Unlock your full potential by mastering the most common Water Reclamation and Reuse interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Water Reclamation and Reuse Interview

Q 1. Describe the different stages of wastewater treatment.

Wastewater treatment is a multi-stage process designed to remove contaminants from wastewater, making it safe for discharge or reuse. Think of it like cleaning a very dirty shirt – you need several steps to get it sparkling clean. The typical stages are:

- Preliminary Treatment: This involves removing large debris like sticks, rags, and grit using screens and grit chambers. Imagine a strainer catching the larger food particles before you wash dishes.

- Primary Treatment: This stage uses gravity to settle out heavier solids, forming sludge at the bottom of a sedimentation tank. Think of letting the mud settle at the bottom of a muddy puddle.

- Secondary Treatment: Here, biological processes break down dissolved organic matter. This is often done using activated sludge, where microorganisms consume the organic pollutants. Think of this as using detergent to dissolve food stains on the shirt.

- Tertiary Treatment: This is an advanced treatment step focused on removing remaining nutrients (nitrogen and phosphorus) and pathogens. Methods include filtration, disinfection, and advanced oxidation processes. This is like a final rinse to remove any lingering soap residue.

- Sludge Treatment: The sludge collected during primary and secondary treatment is further processed through thickening, digestion, and dewatering before disposal or reuse.

The specific processes and intensity of each stage depend on the quality of the influent wastewater and the intended effluent quality, varying by local regulations and the intended use of the treated water.

Q 2. Explain the principles of membrane filtration in water reclamation.

Membrane filtration in water reclamation uses semi-permeable membranes to separate contaminants from water. Imagine a sieve with incredibly tiny holes – only water molecules can pass, leaving behind pollutants. Several types of membrane filtration are used:

- Microfiltration (MF): Removes suspended solids and bacteria.

- Ultrafiltration (UF): Removes smaller particles, viruses, and some dissolved organic matter.

- Nanofiltration (NF): Removes salts, multivalent ions, and organic molecules.

- Reverse Osmosis (RO): The most advanced method, removing almost all dissolved solids, including salts. It’s like using a super-efficient sieve to remove even the smallest impurities.

Membrane filtration offers high efficiency, automated operation, and produces high-quality water suitable for reuse. The choice of membrane technology depends on the desired effluent quality and cost considerations. For example, RO is effective for potable reuse, but it is more energy-intensive than MF.

Q 3. What are the common disinfection methods used in water reclamation?

Disinfection is a crucial step in water reclamation to eliminate harmful pathogens. The goal is to kill or inactivate disease-causing microorganisms like bacteria and viruses. Common methods include:

- Chlorination: Using chlorine gas or hypochlorite solutions, a well-established and cost-effective method. However, it can produce disinfection byproducts (DBPs).

- UV Disinfection: Exposing water to ultraviolet light, a more environmentally friendly option, with no DBP formation. However, the effectiveness can be reduced by turbidity.

- Ozone Disinfection: Using ozone gas, a powerful oxidant that effectively inactivates pathogens. It also has fewer DBPs than chlorine but is more expensive to implement.

- Chloramine Disinfection: A combination of chlorine and ammonia, providing longer-lasting disinfection in distribution systems. However, it can have other DBP issues.

The selection of a disinfection method is based on factors such as cost, effectiveness, potential DBP formation, and local regulations. Often, a combination of methods is used for enhanced efficacy and safety.

Q 4. How do you monitor and control water quality parameters during treatment?

Continuous monitoring and control are vital to ensure consistent water quality throughout the treatment process. This involves using automated sensors and laboratory analysis to track key parameters:

- pH: Measures the acidity or alkalinity of the water.

- Turbidity: Indicates the cloudiness of the water.

- Dissolved Oxygen (DO): Crucial for the effectiveness of biological processes.

- Nutrient levels (Nitrogen and Phosphorus): To evaluate the efficiency of nutrient removal.

- Pathogen indicators (e.g., E. coli): To ensure effective disinfection.

Automated control systems adjust the treatment processes based on real-time monitoring data. For example, if the DO level drops below a certain threshold, the aeration rate in the activated sludge process is increased. Regular laboratory analysis provides more detailed information and verifies the accuracy of automated sensors. This is akin to a doctor regularly checking a patient’s vital signs – ensuring everything operates within the desired range.

Q 5. What are the key regulations and standards governing water reuse?

Regulations and standards for water reuse vary significantly depending on the intended application and geographic location. Key aspects typically covered include:

- Water Quality Standards: These define the acceptable limits of various contaminants in reclaimed water based on its intended use (e.g., irrigation, industrial use, potable reuse).

- Treatment Requirements: Regulations specify the minimum treatment levels required to achieve the desired water quality standards.

- Monitoring and Reporting: Facilities must regularly monitor water quality parameters and report their findings to the regulatory authorities. This helps ensure accountability and transparency.

- Public Health Protection: Regulations prioritize safeguarding public health by minimizing risks associated with water reuse.

