The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Working with power tools and machinery interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Working with power tools and machinery Interview

Q 1. Describe your experience with different types of power saws.

My experience with power saws spans a wide range, encompassing various types and applications. I’m proficient with circular saws, both handheld and those mounted on miter saws and radial arm saws. I’ve extensively used reciprocating saws (saws-alls) for demolition and intricate cutting, and I’m comfortable with jigsaw work for detailed cuts in wood, metal, and plastics. Furthermore, I have significant experience with worm drive saws, known for their power and ability to handle tough materials, and I’m adept at using a variety of blades to optimize cuts based on material and desired finish. For example, when working with hardwoods, a fine-tooth blade is crucial for precision and to avoid tear-out, whereas a coarser blade might be preferred for ripping through softer woods like pine. Each saw type presents unique challenges and requires specific techniques for safe and efficient operation. My expertise extends to understanding the nuances of blade selection, proper setup, and the avoidance of common pitfalls associated with each tool.

Q 2. Explain the safety procedures for operating a table saw.

Safety is paramount when operating a table saw. Before even turning the saw on, a thorough pre-operation check is essential. This includes ensuring the blade is sharp, properly aligned, and securely mounted. The blade guard and anti-kickback pawls must be in place and functioning correctly. Never reach over the blade. Always use a push stick to feed material, especially small pieces, preventing your hands from entering the danger zone. The riving knife, a critical safety feature, must also be correctly positioned to prevent the wood from pinching the blade and causing kickback. Maintain a firm grip on the workpiece and support it throughout the cut. After completing the cut, ensure the blade has stopped spinning completely before removing the workpiece. Wearing appropriate safety gear – eye protection, hearing protection, and dust masks – is mandatory. Regular maintenance, including blade sharpening and lubrication, is key to preventing accidents.

I always emphasize the importance of using a featherboard or hold-down device to secure the workpiece and prevent it from moving during the cut. I’ve witnessed firsthand the devastating consequences of neglecting these precautions – a kickback can launch a piece of wood with significant force, potentially causing serious injury.

Q 3. How do you maintain and troubleshoot a drill press?

Maintaining a drill press involves regular cleaning, lubrication, and belt tension checks. Keeping the chuck clean and free of debris is vital for accurate and secure bit changes. Lubricating moving parts, like the quill and spindle, reduces friction and extends the life of the machine. Checking and adjusting the belt tension ensures optimal power transfer and prevents slippage. Troubleshooting typically involves identifying unusual noises or vibrations. For instance, a grinding sound during operation could indicate a dull or damaged drill bit, or a worn bearing. Excessive vibration might point to problems with the motor mounts or a loose chuck. Regularly inspecting the chuck key and ensuring it’s stored safely after each use is crucial to preventing accidents.

For example, if the drill press is not feeding properly, the first thing I’d check would be the chuck tightness, then the belt tension, and finally, I’d inspect the quill for any signs of binding or damage. A thorough understanding of the machine’s mechanics and the ability to perform basic maintenance are key to ensuring its longevity and preventing costly repairs.

Q 4. What are the different types of welding processes, and which are you proficient in?

Welding processes encompass a wide range of techniques, each suited to different materials and applications. I’m proficient in several, including Shielded Metal Arc Welding (SMAW), commonly known as stick welding, Gas Metal Arc Welding (GMAW), also called MIG welding, and Gas Tungsten Arc Welding (GTAW), better known as TIG welding. SMAW uses a consumable electrode coated with flux to protect the weld from atmospheric contamination. GMAW uses a continuous feed wire and a shielding gas for faster, cleaner welds. GTAW uses a non-consumable tungsten electrode and a shielding gas, producing high-quality, precise welds ideal for critical applications. My skills also extend to understanding the nuances of different filler materials, amperage settings, and techniques for various metal types, including steel, stainless steel, and aluminum.

For example, I’d select SMAW for a quick, robust field repair where portability and ease of setup are important. For a production environment requiring high-quality welds on stainless steel, I’d utilize TIG welding for its precise control and excellent weld appearance.

Q 5. Describe your experience with CNC machining.

My CNC machining experience includes programming, operating, and maintaining a variety of CNC milling machines and lathes. I’m proficient in using CAD/CAM software to design and generate CNC programs, including G-code. I’m familiar with various machining processes, such as milling, turning, drilling, and tapping. I have experience working with different materials, including aluminum, steel, and plastics. My expertise extends to troubleshooting common issues encountered during CNC machining, such as tool breakage, inaccurate dimensions, or machine malfunctions. I’m also experienced in setting up and optimizing machining parameters to ensure efficient and high-quality production. For example, I have experience working with both subtractive and additive manufacturing techniques.

I’ve successfully managed complex projects requiring precise tolerances and intricate geometries. My experience includes working with various control systems and software packages, allowing me to adapt quickly to new environments and technologies.

