Unlock your full potential by mastering the most common Weld Parameter Development interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Weld Parameter Development Interview

Q 1. Explain the relationship between welding current, voltage, and travel speed.

The relationship between welding current, voltage, and travel speed is fundamental to achieving a quality weld. Think of it like this: current is the heat input, voltage is the potential for heat, and travel speed controls how long that heat is applied to a single point.

- Welding Current (Amps): Higher current means more heat. This is crucial for melting the base metal and filler material. Too low, and you’ll get insufficient fusion; too high, and you’ll burn through the material.

- Voltage (Volts): Voltage affects the arc length and penetration depth. A higher voltage usually leads to a longer arc and deeper penetration, while a lower voltage creates a shorter arc with shallower penetration.

- Travel Speed (in/min or mm/min): Travel speed determines the amount of heat applied to a specific area. Slow speed with high current results in a wide, deep weld bead; fast speed with low current creates a narrow, shallow weld bead. Finding the right balance is key to controlling weld bead geometry and ensuring complete fusion.

For example, welding thick steel might require a high current and voltage with a moderate travel speed to ensure complete penetration. Thin sheet metal, on the other hand, would necessitate a lower current and voltage, potentially with a faster travel speed to avoid burning through.

Q 2. Describe the impact of different shielding gases on weld quality.

Shielding gases play a crucial role in protecting the weld pool from atmospheric contamination, which can lead to porosity, cracking, and reduced mechanical properties. The choice of shielding gas depends on the welding process and the type of metal being welded.

- Argon (Ar): Commonly used in Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) for aluminum and stainless steel. Its inert nature prevents oxidation and improves weld quality.

- Helium (He): Used in GTAW for its higher thermal conductivity, which allows for higher welding speeds. However, it is more expensive than Argon.

- Carbon Dioxide (CO2): Primarily used in Gas Metal Arc Welding (GMAW) for steel. It is reactive, creating a shielding environment but also contributing to weld spatter. It’s more cost effective than inert gases.

- Argon-Helium mixtures: Offer a balance between the properties of Argon and Helium. They are commonly used in GTAW to achieve higher welding speeds without sacrificing penetration.

- Argon-CO2 mixtures: Used in GMAW to improve the arc stability and reduce spatter compared to using CO2 alone. The Argon content reduces the reactivity.

Improper shielding gas selection or inadequate gas flow can result in defects such as porosity (gas bubbles in the weld) or oxidation (weakening of the weld due to reaction with oxygen).

Q 3. How do you determine the optimal preheat temperature for a specific weld?

Determining the optimal preheat temperature is critical for welding materials susceptible to cracking or hydrogen embrittlement, especially thicker sections of high-strength steels or other alloys. It involves considering several factors.

- Material Type and Thickness: Thicker sections require higher preheat to prevent rapid cooling and reduce residual stresses. The specific material’s properties also influence the preheat temperature.

- Weld Joint Design: Complex joint geometries may require higher preheat temperatures to ensure uniform heat distribution.

- Welding Process: Some welding processes generate more heat than others, influencing the required preheat temperature.

- Ambient Temperature: Lower ambient temperatures may necessitate a higher preheat temperature to compensate.

The preheat temperature is usually specified in the Welding Procedure Specification (WPS) or determined through reference to the material’s manufacturer’s recommendations. Often, a combination of experience, material data sheets, and sometimes testing (such as preheat temperature testing with controlled cooling rates) is necessary for determining the optimal preheat.

For instance, preheating high-strength low-alloy steel before welding can reduce the risk of cold cracking by slowing down the cooling rate and allowing hydrogen to diffuse out.

Q 4. What are the common defects found in welds and their causes?

Numerous defects can occur during welding, each with its own characteristic appearance and cause. Some common examples include:

- Porosity: Gas pores or holes within the weld metal, often caused by insufficient shielding gas coverage, moisture contamination, or excessive welding speed.

- Cracking: Fractures in the weld metal or heat-affected zone (HAZ), resulting from residual stresses, hydrogen embrittlement, or improper preheating/post-weld heat treatment.

- Incomplete Penetration: The weld doesn’t fully fuse with the base material, indicating insufficient heat input or improper welding technique.

- Undercutting: A groove melted into the base metal adjacent to the weld toe, often caused by excessive current, incorrect welding angle, or insufficient shielding gas coverage.

