Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Water Purification System Maintenance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Water Purification System Maintenance Interview

Q 1. Describe your experience with troubleshooting malfunctioning reverse osmosis (RO) systems.

Troubleshooting malfunctioning reverse osmosis (RO) systems requires a systematic approach. I begin by assessing the system’s overall performance, checking for low water production, high TDS in the purified water, or unusual noises. This initial assessment helps pinpoint the likely area of the problem. For instance, low water production often indicates a clogged pre-filter, a faulty pump, or membrane failure. High TDS points towards membrane fouling or a failing membrane.

My troubleshooting steps usually involve:

- Visual Inspection: Checking all connections for leaks, inspecting the pre-filters for clogging, and examining the pressure gauge for proper pressure levels.

- Testing: Measuring TDS levels at various stages of the system (pre-filter, post-filter, and purified water output) to identify where the problem lies. I also check the water pressure at the inlet.

- Component Replacement: If necessary, I replace clogged pre-filters, damaged membranes, or faulty pumps. For example, I recently diagnosed a system with consistently high TDS post-RO. After thorough testing, I identified a failing RO membrane as the culprit, replacing it solved the issue immediately.

- System Cleaning: In cases of membrane fouling (accumulation of contaminants on the membrane surface), I perform a chemical cleaning following the manufacturer’s guidelines. This usually involves using citric acid or other specialized cleaning solutions.

Through this systematic process, I can quickly and effectively diagnose and resolve most RO system malfunctions, minimizing downtime and ensuring optimal water quality.

Q 2. Explain the process of membrane cleaning and replacement in a water purification system.

Membrane cleaning and replacement are crucial for maintaining the efficiency and lifespan of a water purification system. The frequency of these procedures depends on factors such as the water source quality and the system’s usage. Regular cleaning prevents membrane fouling, which reduces purification efficiency and increases pressure requirements.

Membrane Cleaning: This process typically involves using a chemical cleaning solution specific to the membrane type. The solution is circulated through the membrane for a predetermined time, dissolving accumulated minerals and organic matter. The specific procedure and cleaning solution are always dictated by the manufacturer’s instructions. Improper cleaning solutions or techniques can damage the membranes. After the cleaning cycle, the system is thoroughly rinsed to remove any residual cleaning solution.

Membrane Replacement: Membranes have a limited lifespan, typically ranging from 1 to 3 years, depending on usage and water quality. As membranes age, their performance deteriorates, leading to decreased water production and increased TDS. Replacement is necessary when the membrane can no longer efficiently purify water, despite thorough cleaning attempts. Replacement involves carefully removing the old membrane and installing a new one of the same type, ensuring proper sealing to prevent leaks.

Think of a coffee filter – after several uses, it becomes clogged and needs replacing. Similarly, the RO membrane can become clogged with impurities, requiring either cleaning or eventually, replacement.

Q 3. What are the common causes of high total dissolved solids (TDS) in purified water?

High total dissolved solids (TDS) in purified water, after a water purification system, indicates that the system isn’t effectively removing dissolved minerals and salts. Several factors can contribute to this problem:

- Faulty or Fouled Membrane: The most common cause. A damaged or clogged RO membrane cannot efficiently remove dissolved solids.

- Clogged Pre-filters: If the pre-filters aren’t regularly replaced, they become clogged with sediment and other particles, reducing the effectiveness of the RO membrane.

- High TDS in Source Water: If the source water itself has a very high TDS, the system may struggle to reduce it to acceptable levels, even if functioning correctly. This requires a more powerful or multi-stage filtration system.

- Leaking System Components: A leak in the system can bypass the filtration stages, causing unpurified water to mix with the purified water, resulting in higher TDS.

- Improper System Operation: Incorrect water pressure or flow rate can affect purification efficiency.

Identifying the root cause requires a methodical approach, involving checking pre-filter condition, TDS measurements at different stages, and assessing membrane condition. A recent case involved a client with persistently high TDS. I traced the issue to a hairline crack in the RO membrane housing, causing unfiltered water to bypass the membrane.

Q 4. How do you maintain optimal pressure levels within a water purification system?

Maintaining optimal pressure levels is critical for efficient water purification. Most systems require a specific pressure range for optimal performance. Insufficient pressure reduces water flow and purification efficiency, while excessive pressure can damage the membranes and other components.

Pressure maintenance involves:

- Regular Pressure Gauge Checks: Monitoring the inlet and outlet pressure gauges to ensure they’re within the manufacturer’s specified range.