Q 6. Explain the importance of regular maintenance for power tools.

Regular maintenance is crucial for extending the lifespan of power tools and ensuring their safe and efficient operation. Neglecting maintenance can lead to premature wear, reduced performance, and increased risk of accidents. A routine maintenance schedule should include inspecting cables for damage, cleaning and lubricating moving parts, sharpening cutting blades, and replacing worn parts. This helps avoid unexpected breakdowns during critical tasks, saves on repair costs in the long run, and most importantly, significantly enhances safety. For example, a dull blade on a circular saw increases the chance of kickback and potentially serious injury. Regular sharpening is vital to both performance and safety.

I’ve learned this lesson firsthand. Once, a colleague ignored a warning sign about a faulty motor on a drill press, which later caused a breakdown mid-job, resulting in lost time and a costly repair.

Q 7. How do you identify and address potential hazards when using power tools?

Identifying and addressing potential hazards when using power tools requires a proactive and systematic approach. A thorough risk assessment before starting any project is crucial. This involves identifying all potential hazards, such as exposed wires, sharp edges, moving parts, or hazardous materials. Implementing appropriate control measures is then critical. These can range from using personal protective equipment (PPE), such as safety glasses, hearing protection, and gloves, to utilizing machine guards, lockout/tagout procedures, and proper ventilation. Establishing a safe workspace free from clutter and obstructions is also vital. Regular inspections of tools and equipment are necessary to identify and address potential issues before they escalate into accidents. Finally, being attentive and fully focused on the task at hand is crucial, particularly when operating complex machinery. A momentary lapse in concentration can lead to serious consequences.

For example, while working with a lathe, I always ensure the chuck is properly secured and the work piece is firmly held to prevent unexpected ejection. My habit of performing a thorough pre-operation check has prevented many potential accidents.

Q 8. What safety precautions do you take when working with heavy machinery?

Safety is paramount when operating heavy machinery. My approach is a layered one, starting with a thorough pre-operation inspection. This includes checking for any loose parts, ensuring all guards are in place and functioning correctly, and verifying that all safety interlocks are engaged. I then assess the work area for potential hazards – is it properly lit, are there trip hazards, is there sufficient space for the operation? Personal Protective Equipment (PPE) is non-negotiable; this includes safety glasses, hearing protection, steel-toe boots, and often, a hard hat and gloves depending on the specific machine. Before starting the machine, I ensure I have a clear understanding of the operating procedures, including emergency shut-off procedures. Throughout the operation, I maintain a focused and alert state, avoiding distractions and constantly monitoring the machine’s performance. Finally, regular maintenance and adherence to the manufacturer’s guidelines are essential for preventing malfunctions and ensuring ongoing safety.

For example, when operating a forklift, I would always check the forks for damage before loading, ensuring the load is properly secured and balanced, and I’d use the horn appropriately to warn others. With a lathe, I ensure the chuck is properly tightened, the workpiece is securely clamped, and the speed is appropriately set for the material being worked. Safety isn’t just a checklist; it’s a mindset.

Q 9. Describe your experience with different types of hand tools.

My experience with hand tools spans decades and encompasses a wide range of applications. I’m proficient with basic tools like hammers, screwdrivers, wrenches (both open-end and socket), pliers (various types including slip-joint and locking), and saws (hand saws, hacksaws, coping saws). Beyond the basics, I’m experienced with more specialized tools such as chisels, punches, levels, measuring tapes, calipers, and various types of files. I understand the importance of selecting the right tool for the job, for instance, using a Phillips head screwdriver on a Phillips head screw, and the proper technique for using each tool to maximize efficiency and safety. I also appreciate the quality and craftsmanship of tools; a well-maintained tool is a safe and efficient tool. Regular sharpening and cleaning are part of my routine.

For instance, when working on fine cabinetry, I rely on precision tools like marking gauges and specialized chisels for accurate joinery. For heavier construction work, I’ll select more robust tools that can handle the stress. The ability to adapt to different tasks by selecting the appropriate tools is crucial for successful and efficient work.

Q 10. How do you ensure the accuracy and precision of your work when using power tools?

Accuracy and precision with power tools require a multi-faceted approach. It begins with careful planning and measurement. I always double-check my measurements and make precise markings before starting any power tool operation. Using appropriate jigs and fixtures greatly enhances accuracy; for example, a miter box for accurate angled cuts or a drill press for precise hole locations. The correct speed and feed rates for the material being worked are crucial; using too high a speed can lead to burning or inaccurate cuts, while too low a speed can cause excessive pressure and binding. Regular maintenance of the power tools themselves is paramount. A well-maintained tool will perform more accurately than one that is worn or poorly calibrated.

