Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Working with Sharp Objects interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Working with Sharp Objects Interview

Q 1. Describe your experience handling scalpels.

My experience with scalpels spans over a decade, encompassing diverse surgical procedures. I’ve handled a wide range of scalpel types, from the standard #3 handle with various blade sizes to more specialized designs like disposable scalpels and those with retractable blades. Proficiency involves not just holding the instrument correctly—which includes a relaxed yet firm grip to prevent slippage and fatigue—but also understanding the optimal blade angle and pressure for precise incisions. For example, a shallow angle is often preferred for delicate tissue dissection, while a steeper angle might be necessary for thicker skin. I always prioritize a steady hand and careful control to minimize the risk of injury to both the patient and myself. Years of practice have honed my dexterity and allowed me to perform intricate procedures with confidence and precision.

Q 2. Explain the proper sterilization techniques for surgical instruments.

Proper sterilization of surgical instruments is paramount to prevent infection. It’s a multi-step process, and deviations can have serious consequences. The most common method is steam sterilization, using an autoclave. This involves placing instruments in sterilizing pouches or trays, ensuring they aren’t overcrowded to allow for proper steam penetration. The autoclave cycle parameters, including temperature (typically 121-134°C) and time (usually 15-20 minutes), must be strictly followed and monitored. After the cycle, instruments are carefully removed, ensuring no contamination occurs, and allowed to cool before use. Alternatively, ethylene oxide gas sterilization is employed for heat-sensitive instruments, but requires specialized equipment and longer processing times with subsequent aeration to remove residual gas. All processes must adhere to strict protocols and documentation to maintain sterility and ensure patient safety. Regular quality control checks, including spore testing, are crucial to verify the effectiveness of the sterilization procedures.

Q 3. What safety precautions do you take when using knives in a kitchen setting?

Kitchen knives, while less precise than surgical instruments, still demand respect. My safety precautions are simple but effective. First, I always use a sharp knife; a dull knife requires more force, increasing the risk of slippage. Second, I utilize the correct knife for the task – a paring knife for delicate work, a chef’s knife for chopping, etc. Third, I maintain a firm grip, keeping my fingers curled and away from the blade’s path. Fourth, I never attempt to catch a falling knife. I have a designated knife block for safe storage, and I ensure the knives are kept clean and dry to prevent corrosion. Finally, I never leave a knife unattended, especially within reach of children. I remember an incident where a slightly dulled knife slipped while preparing vegetables – luckily, I had a firm grip and was able to avoid injury. This experience reinforced the importance of always using sharp knives and maintaining a firm, controlled grip.

Q 4. How would you handle a broken scalpel blade?

Handling a broken scalpel blade requires immediate and careful action. The first priority is to ensure the safety of myself and anyone nearby. I would never attempt to pick up the blade with bare hands. Instead, I would use forceps or a brush and dustpan to carefully collect the fragments. All pieces, no matter how small, must be accounted for. The fragments would be placed in a designated sharps container designed specifically for disposing of broken blades and other sharp medical waste. This container is puncture-resistant and clearly labeled. Proper disposal protocols should always be strictly followed to prevent accidental injuries and comply with safety regulations.

Q 5. Describe your experience with different types of blades and their appropriate uses.

My experience encompasses various blade types. Scalpel blades, for instance, come in a range of sizes and shapes (e.g., #10, #11, #15) each suited for specific surgical tasks. #10 blades are excellent for long, precise incisions, while #15 blades are ideal for smaller, more detailed work. Similarly, I’ve worked with specialized blades for ophthalmic or neurosurgical procedures, each designed for delicate manipulation in specific anatomical regions. Even in the kitchen, different knives have diverse applications. A serrated knife excels at cutting bread, while a boning knife is perfect for separating meat from bone. Understanding the appropriate blade for a task is crucial for efficiency and safety. Misusing a blade can lead to poor results and potential injury.

Q 6. Explain the difference between various types of surgical scissors and their applications.