Examples include the EPA’s guidelines for water reuse and the specific regulations set by state and local agencies. It’s like a recipe with clear instructions and quality checks to ensure the final product is safe and meets the standards. Understanding and complying with these regulations is crucial for any water reuse project.

Q 6. Explain the concept of potable water reuse and its challenges.

Potable water reuse refers to the treatment of reclaimed wastewater to a level suitable for drinking. This is a highly advanced process, demanding stringent treatment and monitoring to ensure public health safety. The concept offers a sustainable solution for water-scarce regions.

Challenges associated with potable reuse include:

- High treatment costs: Achieving potable water quality requires extensive and expensive treatment processes, including advanced oxidation, membrane filtration, and advanced disinfection.

- Public perception and acceptance: Overcoming public concerns about the safety and acceptability of drinking reclaimed wastewater is crucial. Education and outreach are key factors in improving public acceptance.

- Regulatory hurdles: Navigating the complex regulatory framework and obtaining necessary permits can be challenging. The regulatory landscape is constantly evolving.

- Trace organic contaminant removal: Removing emerging contaminants such as pharmaceuticals and personal care products remains a challenge, requiring ongoing research and development.

Successful potable reuse projects require careful planning, comprehensive risk assessment, robust monitoring, and strong public engagement. This is a challenging but important frontier for sustainable water management.

Q 7. Describe different types of reclaimed water applications.

Reclaimed water, also known as recycled water, has a wide range of applications depending on its quality:

- Irrigation: Used extensively for agricultural irrigation, landscaping, and golf courses. This is a cost-effective and sustainable way to conserve potable water resources. Examples include irrigation of parks and gardens in arid regions.

- Industrial Use: Used in various industrial processes requiring large volumes of water, such as cooling towers and manufacturing. This reduces the demand for fresh water supplies.

- Toilet Flushing and Non-Potable Water Supply: Used for toilet flushing, fire suppression, and other non-potable applications, conserving potable water for drinking and other critical uses.

- Groundwater Replenishment: Injecting treated wastewater into aquifers to replenish groundwater supplies, especially valuable in areas facing groundwater depletion.

- Potable Reuse: As discussed previously, this represents the most advanced application where reclaimed water is treated to drinking water standards.

The suitability of reclaimed water for a specific application depends on its quality and the specific requirements of the end-use. For instance, irrigation typically requires less stringent treatment than potable reuse.

Q 8. How do you manage sludge produced during wastewater treatment?

Sludge management is a crucial aspect of wastewater treatment. Sludge, the semi-solid byproduct of the treatment process, contains a significant amount of organic matter, nutrients, and pathogens. Improper management can lead to environmental pollution and public health risks. Effective sludge management involves a combination of processes aimed at reducing its volume, stabilizing its contents, and disposing of or beneficially reusing it.

- Thickening: This process concentrates the sludge, reducing its volume and making subsequent treatment steps more efficient. Common methods include gravity thickening and centrifugation.

- Digestion: Anaerobic digestion is frequently used. In this process, microorganisms break down the organic matter in the absence of oxygen, producing biogas (primarily methane and carbon dioxide), which can be captured and used for energy generation. This significantly reduces the sludge volume and stabilizes it.

- Dewatering: Further reduces the sludge’s water content, making it easier to handle and transport. Methods include belt filter presses, centrifuges, and drying beds.

- Disposal or Beneficial Reuse: The final step involves either disposing of the sludge in a landfill (requiring stringent regulations to minimize environmental impact), or utilizing it beneficially. Beneficial reuse options include land application (as a soil amendment after careful testing and permitting), incineration with energy recovery, and co-digestion in biogas plants.

For example, a large wastewater treatment plant might use anaerobic digestion to generate biogas to power its operations, significantly reducing its carbon footprint. The dewatered sludge could then be used as a soil amendment on agricultural land after rigorous testing to ensure it meets safety standards.

Q 9. What are the energy efficiency considerations in water reclamation?

Energy efficiency is paramount in water reclamation, considering the energy-intensive nature of the processes involved. Minimizing energy consumption not only reduces operating costs but also contributes to environmental sustainability.

- Optimized aeration systems: Aeration is crucial in biological treatment but consumes significant energy. Using advanced aeration strategies, like fine-bubble diffusers and oxygen transfer optimization, improves efficiency.

- Energy recovery from biogas: Anaerobic digestion generates biogas, which can be used to power the plant’s operations, reducing reliance on external energy sources. This is a great example of a circular economy approach.

- Variable speed drives: Implementing variable speed drives on pumps and other equipment allows for adjusting operational speeds based on demand, optimizing energy use.

- Renewable energy integration: Incorporating solar panels or wind turbines to supply some or all of the plant’s energy needs greatly contributes to sustainability and reduced reliance on fossil fuels.

- Process optimization: Utilizing advanced process control systems and data analytics helps fine-tune operational parameters, minimizing energy consumption while maintaining treatment efficiency.