For example, when using a router, I’ll use a template and a router guide to ensure consistent and accurate cuts. When using a table saw, I ensure the blade is properly aligned and the fence is set to the correct measurement. Understanding the limitations of the tool is also key; I wouldn’t try to make a delicate cut on a powerful, coarse saw; I’d choose a tool appropriate for the task.

Q 11. What is your experience with different types of metalworking machinery?

My experience with metalworking machinery is extensive, encompassing various types of equipment. I’m proficient in operating lathes, milling machines, drill presses (both benchtop and floor standing), and band saws for metal. I understand the importance of selecting the right cutting tools and speeds for different metals (steel, aluminum, brass, etc.), and I’m skilled in techniques such as turning, milling, drilling, and sawing. I’m also familiar with the safety protocols specific to each machine, including proper work holding techniques to avoid accidents. Furthermore, I have experience with metal fabrication processes such as welding (MIG, TIG, stick) and grinding. I am also familiar with sheet metal work, including shearing, bending, and forming.

A specific example is working with a lathe to create a precisely machined shaft. The process requires selecting the correct cutting tool, setting the appropriate speeds and feeds, and carefully monitoring the process to ensure accuracy and a smooth finish. Understanding the principles of metal removal and the characteristics of the different metals is key to success.

Q 12. Explain your troubleshooting process for malfunctioning power tools.

Troubleshooting malfunctioning power tools follows a systematic approach. First, I’d check for obvious issues like power supply (cord, outlet, circuit breaker). Then, I’d inspect the tool itself for any visible damage, loose connections, or signs of wear and tear. If the issue persists, I’d refer to the owner’s manual for troubleshooting suggestions. For more complex problems, I’d check for things like worn brushes (in motors), damaged switches, or problems with the internal components (this often requires specialized knowledge). If I’m unable to diagnose and resolve the issue myself, I’d contact a qualified repair technician.

For example, if a drill is not spinning, I would first check if it’s plugged in and that the outlet is working. If that doesn’t solve the problem, I might check the brushes, the switch, and eventually the motor windings, consulting the user manual or a schematic diagram to guide my troubleshooting.

Q 13. How do you select the appropriate tool for a specific task?

Selecting the appropriate tool for a specific task involves considering several factors. First, the material being worked needs to be considered; different materials require different tools and techniques. Second, the size and scale of the task influences the choice; a small project may require hand tools, while a larger project may necessitate power tools. Third, the desired precision and finish quality dictate the tool selection. Finally, the safety aspects are always paramount; the tool chosen must be safe to operate and appropriate for the skill level of the operator.

For example, drilling a small hole in a piece of wood might involve a hand drill or a small electric drill, while drilling a large number of holes might necessitate a drill press. Similarly, cutting a precise dovetail joint would require specialized hand tools, while cutting a large number of similar pieces might benefit from a router or table saw.

Q 14. Describe your experience with woodworking machinery.

My woodworking machinery experience includes operating table saws, band saws, jointers, planers, shapers, and routers. I’m familiar with various cutting techniques and the importance of maintaining sharp blades and proper alignment. I’m experienced in creating various joints, including dadoes, rabbets, mortise and tenons, and dovetails. I understand the importance of selecting the right feed rate and speed for the type of wood and cut. Safety is always a primary consideration, and I always follow proper safety procedures and use appropriate PPE.

For example, when using a table saw, I’d use a push stick for safety and ensure that the blade is perfectly aligned and the fence is properly adjusted for accurate cuts. When using a jointer, I’d always feed the wood carefully to avoid kickback. I am also skilled in using hand-held woodworking tools to complement the capabilities of the larger machines.

Q 15. What is your experience with hydraulic systems?

My experience with hydraulic systems spans over ten years, encompassing design, maintenance, and troubleshooting. I’ve worked extensively with systems ranging from small-scale applications like hydraulic presses used in workshops to larger, more complex systems found in heavy machinery like excavators and forklifts. My expertise covers understanding hydraulic schematics, identifying and rectifying leaks, performing routine maintenance like fluid changes and filter replacements, and diagnosing and repairing more complex issues like pump failures or valve malfunctions. For instance, I once successfully diagnosed a faulty directional control valve on a large industrial crane by systematically checking pressure readings at various points in the system, ultimately saving the company significant downtime and repair costs.

I’m proficient in understanding the principles of hydraulic pressure, flow rate, and fluid power, which are crucial for both preventative maintenance and efficient troubleshooting. I also have hands-on experience with various hydraulic components, including pumps, valves, cylinders, and accumulators. This practical experience allows me to effectively identify potential failure points and prevent costly breakdowns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of torque and its importance in machinery operation.

Torque is the rotational force that causes an object to rotate around an axis. Think of it like this: if you’re trying to loosen a stubborn bolt, the amount of ‘twisting’ force you apply is the torque. In machinery, torque is absolutely critical because it determines the power available to perform work. A higher torque value means a greater ability to overcome resistance and drive a load, such as turning a shaft, driving a conveyor belt, or cutting through material.