Surgical scissors come in numerous variations, each with a specific application. Metzenbaum scissors, with their long, delicate blades, are ideal for dissecting delicate tissues. Mayo scissors, with stronger, shorter blades, are better for heavier cutting. Iris scissors, with their extremely fine tips, are used for intricate work in ophthalmology. Other specialized scissors include curved scissors for reaching around structures and bandage scissors for cutting bandages without snagging the surrounding skin. The choice of scissors depends heavily on the procedure and the tissue being manipulated. Using the incorrect scissor can lead to damage to the tissue or inefficient cutting.

Q 7. How do you ensure the sharpness of your tools is optimal for the task?

Maintaining optimal sharpness is crucial for precision and safety. For scalpels and other surgical instruments, sharpening is typically performed by trained professionals using specialized honing stones. This is a delicate process requiring considerable skill to avoid damaging the blade. For kitchen knives, a honing steel can be used to realign the blade’s edge, maintaining sharpness between professional sharpening. Regular sharpening ensures clean cuts, prevents excessive force, and reduces the risk of accidental slips. For instance, a dull scalpel can cause tearing of tissue, leading to increased bleeding and longer healing times. A sharp instrument on the other hand, enables clean and precise incisions, minimizing tissue trauma.

Q 8. Describe your experience with sharpening techniques for various tools.

Sharpening techniques vary greatly depending on the tool. For knives, I frequently use honing steel to realign the blade’s edge, followed by sharpening with whetstones of progressively finer grits. The process involves maintaining a consistent angle, typically between 15-20 degrees, and applying even pressure. For chisels and plane blades, I often use a sharpening stone and a honing guide for precision. I also utilize specialized tools like diamond sharpeners for particularly hard materials and motorized sharpening systems for efficiency with larger quantities of tools. My approach always considers the material of the blade (steel type, hardness) and its intended use. For example, a chef’s knife needs a different edge than a wood carving knife.

- Whetstones: These offer precise control over the sharpening process, allowing for adjustments based on the blade’s condition.

- Honing steel: This straightens the blade’s edge, maintaining sharpness between sharpening sessions. It’s not a sharpening tool itself.

- Electric sharpeners: These are faster for routine maintenance, but often lack the precision of manual methods.

Q 9. What are the signs of a dull blade, and how does this impact performance and safety?

A dull blade exhibits several signs: It requires more force to cut, leaves a jagged or uneven cut, and may feel ‘rough’ along its edge. A dull blade is significantly less efficient, requiring more effort and potentially causing damage to the material being worked on. More importantly, a dull blade is far more dangerous! A sharp blade requires less pressure to cut, resulting in greater control and a reduced risk of slippage and accidental injuries. The force needed to compensate for a dull blade dramatically increases the chance of the tool slipping and causing harm.

Think of it like trying to cut a tomato with a dull butter knife versus a sharp paring knife. The dull knife would crush the tomato, requiring far more pressure, potentially injuring you as your hand slips. The sharp knife effortlessly slices the tomato with minimal pressure and precision.

Q 10. How do you maintain the cleanliness and hygiene of your sharp instruments?

Maintaining hygiene with sharp instruments is crucial. After each use, I thoroughly clean the blades with warm soapy water, paying close attention to crevices. For tools that have come into contact with potentially contaminated materials (like food or biological samples), I’ll use a suitable disinfectant, following the manufacturer’s instructions carefully. Sterilization may be required depending on the application. Tools are then carefully dried and stored in a designated, protected location, preferably in a protective sheath or case to prevent damage and accidental injury.

Regular inspection for rust or other signs of deterioration is also essential. Damaged tools should be replaced or professionally repaired.

Q 11. What are your strategies for preventing accidental cuts or injuries?

Preventing accidental cuts involves a multifaceted approach: Always using sharp tools (a sharp blade requires less pressure, reducing the chance of slippage); maintaining a clear and organized workspace; using appropriate safety equipment such as cut-resistant gloves when necessary; and being fully attentive and focused on the task at hand. Never rush. I also employ strategies such as using a cutting board to stabilize work and using push cuts instead of pull cuts wherever possible. Furthermore, regular tool maintenance keeps them in top shape, minimizing the risk of unexpected slips.