- Slag Inclusion: Trapped slag (molten flux) within the weld, indicating improper cleaning between weld passes.

- Lack of Fusion: A lack of bonding between the weld metal and base material, stemming from poor joint preparation or insufficient heat input.

Identifying these defects requires careful visual inspection, often supplemented by non-destructive testing (NDT) methods such as radiographic testing (RT) or ultrasonic testing (UT).

Q 5. Explain the importance of weld penetration and how it’s controlled.

Weld penetration refers to the depth to which the weld metal fuses with the base material. It’s a critical factor affecting the strength and integrity of the weld. Sufficient penetration ensures complete joint fusion and prevents incomplete welds. Insufficient penetration leads to weakness, while excessive penetration can cause burn-through.

Weld penetration is controlled by several parameters:

- Welding Current: Higher current increases penetration.

- Voltage: Higher voltage increases penetration.

- Travel Speed: Slower travel speed increases penetration.

- Electrode Angle: The angle of the electrode or welding torch influences the direction and extent of penetration.

- Joint Design: The shape and fit-up of the joint affect heat distribution and penetration.

- Shielding Gas: The type and flow rate of shielding gas influences the arc stability and penetration.

Controlling these parameters is crucial. For example, in a butt joint, consistent penetration across the entire joint is paramount; otherwise, you risk a weakened area. Proper pre-weld joint preparation, such as ensuring proper fit-up and cleaning, also plays a significant role in achieving the desired penetration.

Q 6. How do you interpret a weld procedure specification (WPS)?

A Weld Procedure Specification (WPS) is a document that outlines the parameters and procedures for a specific welding operation. It’s essentially a recipe for a successful weld. Interpreting a WPS requires understanding its components:

- Essential Variables: These parameters directly influence the weld’s mechanical properties and must be strictly controlled. Examples include welding current, voltage, travel speed, preheat temperature, and shielding gas type/flow rate. Any changes require a new WPS qualification.

- Non-Essential Variables: These parameters have less impact on the final weld quality, such as electrode type (within a specified range) or post-weld heat treatment.

- Base Materials: Specifies the exact composition and thickness of the materials being welded.

- Welding Process: States the specific welding method (e.g., GMAW, GTAW, SMAW).

- Joint Design: Details the type of weld joint (e.g., butt, fillet, lap).

- Qualification Tests: Documents the tests performed (e.g., tensile, bend, macro-etch) to verify that the WPS produces acceptable welds.

By carefully examining the WPS, a welder can ensure they are following the approved procedures to create consistent, high-quality welds that meet the required standards. Deviations from the WPS must be documented and may require further qualification.

Q 7. Describe different types of weld joints and their applications.

Various weld joints cater to different needs and applications, each with strengths and weaknesses:

- Butt Joint: Two pieces of metal joined end-to-end. Strongest for full penetration welds. Common in pipelines and structural steel.

- Lap Joint: One piece overlaps the other. Simple to produce but less strong than a butt joint, often used where strength is less critical.

- T-Joint: One piece joins the side of another, like a ‘T’. Versatile but requires careful preparation to ensure full penetration.

- Corner Joint: Two pieces joined at a corner, often used for structural frameworks.

- Edge Joint: Edges of two pieces are joined, frequently used for sheet metal or thin materials.

- Fillet Joint: A triangular weld joining two intersecting pieces. Widely used, offering strong, ductile welds for structural applications or sheet metal joining.

The selection of the appropriate weld joint depends on the application’s requirements, the materials involved, and the desired strength and durability. For example, a butt joint is ideal for situations requiring maximum strength, while a fillet joint might suffice for less demanding applications.

Q 8. What are the advantages and disadvantages of different welding processes (e.g., GMAW, SMAW, GTAW)?

Choosing the right welding process depends heavily on the application. Each method offers unique advantages and disadvantages. Let’s compare three common processes: Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), and Gas Tungsten Arc Welding (GTAW).

GMAW (MIG):

- Advantages: High deposition rates, good penetration, relatively easy to learn, versatile with different shielding gases and wire types, suitable for automation.

- Disadvantages: Susceptible to porosity (holes in the weld) if not properly shielded, requires a constant power source, can be less aesthetically pleasing than GTAW.

SMAW (Stick):

- Advantages: Portable, relatively inexpensive equipment, can be used in all positions (vertical, overhead, etc.), works well in outdoor conditions.

