The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Welding Machine Troubleshooting interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Welding Machine Troubleshooting Interview

Q 1. Explain the troubleshooting steps for a MIG welder that is not feeding wire properly.

Troubleshooting a MIG welder with wire feed issues involves a systematic approach. Think of the wire feed system as a simple conveyor belt; if something is jamming the belt, the product (weld wire) won’t move. First, check the simplest things: is the wire spool properly seated and rotating freely? Is the drive roll properly engaged and adjusted? Is the wire kinked or damaged anywhere between the spool and the gun? These visual inspections are crucial.

- Drive Roll Adjustment: Insufficient tension can cause poor wire feed. Adjust the drive rolls to ensure firm but not excessive grip on the wire. Too much pressure can also cause problems.

- Wire Liner Issues: Inspect the wire liner inside the welding gun and the conduit connecting it to the welder. A damaged or obstructed liner can severely restrict wire movement. Replace any damaged sections.

- Contaminants: Sometimes, small bits of metal, weld spatter, or even dust can jam the feed mechanism. Clean out any debris from the wire feed system.

- Power Supply: Ensure the welder is receiving adequate power. Low voltage can weaken the motor’s ability to drive the wire properly.

- Motor Problems: If the above checks don’t solve the problem, the wire feed motor itself might be faulty. This usually requires professional repair or replacement. Listen for unusual sounds like grinding or squealing from the motor.

Remember to always disconnect the power source before any internal inspection or adjustment.

Q 2. How do you diagnose and repair a short circuit in a welding machine?

A short circuit in a welding machine is a dangerous situation that can cause overheating, damage to components, and even fire. Think of it as a shortcut in the electrical pathway, creating an unexpected high current flow. Diagnosis starts with safety – always disconnect the power!

- Visual Inspection: Carefully examine all wiring, connectors, and components for any visible damage, such as frayed wires, melted insulation, or burn marks. Pay close attention to areas with high current flow, like the power leads and the welding gun.

- Continuity Testing: Using a multimeter, test for continuity in the suspected area of the short. A short circuit will show near-zero resistance between two points that shouldn’t be connected. This is where understanding your welder’s electrical schematic is crucial.

- Isolation Testing: If a short is suspected within a component (e.g., a transformer), insulation resistance testing with a megohmmeter might be necessary. This test measures the insulation’s ability to resist current flow.

- Repair: Once the short is located, the faulty wiring or components must be repaired or replaced. Use proper wire gauge and insulation to ensure safety. All connections should be secure and well-insulated.

Example: Let’s say you find a short circuit in the welding gun cable. You’ll need to carefully trace the cable, identify the exact location of the short (often a broken wire touching the cable shielding), cut out the damaged section, and then splice in new wiring using proper techniques. Always ensure the repair is electrically sound and mechanically robust.

Q 3. Describe the process for troubleshooting a welding machine that is producing inconsistent welds.

Inconsistent welds are often the result of several interacting factors. Think of welding as a precise chemical reaction; if any parameter changes, the weld quality suffers. Troubleshooting this requires a systematic approach, checking various inputs:

- Welding Parameters: Start by reviewing the welding parameters (voltage, amperage, wire feed speed, travel speed). Even small variations can significantly impact weld quality. Document your settings and try minor adjustments. An inconsistent weld bead might indicate an inconsistent input.

- Workpiece Material and Preparation: The type of metal, its thickness, and surface cleanliness all play a crucial role. Make sure the materials are clean and free from rust, paint, or other contaminants.

- Gas Flow (for MIG/TIG): Inadequate gas coverage can lead to porosity and poor penetration. Ensure the gas flow rate is correct and there are no leaks in the gas lines.

- Electrode (for Stick Welding): If using stick welding, a damaged or contaminated electrode will cause inconsistent results. Use fresh electrodes of the appropriate type.

- Ground Connection: A poor ground connection leads to erratic arc behavior and inconsistent welding. Verify a good clean connection to the workpiece and ensure the ground cable is in good condition.

Systematic adjustment of each parameter, combined with careful observation of the weld bead’s appearance (penetration, width, spatter, etc.), is key to pinpoint the root cause. Sometimes, several factors work together to produce a suboptimal weld. A poorly maintained machine could cause inconsistent parameters over time.

Q 4. What are the common causes of arc blow and how can they be mitigated?

Arc blow is the deflection of the welding arc due to magnetic fields generated by the welding current. Imagine a tiny magnet pushing the arc away from its intended path. It often leads to irregular welds. The main causes are:

- High Current: Higher welding currents generate stronger magnetic fields, increasing the likelihood of arc blow.

- Poor Workpiece Geometry: Complex shapes or uneven metal thicknesses can create localized magnetic fields that deflect the arc.