Imagine trying to carve a piece of wood with a dull knife – you’d be much more likely to slip and cut yourself. A sharp knife requires less force, giving you greater control and minimizing the risk.

Q 12. How do you dispose of used sharp objects safely and according to regulations?

Disposal of used sharp objects is a critical aspect of safety and environmental responsibility. I always use puncture-resistant containers specifically designed for sharps disposal. These containers are usually clearly marked and color-coded. Once the container is nearly full, it’s sealed securely and disposed of according to local regulations and guidelines, usually through a designated medical waste disposal service or approved hazardous waste disposal route. Never throw sharp objects into regular trash.

Failure to properly dispose of sharps can lead to serious injuries for waste handlers and the spread of infectious diseases.

Q 13. Describe a time you made a mistake while using sharp objects. What did you learn?

During a particularly rushed project, I inadvertently sliced my finger while using a box cutter. I was distracted and didn’t maintain my usual level of focus and caution. The experience reinforced the importance of maintaining awareness, even during periods of high pressure. I learned the hard way that even a minor lapse in concentration can have serious consequences. Now, I always take a few moments to mentally check in before starting any task involving sharp objects, ensuring I’m focused and fully alert. I also prioritize good lighting and a clutter-free workspace.

Q 14. What is your understanding of ergonomic principles in handling sharp tools?

Ergonomic principles are central to safe and efficient use of sharp tools. Maintaining a comfortable and neutral posture reduces strain and fatigue, decreasing the risk of accidental injuries. Using tools with properly sized handles, and avoiding awkward grips or prolonged repetitive movements, are crucial. Utilizing tool rests and supports whenever possible helps maintain a steady hand and reduces the chance of slips. Regular breaks are also important to prevent fatigue and ensure sustained focus and control. Ignoring ergonomics often leads to muscle strain, repetitive strain injuries, and ultimately, a greater risk of accidents.

For example, using a comfortable, well-fitting knife handle allows for better control and less strain on the hand and wrist than a poorly designed one. A suitable cutting board height prevents you from bending awkwardly and protects your back from excessive strain.

Q 15. Explain the importance of regular maintenance for sharp instruments.

Regular maintenance of sharp instruments is paramount for safety, efficiency, and longevity. A dull instrument requires more force to perform its task, increasing the risk of slips, accidents, and injury. Moreover, a damaged or poorly maintained instrument can compromise the precision and quality of the work.

- Sharpening: Regular sharpening keeps blades at peak performance, ensuring clean cuts and reducing the risk of slippage. The frequency depends on the instrument and usage; some require daily sharpening, others less frequently.

- Cleaning and Disinfection: Thorough cleaning after each use prevents the buildup of debris and potential contamination, crucial in fields like surgery or food preparation. Disinfection protocols must be followed depending on the application.

- Storage: Proper storage in sheaths, cases, or designated racks prevents damage, accidental cuts, and keeps the instruments organized.

- Inspection: Regularly inspecting for damage – cracks, chips, rust, or warping – is vital. Damaged instruments should be immediately removed from service and replaced or repaired.

For example, a surgeon’s scalpel needs meticulous care to maintain its sterile condition and razor-sharp edge for precise incisions, while a chef’s knife requires sharpening to efficiently slice vegetables and meats without tearing.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you assess the condition of a sharp instrument before using it?

Assessing the condition of a sharp instrument is a crucial first step before any task. It involves a visual inspection and sometimes a tactile check.

- Visual Inspection: Look for any signs of damage, such as chips, cracks, rust, or bends in the blade. Check for any looseness in the handle or any signs of wear and tear.

- Tactile Check (Careful!): Gently run your finger (protected with a glove if appropriate) along the edge of the blade to feel for smoothness and sharpness. A dull blade will feel rounded, while a sharp blade will have a distinct, crisp edge. Exercise extreme caution during this process.

- Testing (for specific applications): For cutting instruments, a test cut on a suitable material may be necessary to confirm sharpness. This should only be done in a safe and controlled environment.

Imagine a carpenter using a chisel: a quick visual inspection reveals a chipped edge. Using it would be risky, leading to poor work and possible injury. The carpenter should either sharpen or replace the chisel before proceeding.

