power is present, I’d listen for unusual sounds – grinding, squealing, or humming – which often indicate bearing wear, impeller damage, or cavitation. Next, I’d inspect the pump’s physical condition, looking for leaks, loose connections, or visible damage to the seals or housing. If the problem isn’t immediately apparent, I might utilize a pressure gauge to check the discharge pressure; a significantly lower pressure than expected could signify a blockage or impeller issue. Finally, I’d examine the pump’s vibration. Excessive vibration often points to misalignment, worn bearings, or internal mechanical problems. Solving the problem depends on the diagnosis. A simple fix might be replacing a blown fuse or tightening loose bolts. More complex repairs might involve replacing the seals, bearings, or even the entire impeller or motor. For instance, I once diagnosed a pump failure caused by a clogged suction line due to rags entering the system. Simple unclogging solved the issue, highlighting the importance of proactive preventative measures such as installing proper screening devices.

Q 9. Describe your experience with troubleshooting SCADA systems in a wastewater treatment plant.

My experience with SCADA (Supervisory Control and Data Acquisition) systems in wastewater treatment involves extensive troubleshooting using historical data analysis. I’m proficient in identifying trends and anomalies in real-time data that might indicate impending issues, allowing for preventative maintenance. For example, I once used SCADA data to detect a gradual decrease in aeration tank dissolved oxygen levels over several days, prompting me to investigate the aeration system’s efficiency before a complete failure occurred. This prevented significant operational disruptions. I’m comfortable using SCADA systems to remotely monitor and control various processes, from pump operation to chemical dosing. When troubleshooting, I use the SCADA system’s alarm history and event logs to pinpoint the sequence of events leading to a problem. The data visualization tools are invaluable in identifying correlations between different process parameters and pinpointing the source of malfunctions. I also have experience with configuring SCADA alarms and adjusting control strategies to optimize plant operations and prevent future problems.

Q 10. How do you handle unexpected influent surges?

Unexpected influent surges, or sudden increases in wastewater flow, are a common challenge. My approach involves a multi-pronged strategy. First, I’d immediately assess the extent of the surge using flow meters and SCADA data. Then, I’d identify the likely cause; this could range from rainfall runoff to a sewer line break. Depending on the severity and cause, my response would vary. For minor surges, the plant’s existing capacity might handle the increase with minimal impact. However, for major surges, I might employ strategies like diverting excess flow to equalization basins (storage tanks), increasing the aeration rate in activated sludge tanks to maintain oxygen levels, and adjusting chemical dosing to maintain treatment efficiency. In extreme cases, I might need to temporarily bypass certain treatment units to protect the system from overload. For example, during a significant rainfall event, I once implemented an emergency bypass strategy that safely diverted a portion of the surge flow, preventing an operational shutdown. This highlights the importance of having emergency plans and robust system redundancy.

Q 11. What safety protocols do you follow when troubleshooting wastewater equipment?

Safety is paramount. Before initiating any troubleshooting, I always follow a strict safety protocol. This includes performing a thorough risk assessment, identifying potential hazards (e.g., confined spaces, hazardous chemicals, electrical equipment), and using appropriate personal protective equipment (PPE), such as safety glasses, gloves, and respirators. I’d ensure the equipment is properly locked out and tagged out before commencing any work, preventing accidental start-ups. I strictly adhere to all relevant safety regulations and company procedures. I also follow proper procedures for handling hazardous materials and dispose of waste according to guidelines. Teamwork and communication are key; I’d never attempt complex troubleshooting alone. I’d inform colleagues of my activities and ensure there’s someone available for assistance in case of an emergency. A clear understanding and adherence to safety guidelines are essential not just for individual well-being but also for ensuring efficient and safe operations in the wastewater treatment plant.

Q 12. How do you interpret wastewater laboratory results?