- AC Welding: AC welding is more prone to arc blow due to the constantly reversing current which generates constantly changing magnetic fields.

- Nearby Magnetic Fields: External magnetic fields from other equipment or even large metal structures in the vicinity can interfere with the arc.

Mitigation strategies:

- Reduce Current: Lowering the welding current reduces the magnetic field strength.

- Adjust Workpiece Orientation: Changing the position or orientation of the workpiece can minimize the effect of magnetic fields. Sometimes, a simple repositioning can make a big difference.

- Use AC Balance Control (for AC Welding): Adjusting the AC balance control on the welder can help to balance the magnetic fields.

- Shielding: In some cases, magnetic shielding around the work area can mitigate external magnetic fields.

- Welding Techniques: Employing appropriate welding techniques, such as shorter arc length, can reduce the severity of arc blow.

Q 5. How do you identify and resolve problems related to gas flow in a TIG welder?

Gas flow problems in a TIG welder can severely affect weld quality, leading to porosity, incomplete fusion, and even contamination. Think of the shielding gas as a protective blanket; if there’s not enough, the weld is exposed to the atmosphere. Troubleshooting gas flow involves checking several points:

- Gas Cylinder Pressure: Ensure the gas cylinder has sufficient pressure. A low pressure reading means it needs refilling.

- Gas Regulator: Check that the gas regulator is properly adjusted and functioning correctly. A faulty regulator can impede gas flow.

- Gas Hose and Connections: Inspect the gas hose for any kinks, leaks, or damage. Pay close attention to all connections, making sure they are tight and free from leaks.

- Flow Meter: Verify that the gas flow meter is accurate and indicating the correct flow rate. A malfunctioning flow meter needs replacing.

- Gas Lens/Cup: The TIG torch should have a properly fitted gas lens or cup to ensure the gas is channeled appropriately to the weld zone.

- Leaks: Use soapy water to check for leaks along the gas line. Bubbling indicates a leak that needs to be repaired.

Example: Imagine a TIG welder producing a porous weld. After checking the cylinder pressure and regulator, a soapy water test reveals a leak at the connection between the gas hose and the torch. Tightening the connection solves the issue and improves weld quality.

Q 6. Explain the safety procedures you follow when troubleshooting welding equipment.

Safety is paramount when troubleshooting welding equipment. Before touching any electrical component, always disconnect the power source. This is the most crucial step.

- Lockout/Tagout: Use a lockout/tagout system to prevent accidental re-energization of the equipment.

- Personal Protective Equipment (PPE): Wear appropriate PPE including safety glasses, gloves, and flame-resistant clothing.

- Ventilation: Ensure adequate ventilation to prevent build-up of harmful fumes.

- Fire Safety: Keep a fire extinguisher nearby and be aware of potential fire hazards. Welding often generates sparks and hot metal, so caution is vital.

- Awareness of Hazards: Be aware of potential hazards associated with high voltage, hot metal, and moving parts.

- Professional Help: If unsure about any repair, consult a qualified welding technician or service professional. Do not attempt repairs that are beyond your skill level.

Never compromise safety; a minor injury can quickly escalate into a serious incident.

Q 7. How do you interpret welding machine error codes?

Welding machine error codes provide valuable clues to diagnose problems. Each manufacturer has its unique code system, so you’ll need the specific manual for your welder.

- Consult the Manual: The first step is always to refer to the welder’s manual. The manual will contain a list of error codes with their meanings and troubleshooting steps.

- Code Identification: Identify the exact error code displayed on the machine’s digital panel.

- Understanding the Code: Read the manual to find the description of the specific error code. This description will help narrow down the potential causes of the problem.

- Troubleshooting Steps: The manual usually provides troubleshooting steps to address each error code. These steps might involve checking specific components, making adjustments to settings, or replacing faulty parts.

- Error Code Logging: Some welders have error code logging, recording the sequence of errors. This can be useful for more complex fault analysis.

Example: A code ‘E03’ might indicate a problem with the wire feed motor. The manual will specify the steps to diagnose the issue, including checking power supply, motor connections, and potentially the motor itself.

Q 8. What are the common causes of overheating in a welding machine?

Overheating in a welding machine is a serious issue that can damage components and lead to unsafe operating conditions. It’s often a symptom of underlying problems, not a problem itself. Think of it like a car overheating – the engine is struggling. We need to find out why.

- Poor Ventilation: Insufficient airflow around the machine prevents heat dissipation. Imagine trying to bake a cake in a sealed oven – it’ll overheat! Dust buildup on cooling fins further exacerbates this.

- High Duty Cycle Exceeded: Welding machines have a duty cycle – the percentage of time they can operate at full power before needing to cool down. Exceeding this consistently leads to overheating. This is like constantly running a marathon without rest.