Q 17. What are the common risks associated with working with sharp objects?

Working with sharp objects inherently involves various risks, some minor and some potentially life-threatening.

- Cuts and Lacerations: This is the most common risk, ranging from minor cuts to deep wounds requiring stitches or even surgery. The severity depends on the sharpness of the object, the force of the impact, and the location of the injury.

- Punctures: Sharp objects can easily penetrate the skin, potentially leading to infections if not treated properly. Deep punctures can damage nerves, tendons, and other tissues.

- Slips and Falls: If the instrument slips during use, it can result in injury to the user or damage to surrounding materials or equipment.

- Eye Injuries: Flying debris from cutting or accidental contact with the sharp object can cause serious eye damage.

- Transmission of Diseases: In some contexts, like healthcare settings, contaminated sharp objects pose a risk of bloodborne pathogen transmission.

For instance, a poorly handled scalpel in surgery can cause serious complications for the patient and the medical team. Similarly, improper handling of a kitchen knife could result in a severe hand injury.

Q 18. Describe your understanding of different blade materials and their properties.

Different blade materials offer unique properties, impacting their sharpness, durability, and resistance to corrosion.

- High-Carbon Steel: Offers excellent hardness and edge retention but can be prone to rust if not properly cared for. Common in many kitchen knives and woodworking tools.

- Stainless Steel: Known for its resistance to corrosion and stain resistance, but typically less hard than high-carbon steel, resulting in slightly lower edge retention. Widely used in surgical instruments and kitchen knives.

- Ceramic: Incredibly sharp and durable, but can be brittle and prone to chipping. Often used in high-precision cutting tools, but not ideal for heavy-duty tasks.

- Titanium: Extremely lightweight, corrosion-resistant, and strong. Often used in specialized applications where weight and corrosion resistance are critical.

A surgeon might opt for stainless steel scalpels for their corrosion resistance and ease of sterilization, whereas a chef might prefer a high-carbon steel knife for its superior sharpness and ability to hold an edge.

Q 19. What are the safety regulations you follow when handling sharp objects?

Safety regulations when handling sharp objects vary depending on the context (kitchen, lab, operating room), but several universal principles apply:

- Always use appropriate Personal Protective Equipment (PPE): This includes cut-resistant gloves, safety glasses, and sometimes a lab coat or apron.

- Maintain a clean and organized workspace: A cluttered workspace increases the risk of accidents.

- Use sharp objects only for their intended purpose: Avoid using tools for tasks they are not designed for.

- Never leave sharp objects unattended: Store them securely in designated areas when not in use.

- Use proper techniques: Always use the correct grip and cutting techniques to avoid slips and accidents. This includes maintaining a firm grip, using controlled movements and avoiding unnecessary force.

- Dispose of sharp objects properly: Use puncture-resistant containers for disposal of used sharps.

- Follow specific guidelines: Be aware of and adhere to all institution-specific safety regulations.

In a laboratory setting, for example, strict protocols dictate the disposal of needles and scalpels in designated sharps containers to prevent accidental needle sticks.

Q 20. How would you respond to a colleague’s unsafe handling of sharp objects?

Responding to a colleague’s unsafe handling of sharp objects requires a tactful but firm approach, prioritizing safety and avoiding confrontation.

- Approach with concern: Privately address the colleague, expressing concern for their safety and the safety of others.

- Explain the risk: Clearly and calmly explain the potential dangers of their actions and the specific regulations that are being violated.

- Offer assistance and training: Provide guidance and resources on safe handling techniques. Suggest refresher training if necessary.

- Report if necessary: If the behavior persists or poses a significant risk, report it to the appropriate supervisor or safety officer.

For example, if I observed a colleague carelessly tossing a scalpel into a regular trash can, I would approach them privately, emphasize the risk of accidental needle sticks, and explain proper sharps disposal procedures. If the unsafe behavior continued, I would report it to a supervisor.

Q 21. Describe your experience with various types of cutting tools.