Interpreting wastewater lab results requires a thorough understanding of various parameters and their significance. I start by examining the key indicators: Total Suspended Solids (TSS), Biochemical Oxygen Demand (BOD), Chemical Oxygen Demand (COD), ammonia, and nitrates. High TSS indicates poor solids removal, potentially due to problems in the primary clarifiers or secondary treatment processes. Elevated BOD and COD suggest a high organic load, indicating insufficient treatment capacity or operational issues. Ammonia levels reveal the effectiveness of nitrification, while high nitrate levels indicate successful nitrification but potentially a problem with denitrification. I correlate these results with the plant’s operational data from the SCADA system to identify potential causes. For instance, consistently high BOD could indicate a problem with aeration, sludge age, or an influent quality issue. By cross-referencing lab data with operational parameters, I can pinpoint the specific treatment unit causing the problem and develop targeted solutions. I also consider seasonal variations and historical data for a comprehensive analysis.

Q 13. What are the common causes of high TSS (Total Suspended Solids) levels?

High TSS levels – meaning too many solids suspended in the wastewater – can stem from several sources. Problems in the primary clarifiers are a common culprit; insufficient settling time, improper sludge removal, or inadequate flow distribution can leave solids suspended. Failure in the secondary treatment process, such as problems with the aeration system in activated sludge plants or malfunctioning trickling filters, can also result in high TSS. Influent quality variations play a significant role; increased storm water inflow can dramatically increase TSS, as can industrial discharges containing high concentrations of suspended solids. Finally, problems with the final clarifiers, such as insufficient settling time or sludge blanket build-up, can also contribute to high TSS. Addressing high TSS necessitates investigating each of these potential sources, utilizing both operational data and lab results to pinpoint the exact cause and implement the appropriate corrective actions, which may involve adjusting operational parameters, performing maintenance on equipment, or addressing influent quality issues.

Q 14. Explain your experience with troubleshooting aeration systems.

Troubleshooting aeration systems is critical for efficient wastewater treatment. My approach begins with assessing the dissolved oxygen (DO) levels in the aeration tanks. Low DO levels indicate insufficient oxygen transfer. I’d then examine the air flow rate, checking for blockages in the air supply lines or problems with the blowers themselves. I’d also inspect the diffusers for clogging or damage; compromised diffusers reduce the efficiency of oxygen transfer. I’d look at the air pressure readings to identify any pressure drops in the system indicating blockages or leaks. If the blowers are functioning correctly, and there are no obvious blockages, then I would check the dissolved oxygen sensors for calibration or faults. Once the problem is identified, the solution might range from simple cleaning and maintenance of diffusers, to blower repairs or replacements, or even adjustments to the aeration control strategy. For example, I once addressed consistently low DO levels by implementing a more effective cleaning schedule for the aeration diffusers, significantly improving the system’s efficiency. This highlighted the crucial role of regular preventive maintenance in ensuring optimal aeration system performance.

Q 15. How do you address odor control issues in a wastewater treatment plant?

Odor control in wastewater treatment is crucial for both environmental and community relations. Unpleasant smells arise from the release of volatile organic compounds (VOCs) produced during the breakdown of organic matter. Addressing this involves a multi-pronged approach focusing on prevention and treatment.

- Improved Process Control: Maintaining optimal operational parameters is key. For example, ensuring proper aeration in activated sludge processes minimizes anaerobic conditions where odor-causing compounds thrive. Regular monitoring of pH and temperature helps prevent the creation of malodorous byproducts. Think of it like controlling the recipe in a kitchen – the right ingredients and process prevent foul smells.

- Biological Treatment: Enhancing the biological process by optimizing microbial activity effectively degrades odor-causing compounds. This can be done by adjusting nutrient levels or adding specific microbial cultures. Think of it as adding beneficial bacteria to ‘eat’ the smelly substances.

- Chemical Treatment: Chemical treatments using odor masking agents or oxidizers can neutralize or reduce the intensity of odors. However, this should be viewed as a secondary treatment, not a primary solution, as it simply masks the underlying problem.

- Physical Control: Techniques such as covered basins, enclosed clarifiers, and efficient ventilation systems prevent the escape of odor-causing gases. Think of it like sealing a container to prevent the smell from escaping.

- Regular Maintenance: Regular cleaning, sludge removal, and equipment maintenance prevent the build-up of organic matter which is a major source of odors.

In one project, we tackled a persistent sulfide odor problem by implementing a combination of improved aeration, adding a chemical oxidant to target hydrogen sulfide, and upgrading the ventilation system. This resulted in a significant reduction in odor complaints and improved the working conditions for plant operators.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with maintaining and troubleshooting various types of pumps.