- Boost Pump Adjustment: If the inlet pressure is too low, a boost pump can increase it to the required level. This needs careful adjustment to avoid over-pressurization.

- Leak Detection and Repair: Addressing any leaks promptly, as leaks reduce system pressure and compromise its performance.

- Pre-filter Maintenance: Clogged pre-filters increase the pressure drop across the system, so regular replacement is crucial.

Think of it like watering your garden: Too little pressure, and the water barely reaches the plants; too much pressure, and you risk damaging the hose. Similarly, precise pressure control is essential for efficient and safe operation of the water purification system.

Q 5. Describe your experience with UV disinfection systems and their maintenance.

UV disinfection systems utilize ultraviolet light to kill bacteria and viruses in water. Maintenance focuses on ensuring the lamp’s effectiveness and the system’s overall cleanliness.

My experience includes:

- Lamp Replacement: UV lamps have a limited lifespan and require periodic replacement, usually indicated by a decrease in UV intensity. This involves carefully removing the old lamp and installing a new one, ensuring proper alignment and contact.

- Quartz Sleeve Cleaning: The quartz sleeve that encases the UV lamp can become coated with minerals and organic matter, reducing UV transmission. Regular cleaning, often using a mild acid solution following manufacturer’s instructions, is necessary to maintain its transparency.

- Sensor Calibration: UV systems often have a sensor to monitor UV intensity. Periodic calibration ensures accurate readings and ensures the lamp is operating at its optimal intensity.

- System Inspection: Regular visual inspections check for leaks, damaged components, and proper functionality.

For example, I once worked on a system where the UV lamp had degraded, leading to a significant drop in disinfection efficiency. Replacing the lamp immediately rectified the issue and restored the desired level of disinfection.

Q 6. Explain the importance of regular water quality testing and analysis.

Regular water quality testing and analysis are indispensable for ensuring the system’s effectiveness and the safety of the purified water. Testing provides valuable insights into the system’s performance and allows for proactive maintenance.

The importance lies in:

- Monitoring System Performance: Testing allows us to track TDS, pH, bacterial contamination, and other parameters to assess the system’s purification efficiency over time. Any significant deviation from the baseline indicates potential problems.

- Proactive Maintenance: Early detection of issues through testing enables timely intervention, preventing more significant problems and costly repairs. For instance, a rise in bacterial count could indicate a failing UV lamp, allowing for prompt replacement.

- Ensuring Water Safety: Regular testing confirms that the purified water meets the required safety standards, protecting consumers from potential health risks. I always ensure that my testing protocols comply with all relevant regulations.

- Compliance: In many jurisdictions, regular water quality testing is mandated for commercial water purification systems. This ensures compliance with local regulations and ensures the business avoids legal issues.

Think of it like a medical checkup – regular testing allows for early detection and treatment of potential health problems.

Q 7. What are the safety procedures you follow when handling chemicals used in water treatment?

Safety is paramount when handling chemicals used in water treatment. These chemicals can be corrosive, toxic, or harmful if mishandled. My safety procedures include:

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including gloves, eye protection, and a lab coat, when handling any chemicals. This protects against splashes and inhalation.

- Proper Chemical Handling: Following the manufacturer’s instructions carefully, paying close attention to storage, mixing, and disposal guidelines. This ensures safe and effective usage.

- Ventilation: Working in a well-ventilated area to minimize exposure to chemical fumes. This minimizes the risk of inhalation of harmful chemicals.

- Spill Response Plan: Having a clear spill response plan in place to handle accidental spills safely and efficiently. This plan should include procedures for containment, neutralization, and cleanup.

- Waste Disposal: Following all local and national regulations for proper disposal of chemical waste, to prevent environmental contamination.

- Training and Knowledge: Continuous training and updating on safe chemical handling practices. This ensures that I always follow the safest and most effective procedures.

I always prioritize safety, ensuring that all procedures are carried out according to the highest safety standards. A safe working environment protects both myself and the environment.

Q 8. How do you identify and address scaling issues in water purification systems?

Scaling, the buildup of mineral deposits on surfaces, is a common problem in water purification systems. It reduces efficiency and can damage equipment. Identifying scaling involves visually inspecting components like pipes, membranes, and filters for white or chalky deposits. We can also measure water hardness using a simple test kit to quantify the mineral content. Addressing scaling involves a multi-pronged approach. Regularly cleaning with appropriate descaling solutions, based on the type of scale (e.g., citric acid for calcium carbonate), is crucial. For severe scaling, physical removal may be needed, followed by a thorough cleaning. Preventative measures include pre-treatment such as water softening or using scale inhibitors in the system. For instance, in a reverse osmosis (RO) system, I’ve seen significant improvements by installing a pre-filter to remove larger particles that contribute to scaling on the RO membranes.