- Disadvantages: Lower deposition rates compared to GMAW, requires more skill to achieve good welds, slag removal is necessary, prone to undercut and other weld defects.

GTAW (TIG):

- Advantages: Produces high-quality welds with excellent appearance, precise control over the weld pool, good for thin materials and dissimilar metals, easily automated.

- Disadvantages: Lower deposition rates, requires higher skill level, slower process, more expensive equipment, less portable.

Example: For a large-scale project requiring high deposition rate and automation, GMAW would be preferred. For critical aerospace applications demanding high quality and precision, GTAW is the more suitable choice. SMAW might be ideal for field repairs where portability and simplicity are prioritized.

Q 9. How do you qualify a welder?

Welder qualification is crucial for ensuring consistent weld quality and safety. It typically involves a combination of written tests, practical demonstrations, and review of past performance. The specific requirements depend on the codes and standards applicable to the project (e.g., ASME Section IX, AWS D1.1).

The process usually includes:

- Written Examination: Tests the welder’s knowledge of welding procedures, safety, metallurgy, and code requirements.

- Practical Test (Performance Qualification): The welder must produce several weld test specimens according to specific procedures. These specimens are then inspected for various defects (porosity, cracks, lack of fusion) using visual inspection, radiography, or other non-destructive testing methods.

- Procedure Qualification Record (PQR): This document records the welding parameters used during the performance qualification test. It serves as a blueprint for subsequent welding operations using the same parameters.

- Welding Procedure Specification (WPS): Based on the PQR, this document outlines the detailed welding procedures to be followed for a specific application, including materials, preheating, post-weld heat treatment, and other relevant details. It serves as the instruction manual for welders.

Example: A welder working on a pressure vessel would need qualification according to ASME Section IX, which involves rigorous testing and documentation.

Q 10. Explain the importance of proper joint design in welding.

Joint design is critical because it directly impacts the weld’s strength, integrity, and overall quality. A poorly designed joint can lead to weld defects, reduced strength, and potential failure.

Factors to consider include:

- Joint Type: The geometry of the joint (e.g., butt, lap, tee, corner) influences the weldability and resulting strength.

- Joint Preparation: This involves beveling or chamfering the edges of the base metal to create a suitable groove for the weld, impacting penetration and weld metal volume.

- Root Opening: The gap between the base metals at the root of the joint affects penetration and the risk of weld defects.

- Material Compatibility: The base metals must be compatible with the filler material and the welding process being used.

Example: A butt joint with proper beveling allows for complete penetration and a stronger weld compared to a lap joint that has less penetration and a larger weld area.

Q 11. How does the material thickness affect welding parameters?

Material thickness significantly influences welding parameters. Thicker materials require higher heat input to ensure proper penetration and fusion. This translates to adjustments in several parameters:

- Welding Current (Amperage): Increased current is needed for thicker materials to melt the metal.

- Welding Voltage: Higher voltage may be required to maintain arc stability with increased current.

- Travel Speed: Travel speed needs to be adjusted accordingly to prevent excessive heat input or insufficient penetration.

- Preheating: Preheating the material before welding might be necessary for thicker sections to reduce thermal stresses and prevent cracking, especially in certain metals.

Example: Welding a 1/8 inch plate might only require 60 amps, whereas welding a 1 inch plate might need 200 amps or more, significantly affecting all the other parameters.

Q 12. Describe the role of post-weld heat treatment (PWHT).

Post-Weld Heat Treatment (PWHT) is a crucial step in many welding applications, especially with high-strength steels or those susceptible to cracking. It involves heating the welded assembly to a specific temperature, holding it for a certain time, and then slowly cooling it. The primary purposes are:

- Stress Relief: PWHT reduces residual stresses in the weld and heat-affected zone (HAZ) generated during welding. These stresses can cause cracking or distortion.

- Improved Toughness: In some materials, PWHT can improve the toughness and impact resistance of the weld and HAZ.

- Reduced Hydrogen Embrittlement: Hydrogen can be trapped in the weld during welding, leading to embrittlement. PWHT helps diffuse hydrogen out of the material.

The specific temperature and time parameters depend on the material and the welding process used and are specified in relevant codes and standards.

Example: High-pressure vessels often require PWHT to ensure they can withstand the operating pressures without failure.

Q 13. How do you measure weld bead geometry?

Measuring weld bead geometry is vital to assessing the quality and consistency of a weld. Several aspects are measured:

- Weld Bead Width: The overall width of the weld bead.