My experience encompasses a wide range of pumps, including centrifugal, positive displacement, submersible, and progressing cavity pumps. Troubleshooting these requires a systematic approach that considers the pump’s type, operating conditions, and symptoms.

- Centrifugal Pumps: Common issues include cavitation (due to insufficient net positive suction head), seal failures (due to wear or misalignment), and impeller wear (due to abrasion). Diagnostics often involve pressure readings, vibration analysis, and visual inspection.

- Positive Displacement Pumps: Problems can stem from internal wear, valve failures, or incorrect priming. Troubleshooting often requires specialized knowledge of the pump’s internal components and operating principles. For example, I once repaired a damaged diaphragm in a progressing cavity pump by carefully following the manufacturer’s maintenance manual.

- Submersible Pumps: Specific challenges include motor overheating (due to overloading or bearing wear), cable damage, and clogging. I have experience with the retrieval, repair, and maintenance of this type of pump.

Maintenance involves regular inspections, lubrication, and preventative measures such as the timely replacement of worn parts. A proactive maintenance program significantly reduces downtime and extends the lifespan of pumps.

Q 17. What are the common causes of low dissolved oxygen (DO) levels?

Low dissolved oxygen (DO) in wastewater treatment is a major concern, as it hampers the effectiveness of aerobic biological processes, leading to poor treatment efficiency and potential odor problems. Several factors contribute to low DO levels:

- Insufficient Aeration: The most common cause. This could stem from malfunctions in the aeration system (e.g., air blower failure, clogged diffusers), inadequate aeration capacity, or excessive sludge loading. Think of it like not providing enough air to a campfire – the fire (biological process) will sputter.

- High BOD/COD Loads: Excessive organic matter (BOD – biochemical oxygen demand, COD – chemical oxygen demand) consumes available oxygen more quickly than it can be replenished. It’s like adding too much fuel to a fire; the oxygen is used up too quickly.

- Sludge Bulking: An excess of filamentous bacteria reduces settling in the clarifier, thus releasing sludge which consumes oxygen without contributing to treatment.

- Toxic Inflow: The presence of toxic substances can inhibit the growth of aerobic microorganisms, hindering their oxygen consumption capability. This is like poisoning the fire.

Troubleshooting involves checking aeration system performance, analyzing BOD/COD levels, assessing sludge characteristics, and testing for toxic substances. Adjusting aeration rates, optimizing sludge wasting, and addressing influent issues are often necessary corrective actions.

Q 18. How do you troubleshoot issues related to filter media clogging?

Filter media clogging is a common issue in wastewater treatment that reduces filtration efficiency and necessitates interventions. Troubleshooting requires understanding the type of filter (e.g., sand, anthracite, multimedia) and the nature of the clogging.

- Backwashing: The most common solution for most filter types. It involves reversing the flow of water through the filter bed to dislodge trapped solids. The frequency and duration of backwashing depend on several factors including the type of filter media, influent quality, and filtration rate.

- Air Scouring: Often used in combination with backwashing, this method involves injecting air into the filter bed to further dislodge particles. The process helps separate particles and increases the effectiveness of the backwashing.

- Chemical Cleaning: For more severe clogging, chemical cleaning using acids or oxidizing agents might be necessary to dissolve or break down accumulated materials. This should be done very carefully and only after proper consideration of its impacts on filter media and the wastewater treatment process.

- Media Replacement: In cases of irreversible media damage or excessive clogging, replacement of the filter media is necessary. This process often involves the complete decommissioning and recommissioning of the filter units.

In one case, we addressed persistent clogging in a sand filter by optimizing the backwashing schedule and incorporating air scouring. This improved filtration efficiency and reduced the frequency of media replacement, saving significant operational costs.

Q 19. How do you maintain proper chlorine residuals in the disinfection process?

Maintaining proper chlorine residuals is critical for effective disinfection and compliance with discharge regulations. This involves a combination of careful monitoring and adjustments to chlorine feed rates.