For example, in one project, we noticed reduced RO membrane performance. Visual inspection confirmed heavy scaling. We used a specialized citric acid solution to clean the membranes, restoring their performance to 95% of their original capacity. We also implemented a regular descaling schedule, reducing future issues.

Q 9. Describe your experience with different types of filtration media (e.g., sand, carbon).

My experience encompasses a wide range of filtration media. Sand filters are a cost-effective method for removing suspended solids. They require regular backwashing to remove accumulated sediment. I’ve worked extensively with different sand types, selecting the appropriate size and grading based on the water source characteristics and desired filtration level. Granular activated carbon (GAC) is effective in removing organic compounds, chlorine, and taste and odor issues. I’ve handled GAC replacement and reactivation procedures, ensuring optimal adsorption capacity. Other media I’m familiar with include anthracite coal (used in conjunction with sand for improved filtration), and specialized media like KDF (kinetic degradation fluxion) which removes heavy metals. The choice of media depends on the specific contaminants needing removal and the system’s design.

For example, in a rural community project, we used a multi-media filter bed containing sand, anthracite, and GAC to treat surface water with high levels of turbidity, organic matter and chlorine. This layered approach provided effective filtration, ensuring safe drinking water. Regular monitoring and backwashing ensured optimal system performance.

Q 10. How do you troubleshoot issues related to pump malfunctions in a water treatment plant?

Troubleshooting pump malfunctions involves a systematic approach. First, I check basic parameters like power supply, fuses, and circuit breakers. A simple issue could be a tripped breaker or a loose connection. Then, I listen for unusual noises – grinding, humming, or unusual vibrations indicate mechanical problems. I’ll inspect the pump casing for leaks and check pressure gauges to assess if the pump is generating the required pressure. Low pressure could signal a problem with impellers, seals, or suction issues. High pressure could indicate clogging or a malfunctioning pressure switch. Sometimes, simple issues like airlocks in the system can be resolved by purging the lines. More complex problems may require motor testing, impeller replacement, or seal repair. If the problem persists, specialized pump repair technicians might be called in.

In one instance, a high-pressure alarm triggered on a main booster pump. Initial checks revealed no obvious issues. Eventually, we discovered a partially blocked strainer on the suction side, restricting water flow and causing excessive pressure. Cleaning the strainer resolved the problem highlighting the importance of regular inspection of all components.

Q 11. Explain your understanding of water purification system automation and control systems.

Water purification system automation uses Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems to monitor and control various aspects of the treatment process. This includes automated control of pumps, valves, chemical dosing, and backwashing cycles. Sensors continuously monitor parameters like pressure, flow rate, pH, and turbidity, providing real-time data. The PLC uses this data to make adjustments and trigger alarms if parameters fall outside set ranges. SCADA systems provide a centralized interface to visualize process parameters, control equipment, and generate reports. Automation improves efficiency, optimizes resource use, and enhances safety by reducing manual intervention.

For instance, I’ve worked with a plant utilizing a SCADA system that remotely monitored and controlled all aspects of the treatment plant, from chemical feed to filter backwashing. The system generated daily reports and alerted operators of any deviations from normal operating conditions which allowed for proactive maintenance and improved efficiency.

Q 12. How do you interpret water quality reports and identify potential problems?

Interpreting water quality reports involves carefully reviewing various parameters. Key indicators include turbidity (measuring water clarity), pH (acidity/alkalinity), dissolved solids (minerals and salts), specific contaminants (e.g., heavy metals, pesticides), and microbiological parameters (bacteria and viruses). I compare the results against regulatory standards and the treatment plant’s performance goals. Deviations from the norm can point to issues. For instance, unexpectedly high turbidity could suggest a problem with the pre-treatment system. Elevated levels of a specific contaminant might indicate a malfunction in a particular treatment unit or a problem with the source water. Understanding the correlation between different parameters is crucial for identifying the root cause of any water quality issues.

For example, a sudden increase in coliform bacteria in the final treated water indicated a potential problem with the disinfection process. We investigated the chlorine dosing system and discovered a malfunctioning chlorine pump leading to sub-optimal disinfection. Prompt action corrected the issue and prevented a potentially serious health hazard.

Q 13. What is your experience with preventative maintenance schedules for water purification equipment?