- Internal Component Failure: Faulty capacitors, resistors, or transistors within the power supply or control circuit can generate excessive heat. This is akin to a short circuit in your home’s electrical system.

- Wiring Issues: Loose connections or damaged wiring can lead to increased resistance and heat generation. This is like a frayed wire sparking in your house.

- Overload: Attempting to weld with a machine that’s underpowered for the job, or using incorrect settings, will cause excessive stress and heat.

Troubleshooting involves checking ventilation, verifying duty cycle adherence, inspecting internal components for damage or burning, carefully checking wiring, and ensuring the machine is appropriately matched to the welding task.

Q 9. Describe the different types of welding machine power sources and their troubleshooting specifics.

Welding machine power sources vary, each with its own troubleshooting quirks. Understanding the differences is crucial for effective repair.

- Transformer-based Machines: These use a transformer to step down the voltage. Problems often involve shorted windings (leading to overheating and reduced output), loose connections, or faulty taps.

- Rectifier-based Machines (DC): These rectify AC power to DC. Troubleshooting focuses on diodes (they can fail and cause reduced output or sparking), capacitors (which store energy and can overheat or fail), and the smoothing circuit.

- Inverter-based Machines (DC/AC): These use high-frequency switching to create efficient power. Troubleshooting is more complex and often involves checking the IGBTs (Insulated Gate Bipolar Transistors), which act like high-speed switches – a failure here can lead to a non-functional machine. Diagnosing these often requires specialized equipment.

- Constant Current (CC) vs. Constant Voltage (CV): CC machines maintain a constant current regardless of arc length, while CV machines maintain a constant voltage. Troubleshooting varies based on this – a CC machine with arc instability might have a problem with its current regulation, while a CV machine with poor arc stability might have a voltage regulation problem.

For all types, visual inspection, testing with a multimeter, and sometimes specialized electronic diagnostic tools are vital.

Q 10. How do you troubleshoot a welding machine with intermittent arc starting issues?

Intermittent arc starting suggests a problem in the circuit that initiates the arc. It’s like a car that sometimes refuses to start – several culprits could be at play.

- Worn-out or Contaminated Electrodes: Dirty or blunt electrodes can prevent proper arc initiation. Cleaning or replacing them is often the first step.

- Faulty Contact Tips: These transfer the current to the electrode. Wear or contamination can create poor contact.

- Dirty Work Clamps: Poor connection between the ground clamp and the workpiece causes inconsistent arc starting.

- Contaminated Workpiece: A dirty or coated workpiece can hinder arc formation.

- Low Open Circuit Voltage: The machine may not be providing enough voltage to overcome the starting resistance.

- Control Circuit Issues: A faulty trigger switch, control board, or faulty wiring in the control circuit is a possibility.

Troubleshooting this involves systematic checking. Start with the simple things—cleaning and inspecting electrodes and clamps—before moving to more complex checks on the control circuit and open-circuit voltage.

Q 11. What are the potential problems associated with worn welding machine components, and how are they addressed?

Worn components significantly impact welding machine performance and safety. Ignoring them is akin to driving a car with worn-out brakes. Problems include:

- Worn Contact Tips: Lead to inconsistent arc, reduced current transfer, and increased heat generation.

- Worn Electrodes: Produce inconsistent welds, weak penetration, and increased spatter.

- Worn Drive Rollers (in wire feed machines): Result in erratic wire feed, uneven welds, and potential wire jams.

- Worn Power Supply Components: May cause overheating, reduced output, and unstable arcs. A failing capacitor in a power supply, for example, can show reduced output.

- Worn or Damaged Cables: Create voltage drop, poor connections, and potential hazards.

Addressing these issues means regular inspection and timely replacement. Worn components should be replaced with OEM (Original Equipment Manufacturer) parts whenever possible to ensure compatibility and safety.

Q 12. Explain the process for checking and maintaining the grounding system of a welding machine.

A properly grounded welding machine is crucial for safety. A poorly grounded machine is a shock hazard. Checking the grounding system involves:

- Inspecting the Ground Cable: Look for damage, fraying, or loose connections. The ground cable needs to be thick enough to handle the welding current.

- Testing the Ground Connection: Use a multimeter to measure the resistance between the machine ground terminal and a known good ground point (such as a water pipe). Low resistance (ideally under 1 ohm) indicates a good ground.

- Checking the Ground Clamp: Ensure the clamp is clean and makes good contact with the workpiece. A poor connection here will bypass the grounding system.

- Verifying the Grounding Point: The grounding point itself should be capable of handling the welding current safely and have low resistance to ground.

Maintaining the grounding system is about keeping the cable intact, cleaning the clamp regularly, and ensuring the connection to earth is robust. Remember to turn the machine off before conducting any of these checks!

