Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Working safely on ladders and scaffolding interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Working safely on ladders and scaffolding Interview

Q 1. What are the different types of ladders and their appropriate uses?

Ladders come in various types, each suited for specific tasks. Choosing the right ladder is crucial for safety and efficiency.

- Step Ladders: Ideal for short-to-medium height tasks where you need a stable platform. Think of painting a wall or changing a lightbulb.

- Extension Ladders: Used for reaching significant heights, like cleaning gutters or working on high ceilings. They extend to reach different heights, providing versatility.

- Single Ladders: Leaned against a vertical surface for access to elevated areas. Common in construction or maintenance work.

- Combination Ladders (A-frame/Extension): Offer flexibility. They can be used as a stepladder or extended into a single ladder. Great for diverse jobs around the house or on a construction site.

- Scaffold Ladders: Larger and more robust ladders with wider platforms, providing more stability and work area for heavier tasks or when carrying multiple tools.

Remember to always select a ladder appropriate for the height and the weight of the worker plus any materials being carried.

Q 2. Explain the three-point contact rule for ladder safety.

The three-point contact rule is fundamental for ladder safety. It ensures you always maintain a secure grip and stable footing.

This means that at all times, you should have two hands and one foot, or two feet and one hand, in contact with the ladder. Never have both hands or both feet on the ladder while moving or reaching.

Example: When climbing, maintain a firm grip with both hands on the ladder rungs, placing one foot securely on a rung at a time. When reaching, keep one hand securely on the ladder and the other free to do the work, transferring your body weight as you do so to maintain stability. This technique prevents accidental falls by ensuring at least three points of contact throughout the whole process of using a ladder.

Q 3. What are the maximum safe load limits for various ladder types?

Maximum safe load limits vary greatly depending on the ladder type, material (fiberglass, aluminum, wood), and manufacturer. Never exceed the manufacturer’s stated load limit, which is usually found on a label on the ladder itself. This limit includes the weight of the user and any tools or materials being carried.

For example, a small stepladder might have a limit of 200 lbs, while a heavy-duty extension ladder could have a limit of 300 lbs or more. Always check the label before use to ensure you’re within the safe working load. Using a ladder beyond its load limit significantly increases the risk of collapse and injury.

Q 4. Describe the proper inspection procedures for ladders before use.

Inspecting a ladder before each use is vital for preventing accidents. A thorough inspection should include:

- Structural Integrity: Check for cracks, bends, splits, or damage to the rails, rungs, and feet. Replace any damaged ladder.

- Rungs and Steps: Inspect for any loose, broken, or damaged rungs or steps. Loose parts indicate wear and tear, and use should be discontinued.

- Feet: Ensure the feet are undamaged, non-slippery, and provide secure footing on the surface.

- Fasteners: For extension ladders, check all locking mechanisms and latches to ensure they’re secure and functioning correctly. Inspect rivets and other fasteners for looseness or damage.

- Overall Condition: Look for any signs of excessive wear or tear. A ladder showing significant wear should be retired from service.

If you find any issues during your inspection, do not use the ladder. A damaged ladder is a dangerous ladder!

Q 5. What are the common hazards associated with ladder use?

Numerous hazards are associated with ladder use. These include:

- Falls: This is the most common and serious hazard, often due to improper setup, slippery surfaces, reaching too far, or exceeding the weight limit.

- Electrocution: Contact with overhead power lines is a significant risk, especially when working near electrical wires. Ensure adequate clearance before starting work.

- Slips and Trips: Wet or uneven surfaces can cause falls. Always ensure a stable and clean working surface.

- Overreaching: Reaching beyond the ladder’s limits can cause loss of balance and falls. Climb down and reposition the ladder instead of overreaching.

- Improper Setup: Incorrectly setting up a ladder increases the risk of instability and falls. Ensure proper angle, level ground, and secure base.

- Dropped Objects: Dropped tools or materials from a height can cause injury. Use tool belts or other equipment to avoid dropping tools.

Q 6. How do you ensure stability when working on a ladder?

Stability is paramount when working on a ladder. Several factors contribute to stability:

- Proper Setup: The ladder should be placed on a firm, level surface, at the correct angle (generally a 4:1 ratio – for every four feet of height, the base should be one foot away from the wall). Ensure the ladder’s feet are positioned securely.

- Foot Placement: Place your feet firmly and evenly on the rungs or steps, avoiding quick, jerky movements.

- Body Positioning: Keep your body centered on the ladder, avoiding leaning or overreaching. Keep your center of gravity within the ladder’s base.

- Weight Distribution: Distribute your weight evenly across both feet to improve balance and stability.

- Avoid Distractions: Eliminate distractions that can compromise your focus and balance.