Preventative maintenance is crucial for ensuring reliable operation and extending the lifespan of water purification equipment. Schedules are based on manufacturer recommendations, equipment type, and operational conditions. They typically include regular inspections, cleaning, lubrication, and replacement of worn-out parts. For example, membranes in RO systems need regular cleaning to maintain performance. Pumps require periodic lubrication and seal checks. Filters need backwashing or replacement as needed. A well-defined schedule prevents catastrophic failures, minimizes downtime, and optimizes operational costs. Detailed logs track all maintenance activities, enabling efficient monitoring and providing a history for future reference.

In one plant, we implemented a detailed PM schedule resulting in a 20% reduction in unplanned downtime and a 15% decrease in repair costs over a two-year period. The proactive approach significantly improved the reliability of the entire system.

Q 14. Describe your experience with different types of water purification technologies (e.g., RO, UF, MF).

My experience includes various water purification technologies. Reverse Osmosis (RO) utilizes semi-permeable membranes to remove dissolved salts and other impurities. It’s highly effective but energy-intensive. Ultrafiltration (UF) uses membranes with larger pores than RO, removing suspended solids, bacteria, and some viruses. It’s less energy-intensive than RO. Microfiltration (MF) is similar to UF but with even larger pores, primarily removing larger suspended particles. The choice of technology depends on the water quality, desired level of purification, and cost considerations. Often, these technologies are used in combination. For example, a multi-stage system might use MF followed by UF and then RO for optimal results. Each process requires different maintenance protocols; for example, RO membranes are more prone to scaling and fouling than UF membranes.

I’ve worked on projects using all three technologies. In one instance, we used an MF/UF system followed by disinfection to treat wastewater for reuse in irrigation; the pre-filtration steps protected the disinfection system and allowed for efficient water reuse. Another project used RO to produce high-quality water for industrial use, emphasizing maintenance strategies to prevent membrane fouling and ensure longevity.

Q 15. How do you ensure compliance with relevant water quality regulations and standards?

Ensuring compliance with water quality regulations is paramount in water purification. This involves a multi-faceted approach, beginning with a thorough understanding of the relevant standards – for example, the EPA’s Safe Drinking Water Act in the US, or equivalent regulations in other countries. We maintain a comprehensive compliance program that includes:

- Regular testing: We conduct frequent water quality testing, following a meticulously planned schedule, to monitor parameters like pH, turbidity, chlorine residual, and microbial counts. The frequency and specific tests are determined by the regulations and the specific system’s design.

- Record-keeping: Meticulous documentation is crucial. We maintain detailed logs of all testing results, maintenance activities, chemical additions, and any corrective actions taken. This ensures traceability and facilitates audits.

- Calibration and maintenance: All monitoring instruments and equipment are regularly calibrated and maintained according to manufacturer’s recommendations and regulatory guidelines. This prevents inaccurate readings and ensures reliable data.

- Staff training: Our staff undergoes regular training on water quality regulations, testing procedures, and best practices for safe operation and maintenance. This ensures everyone understands their responsibilities and the importance of compliance.

- Audits and inspections: We welcome and actively participate in regular audits and inspections by regulatory bodies to demonstrate our commitment to compliance and identify any areas for improvement.

For instance, in one project, we discovered a slight deviation in chlorine levels during a routine check. By promptly investigating, we identified a minor leak in the chlorine feed line and rectified it before any violation occurred, demonstrating our proactive approach to compliance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with troubleshooting issues related to chlorine disinfection.

Troubleshooting chlorine disinfection issues requires a systematic approach. Problems often manifest as insufficient residual chlorine, high levels of chlorine byproducts, or the presence of chlorine-resistant organisms. My approach includes:

- Identifying the problem: This involves reviewing chlorine residual readings, checking for unusual water quality parameters (e.g., increased turbidity), and examining operational logs for any changes in feed rates or other relevant factors.

- Checking the chlorination system: This involves inspecting the chlorine feed system for leaks, blockages, or malfunctioning components such as the pump, injector, or flow meter. Accurate calibration is key.

- Assessing water flow and contact time: Ensuring adequate contact time between chlorine and water is critical for effective disinfection. Problems here might involve faulty flow control valves or insufficient tank residence time. This often requires flow calculations and understanding of hydraulic residence time.

- Evaluating water quality: High levels of organic matter or other contaminants can consume chlorine, reducing the residual. Understanding the water source’s characteristics is vital for adjusting the chlorine feed rate accordingly.

- Testing for chlorine byproducts: Excess chlorine can lead to the formation of undesirable byproducts like trihalomethanes (THMs). Regular testing and adjustments to the chlorination process can mitigate this risk.