Q 13. How do you diagnose and repair problems with the control system of a welding machine?

Troubleshooting a welding machine’s control system can be complex, often requiring specialized knowledge and equipment. It’s akin to diagnosing a computer – systematic troubleshooting is key.

- Check the obvious: Begin with visual inspections of switches, displays, and wiring. Loose connections, burned components, or broken wiring are often to blame.

- Test the input devices: Check the trigger switch, wire feed controls (if applicable), and any other user inputs for proper function.

- Inspect the control board: Look for burned or damaged components. This requires some electronics knowledge and possibly a circuit diagram.

- Use a multimeter: Test voltages and signals at various points in the control circuit, guided by the wiring diagram.

- Consult schematics: This is crucial for understanding the control system’s logic.

- Check safety interlocks: Many machines have safety features that shut down the power if a problem is detected. Check these to ensure they’re functioning correctly.

Repairing control system issues may involve component replacement, circuit board repair (often best left to professionals), or even complete control system replacement. Remember, working on control circuits involves working with high voltages, so prioritize safety.

Q 14. What are the common causes of inconsistent weld penetration?

Inconsistent weld penetration means the weld isn’t fully fusing the materials, creating a weak joint. It’s like trying to weld two pieces of metal with glue instead of proper fusion. Several factors contribute:

- Incorrect Welding Parameters: Using the wrong amperage, voltage, or welding speed will always lead to issues.

- Poor Joint Preparation: Gaps, misalignment, or contamination between the base materials will prevent proper fusion.

- Insufficient Heat Input: Not enough heat applied to the weld area leads to incomplete melting and fusion.

- Electrode Type and Condition: Incorrect electrode choice, or a worn or contaminated electrode, will dramatically impact weld quality.

- Machine Issues: Problems with the power supply, leading to inconsistent current or voltage output.

- Workpiece Material: Certain materials (e.g., stainless steel) require special consideration in terms of weld parameters and heat input.

Troubleshooting requires carefully reviewing the welding procedure, the machine’s settings, the joint preparation, and the electrode condition. Adjusting welding parameters based on material thickness and type is crucial for obtaining consistent and complete penetration.

Q 15. Describe the troubleshooting process for a welding machine with excessive spatter.

Excessive spatter in welding is a common problem often indicating issues with the welding parameters, consumables, or the machine itself. Think of spatter like tiny metal fireworks – too much means something’s not quite right.

Troubleshooting starts with systematically checking several areas:

- Welding Parameters: Incorrect voltage, amperage, or wire feed speed are primary culprits. Start by reviewing the recommended settings for your chosen welding process and material. A slight adjustment can drastically reduce spatter. For example, if you are using MIG welding and observing excessive spatter, try reducing the amperage slightly, and increase the wire feed speed. This often results in a more stable arc and less spatter.

- Consumables: Check the condition of your welding wire. A worn-out contact tip or a nozzle clogged with spatter can significantly increase spatter. Replacing these components is a simple and often effective fix. Also, ensure you’re using the correct diameter wire for your settings. Consider the type of shielding gas used as well. An improperly mixed or contaminated gas supply can affect the quality of the weld and increase spatter.

- Machine Issues: While less common, problems within the welding machine itself can cause excessive spatter. This might involve a faulty wire feeder motor, a problem with the power supply, or a failing control board. These issues often require professional diagnosis and repair.

Step-by-Step Troubleshooting:

- Verify the welding parameters against the manufacturer’s recommendations.

- Inspect and replace worn contact tips and nozzles.

- Check for any obstructions in the gas flow and ensure the gas is clean and at the correct pressure.

- If spatter persists, consult the welding machine’s manual or contact a qualified technician for more in-depth diagnostics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and rectify problems related to voltage fluctuations affecting welding performance?

Voltage fluctuations are a major enemy of consistent welding. They can lead to inconsistent welds, increased spatter, and even damage the welding machine. Imagine trying to bake a cake with an oven that keeps changing temperatures – the outcome would be unpredictable. The same applies to welding.

Identifying the source of the fluctuations is crucial. You can use a voltmeter to monitor the voltage at the outlet supplying the welder. Consistent dips or surges point to a problem with the power supply. If the voltage is stable at the outlet but fluctuates at the welder, the problem lies within the welder itself. This often points to internal wiring or component failure.

Rectification strategies:

- Power Supply Issues: Addressing power supply fluctuations might involve upgrading your home’s electrical system, installing a voltage regulator, or consulting an electrician to identify and fix the problem at the source.

- Welding Machine Issues: If the issue is internal, professional service is usually required. A qualified technician can diagnose faulty components and conduct necessary repairs.

Practical Example: I once worked on a site where welding was inconsistent due to fluctuating voltage at the outlet. The solution was to install a dedicated, heavier-gauge line to the workshop, ensuring a stable power supply.