- Weld Bead Height (Reinforcement): The height of the weld bead above the base metal.

- Weld Bead Penetration: The depth of the weld penetration into the base metal.

- Weld Bead Profile: The overall shape of the weld bead (convex, concave, or flat).

Measuring tools include:

- Ruler or Caliper: For simple measurements of width and height.

- Weld Bead Profilometer: A more sophisticated instrument for detailed profile measurements.

- Cross-sections: A destructive method where the weld is sectioned and examined microscopically to determine penetration and fusion.

Example: Excessive reinforcement might indicate excessive heat input or an improper welding technique.

Q 14. Explain the concept of weld spatter and how to minimize it.

Weld spatter is the ejection of molten weld metal droplets from the weld pool during the welding process. It can lead to several issues:

- Porosity: Spatter can create pores or inclusions in the weld, reducing its strength and integrity.

- Incomplete Fusion: Spatter can interfere with proper fusion between the weld metal and the base metal.

- Surface Defects: Spatter can leave an uneven and rough surface on the weld.

- Safety Hazard: Spatter can cause burns or eye injuries.

Minimizing spatter can be achieved through various methods:

- Proper Welding Technique: Using the correct welding parameters and maintaining a consistent arc length is crucial.

- Adjusting Welding Parameters: Lowering the current or increasing the voltage can sometimes reduce spatter.

- Using Spatter-Reducing Additives: Some welding consumables are designed to minimize spatter.

- Shielding Gas Selection: Choosing the right shielding gas can also improve weld quality and reduce spatter.

- Cleanliness: Ensuring the base metal is clean and free of contaminants minimizes spatter formation.

Example: Using a pulsed GMAW process can significantly reduce spatter compared to a continuous current process.

Q 15. What are the safety precautions associated with welding?

Welding safety is paramount. It involves a multifaceted approach encompassing personal protective equipment (PPE), environmental controls, and procedural adherence. Think of it like this: welding is inherently dangerous; proper safety measures are your armor.

- PPE: This is your first line of defense. It includes eye protection (auto-darkening welding helmets are crucial), hearing protection (to mitigate the intense noise), protective clothing (leather aprons, gloves, and long-sleeved shirts to prevent burns and sparks from reaching your skin), and respiratory protection (for fumes generated during certain welding processes, especially in confined spaces).

- Environmental Controls: Ensure adequate ventilation to remove harmful fumes and gases. In confined spaces, you might need specialized ventilation systems or even atmospheric monitoring. Proper shielding around the welding area is essential to protect bystanders from sparks and radiation.

- Procedural Adherence: Following established safety protocols is crucial. This includes things like fire prevention measures (having a fire extinguisher readily available and ensuring flammable materials are not nearby), safe handling of compressed gases (checking for leaks, using proper regulators, and storing cylinders correctly), and awareness of potential electrical hazards (working with properly insulated equipment and grounding).

For example, I once witnessed a welder who didn’t use the proper eye protection. A small piece of slag ejected and hit their exposed skin; it resulted in a painful burn. This incident highlighted the importance of always wearing appropriate PPE, even for seemingly quick tasks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot common welding problems?

Troubleshooting welding problems requires a systematic approach. I usually follow a process of observation, analysis, and adjustment. Imagine it like detective work; you need to find the clues to solve the mystery.

- Visual Inspection: First, carefully examine the weld. Look for porosity (small holes), cracks, undercut (a groove at the weld toe), lack of fusion (incomplete joining of the base metals), excessive spatter (small metal droplets), and inconsistent bead shape.

- Analysis of Variables: Consider the welding parameters (current, voltage, travel speed, wire feed speed, shielding gas flow rate), the base metal properties (type, thickness, cleanliness), and the joint design (joint type, fit-up). Incorrect settings can lead to many problems. For instance, insufficient current can lead to incomplete fusion, while excessive current might cause excessive spatter and burn-through.

- Adjustment and Retesting: Based on your analysis, systematically adjust the welding parameters and retest. Keep detailed records of each adjustment to understand its impact on the weld quality.

For instance, if I observe excessive porosity in a Gas Metal Arc Welding (GMAW) weld, I would investigate the shielding gas flow rate. A low flow rate might not provide adequate protection from atmospheric contamination, leading to porosity. I would then increase the gas flow rate and re-weld, documenting the change and result.