- Use Safety Equipment: Consider using a harness and fall arrest system for added protection, especially when working at considerable heights.

Q 7. What are the safety regulations regarding working heights?

Safety regulations regarding working heights vary by location and industry, but common themes include:

- Fall Protection: At certain heights, fall protection systems (harnesses, guardrails, safety nets) become mandatory. These regulations often stipulate specific heights at which fall protection is required.

- Ladder Usage Restrictions: Some jurisdictions may limit the use of ladders beyond a specific height, recommending the use of scaffolding or other access equipment for greater heights.

- Training Requirements: Workers are often required to undergo training on safe ladder and scaffolding practices before working at heights.

- Risk Assessments: Before any work at height, a thorough risk assessment should be conducted to identify potential hazards and implement appropriate control measures.

- Permit to Work Systems: In many industries, a permit-to-work system may be in place for high-risk activities involving work at heights. This ensures that necessary precautions are in place before work begins.

Always consult with your employer and relevant safety regulations for your specific location and industry.

Q 8. Explain the different types of scaffolding systems.

Scaffolding systems come in various types, each designed for specific applications and jobsite conditions. The choice depends on factors like the height, the type of work, and the ground conditions. Here are a few common types:

- Independent Tied Scaffolding: This is a freestanding scaffold, typically used for smaller projects where it’s not feasible or safe to tie it to a building. Imagine it like a free-standing tower.

- Suspended Scaffolding: This type hangs from a structure using ropes or cables. Think of the kind of scaffolding you might see window cleaners using on tall buildings. It’s incredibly versatile but requires meticulous rigging and safety checks.

- Facade Scaffolding: This system is attached directly to the building’s facade. It’s often used for exterior work on tall buildings, offering a stable platform close to the work area.

- Tube and Clamp Scaffolding: This is a very common and adaptable system that uses tubes and clamps to create a custom scaffold configuration. It’s very versatile and widely used for its ease of assembly and adaptability.

- System Scaffolding: This prefabricated system utilizes standardized components for faster and easier assembly, often favored for larger projects due to its efficiency.

Choosing the right scaffolding system is crucial for safety and efficiency. A poorly chosen system can lead to accidents and project delays.

Q 9. Describe the components of a typical scaffold.

A typical scaffold, regardless of the specific type, comprises several key components. Think of it like building with LEGOs, but with safety as the top priority.

- Base Plates/Mudsills: These provide a stable foundation on the ground, distributing the load evenly and preventing sinking.

- Standards (Uprights): These vertical supports form the scaffold’s frame.

- Ledgers (Transoms): These horizontal members connect the standards, providing support for the work platforms.

- Putlogs: These are horizontal beams which support the ledgers.

- Work Platforms (Decking): These are the platforms where workers stand and perform tasks. They should be solid, level, and non-slip.

- Guardrails and Toeboards: These are essential safety features that prevent falls. Guardrails surround the platform, while toeboards prevent objects from falling off.

- Braces and Diagonal Supports: These add stability and prevent the scaffold from collapsing under load.

- Castors (if applicable): These allow the scaffold to be moved easily.

Each component plays a critical role in ensuring the scaffold’s stability and safety. A missing or damaged component can compromise the entire structure.

Q 10. What are the proper procedures for erecting and dismantling scaffolding?

Erecting and dismantling scaffolding are high-risk activities requiring strict adherence to safety procedures. Think of it like a carefully choreographed dance – every step needs to be precise and safe.

Erecting Scaffolding:

- Plan: Carefully plan the scaffold layout, ensuring it’s stable and suitable for the task.

- Prepare the Ground: Ensure a level and stable base.

- Assemble the Base: Start by building a stable base, attaching base plates and standards.

- Add Ledgers and Platforms: Install ledgers and platforms, ensuring they’re secure and level.

- Install Braces: Add diagonal braces for stability.

- Guardrails and Toeboards: Install guardrails and toeboards.

- Inspect: Thoroughly inspect the scaffold before use.

Dismantling Scaffolding:

- Plan: Develop a dismantling plan, ensuring a safe sequence of removal.

- Remove Platforms and Ledgers: Begin by removing platforms and ledgers from the top down.

- Remove Braces: Carefully remove braces.

- Lower Standards: Carefully lower standards.

- Inspect Components: Inspect all components for damage.

Always follow manufacturer’s instructions and applicable safety regulations during both erection and dismantling.

Q 11. What are the safety regulations for working on scaffolding?

Safety regulations for working on scaffolding are stringent and designed to minimize risk. They vary by region but generally include:

- Competent Personnel: Only trained and competent personnel should erect, dismantle, and use scaffolding.