For example, I once encountered consistently low chlorine residuals in a system despite sufficient chlorine feed. A thorough investigation revealed biofouling in the chlorine contact chamber, reducing the effective contact time. Cleaning the chamber resolved the issue.

Q 17. Explain the process of conducting a complete system shutdown and restart for maintenance.

A complete system shutdown and restart for maintenance is a crucial procedure. Safety is paramount, requiring a standardized and documented procedure. The process involves:

- Planning and scheduling: This involves coordinating with all stakeholders, including operators, maintenance personnel, and potentially clients. A detailed work plan outlining all tasks and expected downtime is essential.

- System isolation: This involves safely isolating the system from the water source and distribution network, using valves and other isolation devices. Verification that isolation is complete is vital before proceeding.

- Equipment shutdown: All pumps, filters, and other equipment are shut down in a safe and orderly manner, following manufacturer’s instructions.

- Maintenance activities: This includes tasks such as filter backwashing, membrane cleaning (if applicable), chemical cleaning, equipment inspections, and repairs.

- System flushing: Following maintenance, the system is thoroughly flushed to remove any debris or contaminants accumulated during the process.

- System startup: The system is restarted in a phased manner, monitoring pressure, flow rates, and water quality parameters at each stage.

- Verification and testing: After startup, comprehensive testing is conducted to verify that the system is functioning correctly and water quality meets standards.

Think of it like servicing a car; you wouldn’t start work before ensuring it’s safely jacked up and disconnected from power.

Q 18. What are the common causes of microbial contamination in purified water, and how do you prevent it?

Microbial contamination in purified water is a serious concern. Common causes include:

- Biofilm formation: Biofilms are colonies of microorganisms that adhere to surfaces within the water system, providing a protected environment for growth.

- Ingress of contaminants: Contamination can enter the system through leaks, cracks, or inadequate disinfection of the source water.

- Insufficient disinfection: Inadequate chlorine levels or other disinfection methods can fail to eliminate microorganisms.

- Stagnant water: Water that remains stagnant in parts of the system can support microbial growth.

Prevention strategies include:

- Regular cleaning and disinfection: This includes routine cleaning and disinfection of the system, focusing on areas prone to biofilm formation.

- Proper system design: A well-designed system minimizes dead legs (areas of stagnant water) and facilitates easy cleaning and maintenance.

- Effective disinfection: Ensuring adequate disinfection throughout the system using appropriate methods and maintaining sufficient residual chlorine.

- Regular monitoring: Continuous monitoring of microbial levels through regular testing and analysis provides early detection of any contamination.

- Material selection: Choosing materials resistant to biofilm formation and corrosion.

For example, a system exhibiting high bacterial counts may indicate insufficient chlorine residual or a leak introducing contaminants. Addressing these root causes is key.

Q 19. How do you manage and dispose of hazardous waste generated during water treatment?

Hazardous waste management is crucial in water treatment. This involves proper handling, storage, and disposal of materials like spent activated carbon, used filter media, and certain cleaning chemicals. We follow a strict protocol:

- Waste characterization: Identifying the type and quantity of hazardous waste generated, based on regulatory definitions and safety data sheets (SDS).

- Proper storage: Storing hazardous waste in appropriately labeled containers and designated storage areas, ensuring compliance with regulations and safety standards.

- Transportation: Using licensed and insured waste haulers to transport hazardous waste to permitted disposal facilities.

- Record-keeping: Meticulous documentation of waste generation, storage, transportation, and disposal, including manifests and other required paperwork.

- Compliance with regulations: Adhering to all local, state, and federal regulations regarding hazardous waste management. This often involves working with environmental consultants to ensure all necessary permits and approvals are in place.

We treat used activated carbon as hazardous waste due to the potential for adsorbed contaminants. It’s crucial to document every step of its handling and disposal to maintain compliance.

Q 20. Describe your experience with using and maintaining water quality monitoring instruments.

Water quality monitoring instruments are essential for ensuring the effectiveness of our purification systems. My experience includes working with various instruments such as:

- Turbidimeters: Measure water clarity, indicating the presence of suspended particles.

- pH meters: Measure the acidity or alkalinity of water.

- Chlorine analyzers: Measure the concentration of chlorine in the treated water.

- Conductivity meters: Measure the ability of water to conduct electricity, indicating the presence of dissolved ions.

- Microbial testing equipment: Used for bacterial plate counts and other microbial analyses.

Maintaining these instruments involves:

- Regular calibration: Following manufacturer’s instructions and using certified calibration standards to ensure accurate readings.