For instance, a plant might invest in a cogeneration system to produce electricity and heat from biogas, significantly reducing its energy bill and greenhouse gas emissions.

Q 10. Explain the role of biological processes in wastewater treatment.

Biological processes are fundamental to modern wastewater treatment. Microorganisms, primarily bacteria, are utilized to break down organic matter present in wastewater, removing pollutants and reducing the overall demand for oxygen in the water body.

- Activated Sludge Process: This widely used process involves aerating wastewater in a tank containing microorganisms, forming activated sludge. These microorganisms consume organic matter, creating flocs that settle out, producing clarified effluent and a concentrated sludge stream.

- Trickling Filters: Wastewater is trickled over a bed of media (rocks, plastics) coated with biofilm of microorganisms that consume organic matter.

- Membrane Bioreactors (MBRs): These combine biological treatment with membrane filtration, achieving very high levels of treatment efficiency and producing a high-quality effluent. They are more energy intensive but better suited for reuse applications.

Think of it as a natural digestive system for wastewater. The microorganisms ‘eat’ the pollutants, converting them into less harmful substances. The resulting clarified water is then much safer for discharge or reuse.

Q 11. How do you address nutrient removal (nitrogen and phosphorus) in wastewater?

Nutrient removal (nitrogen and phosphorus) is crucial for preventing eutrophication in receiving waters, which can lead to algal blooms, oxygen depletion, and harm to aquatic life. Effective nutrient removal strategies include:

- Biological Nutrient Removal (BNR): This involves employing specific microbial processes to remove nitrogen through nitrification (conversion of ammonia to nitrate) and denitrification (conversion of nitrate to nitrogen gas), and phosphorus through biological uptake by microorganisms.

- Enhanced Biological Phosphorus Removal (EBPR): This utilizes specific types of bacteria that accumulate phosphorus within their cells during anaerobic conditions. These cells are then removed from the system, taking the phosphorus with them.

- Chemical Precipitation: The addition of chemicals like ferric chloride or alum can precipitate phosphorus out of solution, removing it from the wastewater stream. This requires careful monitoring of chemical dosing and sludge disposal.

- Membrane Filtration: MBR systems effectively remove both nitrogen and phosphorus along with other contaminants, often achieving very high removal rates.

A common example of BNR involves using a combination of anoxic (low-oxygen) and aerobic (high-oxygen) conditions to facilitate both nitrification and denitrification. In EBPR, careful control of the process is crucial to maintain the specific microbial communities needed for phosphorus removal.

Q 12. Describe the different types of filtration used in water treatment.

Filtration plays a vital role in water treatment, removing suspended solids and other impurities. Various types of filtration are used depending on the desired level of treatment and the nature of the contaminants:

- Screen Filtration: Removes large debris using screens or bar racks at the initial stages of treatment.

- Rapid Sand Filtration: Water is passed through a bed of sand, removing suspended solids. Backwashing is necessary to clean the filter bed.

- Slow Sand Filtration: A more traditional method using a thicker bed of sand and relying on biological processes within the filter bed to remove contaminants. It’s less common in large-scale plants.

- Membrane Filtration: This includes microfiltration (MF), ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO). These advanced filtration techniques remove very small particles and dissolved substances, producing high-quality water suitable for reuse or potable purposes.

- Dual Media Filtration: Uses a combination of different filter media (e.g., anthracite coal and sand) to improve filtration efficiency.

For example, a water reclamation facility may use microfiltration to remove bacteria and viruses after the biological treatment stage to make it suitable for non-potable reuse. Reverse osmosis is often the final step in producing potable reuse water.

Q 13. What are the potential health risks associated with reclaimed water reuse?

While reclaimed water reuse offers significant environmental and economic benefits, it’s crucial to address potential health risks. These risks are mitigated through stringent treatment processes and robust monitoring programs. However, potential concerns include:

- Pathogens: While advanced treatment effectively removes most pathogens, residual microorganisms could potentially pose a risk if treatment isn’t properly managed.

- Chemical Contaminants: Certain chemicals, such as pharmaceuticals and personal care products (PPCPs), may persist in reclaimed water and could have long-term health effects. Emerging contaminants are a particular concern, requiring ongoing research and monitoring.

- Exposure Routes: The potential for exposure to reclaimed water depends on its intended use. Direct contact, inhalation of aerosols, or ingestion pose varying degrees of risk.

To minimize these risks, stringent regulations and guidelines govern reclaimed water reuse. These include setting maximum contaminant levels (MCLs) for various parameters, regular monitoring of water quality, and implementing effective risk management strategies. For example, reclaimed water used for irrigation is less risky than that used for indirect potable reuse.

Q 14. How do you ensure the safety and security of a water reclamation facility?

Ensuring the safety and security of a water reclamation facility is critical. It involves safeguarding both the physical infrastructure and the quality of the treated water.

- Physical Security: This includes perimeter fencing, access control systems, surveillance cameras, and security personnel to prevent unauthorized access and vandalism.