- Regular Inspection: Scaffolding must be regularly inspected before each use and after any significant event (like a storm).

- Safe Access and Egress: Safe access and exit points should be provided.

- Load Limits: The scaffold should never be overloaded.

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including hard hats, safety harnesses, and fall protection systems.

- Weather Conditions: Scaffolding shouldn’t be used in severe weather conditions (high winds, heavy rain, etc.).

- Proper Signage: Appropriate signage should be displayed to warn of potential hazards.

Failure to comply with safety regulations can lead to serious injuries or fatalities. Treat scaffolding safety as a paramount concern.

Q 12. How do you inspect scaffolding for stability and safety?

Inspecting scaffolding for stability and safety is a crucial step before every use. A visual inspection alone isn’t enough; you need to be thorough.

- Visual Inspection: Check for any damage to components (bent standards, cracked platforms, loose bolts).

- Structural Integrity: Verify all connections are secure and that the scaffold is plumb (vertical) and level.

- Base Stability: Ensure the base is firm and level, free from obstructions.

- Load Capacity: Verify that the scaffold’s load capacity is not exceeded. Consider the weight of materials, workers, and tools.

- Guardrails and Toeboards: Check that guardrails and toeboards are correctly installed and in good condition.

- Bracing: Verify all bracing is secure and adequately supporting the structure.

- Access and Egress: Ensure safe and convenient access and egress points.

If any defects are found, the scaffold must not be used until the necessary repairs or replacements are made. Document all inspections and repairs meticulously.

Q 13. What are the common hazards associated with scaffolding use?

Scaffolding, while a necessary tool, presents several hazards if not handled correctly. These include:

- Falls from Height: This is the most significant hazard, leading to serious injuries or fatalities. This risk is mitigated through proper guardrails, toeboards, and fall arrest systems.

- Collapses: Scaffold collapses can occur due to overloading, improper erection, or damage to components. Regular inspection and proper erection techniques minimize this risk.

- Electrocution: Contact with overhead power lines is a serious risk. Planning and awareness of overhead power lines are crucial.

- Material Falls: Dropped tools or materials can cause injuries to workers below. Proper procedures for handling materials and the use of toeboards are vital.

- Slips, Trips, and Falls: These can happen on uneven or cluttered platforms. Keeping the platform clean and free of obstructions reduces this risk.

Understanding these hazards and implementing preventative measures is critical for maintaining a safe work environment.

Q 14. What are the requirements for guardrails and toeboards on scaffolding?

Guardrails and toeboards are critical safety components that prevent falls and dropped objects. Regulations regarding their requirements vary by location, but general guidelines apply.

- Guardrails: Guardrails should be at least 42 inches high and strong enough to withstand a significant load. They should be continuous around the perimeter of the platform.

- Mid-rails: Many regulations mandate mid-rails, placed approximately halfway between the top rail and the platform, providing added protection.

- Toeboards: Toeboards are usually at least 4 inches high and should be solid or have closely spaced openings to prevent objects from falling through.

Think of guardrails and toeboards as a safety net, providing essential protection against falls and dropped materials. Never compromise on their installation or maintenance.

Q 15. Explain the importance of proper fall protection when working at heights.

Proper fall protection is paramount when working at heights because falls are a leading cause of serious injuries and fatalities in the workplace. Imagine a simple slip – the consequences at height are exponentially worse than on the ground. Fall protection prevents or mitigates the impact of a fall, significantly reducing the risk of severe injury or death. It’s not just about safety regulations; it’s about safeguarding human lives and preventing the devastating consequences of a fall.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of fall protection equipment?

Several types of fall protection equipment exist, each designed for specific situations. They include:

- Safety Harnesses: Worn around the waist and legs, providing a secure anchor point for a lanyard or lifeline.

- Lanyards: Connect the harness to an anchorage point, restricting movement and preventing a fall. They come in various lengths and designs, including shock-absorbing lanyards to minimize impact forces.

- Lifelines: A continuous line that runs along a structure, providing a connection for a worker’s harness. They’re typically used for work along edges or across spans.

- Self-Retracting Lifelines (SRLs): A retractable lifeline that automatically retracts the worker to a secure position, significantly reducing fall distance and impact forces. These are often preferred over traditional lanyards.

- Guardrails: Physical barriers that prevent falls from edges, often found on scaffolding platforms or rooftops.

- Safety Nets: Nets positioned beneath work areas to catch falling workers. They’re often used in situations where other forms of fall protection are impractical.

The choice depends on the specific job, the height, and the surrounding environment.

Q 17. How do you select the appropriate fall protection equipment for a specific task?