- Chlorine Feed Control: The chlorine feed rate needs to be adjusted based on the flow rate and characteristics of the wastewater, especially its organic load. This often requires an automated control system that adjusts feed rates based on real-time measurements.

- Monitoring Residual Chlorine: Regularly measuring residual chlorine levels at various points in the disinfection process is crucial to ensure adequate disinfection without exceeding regulatory limits. The frequency of measurements and the location are determined by the treatment process and discharge requirements.

- Contact Time: Ensuring sufficient contact time between the chlorine and the wastewater is also critical for effective disinfection. This is often dictated by design of disinfection tank.

- Chlorine Demand: The wastewater’s chlorine demand (the amount of chlorine consumed by the organic matter) needs to be considered in determining the appropriate feed rate. Higher chlorine demand necessitates higher feed rates.

Precise control over chlorine dosage is essential and is usually done through automated systems and SCADA (Supervisory Control and Data Acquisition). These systems measure influent flow and adjust chemical feed automatically, guaranteeing sufficient disinfection within permissible limits.

Q 20. What are the regulatory requirements for wastewater discharge in your region?

(Note: This answer will need to be tailored to the specific region. The following is a general example.)

Regulatory requirements for wastewater discharge vary by location but generally focus on protecting public health and the environment. In my region, key regulations include:

- Effluent Limits: Strict limits are imposed on various parameters, including BOD, suspended solids (SS), ammonia, total phosphorus, and various pathogens. These limits are designed to ensure the treated wastewater meets specific quality standards before discharge.

- Reporting Requirements: Regular reporting of discharge data, including flow rates, effluent parameters, and any operational issues, is mandatory. These reports are submitted to regulatory bodies which check and verify compliance.

- Permitting: A discharge permit is required from the relevant environmental authority, outlining the allowed discharge limits and operational conditions. This permit must be obtained before discharging treated wastewater into any receiving water.

- Spill Response Plans: Plants are required to develop and maintain comprehensive spill response plans detailing actions to be taken in case of accidental releases of untreated or inadequately treated wastewater.

Non-compliance can result in significant penalties, including fines and even plant closure. Therefore, adherence to these regulations is paramount for any wastewater treatment facility.

Q 21. Describe your experience with troubleshooting anaerobic digesters.

Anaerobic digesters are complex biological reactors that require careful monitoring and troubleshooting. Problems can arise from various sources:

- Digester Failure: Digester failure can lead to accumulation of volatile fatty acids (VFAs), indicating an imbalance in the microbial community. Troubleshooting often involves analyzing VFAs, pH, alkalinity, and volatile solids (VS) to understand the cause and take corrective actions like adding alkalinity or adjusting the feed rate. Think of this as an upset stomach – the right treatment can restore balance.

- Low Gas Production: Reduced biogas production might be due to low organic loading rate, low temperature, or imbalances in the microbial community. Adjusting feed rate, increasing temperature, or inoculating the digester with appropriate microbes can help resolve the issue.

- Foaming: Excessive foaming can disrupt digester operation and lead to process instability. Identifying the cause (e.g., excessive protein in feedstock) and implementing control measures (e.g., anti-foaming agents, adjusting feedstock) are crucial.

- Scum Layer Build-up: A thick scum layer can hinder gas production and limit mixing. Regular removal of scum through skimming is typically required.

Troubleshooting anaerobic digesters involves a thorough understanding of microbiology, process chemistry, and instrumentation. In one instance, I identified and addressed a decrease in gas production through an increase in temperature and reduction in the flow of organic material to the digester, successfully restoring the system to optimal performance.

Q 22. Explain your understanding of the different types of wastewater collection systems.

Wastewater collection systems are the crucial first step in the wastewater treatment process, responsible for gathering wastewater from various sources and transporting it to treatment facilities. There are primarily two types: separate systems and combined systems.

Separate systems utilize distinct networks for sanitary sewage (from toilets, sinks, etc.) and stormwater runoff. This is generally preferred as it prevents overwhelming treatment plants during heavy rain events and reduces the risk of untreated wastewater entering waterways.

Combined systems, common in older cities, carry both sanitary sewage and stormwater in a single network. During heavy rainfall, these systems can become overloaded, leading to combined sewer overflows (CSOs) that discharge untreated or partially treated wastewater directly into the environment. This poses significant environmental risks and requires expensive mitigation strategies.