My experience with cutting tools encompasses a wide range, from surgical instruments to kitchen knives and woodworking tools. I’ve worked extensively with:

- Surgical Instruments: Scalpels, scissors, forceps, retractors – requiring precise and sterile handling techniques.

- Kitchen Knives: Chef’s knives, paring knives, serrated knives – demanding proficiency in various cutting styles and maintaining sharpness.

- Woodworking Tools: Chisels, plane blades, carving knives – necessitating an understanding of wood grain and appropriate cutting angles.

- Laboratory Tools: Microtomes, dissecting tools – requiring meticulous attention to detail and sterile technique.

This experience has instilled in me a strong understanding of material properties, sharpening techniques, and appropriate safety measures for diverse cutting tool applications.

Q 22. What are the different techniques for precise cutting with sharp instruments?

Precise cutting with sharp instruments demands a combination of technique and understanding of the tool and material. It’s not just about brute force; it’s about controlled application of pressure and precise movements.

Controlled Grip: A firm yet relaxed grip is crucial. Think of holding a pencil while writing – you need control, not a death grip. Different grips suit different tools and tasks. For example, a pinch grip is best for fine detail work with scalpels, while a full-hand grip might be better for larger knives.

Blade Angle: The angle of the blade relative to the material significantly impacts the cut. A steeper angle results in a more forceful cut, while a shallower angle offers more control for delicate work. Think of slicing a tomato versus chopping an onion – the angle changes dramatically.

Cutting Action: Pulling cuts are generally preferred for precise work as they provide more control than pushing cuts. Pushing cuts risk slippage and injury. For instance, when dissecting delicate tissues, a controlled pulling action is essential to avoid tearing.

Blade Sharpening: A sharp blade is paramount. A dull blade requires more force, leading to imprecise cuts and increased risk of injury. Regular sharpening or replacement is essential, depending on the tool and frequency of use.

Q 23. How do you adapt your technique based on the material being cut?

Adapting technique to the material is fundamental for safe and efficient cutting. Different materials require different approaches to avoid damage to the material or injury to the user.

Hard Materials (e.g., bone, metal): These require stronger, more forceful cuts, often with specialized tools designed for hardness. The pressure and angle of the cut needs adjustment to avoid breakage of the blade or tool.

Soft Materials (e.g., tissue, fabric): These demand delicate cuts with a lighter touch and potentially different blade angles to avoid tearing or distortion. Sharpness is especially crucial to prevent jagged edges.

Brittle Materials (e.g., glass, ceramics): These necessitate careful scoring or controlled snapping rather than direct cutting to minimize shattering and injury. Protective eyewear is essential in this case.

For example, when dissecting, I would use a scalpel with a fine, sharp blade at a shallow angle for delicate tissues, while a heavier blade and a more forceful approach might be necessary for denser connective tissues. Similarly, working with leather requires different pressure and blade control compared to working with paper.

Q 24. Describe your experience with using protective equipment when handling sharp objects.

Protective equipment is non-negotiable when handling sharp objects. My experience emphasizes a layered approach to safety.

Cut-Resistant Gloves: These are essential for various tasks, offering protection against accidental cuts and lacerations. The level of protection varies; some gloves offer better protection than others depending on the material and the sharpness of the blade. I always choose gloves appropriate to the task at hand.

Eye Protection: Safety glasses or goggles are crucial to protect against flying debris or accidental blade slippage.

Protective Clothing: Depending on the task, this might include lab coats, aprons, or even full-body protective suits. This prevents cuts to exposed skin.

Appropriate Footwear: Closed-toe shoes are vital to protect feet from dropped instruments or spilled materials.

In my experience, neglecting even a single piece of protective equipment can lead to serious consequences. I consistently prioritize safety as a preventative measure. Once, while working with a particularly sharp ceramic blade, a small fragment chipped off and flew towards my face. My safety glasses prevented a potential eye injury; that incident reinforced my commitment to consistent safety procedures.

Q 25. What are the first aid procedures you follow in the event of a cut or injury?

Immediate and appropriate first aid is crucial in the event of a cut. My approach follows these steps:

Stop the Bleeding: Apply direct pressure to the wound using a clean cloth or bandage. Elevate the injured area if possible.