Q 17. What are the safety precautions when working with high-voltage welding equipment?

Safety is paramount when working with high-voltage welding equipment. Welding involves extremely high currents and voltages, which can cause severe injury or death if safety precautions are not followed meticulously. Consider high voltage like a powerful, untamed animal – it requires respect and careful handling.

Essential safety precautions include:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including a welding helmet with the correct shade filter, welding gloves, flame-resistant clothing, and safety footwear.

- Proper Ventilation: Welding produces fumes and gases which can be harmful to your health. Make sure to work in a well-ventilated area or utilize a fume extractor.

- Grounding: Ensure the welding machine and the workpiece are properly grounded to prevent electrical shocks.

- Isolation and Awareness: Only trained personnel should operate the equipment. Clearly mark the work area, and ensure there are no flammable materials nearby.

- Emergency Procedures: Establish and communicate clear emergency procedures, including how to deal with electric shocks or fires.

- Regular Inspections: Regularly inspect the welding machine and cables for any damage or wear and tear.

Failure to adhere to these safety precautions can lead to severe consequences, including burns, electric shock, eye damage, and respiratory problems.

Q 18. How do you troubleshoot a welding machine that is producing porosity in the weld?

Porosity in a weld, those tiny holes, weakens the joint and is a serious defect. It often suggests a problem with the welding process itself or the material being welded. Think of it as tiny air bubbles trapped in the metal.

Troubleshooting porosity involves considering several factors:

- Shielding Gas: Insufficient or contaminated shielding gas is a common cause. The gas protects the weld pool from atmospheric contamination. Check for leaks in the gas lines, ensure the gas tank is full, and use a gas purity analyzer to verify the gas quality.

- Welding Parameters: Improper welding parameters, such as too low amperage or too slow travel speed, can also cause porosity. Adjusting these parameters often resolves the issue.

- Base Metal: The base metal’s cleanliness and composition can influence porosity. Thoroughly clean the base materials before welding to remove any oil, grease, paint, or rust. Ensure the base material is appropriate for the welding process.

- Joint Design: Poor joint design can trap gases and lead to porosity. Review your weld joint design and ensure proper fit-up and gap.

A systematic approach to eliminating porosity requires meticulous checks of all these areas.

Q 19. Explain the process of diagnosing and repairing problems with the wire feeder mechanism.

The wire feeder is the heart of many welding processes, ensuring a consistent supply of welding wire. Problems with this system lead to inconsistent welds or complete welding failure. Think of it like a car’s fuel injection system; if it malfunctions, the engine won’t run smoothly.

Diagnosing wire feeder issues:

- Visual Inspection: Begin with a visual inspection for obvious problems like worn drive rollers, bent or damaged wire, or obstructions in the wire path.

- Wire Feed Speed: Check the wire feed speed. If it’s too fast or slow, adjust the settings accordingly. An inconsistent feed speed suggests a mechanical problem within the feeder motor or drive system.

- Drive Rollers: Ensure the drive rollers are correctly adjusted to grip the welding wire firmly. Worn or improperly adjusted rollers often cause feed problems.

- Motor Operation: Listen for unusual noises from the wire feeder motor. Grinding or clicking sounds usually signify wear and tear or a malfunction.

Repairing the wire feeder:

- Replace Worn Parts: Replace worn or damaged components such as drive rollers, contact tips and nozzles as needed. Consult the welding machine’s manual for the specific procedures.

- Clean and Lubricate: Clean and lubricate the wire feeder mechanism as per the manufacturer’s recommendations.

- Check Electrical Connections: Verify the electrical connections to the motor and control board.

- Consult a Technician: If the problem persists, it may require the expertise of a qualified technician.

Q 20. Describe how to test the amperage and voltage output of a welding machine.

Testing the amperage and voltage output of a welding machine is a crucial part of regular maintenance and troubleshooting. It confirms the machine is operating within its specifications. Think of it like a regular health check for your machine.

You’ll need a clamp-on ammeter and a voltmeter to conduct the tests. These tools are readily available at most welding supply stores.

Testing Procedure:

- Safety First: Always disconnect the welding machine from the power source before performing any tests.

- Voltage Test: Connect the voltmeter across the output terminals of the welding machine. Make sure the voltmeter is set to the appropriate voltage range (AC or DC, depending on your machine). The reading should match the machine’s rated output voltage.

- Amperage Test: Connect the clamp-on ammeter around the welding cable near the output terminal. Set the ammeter to the correct amperage range. With the machine turned on but not welding (using no load), observe the current draw. A small current is normal, but significant current draw even when not welding indicates an internal problem.

- Weld Test: If possible, perform a test weld and measure the voltage and current during the weld. The reading should be within the operational parameters of the welding machine.