Other variations exist, such as pressure sewers (using pumps to transport wastewater uphill), vacuum sewers (using vacuum pressure for collection), and gravity sewers (relying on gravity for flow). The choice of system depends on factors like topography, population density, and environmental regulations.

Q 23. How do you deal with blocked sewer lines or other collection system issues?

Dealing with blocked sewer lines requires a systematic approach. The first step is to identify the location and cause of the blockage. This often involves using CCTV cameras to inspect the sewer lines, identifying blockages such as grease buildup, root intrusions, or debris. Once the location is pinpointed, various techniques can be employed:

Hydro-jetting: High-pressure water jets are used to dislodge blockages. This is effective for removing grease and debris but less so for substantial root intrusions.

Mechanical cleaning: Using sewer rods or augers to physically break up or remove the blockage. This is effective for a wider range of blockages, including root intrusions.

Chemical cleaning: Using specialized enzymes or chemicals to break down organic matter causing the blockage. This is often used in conjunction with other methods.

For more significant or recurring issues, preventative measures are vital. Regular maintenance including flushing, inspections, and root control programs can prevent blockages and extend the lifespan of the collection system. For example, public awareness campaigns educating residents about proper disposal of fats, oils, and grease can significantly reduce the frequency of grease-related blockages.

Q 24. Describe your experience with preventative maintenance in a wastewater treatment plant.

Preventative maintenance is the cornerstone of efficient and reliable wastewater treatment plant operation. My experience encompasses a wide range of activities, focusing on minimizing downtime and optimizing performance. This includes:

Regular inspections: Scheduled checks of all equipment and infrastructure, including pumps, blowers, aeration systems, and clarifiers, to identify potential issues before they escalate.

Predictive maintenance: Utilizing data from process control instruments (discussed further in the next question) and historical data to predict equipment failures and schedule maintenance proactively, rather than reactively.

Calibration and testing: Regularly calibrating instruments and testing equipment to ensure accuracy and reliability. For example, regular calibration of pH probes in the aeration tanks is crucial for maintaining optimal process conditions.

Cleaning and lubrication: Regular cleaning of equipment components to prevent buildup and ensure optimal functionality. This also includes lubrication of moving parts to prevent wear and tear.

Spare parts management: Maintaining an adequate inventory of essential spare parts to minimize downtime in the event of equipment failures.

Implementing a robust preventative maintenance program is not just about saving money, it’s about safeguarding public health and the environment by ensuring consistent, reliable treatment of wastewater.

Q 25. What is your experience with using process control instruments and data analysis in wastewater treatment?

Process control instruments and data analysis are integral to modern wastewater treatment. I have extensive experience using a variety of instruments including:

Flow meters: Measuring the flow rate of influent and effluent.

pH sensors: Monitoring the pH levels in various treatment stages.

Dissolved oxygen (DO) probes: Monitoring DO levels in aeration tanks.

Turbidity sensors: Measuring the clarity of the effluent.

SCADA (Supervisory Control and Data Acquisition) systems: Collecting and analyzing data from various instruments to provide real-time monitoring and control of the treatment process.

Data analysis allows for identifying trends, detecting anomalies, and optimizing process parameters. For example, analyzing historical data on influent flow, BOD, and sludge production can help predict future performance and plan for necessary adjustments. Statistical process control (SPC) charts are valuable tools for detecting shifts in process performance and preventing problems before they become serious. I’m proficient in using various software packages to analyze this data and create reports.

Q 26. Explain how you would troubleshoot a situation with high BOD (Biochemical Oxygen Demand).

High BOD indicates an excessive amount of organic matter in the wastewater, requiring immediate attention. Troubleshooting involves a systematic approach:

Identify the source: Investigate potential sources of increased organic load. This may involve checking for industrial discharges exceeding permitted limits, infiltration/inflow (I/I) problems in the collection system, or changes in the characteristics of domestic wastewater.

Review operational data: Analyze data from process control instruments (flow, DO, pH, etc.) to identify any deviations from normal operating parameters. This could reveal issues within specific treatment stages (e.g., inefficient aeration in activated sludge tanks).