- Process Control and Automation: Advanced process control systems and automated monitoring systems provide real-time data on treatment performance, allowing for prompt detection and response to any anomalies.

- Redundancy and Backup Systems: Implementing redundant equipment and backup systems ensures continued operation in case of equipment failures.

- Emergency Response Plans: Developing and regularly testing comprehensive emergency response plans addresses potential incidents like power outages, chemical spills, or equipment malfunctions.

- Cybersecurity: Protecting the plant’s control systems from cyber threats is crucial to maintain operational reliability and prevent potential damage.

- Worker Safety: Implementing safety protocols and providing appropriate personal protective equipment (PPE) protects workers from exposure to hazardous materials and ensures a safe work environment.

For example, a facility might use a SCADA (Supervisory Control and Data Acquisition) system to monitor and control all aspects of the treatment process. A well-defined emergency response plan will outline procedures for dealing with a power failure, including backup power generation and safe shutdown procedures.

Q 15. Explain the principles of activated sludge process.

The activated sludge process is a widely used secondary wastewater treatment method that relies on the biological degradation of organic matter by microorganisms. Imagine a tiny city of microorganisms working tirelessly to clean the water. These microbes, primarily bacteria, consume the dissolved organic pollutants in the wastewater, converting them into harmless byproducts like carbon dioxide and water.

Here’s a breakdown of the process:

- Aeration Tank: Wastewater is mixed with activated sludge (a concentrated mixture of microorganisms) in a large aeration tank. Air is pumped into the tank, providing oxygen crucial for the aerobic bacteria to thrive and break down organic matter.

- Clarifier (Secondary Settler): After aeration, the mixture flows into a clarifier. Here, the solids (activated sludge) settle to the bottom, forming a sludge blanket, while the clarified effluent flows out for further treatment.

- Waste Sludge Removal: A portion of the settled sludge (excess biomass) is removed (waste activated sludge) to prevent an excessive buildup of microorganisms. Another part is returned to the aeration tank (return activated sludge), recycling the efficient microbes to treat incoming wastewater.

- Digestion: The waste sludge undergoes anaerobic digestion, breaking down the organic matter further, producing biogas (methane and carbon dioxide) that can be harnessed for energy production.

Essentially, the activated sludge process uses a carefully controlled biological system to effectively remove organic pollutants from wastewater, making it cleaner and safer for discharge or reuse.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the advantages and disadvantages of using different types of membranes?

Membrane technologies are increasingly important in water reclamation and reuse, offering superior treatment capabilities. Different membranes possess distinct advantages and disadvantages:

- Microfiltration (MF): Removes suspended solids and larger bacteria. Advantages: Relatively low energy consumption, easy operation. Disadvantages: Limited removal of dissolved organic matter and viruses.

- Ultrafiltration (UF): Removes smaller particles, including bacteria and some viruses. Advantages: Higher removal efficiency than MF, relatively low cost. Disadvantages: Fouling can be a significant issue, requiring regular cleaning.

- Nanofiltration (NF): Removes dissolved salts, organic matter, and viruses. Advantages: High removal efficiency of many contaminants. Disadvantages: Higher energy consumption than MF and UF, susceptibility to fouling.

- Reverse Osmosis (RO): Removes almost all dissolved substances, including salts and small organic molecules. Advantages: Produces high-quality permeate suitable for potable reuse. Disadvantages: Highest energy consumption among membrane processes, high capital costs, significant fouling potential.

The choice of membrane depends on the desired level of treatment, the characteristics of the wastewater, and the overall cost considerations. For example, RO might be chosen for potable reuse applications, while UF might suffice for industrial reuse.

Q 17. Describe your experience with SCADA systems in water treatment.

I have extensive experience with SCADA (Supervisory Control and Data Acquisition) systems in water treatment plants. In my previous role, we used a SCADA system to monitor and control various aspects of the wastewater treatment process, from influent flow rates and pump operations to aeration tank dissolved oxygen levels and sludge production. We had a system integration of different equipment into the SCADA platform, allowing for centralized control and monitoring.

Specifically, we leveraged the system for:

- Real-time monitoring: Continuous monitoring of key process parameters, allowing for immediate detection of anomalies.

- Process control: Automated control of pumps, valves, and other equipment based on predefined set points and alarms.

- Data logging and reporting: Automated collection and storage of process data, which is essential for compliance and optimization.

- Alarm management: Immediate alerts on critical events, such as high flow rates or low dissolved oxygen levels, enabling timely interventions.

My experience includes troubleshooting SCADA system issues, configuring data historians, and developing custom reports. I’m proficient in several SCADA platforms and have worked with various types of sensors and actuators commonly used in water treatment plants. For example, we used trending analysis from the SCADA data to identify a recurring problem with the aeration blower, leading to its timely replacement and preventing a major plant upset.

Q 18. How do you troubleshoot common problems in a wastewater treatment plant?