- Preventive maintenance: Performing regular cleaning, inspections, and preventative maintenance to prolong the lifespan of the equipment.

- Data logging and analysis: Recording and analyzing data to identify trends and potential problems.

- Troubleshooting: Diagnosing and resolving malfunctions, often requiring knowledge of the instruments’ inner workings.

For instance, I once noticed a drift in a pH meter’s readings. By performing a calibration check, I identified a faulty electrode and replaced it, ensuring accurate monitoring of pH levels.

Q 21. What is your experience with troubleshooting issues related to chemical feed systems?

Chemical feed systems are crucial for delivering precise amounts of chemicals during water treatment. Troubleshooting issues often involves a systematic approach, focusing on:

- Chemical feed pump: Checking for leaks, blockages, or malfunctioning pumps. This often includes inspecting pump diaphragms, seals, and motors.

- Chemical delivery lines: Inspecting the lines for blockages, leaks, or corrosion. This might require flushing or replacement of sections of the lines.

- Chemical storage tanks: Ensuring adequate chemical levels, checking for leaks in the tanks and inspecting for proper agitation (if necessary).

- Control systems: Inspecting the controllers, sensors, and alarms to ensure they are functioning correctly and providing accurate measurements of chemical feed rate and concentration.

- Chemical compatibility: Ensuring the chemicals used are compatible with the materials of construction of the feed system and the water being treated to avoid corrosion or unwanted reactions.

In one instance, a sudden drop in chemical feed rate was traced to a clogged injector. Cleaning the injector quickly restored the proper feed rate and prevented any impact on water quality. A key lesson was always verifying the cleanliness of the injector and the flow control valve during system checks.

Q 22. How do you maintain accurate records of maintenance activities and water quality data?

Maintaining accurate records in water purification is crucial for ensuring system efficiency and regulatory compliance. We use a combination of digital and physical methods. Digitally, we employ a computerized maintenance management system (CMMS). This software allows for scheduling preventative maintenance, tracking repairs, recording water quality test results, and generating reports. Data points like filter changes, chemical additions, pressure readings, and turbidity levels are meticulously logged. We also use sensor-based data logging systems that automatically record key parameters in real-time, minimizing manual data entry and reducing the risk of human error. Physically, we maintain hard copies of critical data in a secure, readily accessible location, serving as a backup and ensuring continuity in case of digital system failures. Each entry is meticulously documented, including dates, times, personnel involved, and any observations made. This dual approach ensures data integrity and accessibility.

Q 23. Explain your understanding of the different types of water purification system designs.

Water purification systems vary greatly depending on the source water quality and desired end-use. Common designs include:

- Membrane-based systems: These utilize membranes like reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) to separate contaminants from water. RO is particularly effective for removing dissolved salts and minerals. The choice of membrane type depends on the specific contaminants present.

- Distillation systems: These boil water and condense the steam, leaving behind impurities. While highly effective at removing many contaminants, they are energy-intensive.

- Adsorption systems: These employ activated carbon or other adsorbent materials to remove organic compounds, chlorine, and other contaminants. Granular activated carbon (GAC) filters are commonly used in various purification stages.

- Ion exchange systems: These use resin beads to remove ions like calcium, magnesium, and other dissolved minerals, often used for softening water.

- Combination systems: Many systems combine multiple techniques for optimal purification. For instance, a typical municipal system might use coagulation, flocculation, sedimentation, filtration (sand, anthracite, GAC), and disinfection (chlorination, UV).

Understanding the strengths and weaknesses of each design is vital for selecting and maintaining an effective system. The optimal choice depends entirely on the specific application and the nature of the contaminants present in the source water.

Q 24. How do you prioritize maintenance tasks based on system criticality and potential risks?

Prioritizing maintenance tasks requires a risk-based approach. We use a combination of factors to determine urgency:

- Criticality of the system: Systems providing potable water for human consumption or critical industrial processes receive higher priority than those used for less critical applications. For example, a malfunction in the RO system supplying drinking water would require immediate attention.

- Potential risks associated with failure: This includes risks to human health (e.g., bacterial contamination), environmental damage (e.g., chemical leaks), and economic losses (e.g., plant downtime). The likelihood and severity of these risks are considered.

- Manufacturer recommendations: We strictly adhere to the manufacturer’s guidelines for preventative maintenance schedules for components like pumps, valves, membranes, and filters.

- Past performance data: Analysis of historical data on equipment failures and maintenance needs helps predict future requirements and proactively address potential issues before they occur.