Check treatment unit performance: Examine the performance of individual treatment units, such as the primary clarifiers, aeration tanks, and secondary clarifiers. Low efficiency in any of these units could contribute to high BOD in the effluent.

Assess sludge quality: Poor sludge quality (e.g., high volatile suspended solids) can indicate problems in the digestion process, potentially leading to higher BOD in the effluent.

Implement corrective actions: Based on the root cause analysis, implement corrective actions. This might involve adjusting aeration rates, improving sludge settling, investigating and addressing I/I problems, or working with industrial dischargers to reduce organic loads.

Monitor results: Continuously monitor BOD levels after implementing corrective actions to ensure the problem is resolved and the effluent quality meets regulatory standards.

For example, if high BOD is linked to inefficient aeration, increasing the aeration rate or optimizing the air distribution system could resolve the issue. If I/I is identified as a significant contributor, repairs to the collection system would be necessary.

Q 27. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations is paramount in wastewater treatment. This involves a multifaceted approach:

Understanding regulations: Thorough understanding of all applicable local, state, and federal environmental regulations, including discharge permits (e.g., NPDES permits in the US). This includes staying updated on any changes or amendments to regulations.

Regular monitoring and testing: Regularly monitoring and testing effluent quality to ensure compliance with permit limits. This involves collecting samples according to the permit requirements and submitting them to accredited laboratories for analysis.

Record keeping: Maintaining accurate and detailed records of all monitoring data, maintenance activities, and any deviations from normal operating parameters. These records are essential for demonstrating compliance to regulatory agencies during inspections.

Reporting: Submitting regular reports to the regulatory agencies as required by the discharge permits. These reports detail the plant’s performance, any deviations from permit limits, and any corrective actions taken.

Employee training: Ensuring all plant personnel are adequately trained on environmental regulations and their responsibilities in maintaining compliance.

Compliance is not just a matter of avoiding penalties; it is about protecting public health and the environment. Proactive management and a culture of compliance are essential for long-term sustainability.

Q 28. Describe a time you had to troubleshoot a complex wastewater problem; what was the outcome?

One challenging situation involved a sudden and significant increase in effluent ammonia levels, exceeding permit limits. Initial investigations revealed no obvious causes within the treatment plant itself. After analyzing operational data, we noticed a correlation between high ammonia levels and rainfall events. This led us to suspect infiltration/inflow (I/I) of ammonia-rich stormwater into the collection system.

We conducted a thorough investigation of the collection system, using CCTV cameras to identify potential infiltration points. This revealed several damaged sewer lines and manholes allowing stormwater infiltration. We collaborated with the municipality’s infrastructure department to prioritize repairs to these compromised sections of the collection system. Additionally, we implemented a temporary strategy to manage ammonia levels at the plant, using enhanced aeration and chemical treatment. Within three months, following the repair of the damaged sewer lines, effluent ammonia levels returned to normal, and we successfully averted potential regulatory sanctions.

This experience reinforced the importance of thorough investigation, interdepartmental collaboration, and the value of integrating both short-term management strategies and long-term infrastructure solutions when dealing with complex wastewater issues.

Key Topics to Learn for Wastewater Troubleshooting Interview

- Wastewater Treatment Processes: Understanding the different stages of wastewater treatment (primary, secondary, tertiary) and their respective unit processes (e.g., screening, grit removal, activated sludge, disinfection).

- Process Control and Instrumentation: Familiarize yourself with common instruments used for monitoring and controlling wastewater treatment processes (e.g., flow meters, pH sensors, dissolved oxygen probes) and their applications in troubleshooting.

- Troubleshooting Common Process Issues: Develop a systematic approach to identify and resolve common problems like high ammonia levels, low dissolved oxygen, sludge bulking, and foaming. Practice analyzing process data to pinpoint the root cause of malfunctions.

- Pump and Blower Systems: Understand the operation, maintenance, and troubleshooting of pumps and blowers crucial for efficient wastewater treatment. This includes recognizing symptoms of malfunctions and knowing appropriate repair procedures.

- Safety Protocols and Regulations: Demonstrate awareness of relevant safety regulations and procedures within wastewater treatment plants. Understanding proper PPE usage and emergency response procedures is essential.