Troubleshooting in a wastewater treatment plant requires a systematic approach. I typically follow these steps:

- Identify the problem: Clearly define the issue. Is there a decrease in effluent quality? Increased energy consumption? Equipment malfunction?

- Gather data: Collect relevant data from various sources, including SCADA systems, laboratory results, and operator logs. Analyze trends and patterns.

- Isolate the source: Using the gathered data, try to pinpoint the source of the problem. This may involve checking individual units, examining process parameters, and evaluating operational procedures. For example, if effluent quality is poor, check the aeration tank DO levels, sludge characteristics, and even the influent quality.

- Implement corrective actions: Based on the identified source, implement appropriate corrective measures. This might involve adjusting process parameters, repairing or replacing equipment, or modifying operational strategies.

- Monitor and evaluate: Continuously monitor the system after implementing corrective actions to ensure the issue is resolved. Collect data to assess the effectiveness of the solution.

For example, if we notice a decrease in effluent quality, I might check the aeration tank dissolved oxygen levels. Low levels suggest insufficient aeration, potentially due to a malfunctioning blower or clogged air diffusers. We’d then investigate and rectify the problem accordingly. A systematic approach and thorough data analysis are key to efficient troubleshooting.

Q 19. What are the economic benefits of water reclamation and reuse?

Water reclamation and reuse offer significant economic benefits. By reusing treated wastewater, communities can reduce their reliance on freshwater sources, lowering the costs associated with water extraction, treatment, and distribution.

Here are some key economic benefits:

- Reduced water costs: Reclaimed water can replace potable water for various non-potable uses, such as irrigation, industrial processes, and toilet flushing, significantly reducing water bills.

- Increased water supply: Water reclamation expands the available water supply, particularly in arid and semi-arid regions where freshwater resources are scarce, improving water security.

- Reduced wastewater treatment costs: In some instances, reclaiming water can reduce the overall volume of wastewater requiring treatment, thus decreasing treatment costs.

- Environmental benefits translating to cost savings: Reduced demand on freshwater resources translates to less strain on the environment and a decreased risk of depletion, impacting ecological preservation and the related costs associated with its negative consequences.

- Energy savings: Producing reclaimed water often requires less energy than extracting and treating freshwater, leading to reduced energy bills.

- Economic development: The development of water reclamation and reuse infrastructure can create jobs and stimulate economic growth.

The specific economic benefits vary depending on the region, the scale of the project, and the specific applications of reclaimed water. However, overall, water reclamation and reuse is a cost-effective strategy for enhancing water security and resource management.

Q 20. How do you manage and interpret water quality data?

Managing and interpreting water quality data is crucial for effective water reclamation and reuse. This involves a multi-step process:

- Data Collection: Data is collected from various sources, including automated sensors (pH, dissolved oxygen, turbidity), laboratory analyses (nutrients, pathogens), and flow meters. We use both online and offline measurements, depending on the parameter.

- Data Validation and Cleaning: Raw data often contains errors or inconsistencies. Data validation involves checking for outliers, inconsistencies, and missing values. Cleaning involves correcting or removing erroneous data.

- Data Analysis: We use statistical methods and data visualization techniques (charts, graphs) to analyze trends, patterns, and correlations in the data. This helps to identify potential problems and assess the effectiveness of treatment processes. For example, trending dissolved oxygen levels over time can indicate potential issues with the aeration system.

- Data Interpretation: This step involves interpreting the analyzed data in the context of regulatory requirements, treatment goals, and operational constraints. We use the data to make informed decisions about operational adjustments, maintenance, and upgrades. For instance, consistently high levels of ammonia would signal a need for modification in our nitrification process.

- Reporting: Water quality data is used to generate reports for regulatory agencies, stakeholders, and internal management. This may involve summarizing key findings, analyzing performance indicators, and identifying areas for improvement.

Software tools, such as statistical packages and SCADA systems, play a crucial role in managing and analyzing water quality data. A thorough understanding of water chemistry and microbiology is essential for accurate interpretation of results.

Q 21. Explain the difference between primary, secondary, and tertiary treatment.

Wastewater treatment typically involves three levels of treatment: primary, secondary, and tertiary. Think of it like cleaning your house – primary is a quick cleanup, secondary is a deep clean, and tertiary is adding the finishing touches.

- Primary Treatment: This involves physical processes that remove large solids and suspended particles. Imagine removing large debris from a river. This can involve screening, grit removal, and sedimentation. The resulting effluent still contains significant amounts of organic matter and dissolved pollutants.

- Secondary Treatment: This uses biological processes to remove dissolved organic matter and further reduce suspended solids. The activated sludge process (described earlier) is a common secondary treatment method. It uses microorganisms to break down organic pollutants. It’s like adding cleaning products to clean the floor and surfaces.

- Tertiary Treatment: This provides additional treatment to remove remaining pollutants not removed during primary and secondary treatment. It aims to achieve a higher level of effluent quality. Tertiary treatment can involve various processes, such as disinfection (using chlorine or UV light to kill pathogens), filtration (removing fine particles), and nutrient removal (removing nitrogen and phosphorus). This is like polishing the house, adding the final touches.