Q 17. Explain the difference between destructive and non-destructive testing methods for welds.

Destructive and non-destructive testing methods are complementary approaches to assess weld integrity. Destructive testing involves the destruction of the welded sample to obtain quantitative data, while non-destructive testing assesses weld quality without causing damage. Think of it as a medical checkup: sometimes you need a minor procedure, and other times you need more invasive tests.

- Destructive Testing: This includes tensile testing (measuring the weld’s strength and ductility), bend testing (assessing its ability to withstand bending forces), hardness testing (measuring the weld’s hardness), and macro and micro examination (examining the weld’s internal structure under a microscope). These methods provide precise data about the weld’s mechanical properties but require sacrificing the tested sample.

- Non-Destructive Testing: This is generally preferred for mass production or when preserving the weld is critical. Common techniques include visual inspection (checking for surface defects), radiographic testing (using X-rays or gamma rays to detect internal flaws), ultrasonic testing (using sound waves to detect internal flaws), and magnetic particle testing (detecting surface and near-surface cracks in ferromagnetic materials).

In practice, I often use a combination of both. For instance, I might use non-destructive testing like ultrasonic inspection during initial production runs to ensure quality and then conduct destructive testing on a small sample to verify the results and obtain more precise strength data.

Q 18. What are some common weldability issues?

Weldability issues stem from the interaction between the welding process, the base metal, and the filler metal. It’s a delicate balance; if one element is off, problems can arise. Think of it as baking a cake – if the ingredients aren’t right, the cake won’t turn out well.

- Poor Joint Design: Improper joint fit-up (gaps, misalignment) leads to incomplete fusion or lack of penetration.

- Base Metal Contamination: Surface contaminants like oil, grease, paint, or rust significantly affect weldability, causing porosity, cracking, or weak welds.

- Incompatible Filler Metal: Using a filler metal with an inappropriate chemical composition or physical properties for the base metal can result in poor weld properties.

- Cold Cracking: This occurs when hydrogen diffuses into the weld metal during cooling, causing stress and cracking, particularly in high-strength steels.

- Heat-Affected Zone (HAZ) Issues: The heat from the welding process can alter the microstructure and properties of the base metal surrounding the weld, leading to embrittlement or softening.

For example, I encountered a situation where cracks were appearing in welds on high-strength steel. After investigation, we discovered that the pre-cleaning process was inadequate, leaving residual oil on the surfaces. Improving the cleaning process solved the problem.

Q 19. How do you choose the right filler metal for a specific application?

Selecting the right filler metal is crucial for achieving the desired weld properties. The choice depends on the base metal type, thickness, welding process, and the required mechanical properties of the final weld. It’s akin to choosing the right paint for your project – you wouldn’t use oil-based paint for a water-based project.

- Base Metal Compatibility: The filler metal’s chemical composition must be compatible with the base metal to ensure good weldability and prevent undesirable reactions or intermetallic compound formation.

- Mechanical Properties: Consider the required strength, ductility, toughness, and hardness of the weld. The filler metal must match these requirements.

- Welding Process: Different welding processes require different filler metal types and forms (solid wire, flux-cored wire, electrodes). For example, SMAW (Shielded Metal Arc Welding) uses coated electrodes, while GMAW uses solid or flux-cored wires.

- Operating Conditions: The weld’s intended service environment influences the choice of filler metal. For high-temperature applications, a high-temperature filler metal would be necessary.

For example, when welding stainless steel, I would select an austenitic stainless steel filler metal with a similar chemical composition to maintain corrosion resistance in the weld.

Q 20. Describe your experience with using and interpreting weld data acquisition systems.

I have extensive experience with data acquisition systems in welding. These systems allow real-time monitoring and recording of welding parameters, providing valuable insights into the welding process and enabling optimization. Think of them as a sophisticated recording device for the welding process, allowing for a detailed analysis of what happened during welding.

I’ve worked with several systems that capture data such as current, voltage, wire feed speed, travel speed, and shielding gas flow rate. This data is crucial for process optimization and quality control. I use this data to create detailed process parameters and identify trends and potential issues. I’ve used this data for applications such as real-time process control, weld parameter optimization, and root cause analysis of weld defects. For example, analyzing the voltage and current during a weld can help identify instances of arcing or short circuiting.

Interpreting the data often involves using statistical analysis techniques and visualization tools to identify patterns, trends, and outliers. For example, a sudden drop in voltage could indicate a short circuit, while a consistent increase in current might indicate excessive heat input. This insight allows for proactive adjustments to prevent weld defects.