- Compare with Specifications: Compare the measurements with the welding machine’s specifications stated in the manual. Significant deviations might indicate a problem needing attention.

Always refer to your specific machine’s manual for detailed testing procedures and safety guidelines.

Q 21. How do you maintain accurate records of welding machine maintenance and repairs?

Maintaining accurate records of welding machine maintenance and repairs is essential for ensuring safety, compliance, and efficient troubleshooting. A well-maintained logbook is a valuable tool, providing a history of the machine’s performance and issues. Think of it as a medical record for your machine.

Methods for maintaining records:

- Digital Logbook: Using a spreadsheet or dedicated maintenance software provides a searchable, organized database of maintenance and repairs.

- Physical Logbook: A physical logbook is simple and can be used in conjunction with digital logs. It can be very beneficial for tracking visual aspects of the machine.

- Key Information: Each entry should include:

- Date of service

- Type of maintenance or repair performed

- Parts replaced

- Technician’s name

- Observations or measurements made

- Photographs before, during and after service where appropriate.

- Regular Inspections: Conduct regular scheduled inspections, even if no problems are apparent. This proactive approach helps prevent major issues.

Importance of Records: Accurate records are invaluable for warranty claims, regulatory compliance, and for identifying recurring issues or trends in machine performance. They also aid in troubleshooting future problems by providing a history of previous repairs and maintenance.

Q 22. What are the common causes of a welding machine producing a weak arc?

A weak welding arc is a common problem with several potential causes. Think of the arc as a tiny lightning bolt; if it’s weak, it’s not getting enough power. This can stem from issues in the power supply, the machine’s internal components, or even the consumables (electrodes, wire, gas).

Insufficient Power Supply: The most straightforward cause. Check your input voltage and amperage. Is the outlet overloaded? Are you using an extension cord that’s too thin or too long? A weak arc can result from inadequate power reaching the machine.

Dirty or Worn Contacts: Welding machine connections, both internal and external, need to be clean and tight. Corrosion, loose connections, or worn-out electrode clamps can restrict current flow, leading to a weak arc. Regular inspection and cleaning are crucial.

Faulty Internal Components: Problems within the machine itself, such as a failing rectifier (converts AC to DC), worn brushes in a motor-generator set, or a damaged control circuit board, can all result in a reduced welding current. This often requires professional diagnosis and repair.

Incorrect Settings: The welding machine’s amperage and voltage settings are critical. If the settings are too low for the material and welding process, the arc will be weak. Always start with the manufacturer’s recommended settings for your chosen material and adjust carefully.

Consumable Issues: For processes like MIG and stick welding, using the wrong diameter or type of electrode or welding wire can weaken the arc. Make sure you’re using the appropriate consumables for your welding process and material.

Q 23. How do you diagnose and repair problems with the gas solenoid valve?

The gas solenoid valve controls the gas flow in gas metal arc welding (GMAW or MIG) and gas tungsten arc welding (GTAW or TIG). A malfunctioning valve can interrupt the shielding gas, leading to poor weld quality, porosity (holes in the weld), or even safety hazards. Diagnosis typically involves visual inspection, testing with a multimeter, and sometimes replacing the valve.

Visual Inspection: Check for any visible damage, loose connections, or debris on the valve or its associated tubing. Look for leaks by spraying soapy water near the connections.

Multimeter Testing: With the valve disconnected from the power supply, check its continuity using a multimeter. A good valve should show continuity when energized; if not, it likely needs replacement.

Testing Functionality: With the valve connected, try initiating a weld. Observe if gas flows when the trigger is pulled. If not, check the valve’s power supply and wiring.

Replacement: If the valve is found to be faulty after testing, replace it with a new valve of the same specifications. Ensure the new valve is properly connected and secured.

Remember safety first! Always disconnect the power supply before performing any maintenance on the gas solenoid valve or any part of the welding machine.

Q 24. Explain the steps to troubleshoot a welding machine that produces excessive heat.

Excessive heat generation in a welding machine can indicate several problems, from simple overloads to more serious internal faults. The goal is to identify the source of this excess heat before it causes further damage.

Check Ventilation: Is the machine’s ventilation system working properly? Is the airflow blocked by dust or debris? Poor ventilation can cause overheating.

Inspect Wiring and Connections: Overheated wiring or loose connections can significantly increase resistance, leading to excessive heat build-up. Look for signs of burning, discoloration, or loose terminals.

Verify Duty Cycle: Welding machines have a duty cycle which specifies the amount of time they can operate continuously before needing to cool down. Exceeding the duty cycle will inevitably lead to overheating. Refer to the machine’s specifications.

Internal Components: If external checks don’t reveal the issue, internal components, such as capacitors, transformers, and rectifiers, might be failing. This usually requires a professional technician to pinpoint and repair the malfunctioning part.