For example, a powerful engine in a vehicle needs high torque at low RPM to accelerate quickly and pull heavy loads. Conversely, a high-speed drill requires a lower torque but high RPM to rotate at a fast speed for drilling holes. Mismatched torque can lead to serious problems. Insufficient torque will lead to the machine stalling or not functioning as designed, while excessive torque can cause damage to components due to overload. I always carefully consider the required torque when selecting tools or machinery for a specific job to ensure efficient and safe operation.

Q 17. How do you interpret technical drawings and blueprints?

Interpreting technical drawings and blueprints is fundamental to my work. I am proficient in reading and understanding various types of drawings, including orthographic projections, isometric views, and assembly drawings. I can identify dimensions, tolerances, materials specifications, and assembly procedures.

My approach involves systematically analyzing each element of the drawing, starting with the title block to understand the drawing’s purpose and scale. Then, I carefully examine views and sections to understand the three-dimensional representation of the part or assembly. I am also adept at using measuring tools to verify dimensions and tolerances during manufacturing or maintenance processes. For example, I’ve used blueprints to fabricate custom jigs for welding and accurately align components during the assembly of complex machinery.

Q 18. What are your experience with pneumatic tools?

I have extensive experience with a wide range of pneumatic tools, from simple impact wrenches and air ratchets to more complex tools like air hammers and sandblasters. I understand the principles of compressed air operation, including pressure regulation, air flow control, and safety precautions. I am experienced in maintaining and troubleshooting pneumatic tools, which often involves identifying and replacing worn seals, repairing air leaks, and ensuring proper lubrication.

For instance, I once repaired an air compressor that was producing insufficient pressure by identifying and replacing a faulty pressure switch. This saved the company significant time and money compared to purchasing a new compressor. I also understand the importance of using the correct air pressure for each tool to prevent damage and ensure optimal performance and efficiency.

Q 19. Describe your experience with preventative maintenance on machinery.

Preventative maintenance is crucial for ensuring the longevity and efficient operation of machinery. My approach to preventative maintenance is proactive and systematic. It involves creating and adhering to a schedule of regular inspections, lubrication, and component replacements. This schedule is tailored to the specific machine’s operational requirements and manufacturer’s recommendations.

My preventative maintenance tasks include checking fluid levels (hydraulic, lubrication), inspecting belts and chains for wear and tear, cleaning and lubricating moving parts, and replacing worn components before they cause major failures. I meticulously document all maintenance activities and keep detailed records to track the history of the equipment. For example, in my previous role, I implemented a preventative maintenance program that reduced equipment downtime by 25% and decreased repair costs by 15%.

Q 20. How do you handle unexpected equipment failures?

Unexpected equipment failures are inevitable, but a methodical approach can minimize downtime and prevent further damage. My first step is always to ensure the safety of myself and others. This involves isolating the malfunctioning equipment, shutting it down if necessary, and addressing any immediate safety hazards.

Next, I conduct a thorough inspection of the equipment to identify the cause of the failure. This often involves checking electrical circuits, hydraulic systems, pneumatic components, and mechanical linkages. I rely on my experience and diagnostic skills to pinpoint the problem, often using troubleshooting charts, manuals, and diagnostic tools. After identifying the cause, I implement the necessary repairs, following all safety protocols and ensuring the equipment functions correctly before returning it to service. I always document the nature of the failure, the repair actions taken, and the outcome. This detailed record-keeping helps prevent future occurrences of the same problem.

Q 21. What is your experience with different types of cutting tools?

My experience encompasses a broad range of cutting tools, including various types of saw blades (circular, band, reciprocating), drill bits (twist, spade, hole saw), milling cutters, lathe tools, and specialized cutting tools for specific materials such as carbide-tipped tools for hard metals and abrasive cutting wheels for concrete. I understand the importance of selecting the appropriate cutting tool for the material being worked and the desired outcome.

For example, I know that using the wrong drill bit for a particular material could result in a dull bit, a damaged workpiece, or even personal injury. I’m skilled in sharpening and maintaining cutting tools to ensure optimal performance and longevity. Furthermore, I’m familiar with safe handling and storage practices to prevent accidents and damage to the tools.

Q 22. How do you ensure the safety of yourself and others when working with power tools and machinery?

Safety is paramount when working with power tools and machinery. It’s not just about following rules; it’s about cultivating a safety-first mindset. My approach is multifaceted and involves several key steps:

- Proper Training and Certification: I always ensure I’m properly trained and certified on any equipment I operate. This includes understanding the machine’s capabilities, limitations, and potential hazards.