Q 21. How do you ensure consistent weld quality during mass production?

Maintaining consistent weld quality in mass production requires a combination of robust process control, meticulous operator training, and regular quality checks. This requires a multifaceted and meticulous approach. It’s like running a well-oiled machine; each component must function correctly for the overall system to perform as intended.

- Standardized Procedures: Develop and implement detailed written welding procedures, specifying the exact welding parameters, pre- and post-weld cleaning, and quality control checks for every weld.

- Operator Training and Certification: Ensure welders are thoroughly trained and certified to perform the welding tasks according to established procedures.

- Equipment Calibration and Maintenance: Regularly calibrate and maintain all welding equipment to ensure accurate and consistent performance. This includes regular inspections and preventative maintenance programs for all equipment.

- Statistical Process Control (SPC): Utilize SPC charts to monitor key weld characteristics and identify potential deviations from target values promptly.

- Regular Quality Checks: Implement a robust quality control system involving visual inspection, non-destructive testing, and possibly destructive testing of samples.

For example, in a large-scale pipeline welding project, we used a combination of standardized procedures, operator training, and real-time monitoring of welding parameters using data acquisition systems. This ensured consistency in weld quality across the entire project.

Q 22. Explain your understanding of statistical process control (SPC) in welding.

Statistical Process Control (SPC) in welding is crucial for ensuring consistent weld quality and minimizing defects. It involves using statistical methods to monitor and control the welding process. Think of it like a doctor regularly checking a patient’s vital signs – we’re constantly monitoring key weld parameters to make sure everything is within acceptable limits.

We use control charts, like X-bar and R charts, to track parameters such as weld penetration, bead width, and reinforcement height. By plotting these parameters over time, we can identify trends, shifts, or outliers indicating potential problems. For example, a sudden increase in weld reinforcement might suggest a problem with the welding current or travel speed. SPC helps us identify these issues before they lead to significant defects or scrap, saving time and resources.

In practice, we establish control limits based on historical data and process capability studies. Data points outside these limits trigger investigations and corrective actions. This proactive approach ensures that the welding process remains stable and predictable, producing consistently high-quality welds.

Q 23. What is the role of heat input in weld quality?

Heat input, the amount of heat energy supplied per unit length of weld, plays a vital role in determining weld quality. It’s like the ‘cooking temperature’ for our weld metal. Too little heat leads to insufficient fusion, incomplete penetration, and potentially brittle welds. Imagine trying to cook a steak on a low flame for too short a time; it wouldn’t cook properly. Conversely, excessive heat input can cause excessive weld spatter, porosity, and increased distortion, similar to overcooking the steak, making it tough and undesirable.

The optimal heat input depends on factors such as base material thickness, type of welding process, and desired weld properties. For instance, thicker materials generally require higher heat inputs to ensure complete penetration, while thinner materials necessitate lower heat inputs to prevent burn-through. Precise control of heat input is achieved through careful manipulation of welding parameters such as current, voltage, and travel speed.

Q 24. How does the base material composition affect weld parameter selection?

Base material composition significantly impacts weld parameter selection. Different materials have varying melting points, thermal conductivities, and susceptibility to cracking and other defects. It’s like cooking different types of meat; you’d use different techniques for a delicate fish compared to a tough cut of beef.

For example, welding stainless steel requires different parameters than welding mild steel. Stainless steel’s higher thermal conductivity means it cools faster, necessitating higher current or preheating to ensure proper fusion. Similarly, certain alloys are prone to cracking, requiring specific parameters to control the cooling rate and minimize stress.

Understanding the base material’s chemical composition, mechanical properties, and metallurgical behavior is crucial for selecting appropriate welding parameters and ensuring optimal weld quality. We often consult material datasheets and welding handbooks to find recommended ranges of welding parameters for different base materials.

Q 25. Describe your experience with different types of welding power sources.

My experience encompasses various welding power sources, including:

- Constant Current (CC) power sources: These maintain a consistent current regardless of arc length variations. They are ideal for manual welding processes like SMAW (Shielded Metal Arc Welding) and are better at controlling heat input in thicker materials.

- Constant Voltage (CV) power sources: These maintain a constant voltage, allowing for easier arc starting and better penetration control. They’re commonly used in GMAW (Gas Metal Arc Welding) and FCAW (Flux-Cored Arc Welding), which often require precise control of the welding speed and arc length.