We often employ a weighted scoring system, combining these factors to create a prioritized task list. This ensures that the most critical tasks are addressed promptly, minimizing potential risks and ensuring system reliability.

Q 25. Describe a time you had to troubleshoot a complex water purification system problem.

In a large municipal water treatment plant, we experienced a significant drop in the effluent quality, specifically an increase in turbidity. Initial investigations revealed no obvious mechanical failures. Through a systematic troubleshooting process, we:

- Checked the raw water quality: We found no significant change in the source water turbidity, ruling out that as the primary cause.

- Inspected the coagulation and flocculation process: We discovered that the chemical dosing system for coagulant had malfunctioned, resulting in insufficient coagulation. The faulty sensor was identified and replaced.

- Verified filter performance: After correcting the chemical dosing, we backwashed the filters to remove accumulated solids. Regular filter performance monitoring was reinforced to identify potential issues earlier.

- Tested the effluent: After adjustments and backwashing, turbidity levels returned to normal. The plant resumed its regular operation.

This experience highlighted the importance of detailed monitoring, systematic troubleshooting, and the value of continuous improvement in our maintenance protocols. We implemented additional sensor redundancy and a more robust alarm system to prevent similar incidents.

Q 26. What are the key performance indicators (KPIs) you monitor to assess the effectiveness of a water purification system?

Key Performance Indicators (KPIs) are critical for assessing the effectiveness of a water purification system. We monitor several parameters, including:

- Water quality parameters: Turbidity, pH, chlorine residual, total dissolved solids (TDS), bacterial count, and presence of specific contaminants (e.g., heavy metals). These indicators ensure the purified water meets regulatory standards and desired quality levels.

- System efficiency: This includes energy consumption, water recovery rate (especially in membrane systems), and chemical usage. Optimized efficiency translates into cost savings and environmental sustainability.

- Equipment reliability: Mean time between failures (MTBF) and mean time to repair (MTTR) for critical components indicate the overall reliability and robustness of the system.

- Compliance with regulations: Regular audits and reports ensure that the system adheres to all relevant health and environmental regulations.

Regular monitoring of these KPIs allows us to identify trends, predict potential problems, and make data-driven decisions to optimize system performance and ensure compliance.

Q 27. How do you stay updated on the latest technologies and best practices in water purification?

Staying updated is paramount in this rapidly evolving field. We employ several strategies:

- Professional memberships: Active participation in organizations like the American Water Works Association (AWWA) provides access to publications, conferences, and networking opportunities with other professionals.

- Industry publications and journals: We regularly read journals like the Journal of the American Water Works Association and other relevant publications to stay abreast of the latest research and technological advancements.

- Conferences and workshops: Attending industry conferences and workshops allows us to learn from experts, see demonstrations of new technologies, and network with peers.

- Manufacturer training: We participate in training courses offered by equipment manufacturers to enhance our knowledge of specific technologies and best practices.

- Online resources: We utilize online resources, including reputable websites and online courses, to access information on the latest technologies and techniques.

Continuous learning is essential for ensuring we utilize the most effective and efficient methods for water purification system maintenance.

Q 28. Describe your experience with working in a team environment to maintain a large-scale water purification system.

Maintaining a large-scale water purification system requires effective teamwork and communication. In my previous role, our team consisted of engineers, technicians, and operators. We used a structured approach:

- Clear roles and responsibilities: Each team member had clearly defined responsibilities, minimizing confusion and maximizing efficiency.

- Regular meetings and communication: We held regular meetings to discuss maintenance schedules, address any issues, and share updates on system performance. We utilize various communication tools for immediate updates.

- Collaborative problem-solving: When problems arose, we worked together to identify the root cause and implement solutions. This fostered a sense of shared ownership and accountability.

- Training and mentorship: Experienced members mentored newer team members, fostering knowledge transfer and improving overall team capabilities.

Successful team collaboration is critical for ensuring the reliable and efficient operation of a large-scale water purification system, minimizing downtime and maximizing the quality of the purified water.

Key Topics to Learn for Water Purification System Maintenance Interview

- Membrane Technology: Understanding different membrane types (RO, UF, MF), their operating principles, and common failure modes. Practical application: Troubleshooting membrane fouling and cleaning procedures.

- Pre-treatment Systems: Knowledge of various pre-treatment methods (filtration, coagulation, flocculation) and their impact on overall system efficiency. Practical application: Selecting appropriate pre-treatment based on source water quality.

- Disinfection Processes: Familiarity with UV disinfection, chlorination, and ozonation; understanding their effectiveness and safety considerations. Practical application: Monitoring disinfectant levels and addressing residual issues.