The level of treatment required depends on the intended use of the treated water and regulatory requirements. For example, water intended for irrigation may only require primary and secondary treatment, while water intended for potable reuse would require tertiary treatment.

Q 22. Describe your experience with designing or managing water reuse projects.

My experience in water reuse projects spans over 15 years, encompassing diverse roles from design to project management. I’ve been involved in projects ranging from small-scale agricultural reuse schemes to large-scale potable reuse facilities. For instance, in one project, I led the design team for a reclaimed water irrigation system for a 500-acre golf course, optimizing water distribution and minimizing energy consumption. This involved detailed hydraulic modeling, selecting appropriate treatment technologies, and navigating permitting processes. In another project, I managed the construction and commissioning of a direct potable reuse plant, ensuring adherence to stringent water quality standards and regulatory compliance. This required close collaboration with engineers, contractors, and regulatory agencies, and meticulous attention to detail throughout the entire project lifecycle.

I’ve developed a strong understanding of various treatment technologies, including membrane filtration (microfiltration, ultrafiltration, reverse osmosis), advanced oxidation processes (AOPs), and disinfection techniques. My expertise also extends to the development of comprehensive water reuse master plans, considering future demands, technological advancements, and community needs.

Q 23. How do you ensure compliance with environmental regulations?

Ensuring compliance with environmental regulations is paramount in water reuse projects. My approach involves a multi-faceted strategy beginning with a thorough understanding of all applicable local, state, and federal regulations. This includes the Safe Drinking Water Act (SDWA), Clean Water Act (CWA), and any specific regulations for reclaimed water reuse in the project area.

We conduct regular monitoring of water quality parameters throughout the entire treatment and distribution process. This involves rigorous sampling and analysis to ensure that the treated water consistently meets the required standards for its intended use. We maintain meticulous records of all testing results, operational data, and maintenance activities. Our team proactively engages with regulatory agencies to ensure transparent communication and address any potential compliance issues promptly. We utilize sophisticated modeling tools to predict water quality and ensure compliance under various operating conditions. This predictive approach allows for proactive adjustments to treatment processes, minimizing the risk of non-compliance.

Q 24. What are the future trends in water reclamation and reuse technology?

The future of water reclamation and reuse is bright, driven by increasing water scarcity and the growing need for sustainable water management. Several key trends are shaping this field:

- Advanced treatment technologies: The development and implementation of more efficient and cost-effective advanced oxidation processes (AOPs), membrane bioreactors (MBRs), and other innovative technologies will continue to improve water quality and expand the possibilities for potable reuse.

- Smart water management: Integration of real-time monitoring, data analytics, and artificial intelligence (AI) will optimize treatment processes, reduce energy consumption, and enhance operational efficiency.

- Direct potable reuse: This practice of treating wastewater to drinking water standards is gaining traction, offering a sustainable solution for water-stressed regions. However, public acceptance and robust regulatory frameworks are critical for its widespread adoption.

- Integrated water resource management: A holistic approach integrating water reclamation and reuse with other water management strategies, like rainwater harvesting and groundwater recharge, will ensure a more resilient and sustainable water supply.

- Resource recovery: Recovery of valuable resources from wastewater, such as energy, nutrients, and reclaimed water, will enhance the economic and environmental viability of water reclamation.

Q 25. Describe your experience working with different stakeholders (e.g., community, regulatory agencies).

Effective stakeholder engagement is critical for successful water reuse projects. I have extensive experience collaborating with diverse stakeholders including community members, regulatory agencies, engineers, contractors, and water utility representatives. My approach prioritizes open communication, transparency, and active listening. I believe in proactive community outreach through public forums, workshops, and educational materials to address concerns and build trust. For example, in one project where there was initial community concern about the safety of reclaimed water, we organized a series of public meetings with experts, providing detailed information on the treatment process and addressing specific questions. This led to a significant increase in public support for the project.

When working with regulatory agencies, I maintain a collaborative relationship based on mutual respect and adherence to regulations. This involves proactive communication, providing detailed documentation, and responding promptly to any requests or inquiries. My approach builds a strong foundation of trust and ensures that projects proceed smoothly while meeting all requirements.

Q 26. How do you incorporate sustainability principles into water reclamation practices?

Sustainability is core to my approach to water reclamation. I incorporate sustainability principles throughout the project lifecycle, starting with the design phase. This involves selecting energy-efficient treatment technologies, minimizing the use of chemicals, and optimizing water reuse pathways to minimize energy and transportation needs.

We also prioritize lifecycle assessments to evaluate the environmental impacts of different treatment options, considering energy consumption, greenhouse gas emissions, and water usage throughout the entire lifecycle of the facility. In addition, we explore opportunities for resource recovery, such as energy generation from biogas or nutrient recovery for agricultural use. By adopting these strategies, we aim to create water reclamation systems that are not only efficient but also environmentally responsible and economically viable.