Clean the Wound: Gently clean the wound with mild soap and water. Avoid scrubbing or using harsh disinfectants. Avoid hydrogen peroxide as it can further damage the wound.

Dress the Wound: Apply a clean dressing to cover the wound and prevent infection. If the wound is deep, gaping, or shows signs of severe bleeding, it requires immediate medical attention.

Seek Medical Attention: If the wound is deep, bleeds profusely, or shows signs of infection (redness, swelling, pus), seek immediate medical attention. Tetanus vaccination status should also be reviewed.

Beyond the immediate steps, ongoing monitoring for signs of infection is crucial. Deep wounds might require stitches or further medical intervention. I’ve personally encountered situations requiring professional medical care after even seemingly minor cuts. Early intervention prevents complications.

Q 26. What is your understanding of the different types of hand protection available?

Hand protection varies significantly depending on the task and the risk. My understanding encompasses several types:

Cut-Resistant Gloves: These range from lightweight gloves suitable for handling less sharp tools to heavy-duty gloves designed for use with extremely sharp instruments like knives or industrial blades. Materials include Kevlar, steel mesh, and specialized polymers.

Chemical-Resistant Gloves: These protect against chemical hazards that may be present alongside sharp objects. For instance, working with solvents and sharp instruments simultaneously requires both types of protection.

Insulated Gloves: These are crucial when handling sharp objects in conjunction with electricity or high temperatures.

Choosing the correct hand protection is crucial. A compromise in protection can result in serious injury. I always assess the risk before selecting the appropriate gloves, ensuring that they are correctly sized and in good condition.

Q 27. How would you assess the risk associated with a particular sharp object task?

Risk assessment for any sharp object task is a systematic process. I typically follow these steps:

Identify Hazards: What sharp objects are involved? What are their sharpness and size? Are there any other hazards present (chemicals, electricity, etc.)?

Identify Who Might Be Harmed: The user, bystanders, or others in the vicinity.

Evaluate the Risks: How likely is it that an injury will occur? How severe could the injury be?

Determine Control Measures: What steps can be taken to minimize or eliminate the risks? This might include using appropriate protective equipment, employing safe work practices, and establishing clear procedures.

Review and Update: Risk assessments aren’t one-time events. They should be reviewed and updated regularly to account for changes in the task, tools, or environment.

For instance, when planning a dissection, I’d carefully consider the sharpness of the instruments, the type of tissue being cut, the potential for accidental needle sticks, and the appropriate PPE. A detailed risk assessment helps me prepare and execute tasks safely.

Q 28. Explain your experience working with power tools involving sharp objects.

My experience with power tools involving sharp objects is extensive and centers on safety protocols. Power tools increase the risk of severe injuries compared to manual tools due to the speed and power involved.

Training and Competency: Proper training on the operation and safety procedures of any power tool is essential before commencing any task. This includes understanding the tool’s limitations and potential hazards.

Machine Guarding: Power tools should have appropriate guards in place to prevent accidental contact with the sharp objects during operation. Guards must be in place and functional before starting work.

Appropriate PPE: Power tool operations demand stringent safety protocols. This includes eye protection, hearing protection, and often additional protective clothing beyond standard PPE for manual sharp object use.

Regular Maintenance: Ensuring that all tools are regularly maintained, well-lubricated, and in good working order minimizes the risk of unexpected malfunctions or blade breakage.

I’ve worked with various power tools, including rotary cutters and specialized surgical instruments, and in every instance, a methodical approach to safety has been paramount. Once, a colleague failed to use the blade guard on a rotary cutter, resulting in a significant injury. This incident underscored the importance of rigorous adherence to safety standards.

Key Topics to Learn for Working with Sharp Objects Interview

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety protocols, including proper handling, storage, and disposal of sharp objects. This includes knowledge of relevant OSHA or industry-specific regulations.

- Tool Selection and Usage: Knowing which tools are appropriate for different tasks and mastering the correct techniques for using scalpels, needles, blades, and other sharp instruments to minimize risk and maximize efficiency. Consider various materials and their impact on tool selection.