- Pulse power sources: Offer precise control over the heat input by delivering current in pulses. This feature helps in achieving better weld quality and reducing spatter, especially with thinner materials or in situations requiring low heat input. I’ve personally used this to achieve high-quality welds in aluminum alloys where controlling heat is paramount.

Selecting the appropriate power source is crucial because it directly impacts the arc characteristics, heat input, and overall weld quality. The choice depends heavily on the welding process, base material, and joint design.

Q 26. How do you address the issue of weld distortion?

Weld distortion, the unwanted deformation of the workpiece during welding, is a common challenge. It’s like trying to build a house with improperly dried wood – the structure warps over time. Addressing it requires a multi-pronged approach.

- Preheating: Reducing the temperature difference between the heated weld zone and the surrounding cooler material. Preheating the base material helps slow down cooling and minimizes distortion.

- Proper joint design: Utilizing designs that inherently minimize distortion, such as using smaller welds or employing techniques like backing plates or fixtures to restrain the workpiece during welding.

- Welding sequence: Optimizing the welding sequence to balance the heat input and minimize distortion. Sometimes welding from the center outward, or in a specific pattern, can greatly reduce overall distortion.

- Post-weld heat treatment (PWHT): This can reduce residual stresses and minimize distortion, but requires careful control of the heating and cooling cycle.

The specific methods employed depend on factors such as the workpiece geometry, material type, and the acceptable level of distortion. It’s often an iterative process, involving experimentation and refinement of techniques to achieve the desired results.

Q 27. What are your experiences in developing and implementing WPSs?

Developing and implementing Welding Procedure Specifications (WPSs) is a critical aspect of my work. A WPS is like a recipe for a consistently good weld, ensuring that every weld meets required quality standards. It meticulously outlines all welding parameters, including the equipment used, base materials, pre- and post-weld treatments, and quality control procedures.

My experience includes:

- Creating WPSs: Based on the requirements of the project, base material, and joint design, I carefully determine the optimal welding parameters through rigorous experimentation and testing.

- Qualification of WPSs: I conduct qualification tests to demonstrate that the chosen parameters consistently produce acceptable welds. These tests often involve destructive testing (e.g., tensile tests, bend tests) to verify the weld’s mechanical properties and visual inspection to ensure the weld’s appearance meets standards.

- Implementing and Monitoring WPSs: Ensuring the welders adhere to the WPS during production and regularly monitoring weld quality through visual inspection and sampling for further testing.

I’m proficient in using various welding codes and standards (like AWS D1.1) to guide the development and qualification of WPSs. It’s crucial to ensure traceability and reproducibility of welding processes for quality assurance and compliance.

Q 28. Describe your experience with process capability studies related to welding.

Process capability studies in welding help determine whether a welding process is capable of consistently producing welds that meet specified quality requirements. It’s like assessing if your cooking method can reliably produce a dish that meets customer expectations.

I’ve conducted several process capability studies using statistical methods such as Cp and Cpk calculations. These indices assess the process’s ability to meet specifications relative to the process variation. For example, a high Cpk value indicates that the process is highly capable and consistently producing welds within the specified tolerance limits. I’ve personally used these studies to justify the use of certain welding processes in critical applications and identify areas where process improvement is needed.

Data collection is a crucial part of these studies. This involves monitoring various parameters like weld penetration, bead width, and mechanical properties over multiple welds and utilizing statistical software to analyze the results and compute the capability indices. Based on the findings, we can identify areas for improvement in the welding process, such as adjustments to welding parameters or changes to the welding procedure to enhance consistency and capability.

Key Topics to Learn for Weld Parameter Development Interview

- Understanding Weld Processes: Gain a strong grasp of various welding methods (e.g., GMAW, GTAW, Resistance Welding) and their underlying principles. This includes understanding heat transfer, material science, and metallurgical changes during the welding process.

- Parameter Selection & Optimization: Learn how to select and optimize weld parameters (voltage, amperage, speed, gas flow, etc.) based on the base material, joint design, and desired weld quality. Understand the impact of each parameter on penetration, bead shape, and mechanical properties.

- Joint Design & Preparation: Explore different joint designs and their influence on weld parameter selection. Understand the importance of proper joint preparation (e.g., cleaning, beveling) to achieve sound welds.