- SCADA Systems (Supervisory Control and Data Acquisition): Familiarity with SCADA systems and their role in monitoring and controlling the entire wastewater treatment process. Knowing how to interpret data from SCADA systems is highly valuable.

- Biological Processes: A strong understanding of the microbial processes involved in wastewater treatment, including the roles of different microorganisms and factors affecting their activity.

- Chemical Treatment: Knowledge of the various chemicals used in wastewater treatment (e.g., coagulants, flocculants, disinfectants) and their applications in solving specific process challenges.

- Data Analysis and Interpretation: Ability to analyze process data (flow rates, effluent quality parameters, etc.) to identify trends, anomalies, and potential problems. Practicing data analysis skills is key.

Next Steps

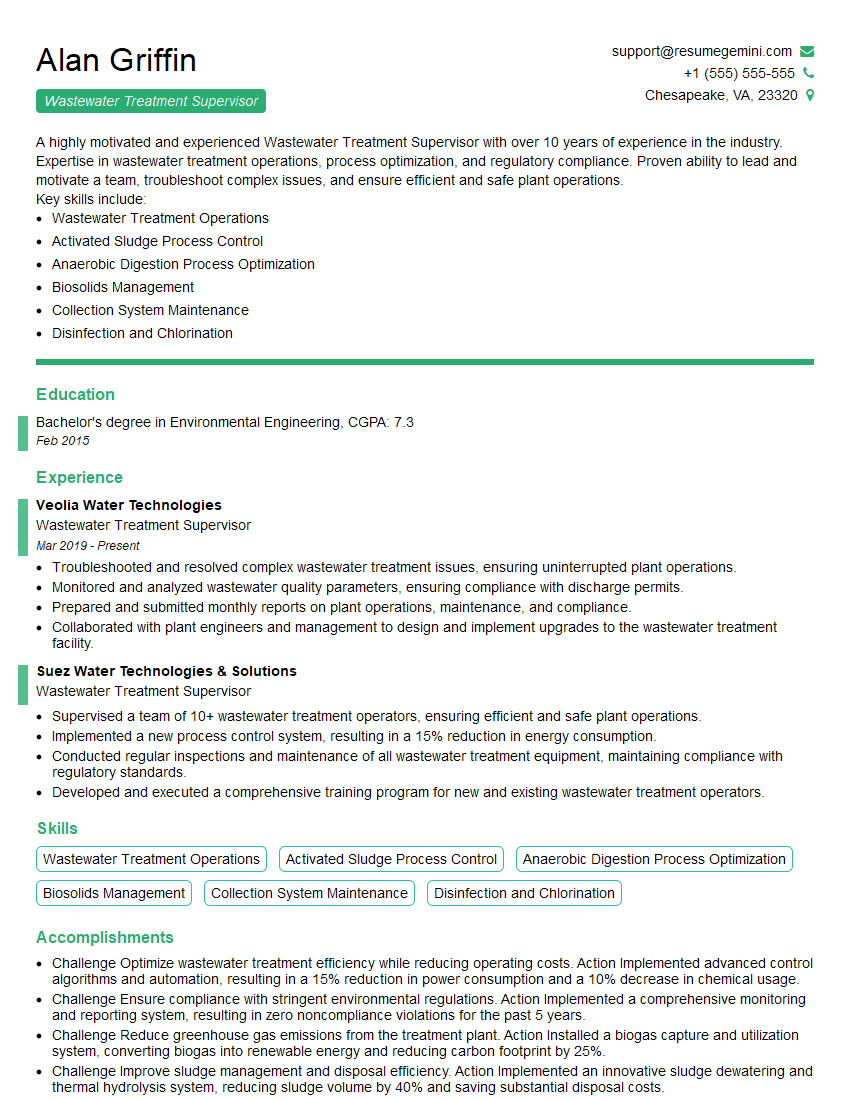

Mastering wastewater troubleshooting is crucial for career advancement in this vital field, opening doors to specialized roles and increased earning potential. To enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your specific needs. Examples of resumes tailored for Wastewater Troubleshooting professionals are provided to guide you. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.