- Personal Protective Equipment (PPE): This is non-negotiable. Appropriate PPE, such as safety glasses, hearing protection, gloves, and sturdy footwear, is worn at all times. The type of PPE varies depending on the task; for example, a face shield would be necessary when grinding.

- Machine Inspection: Before starting any work, I meticulously inspect the machine for any damage, loose parts, or malfunctioning components. A quick visual inspection can prevent serious accidents.

- Safe Work Practices: I adhere strictly to safe operating procedures, including proper setup, workpiece securing, and tool maintenance. This includes never reaching across a moving blade or attempting repairs without disconnecting power.

- Workspace Organization: Maintaining a clean and organized workspace is crucial. Clutter can create tripping hazards and obstruct safe movement around machinery.

- Lockout/Tagout Procedures: When performing maintenance or repairs, I always follow proper lockout/tagout procedures to prevent accidental starts. This ensures the machine is completely de-energized before any work begins.

- Awareness of Surroundings: I’m always mindful of my surroundings and the potential for hazards, including other workers in the area. Clear communication is key in a shared workspace.

For example, during a recent project involving a table saw, I meticulously checked the blade’s alignment, ensured the blade guard was in place, and used push sticks to feed the wood, preventing any accidental contact with the rotating blade. This methodical approach has ensured my safety and the safety of my colleagues throughout my career.

Q 23. Describe a time you had to troubleshoot a complex machinery problem.

I once encountered a complex issue with a CNC milling machine that was producing inconsistent cuts. Initially, the problem seemed simple – the cuts were slightly off-spec. However, after a thorough investigation, the issue proved to be multifaceted.

My troubleshooting process involved:

- Identifying the Symptoms: The inconsistencies were subtle, affecting only certain parts of the milled pieces, suggesting a problem with specific axes or machine settings.

- Data Analysis: I checked the CNC program for errors, ensuring the toolpaths were accurate and consistent. I also reviewed the machine’s operational logs to look for any anomalies in speed, feed rate, or spindle RPM.

- Visual Inspection: A careful visual inspection of the machine revealed slight wear on one of the linear bearings on the X-axis. This was initially imperceptible, but after close examination, it became evident.

- Component Testing: I tested the affected linear bearing using precision measuring tools and discovered it was exhibiting more friction than the others, leading to the inconsistent cuts.

- Solution Implementation: The bearing was replaced with a new one, and the machine was recalibrated. This resolved the issue completely.

This experience highlighted the importance of methodical troubleshooting, attention to detail, and the critical role of data analysis and visual inspection in identifying and resolving complex machinery problems.

Q 24. What is your understanding of OSHA regulations regarding power tools and machinery?

My understanding of OSHA regulations regarding power tools and machinery is comprehensive. OSHA’s focus is on preventing workplace injuries and fatalities related to hazardous energy sources. Key regulations I’m familiar with include:

- Lockout/Tagout (LOTO): This is crucial for controlling hazardous energy during servicing and maintenance. OSHA requires specific procedures to ensure machinery is de-energized and cannot be accidentally restarted.

- Machine Guarding: All moving parts of machinery must be guarded to prevent accidental contact. Guards must be properly designed and maintained to prevent injury.

- Personal Protective Equipment (PPE): OSHA mandates the use of appropriate PPE for all tasks involving power tools and machinery. This includes eye protection, hearing protection, and other relevant equipment depending on the task.

- Training Requirements: Employers are responsible for providing adequate training to employees on the safe operation and maintenance of power tools and machinery. This includes both theoretical knowledge and practical hands-on training.

- Hazard Communication: Employers must communicate workplace hazards to employees through safety data sheets (SDS), labels, and training programs.

I ensure I’m always up-to-date on the latest OSHA guidelines and frequently review relevant safety regulations to ensure compliance and prevent potential accidents. Ignoring these regulations can lead to severe penalties and, more importantly, serious injuries.

Q 25. Explain your experience with using measuring and inspection tools.

My experience with measuring and inspection tools is extensive and covers a wide range of instruments. This includes:

- Calipers (Vernier and Digital): Used for precise measurement of dimensions, ensuring accuracy in manufacturing processes. I’m proficient in using both vernier and digital calipers for various applications.

- Micrometers: For extremely precise measurements, micrometers are essential. I am experienced in using micrometers to measure small components with high accuracy.

- Dial Indicators: These instruments are crucial for checking alignment, runout, and other critical aspects of machine setups and part geometry.

- Levels: Maintaining level surfaces is essential for many machine operations. I routinely use levels to ensure proper alignment and stability.

- Measuring Tapes and Rules: For general measurements and layout work, I utilize measuring tapes and rules.

- Optical Comparators and CMMs (Coordinate Measuring Machines): For complex part inspection, I have experience using optical comparators and CMMs to ensure components meet required specifications.