- Weld Quality Assessment: Master various techniques for assessing weld quality, including visual inspection, destructive testing (e.g., tensile testing, bend testing), and non-destructive testing (e.g., radiographic testing, ultrasonic testing). Understand how these tests relate to weld parameter selection.

- Troubleshooting & Problem Solving: Develop your ability to diagnose and solve common welding problems, such as porosity, cracking, undercut, and incomplete fusion. Learn to systematically analyze weld defects and adjust parameters accordingly.

- Welding Codes & Standards: Familiarize yourself with relevant welding codes and standards (e.g., AWS D1.1, ASME Section IX) and their implications for parameter development and quality control.

- Data Analysis & Interpretation: Understand how to collect, analyze, and interpret data from welding processes to optimize parameters and improve efficiency. This includes familiarity with statistical methods and data visualization techniques.

Next Steps

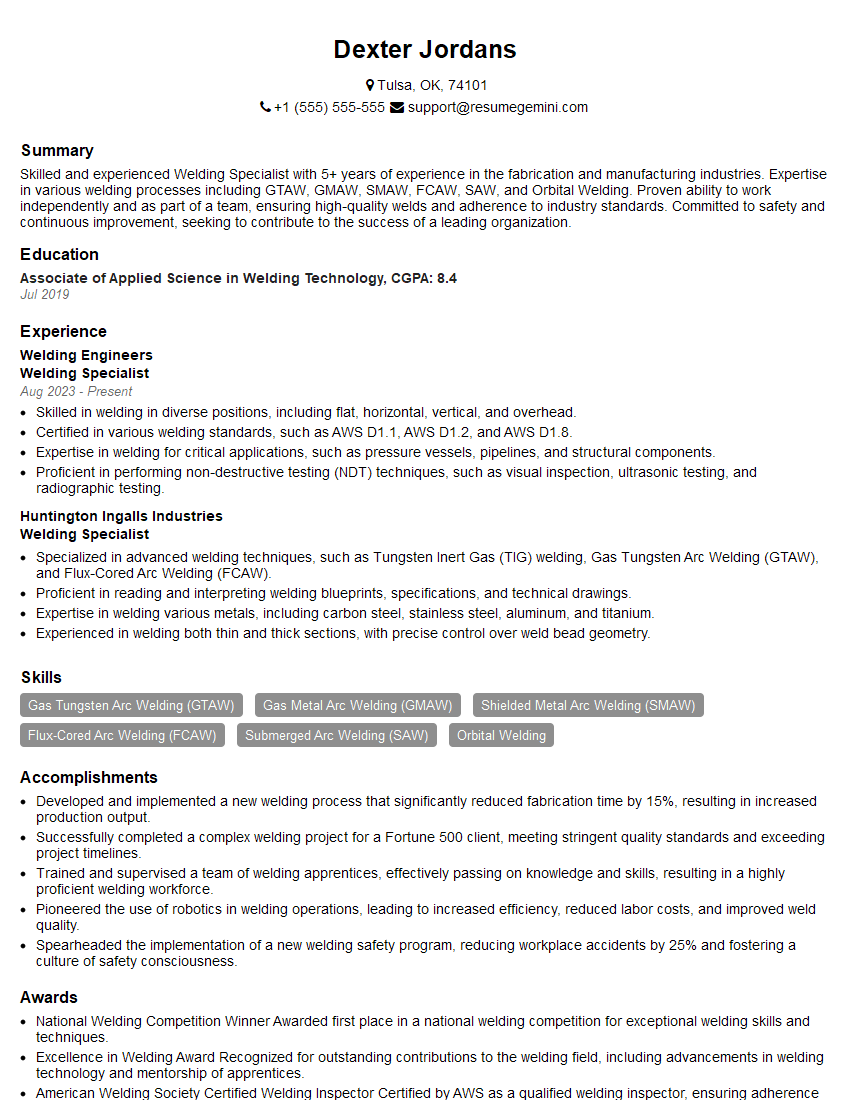

Mastering Weld Parameter Development is crucial for a successful and rewarding career in manufacturing, engineering, and related fields. It opens doors to advanced roles and higher earning potential. To increase your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. We recommend using ResumeGemini to build a professional and impactful resume tailored to highlight your expertise in Weld Parameter Development. Examples of resumes specifically designed for this field are available to guide you. Invest the time to craft a compelling resume—it’s your first impression and a crucial step in securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.