Load Testing: If possible, run a controlled load test under varying conditions. This can help identify whether the overheating is consistently present or only occurs under specific circumstances.

Addressing overheating promptly is crucial as it can damage components, reduce the lifespan of the machine, and pose safety risks.

Q 25. What are the differences in troubleshooting techniques for various welding processes (MIG, TIG, Stick)?

Troubleshooting techniques vary depending on the welding process due to differences in their mechanisms and consumables. MIG welding (using wire), TIG welding (using a tungsten electrode), and stick welding (using coated electrodes) all have unique troubleshooting needs.

MIG Welding: Focus on wire feed issues (incorrect speed, kinks, worn-out liner), gas flow (solenoid valve, gas leaks), and contact tip wear. A poor weld can often be traced back to these areas.

TIG Welding: Pay close attention to tungsten electrode condition (contamination, improper sharpening), gas flow (leaks, insufficient shielding gas), and correct setting of high-frequency start. Tungsten contamination is a common problem here.

Stick Welding: Check electrode coating condition (moisture, damage), proper arc length (too short or too long), and electrode holder for good contact. Electrode selection based on material is also crucial in stick welding.

In all three processes, proper grounding, correct polarity, and power source settings are fundamental aspects of troubleshooting. Each process has its own subtleties, and experience helps in quickly identifying the root cause of the issue.

Q 26. How do you handle unexpected welding machine malfunctions during a critical production run?

Unexpected malfunctions during a critical production run require a calm, methodical approach. Panic only exacerbates the situation. My strategy is based on rapid assessment, prioritization, and contingency planning.

Safety First: Ensure the safety of personnel by immediately isolating the faulty equipment and stopping the welding operation. This is the absolute priority.

Quick Assessment: Determine the nature of the malfunction. Is it a simple issue (like a gas leak) or a more complex problem?

Prioritize Repairs: Decide whether to attempt a quick fix or call in a professional based on the severity of the malfunction and the available expertise. A minor issue might be quickly resolved, while a major problem requires professional attention.

Contingency Plan: If a repair is impossible during the production run, implement a contingency plan. This might involve switching to a backup machine, using alternative welding methods, or temporarily halting the specific section of the production affected by the malfunction.

Documentation is key! Record all details of the malfunction, attempted repairs, and the resolution, including time lost. This information helps in preventative maintenance and future troubleshooting.

Q 27. How do you determine when a welding machine needs professional repair versus simple maintenance?

Distinguishing between routine maintenance and the need for professional repair requires a careful evaluation of the situation. Think of it like a car; sometimes you need an oil change (maintenance), and sometimes you need major engine work (professional repair).

Simple Maintenance: Includes cleaning contacts, inspecting cables, checking gas connections, and replacing consumables. These tasks are often straightforward and can be done by trained personnel.

Professional Repair: Involves complex issues such as internal electrical faults, damaged components (transformers, rectifiers), or mechanical problems that require specialized tools and knowledge to diagnose and repair.

If the problem persists after standard maintenance procedures, the issue is likely complex and beyond the scope of routine maintenance. Unusual noises, sparks, erratic behavior, or significant performance degradation usually indicate the need for professional intervention.

Q 28. Describe your experience with different brands of welding machines and their specific troubleshooting needs.

Throughout my career, I’ve worked with various welding machine brands, each having its own quirks and troubleshooting needs. Miller, Lincoln Electric, and Hobart are prominent examples, each offering a range of models for diverse applications. For instance:

Miller: Miller machines, known for their robustness, often present problems related to worn brushes in motor-generator sets (older models) or issues with sophisticated digital control systems. Understanding their diagnostics codes is vital.

Lincoln Electric: Lincoln Electric machines, known for their reliability, sometimes show issues related to wire feed issues in their MIG welders. Their user interfaces often require a thorough understanding of their operation.

Hobart: Hobart’s simpler models can occasionally have issues with loose connections or overheating due to insufficient ventilation. Their older inverters sometimes develop problems within their power supplies.

Experience with different brands teaches you to recognize the typical failure points of each and allows for efficient and targeted troubleshooting. Familiarity with service manuals and schematics is indispensable when dealing with complex issues.

Key Topics to Learn for Welding Machine Troubleshooting Interview

- Understanding Welding Processes: A solid grasp of different welding processes (MIG, TIG, Stick, etc.) is crucial. This includes understanding their parameters, limitations, and common issues.

- Electrical Systems in Welding Machines: Familiarize yourself with the electrical components (power supply, controls, wiring) and their function within the machine. Be prepared to discuss troubleshooting electrical faults.

- Gas Systems and Flow Control: Learn about the role of shielding gases in welding and how to diagnose problems related to gas flow, leaks, or purity.