- System Automation and Controls: Proficiency in understanding PLC programming, SCADA systems, and automated control strategies for water purification systems. Practical application: Diagnosing and resolving system malfunctions through control system analysis.

- Water Quality Monitoring and Analysis: Understanding key water quality parameters (pH, turbidity, conductivity, etc.) and using appropriate testing methods. Practical application: Interpreting test results to identify operational issues and ensure compliance with regulations.

- Troubleshooting and Repair: Developing systematic approaches to diagnose and resolve common equipment malfunctions (pumps, valves, sensors). Practical application: Performing preventative maintenance and implementing corrective actions.

- Safety Procedures and Regulations: Knowledge of relevant safety protocols and compliance requirements for handling chemicals and operating water purification equipment. Practical application: Adhering to safety regulations and reporting any incidents.

- Sustainability and Optimization: Understanding strategies for minimizing energy consumption, reducing waste, and improving the overall environmental footprint of water purification systems. Practical application: Implementing energy-saving measures and optimizing system performance.

Next Steps

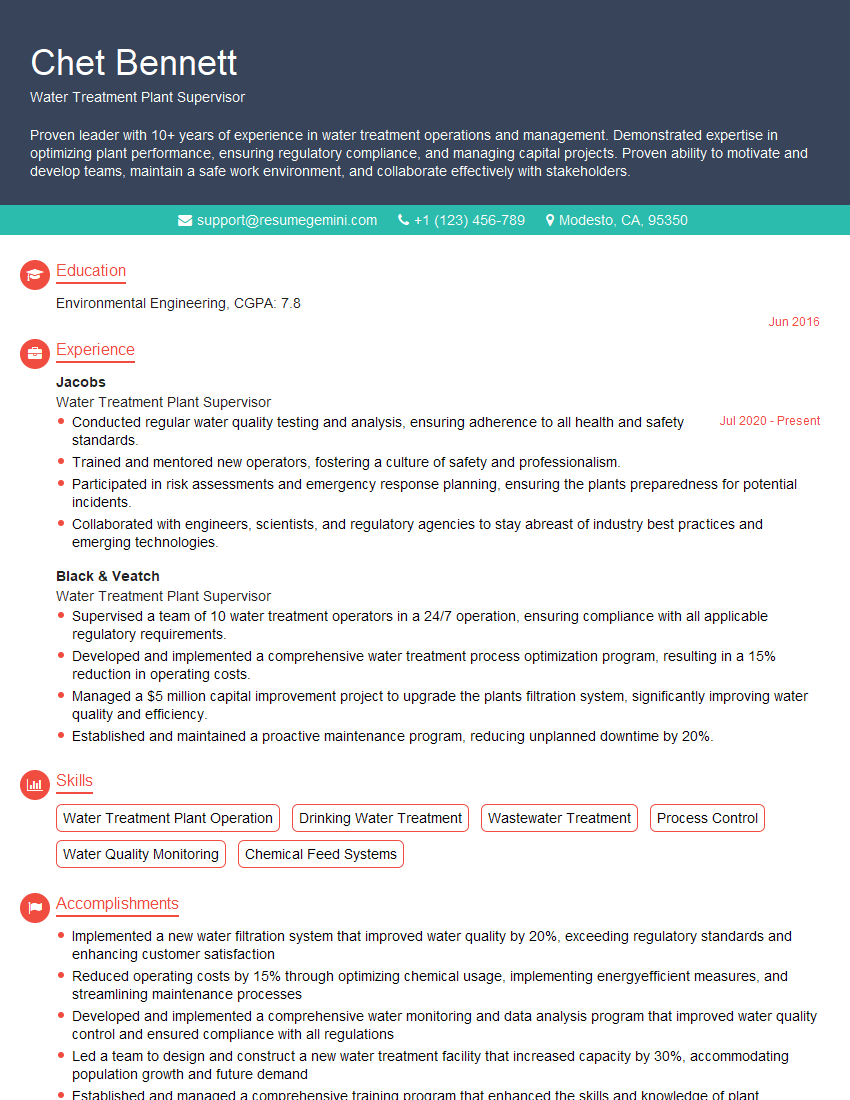

Mastering Water Purification System Maintenance is crucial for career advancement in this vital field. A strong understanding of these systems opens doors to specialized roles, higher salaries, and increased job security. To maximize your job prospects, it’s essential to create an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Water Purification System Maintenance to guide you through the process, ensuring your qualifications shine through to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.