For example, while working on a precision machining project, I used a digital micrometer to measure the diameter of a shaft to an accuracy of 0.001 inches, ensuring that it met the tight tolerances specified in the design.

Q 26. What are your experience with different types of grinding and finishing tools?

My experience with grinding and finishing tools encompasses a variety of equipment and techniques. I’m familiar with:

- Bench Grinders: Used for sharpening tools and removing material from metal parts. I understand the importance of using proper guards and techniques to prevent injury.

- Angle Grinders: These versatile tools are used for cutting, grinding, and polishing various materials. I’m proficient in using different types of grinding wheels and discs with the appropriate safety precautions.

- Belt Sanders: Excellent for smoothing surfaces and removing material quickly. I understand the proper techniques for achieving smooth, even finishes.

- Disc Sanders: Ideal for sanding flat surfaces and curves. I’m familiar with various grits and techniques for different materials.

- Rotary Tools (Dremels): For intricate work and detailed finishing, I routinely use rotary tools with a variety of attachments.

- Orbital Sanders: These reduce swirl marks and provide a more consistent finish compared to other methods.

For instance, I recently used a belt sander to smooth rough edges on a wooden project, followed by an orbital sander to achieve a fine, even finish. The selection of the right tool and appropriate grit is vital in obtaining the desired result.

Q 27. Describe your experience with robotic equipment and programming.

My experience with robotic equipment and programming is moderate. While I haven’t extensively programmed industrial robots, I have worked alongside them and understand their basic operation and safety procedures.

My experience includes:

- Collaborative Robots (Cobots): I’ve worked alongside cobots in a manufacturing environment, understanding their capabilities for repetitive tasks and the safety features designed for human-robot collaboration.

- Robot Cell Operation: I’ve observed and assisted in the operation of robotic cells, learning about their programming, setup, and safety protocols.

- Basic Programming Concepts: I understand basic robot programming concepts, including coordinate systems, path planning, and safety commands. I’m familiar with the need for precise programming to avoid collisions and ensure accurate operation.

Although my experience isn’t extensive in robot programming, my background in machinery and automation provides a solid foundation for learning more advanced techniques. The ability to understand automation concepts improves efficiency and safety in manufacturing.

Q 28. What is your experience with different types of fasteners and joining techniques?

My experience with fasteners and joining techniques is broad, encompassing various methods and materials. This includes:

- Bolts, Nuts, and Washers: I am proficient in using various types of bolts, nuts, and washers, selecting the appropriate size and type for specific applications.

- Screws (Wood, Machine, Self-Tapping): I am experienced in using different types of screws for various materials, ensuring proper installation to avoid damage or failure.

- Rivets: I have experience using rivets for permanent joining of materials, understanding the various types and techniques for proper installation.

- Welding (Basic understanding): While not a welder myself, I have a basic understanding of welding processes and their applications in joining metal components.

- Adhesives and Sealants: I’m familiar with using various adhesives and sealants for bonding different materials, understanding the appropriate selection based on material compatibility and application requirements.

For example, in a recent project, I used high-strength bolts to secure a critical component, ensuring the joint could withstand significant stress. The proper selection of fasteners is crucial to ensure the structural integrity and safety of any assembly.

Key Topics to Learn for Working with Power Tools and Machinery Interview

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety protocols, including proper use of Personal Protective Equipment (PPE), emergency procedures, and lockout/tagout procedures. Practical application involves demonstrating knowledge of specific safety regulations for different tools and machinery.

- Tool Operation and Maintenance: Proficiency in operating various power tools (drills, saws, grinders, etc.) and machinery (lathes, milling machines, etc.). This includes understanding their capabilities, limitations, and proper maintenance techniques to ensure optimal performance and longevity. Practical application includes describing preventative maintenance schedules and troubleshooting common malfunctions.

- Material Selection and Handling: Knowledge of different materials (wood, metal, plastics) and their properties, along with safe handling procedures. This includes understanding the appropriate tools and techniques for working with each material. Practical application involves explaining the selection criteria for materials in specific projects.

- Project Planning and Execution: Ability to read and interpret blueprints, plans, and specifications. This involves understanding the steps involved in completing a project efficiently and safely. Practical application includes describing a project workflow, from initial planning to final inspection.

- Troubleshooting and Problem-Solving: Diagnosing and resolving common issues encountered while operating power tools and machinery. This includes identifying potential hazards and implementing corrective actions. Practical application involves describing how to address equipment malfunctions or material defects.

- Quality Control and Inspection: Understanding quality control measures and performing inspections to ensure the final product meets the required specifications. Practical application involves outlining quality check procedures for specific tasks.