Q 27. What are the challenges in implementing advanced water treatment technologies?

Implementing advanced water treatment technologies presents several challenges. One key challenge is the high capital cost associated with these technologies. Another significant challenge is the need for specialized expertise in operating and maintaining these complex systems. It is crucial to have skilled personnel to manage these technologies, ensure optimal performance, and troubleshoot any issues. The need for robust quality control and assurance throughout the treatment process is another significant challenge, demanding continuous monitoring and analysis to ensure water quality meets stringent standards. Furthermore, public perception and acceptance can be a significant barrier, particularly for direct potable reuse projects. Effective communication and public engagement strategies are essential to address public concerns and build trust.

Q 28. Explain your understanding of life cycle assessment in relation to water reclamation.

Life cycle assessment (LCA) is a crucial tool for evaluating the environmental impacts of water reclamation projects. It involves assessing the environmental burdens associated with each stage of the project’s lifecycle, from raw material extraction and manufacturing of equipment to construction, operation, maintenance, and end-of-life disposal. An LCA of a water reclamation system would assess the energy consumption (electricity, fuels), water usage, greenhouse gas emissions, and the use of chemicals during each phase. This comprehensive analysis helps to identify the hotspots of environmental impact within the project, allowing for informed decision-making to minimize adverse effects. For instance, an LCA might reveal that although a specific membrane technology has high treatment efficiency, its manufacturing process has significant carbon emissions. This information would inform the selection of an alternative technology with a lower overall environmental footprint, even if it has slightly lower treatment efficiency.

Key Topics to Learn for Water Reclamation and Reuse Interview

- Water Quality Parameters: Understanding key indicators like turbidity, pH, dissolved oxygen, and nutrient levels (nitrogen and phosphorus) and their impact on treatment processes.

- Treatment Processes: Familiarize yourself with various treatment technologies including preliminary treatment, primary treatment, secondary treatment (activated sludge, trickling filters), tertiary treatment (membrane filtration, disinfection), and advanced oxidation processes.

- Sludge Management: Learn about sludge handling, thickening, digestion, dewatering, and disposal or beneficial reuse options.

- Disinfection Methods: Understand the principles and applications of various disinfection techniques like chlorination, UV disinfection, and ozonation, and their effectiveness against different pathogens.

- Water Reuse Applications: Explore different applications of reclaimed water, including irrigation, industrial use, groundwater recharge, and potential potable reuse scenarios, along with associated regulations and public perception aspects.

- Process Control and Automation: Gain understanding of SCADA systems, instrumentation, and automated control strategies used in water reclamation facilities.

- Regulations and Compliance: Be familiar with relevant environmental regulations and permits (e.g., discharge permits, water quality standards) and their implications for plant operation.

- Sustainability and Energy Efficiency: Understand the role of energy optimization, renewable energy integration, and resource recovery in modern water reclamation facilities.

- Troubleshooting and Problem-Solving: Develop your skills in identifying, diagnosing, and resolving operational issues and malfunctions within water reclamation systems.

- Health and Safety: Be aware of workplace safety protocols and hazard identification related to chemicals, machinery, and confined spaces within water reclamation facilities.