Selecting the right fall protection equipment involves a thorough risk assessment. Consider these factors:

- Height of the work area: Higher heights necessitate more robust fall protection systems.

- Type of work being performed: Some tasks require more mobility than others, influencing the choice between a lanyard and a lifeline.

- Surrounding environment: Obstructions, weather conditions, and the presence of sharp objects can impact equipment selection.

- Worker’s physical capabilities: The equipment should be comfortable and easy to use for the worker.

- Applicable regulations and standards: Compliance with relevant OSHA or other national standards is critical.

For instance, working on a steep roof might necessitate a lifeline system, while working on a scaffold might only require a guardrail system and harness with a short lanyard for connection. A proper risk assessment is essential before equipment selection.

Q 18. Describe the procedures for using a safety harness and lanyard.

Using a safety harness and lanyard correctly is crucial for effectiveness. Here’s the procedure:

- Inspect Equipment: Before each use, thoroughly check the harness and lanyard for any damage, wear, or defects. Replace damaged equipment immediately.

- Proper Donning: Adjust the harness snugly to the body, ensuring all straps are properly secured and adjusted for a comfortable but firm fit. All buckles must be properly fastened.

- Anchorage Point: Connect the lanyard to a structural member capable of withstanding the forces of a fall. This must be a structurally sound anchor point, not a weak point.

- Maintain 3-point contact: Always maintain three points of contact with the ladder or scaffolding, and never overextend or overreach.

- Inspection during work: Regularly check for any issues during work. A catch or snag on a lanyard, for example, must be dealt with immediately.

- Proper removal: Disconnect the lanyard from the anchorage point *before* removing the harness.

Think of it like a seatbelt in a car – it’s only effective when properly worn and secured.

Q 19. What are the emergency procedures in case of a fall from height?

Emergency procedures after a fall from height are time-sensitive and crucial. They include:

- Call for Emergency Services: Immediately call emergency medical services (911 or your local equivalent).

- Assess the Victim: Check for injuries and provide first aid if qualified. Do not move the victim unless absolutely necessary.

- Secure the Area: Prevent further accidents by securing the area, warning others of the danger.

- Provide Information: Inform emergency services of the situation, the victim’s condition, and the location.

- Cooperate with Authorities: Fully cooperate with emergency responders and any subsequent investigations.

Remember, immediate action can make a significant difference in the outcome of a fall.

Q 20. What are the legal requirements for working at heights?

Legal requirements for working at heights vary by jurisdiction but generally revolve around providing a safe working environment. They often include requirements for:

- Risk Assessments: Conducting thorough risk assessments to identify and mitigate potential hazards.

- Fall Protection Plans: Developing and implementing comprehensive fall protection plans that outline specific procedures and equipment.

- Training and Competence: Ensuring workers are properly trained in safe working practices and the use of fall protection equipment.

- Equipment Inspection and Maintenance: Regular inspection and maintenance of all fall protection equipment to ensure it’s in good working order.

- Record Keeping: Maintaining accurate records of training, inspections, and incidents.

Non-compliance can result in significant fines, legal action, and reputational damage. Always consult the relevant regulations and standards for your region.

Q 21. How do you identify and mitigate risks associated with working on ladders and scaffolding?

Identifying and mitigating risks associated with ladders and scaffolding requires a proactive approach. Here’s how:

- Ladder Inspections: Before each use, inspect ladders for damage (broken rungs, cracked rails, loose fittings). Never use a damaged ladder.

- Proper Ladder Setup: Ensure ladders are placed on a stable, level surface, with the base extending at least one-fourth the working height away from the wall.

- Scaffolding Inspections: Regularly inspect scaffolding for structural integrity, proper bracing, and secure connections. Look for signs of instability or damage.

- Safe Scaffold Access: Ensure safe access and egress points on the scaffolding, and use appropriate fall protection systems.

- Load Limits: Never exceed the weight capacity of ladders or scaffolding.

- Weather Conditions: Avoid using ladders and scaffolding in adverse weather conditions (strong winds, rain, ice).

- Training: All personnel must receive proper training on the safe use and maintenance of ladders and scaffolding.

Remember that safety is not just about following rules; it’s about fostering a safety-conscious culture where everyone takes responsibility for their own safety and the safety of others.

Q 22. What is the role of a competent person in ensuring ladder and scaffolding safety?

A competent person, in the context of ladder and scaffolding safety, is someone with the necessary training, experience, and authority to identify hazards, assess risks, and implement control measures to prevent falls from height. They are responsible for ensuring that all work is carried out safely and complies with relevant regulations and best practices. This includes selecting appropriate equipment, supervising its use, and ensuring proper inspections are conducted.