Next Steps

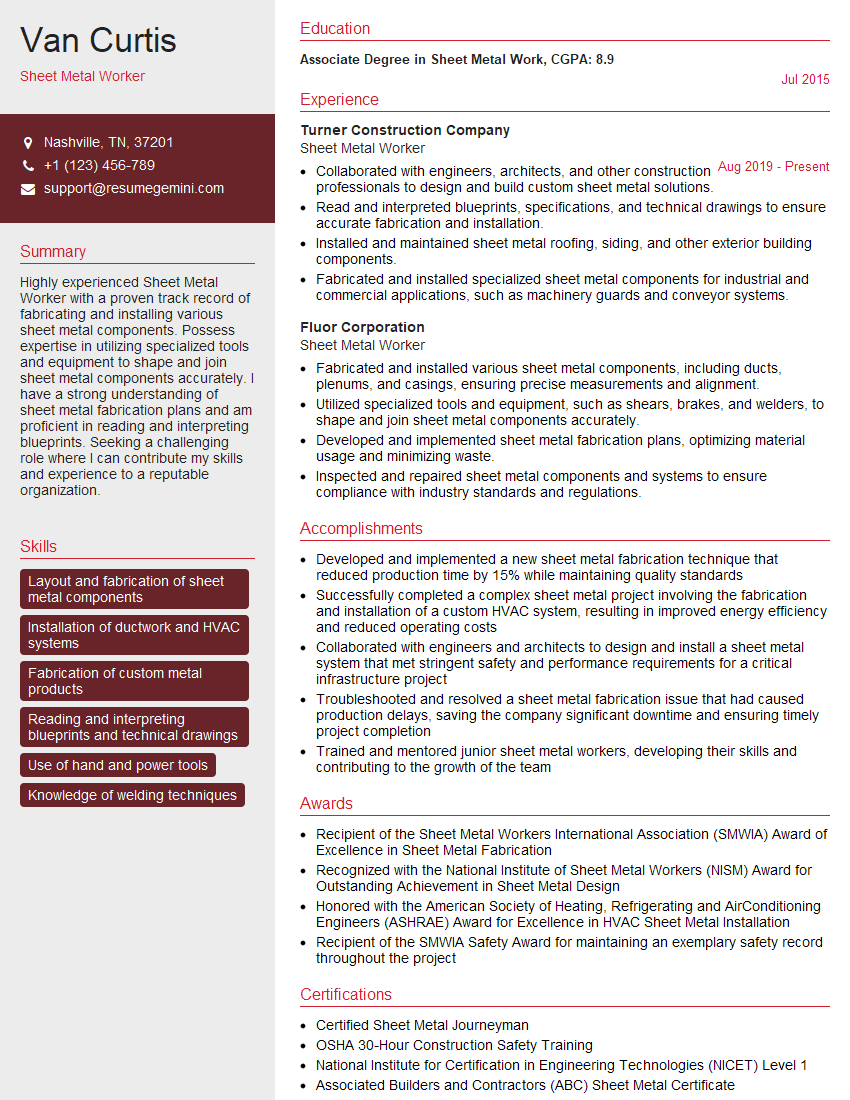

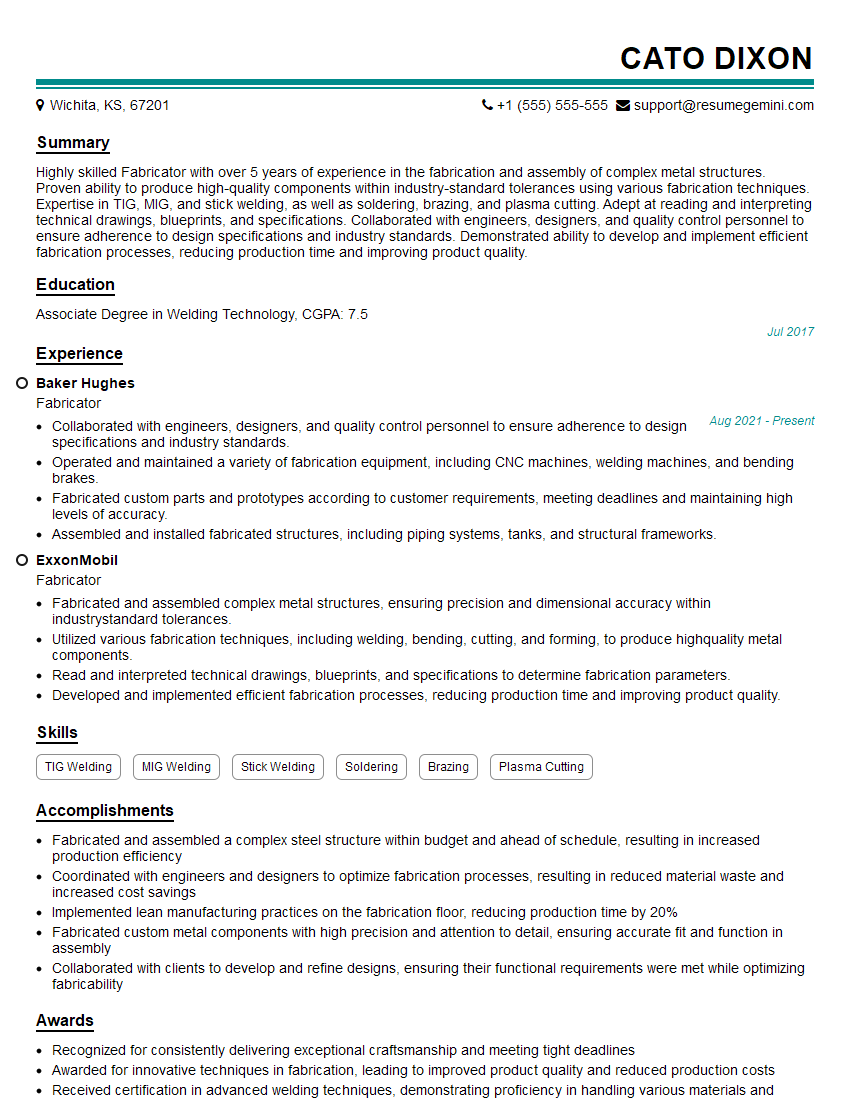

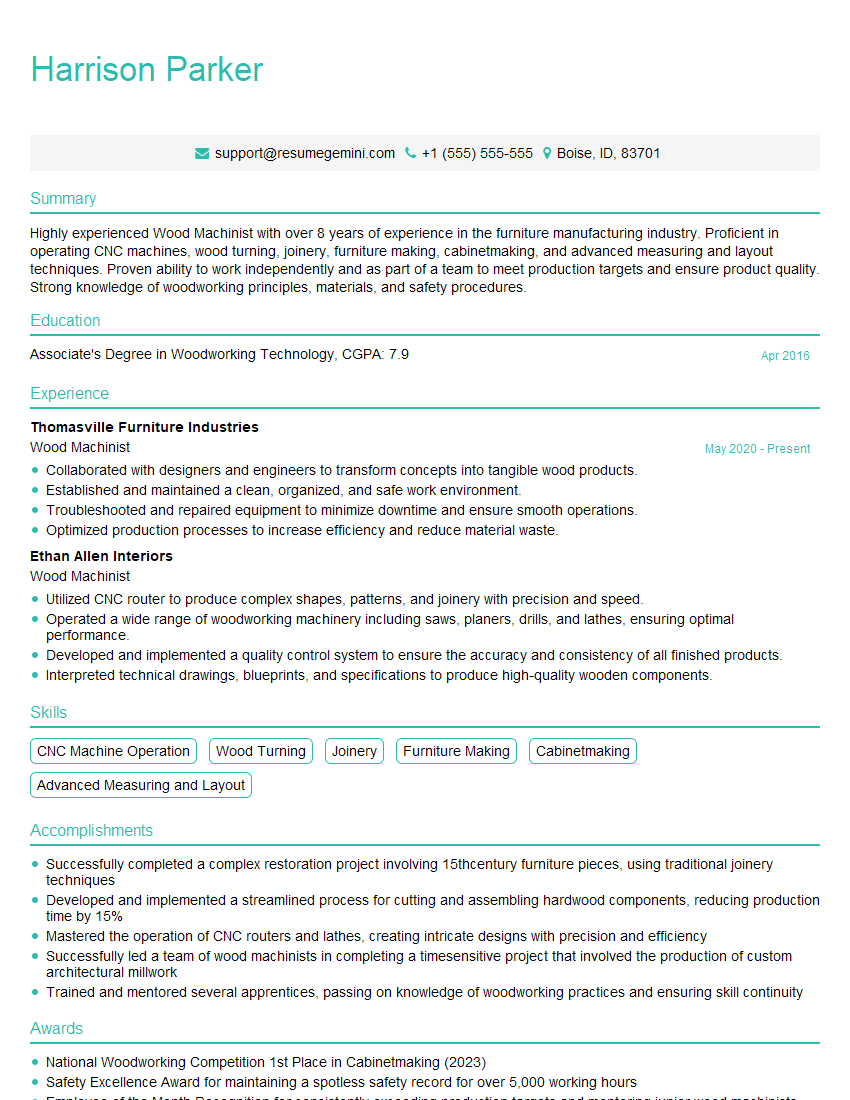

Mastering the safe and efficient operation of power tools and machinery is crucial for career advancement in many skilled trades. A strong understanding of these concepts significantly enhances your employability and opens doors to exciting opportunities. To maximize your job prospects, it’s essential to create a professional and ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your abilities. We provide examples of resumes tailored to Working with power tools and machinery to guide you in creating a document that gets noticed by potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.