Next Steps

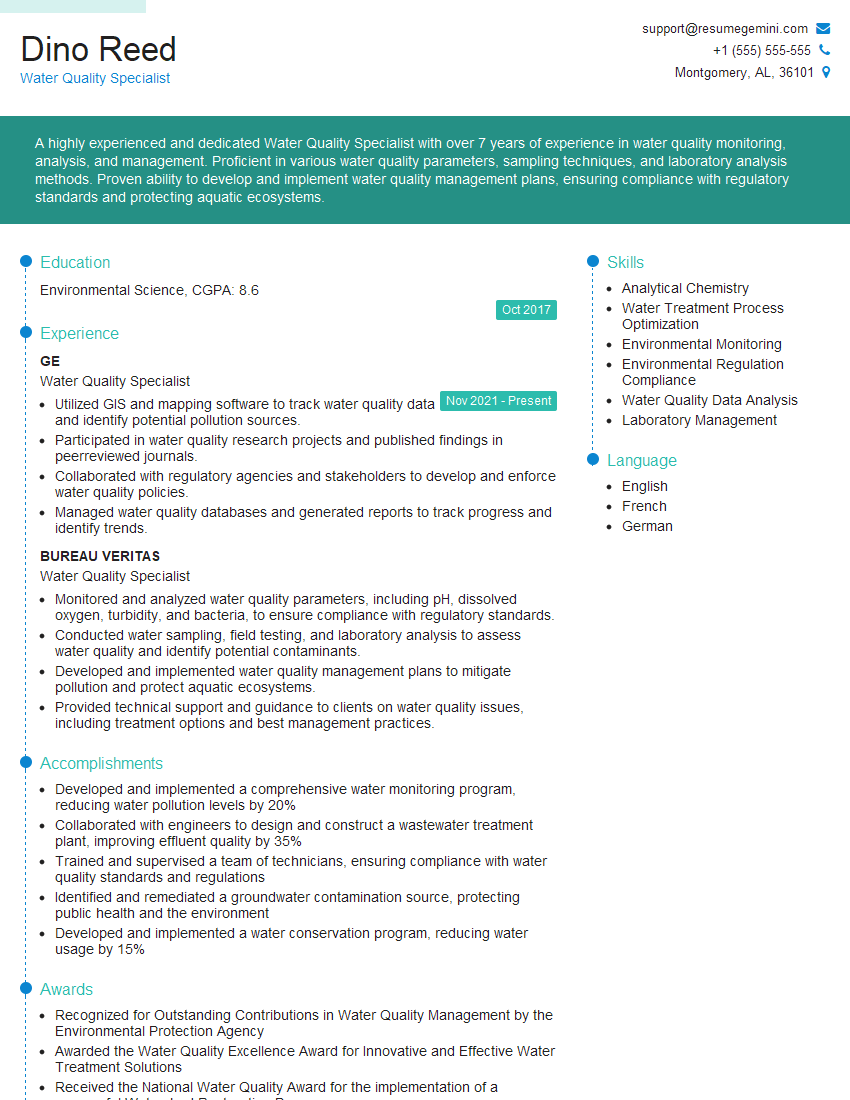

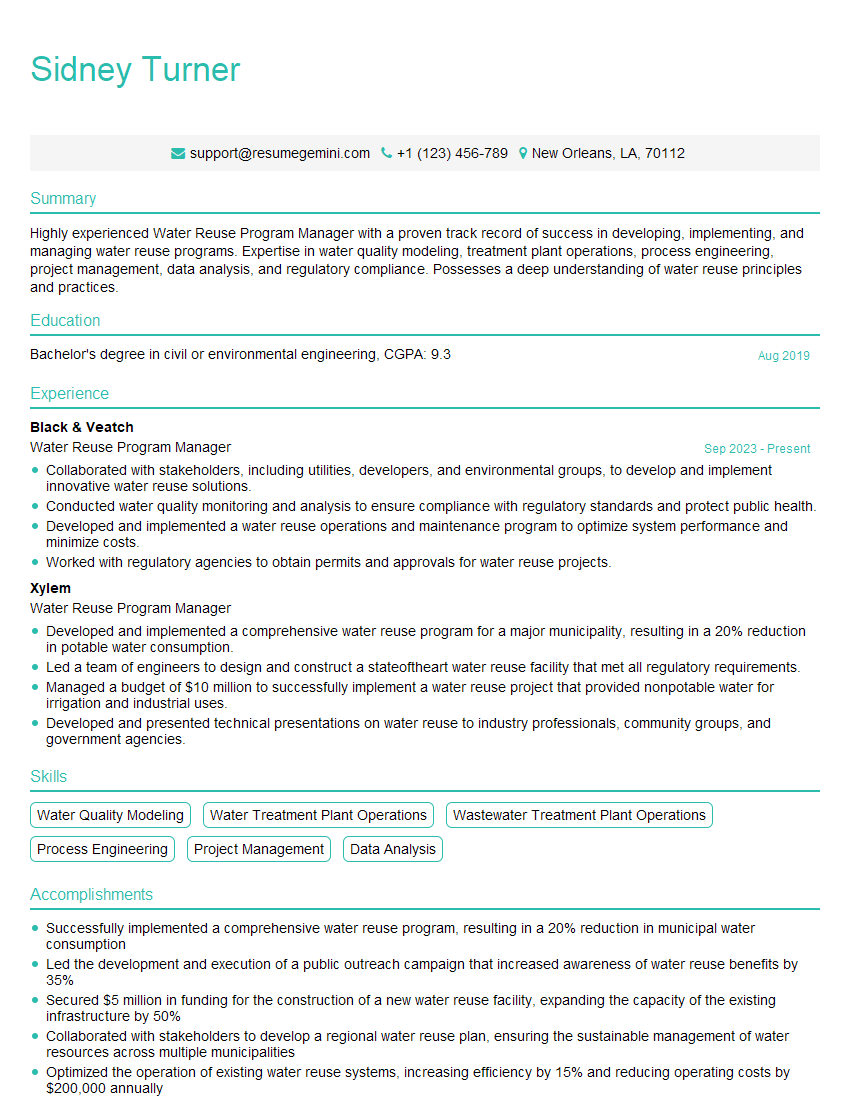

Mastering Water Reclamation and Reuse opens doors to a rewarding career with significant growth potential in a field vital for environmental sustainability and public health. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume is key to getting your application noticed. To maximize your job prospects, leverage the power of ResumeGemini, a trusted resource for building professional and effective resumes. ResumeGemini provides examples of resumes tailored to the Water Reclamation and Reuse sector to help you create a compelling document that highlights your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.