For example, a competent person would ensure that ladders are correctly positioned, extending at least three feet above the landing point, and are suitable for the task. They would also inspect scaffolding for stability, ensuring proper bracing and tie-ins, and confirming that all components are in good working order. They don’t just delegate tasks; they actively oversee the entire process, ensuring that safety is the paramount concern.

Q 23. Describe your experience with conducting toolbox talks on ladder and scaffolding safety.

I regularly conduct toolbox talks on ladder and scaffolding safety, emphasizing practical application and engaging the team. My approach involves using real-life examples of incidents and near misses to highlight the consequences of unsafe practices. I also demonstrate proper techniques using visual aids like diagrams and photos. For instance, I’ll show how to correctly tie off a scaffold, explain the importance of using a fall arrest system, and detail the proper inspection procedure before each use. I encourage active participation by asking questions and prompting discussions to reinforce learning and ensure understanding. Post-talk questionnaires and observations during actual work help me assess the effectiveness of the sessions and adjust my approach as needed. It’s crucial that the information is not just passively received but actively integrated into their work practices.

Q 24. What are your experience with incident reporting related to falls from heights?

My experience with incident reporting related to falls from heights involves meticulous documentation, focusing on factual accuracy and objectivity. This includes gathering information from all involved parties, taking photos of the scene, documenting the equipment used, and identifying the root cause of the incident. I meticulously follow the company’s reporting procedures, ensuring timely submission to relevant authorities and internal management. In one particular case, a fall from a ladder resulted in a minor injury. Through the investigation, we identified a lack of proper footing and inadequate ladder stabilization as contributing factors. This led to revised safety procedures, including mandatory use of stabilizing devices and enhanced training on secure ladder placement. The focus is always on prevention by addressing systemic issues revealed through each incident.

Q 25. How do you communicate safety procedures to colleagues?

Communicating safety procedures effectively involves a multi-faceted approach. I use a combination of methods, including verbal instructions, visual aids (diagrams, videos), written materials (checklists, safety manuals), and practical demonstrations. I tailor my communication style to the audience, ensuring clarity and understanding. For instance, when explaining complex scaffolding procedures, I’ll use a combination of diagrams and hands-on demonstration to reinforce the steps involved. Regular follow-ups and open communication channels also ensure that everyone feels comfortable asking questions and expressing concerns. Transparency and clear communication are vital for building a safety-conscious culture.

Q 26. How do you handle a situation where a colleague is not following safety procedures?

If a colleague is not following safety procedures, my first step is to address the issue directly and privately. I begin with a calm and understanding approach, explaining the potential risks and emphasizing the importance of following the established procedures. I ask them about what might be preventing them from following safety procedures— perhaps a misunderstanding or lack of training. If the behavior continues after addressing the issue privately, I escalate it to the supervisor, documenting the incidents and discussions for reference. Safety is not negotiable; it’s crucial to consistently enforce standards for everyone’s wellbeing. A supportive but firm approach, ensuring compliance without damaging morale, is essential.

Q 27. Explain your understanding of risk assessments and method statements related to working at heights.

Risk assessments and method statements are crucial for planning and executing safe work at heights. A risk assessment identifies potential hazards, evaluates the likelihood and severity of their occurrence, and determines the necessary control measures. For example, a risk assessment for ladder work might identify hazards like unstable ground, overhead obstructions, and the risk of slips and falls. A method statement details the specific steps involved in a particular task, outlining how these identified hazards will be mitigated. This could include using a fall arrest system, securing the ladder, and designating a spotter. The method statement becomes the operational plan, a practical guideline ensuring a safe execution of the work. Both documents are integral for ensuring safe work practices and minimizing the risk of accidents. They are not mere formalities but living documents, regularly reviewed and updated as needed.

Q 28. Describe your experience with different types of access equipment besides ladders and scaffolding.

Beyond ladders and scaffolding, I have experience with a range of access equipment, including aerial work platforms (AWPs), scissor lifts, and cherry pickers. I understand the specific safety procedures for each type of equipment, including pre-use inspections, safe operating procedures, and emergency procedures. For example, operating an AWP requires a thorough understanding of its controls, load limits, and stability considerations. I am also familiar with the relevant regulations and certifications required for operating these pieces of equipment. Proficient knowledge of various access equipment ensures the safest and most efficient methods for performing tasks at height, minimizing risk, and maximizing productivity.

Key Topics to Learn for Working Safely on Ladders and Scaffolding Interview

- Ladder Safety Regulations and Standards: Understanding relevant legislation and best practices for safe ladder usage, including proper setup, inspection, and limitations.

- Scaffolding Types and Construction: Familiarity with different scaffolding types (e.g., mobile, tube and clamp, system scaffold), their components, and safe erection and dismantling procedures.