- Mechanical Components and Maintenance: Understanding the mechanical aspects of welding machines (wire feed mechanisms, torch assemblies, etc.) and their routine maintenance is essential for effective troubleshooting.

- Safety Procedures and Regulations: Demonstrate knowledge of relevant safety regulations and procedures related to welding machine operation and maintenance. This is a critical aspect of the job.

- Diagnostic Techniques: Practice using various diagnostic tools (multimeters, pressure gauges, etc.) and techniques for identifying and isolating faults in welding equipment.

- Troubleshooting Common Welding Defects: Be prepared to discuss common welding defects (porosity, undercut, lack of fusion) and their causes, relating them to potential machine malfunctions.

- Preventive Maintenance: Discuss the importance of preventative maintenance schedules and their impact on machine longevity and reducing downtime.

- Interpreting Error Codes and Diagnostics: Many modern machines provide error codes. Understand how to interpret these codes and use them in troubleshooting.

- Practical Problem-Solving Strategies: Be ready to describe your systematic approach to identifying and resolving issues, showcasing your analytical and problem-solving skills.

Next Steps

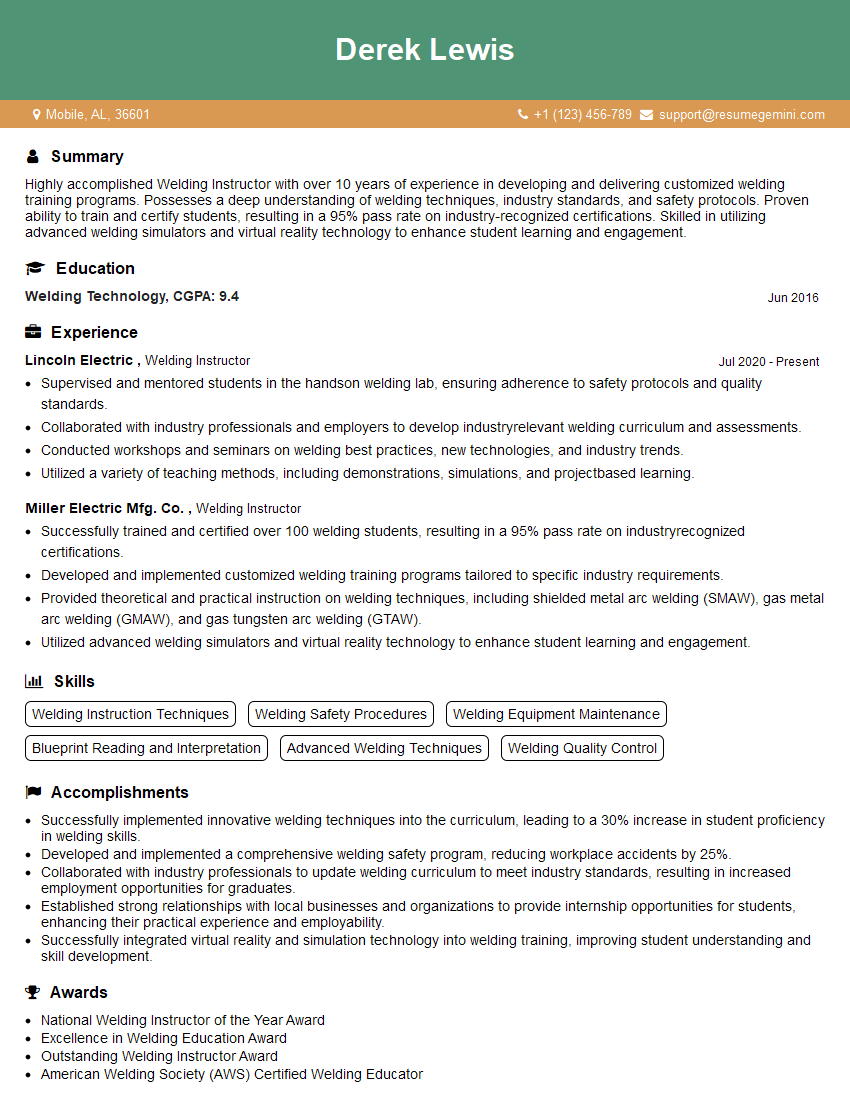

Mastering welding machine troubleshooting is key to advancing your career in this in-demand field. It demonstrates your technical expertise and problem-solving capabilities, making you a highly valuable asset to any employer. To significantly increase your chances of landing your dream job, creating an ATS-friendly resume is crucial. This ensures your application gets noticed by hiring managers. ResumeGemini is a trusted resource that can help you build a professional, impactful resume tailored to the specific requirements of welding machine troubleshooting positions. Examples of resumes tailored to this field are available, giving you a head start in crafting your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.