- Risk Assessment and Fall Protection: Identifying potential hazards associated with ladder and scaffolding work, implementing appropriate risk mitigation strategies, and utilizing personal protective equipment (PPE) effectively.

- Safe Working Practices: Understanding and applying safe working procedures, including load limits, access and egress, and maintaining a safe working environment.

- Emergency Procedures: Knowing how to respond to emergencies such as falls, equipment failures, or weather-related incidents. This includes understanding rescue procedures and emergency contact protocols.

- Practical Application: Scenario-based thinking. Consider how you would react and solve problems in real-world situations involving ladder and scaffolding use. For example, how would you react to finding a damaged ladder or unstable scaffolding?

- Inspection and Maintenance: Regular inspection of ladders and scaffolding for defects and ensuring proper maintenance procedures are followed.

- Communication and Teamwork: Safe work practices often require effective communication and collaboration with colleagues.

Next Steps

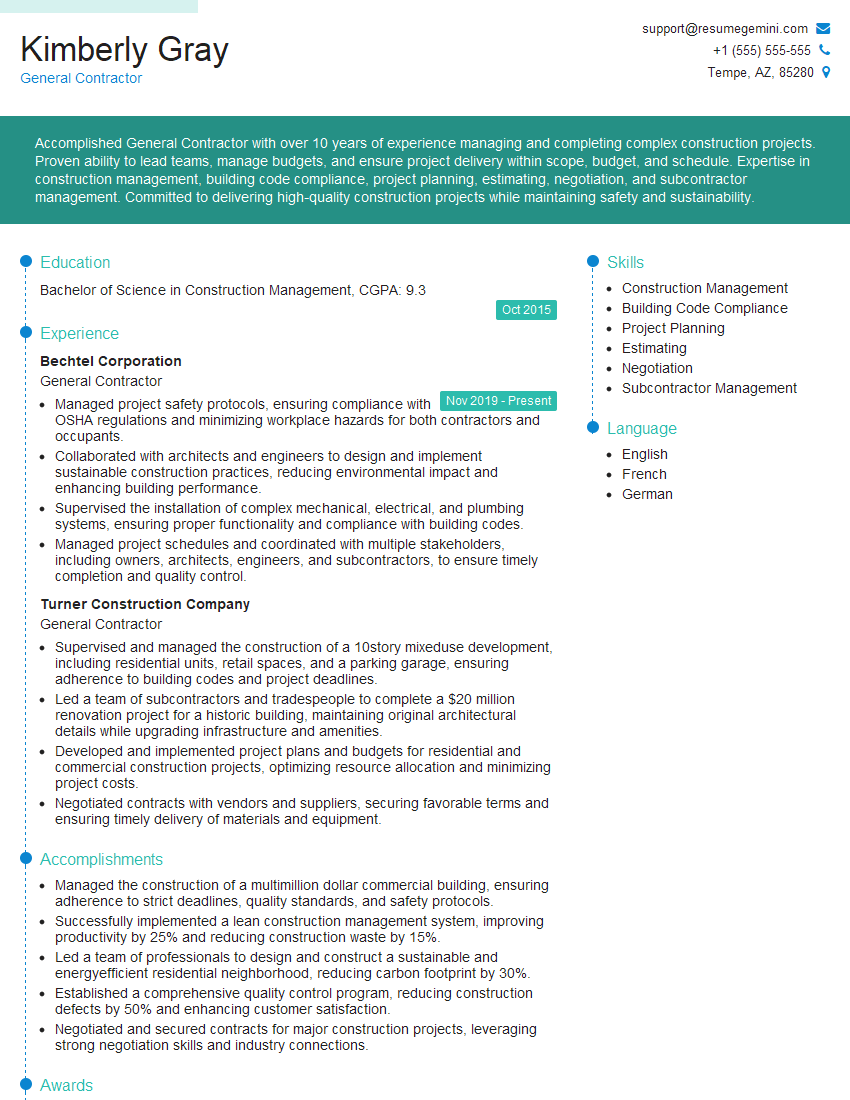

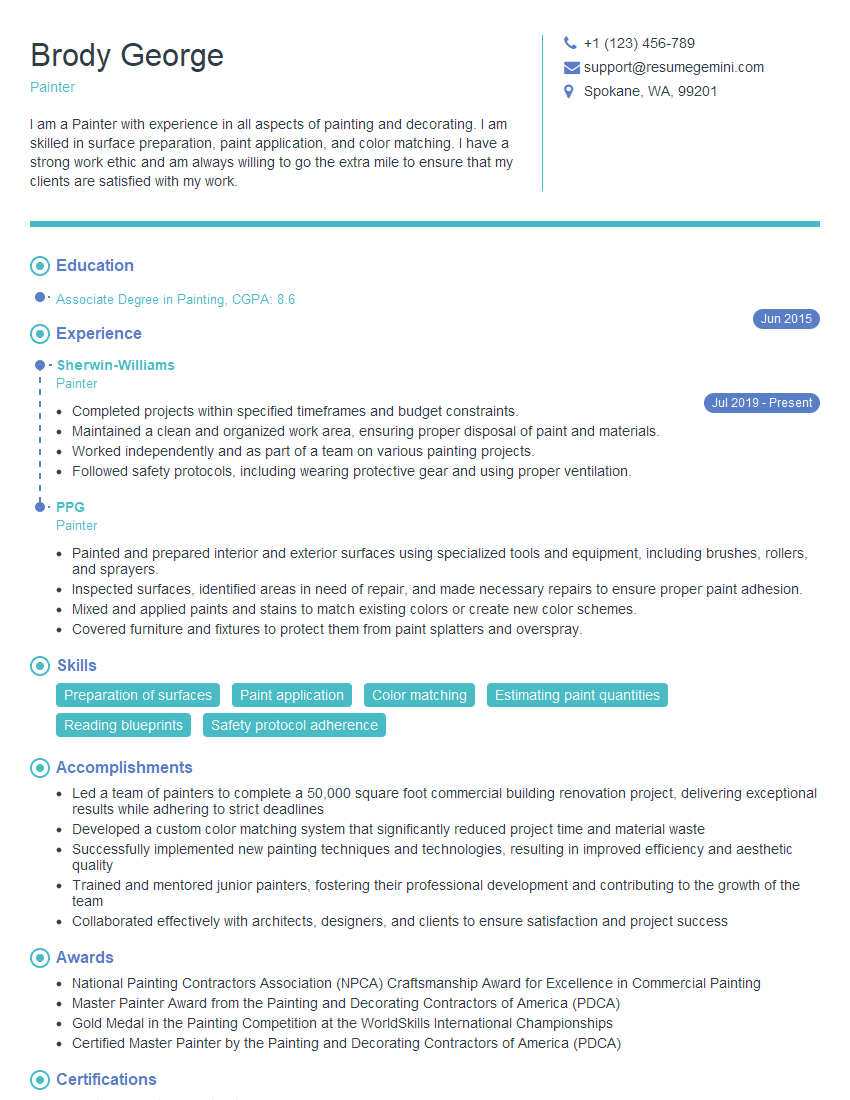

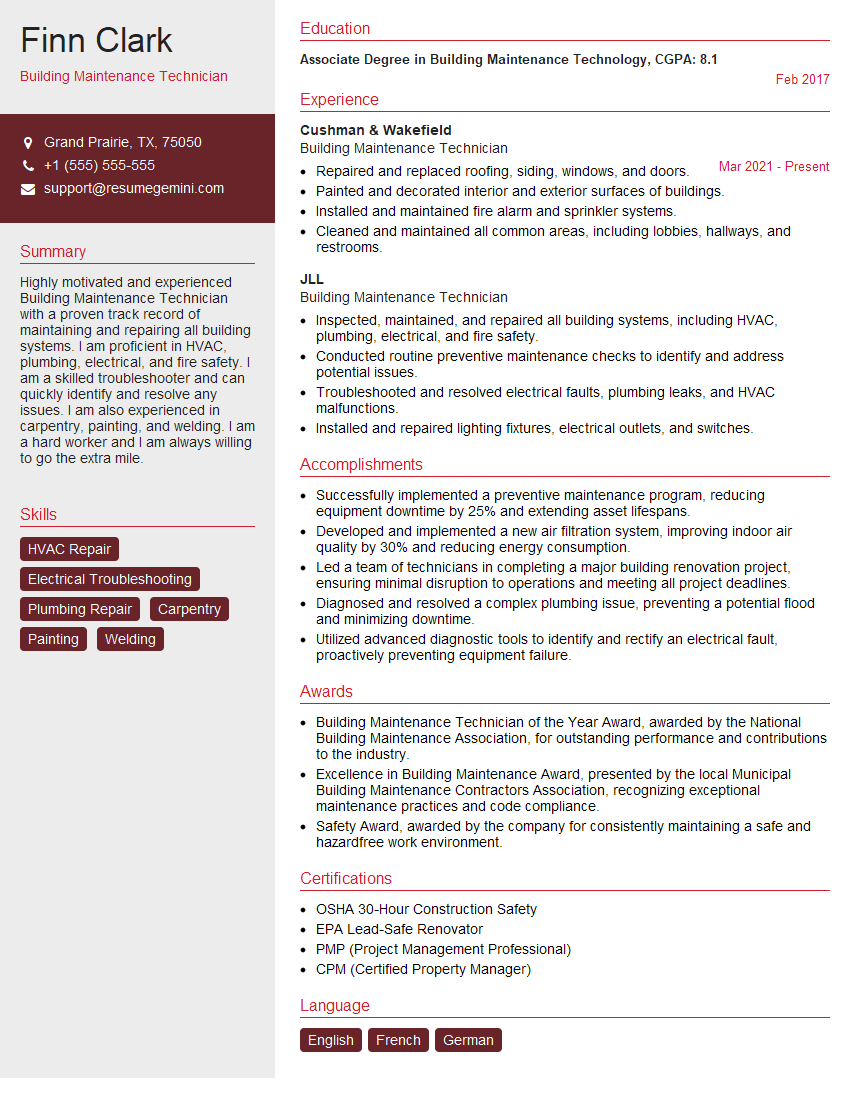

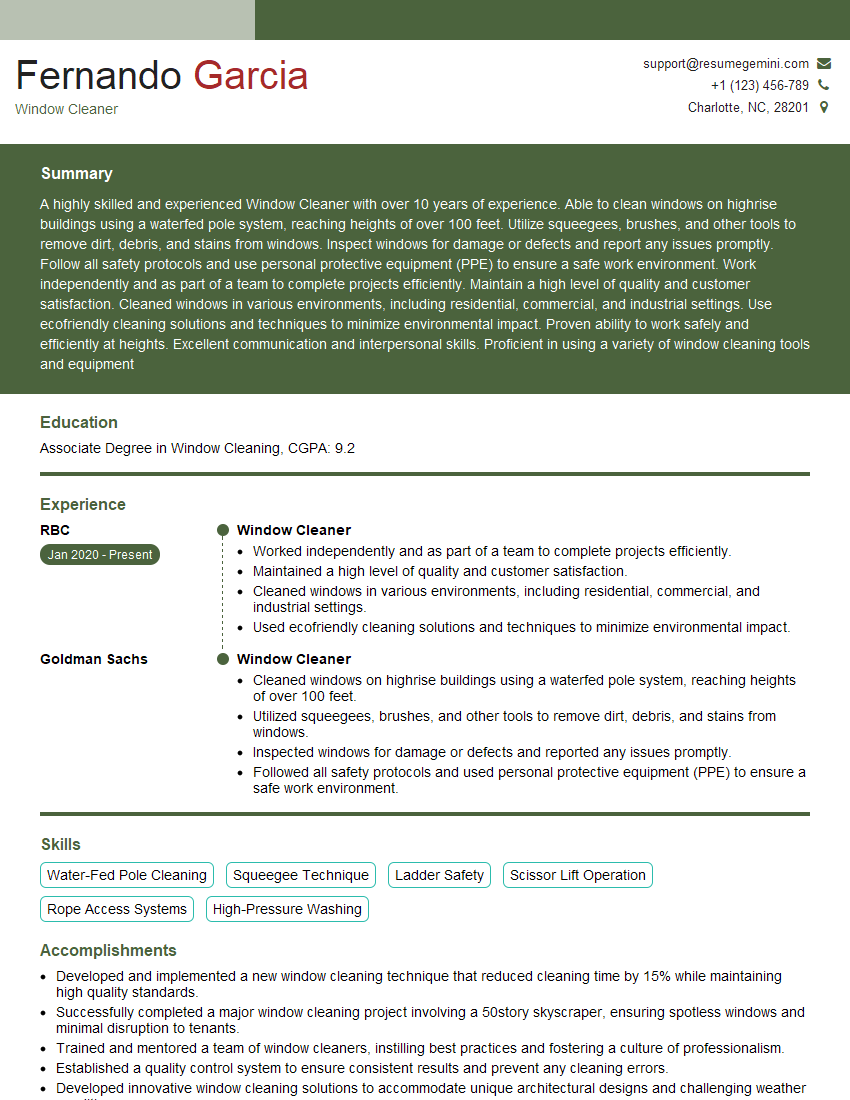

Mastering safe working practices on ladders and scaffolding is crucial for career advancement in many industries. Demonstrating a commitment to safety will significantly enhance your job prospects and showcase your responsibility and professionalism. To increase your chances of landing your dream role, focus on creating an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a compelling and professional resume tailored to the specific requirements of this field. Examples of resumes tailored to working safely on ladders and scaffolding are available within ResumeGemini to help guide your resume creation. Take the time to craft a resume that truly showcases your qualifications, increasing your visibility to potential employers and boosting your chances of success.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.