- Risk Assessment and Mitigation: Developing the ability to identify potential hazards associated with sharp objects and implementing strategies to minimize risks, such as using appropriate protective equipment (PPE) and employing safe work practices.

- Emergency Procedures: Knowing how to respond to accidents involving sharp objects, including first aid procedures and reporting protocols. Understanding the importance of immediate action and post-incident reporting.

- Maintenance and Sterilization: Proper cleaning, sterilization, and maintenance of sharp instruments to prevent contamination and ensure longevity. This includes understanding different sterilization methods and their effectiveness.

- Waste Disposal: Safe and compliant disposal of used sharp objects according to regulatory guidelines. This involves understanding different waste categories and proper container usage.

- Ergonomics and Body Mechanics: Understanding proper posture and techniques to minimize strain and injury when working with sharp objects for extended periods. This includes minimizing repetitive movements and maintaining a comfortable work environment.

Next Steps

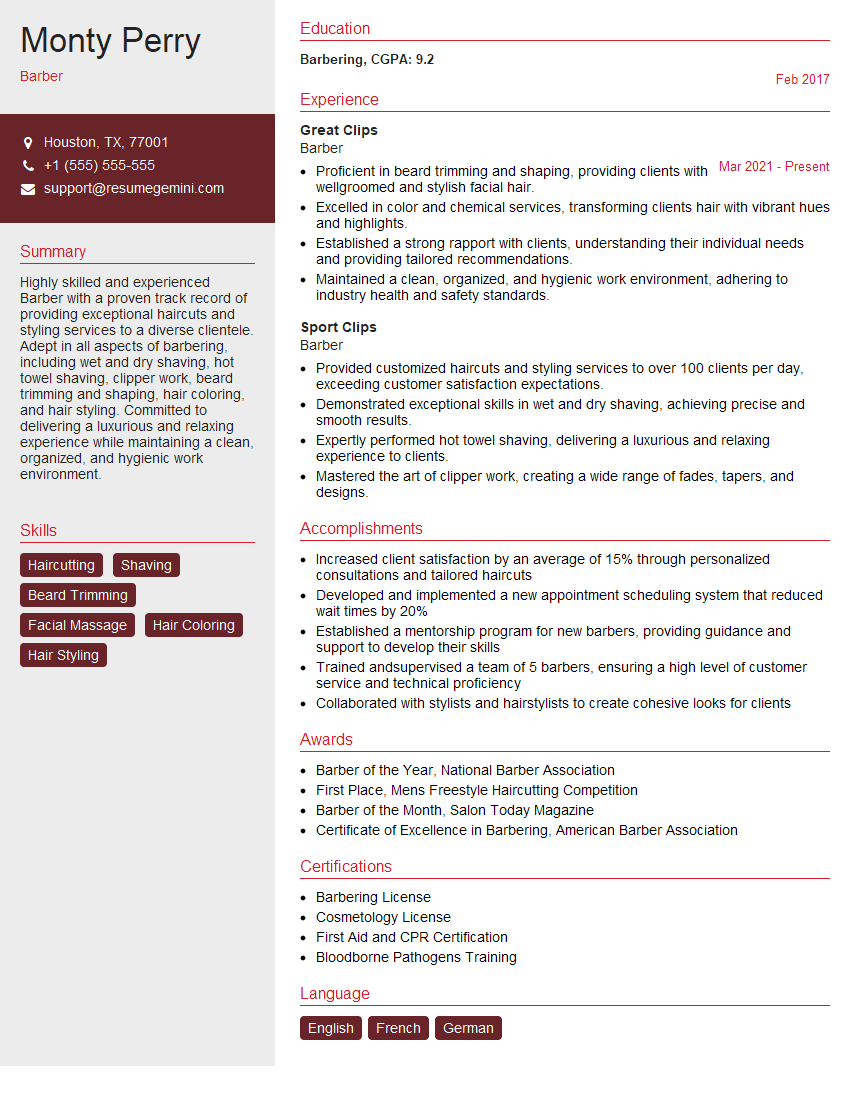

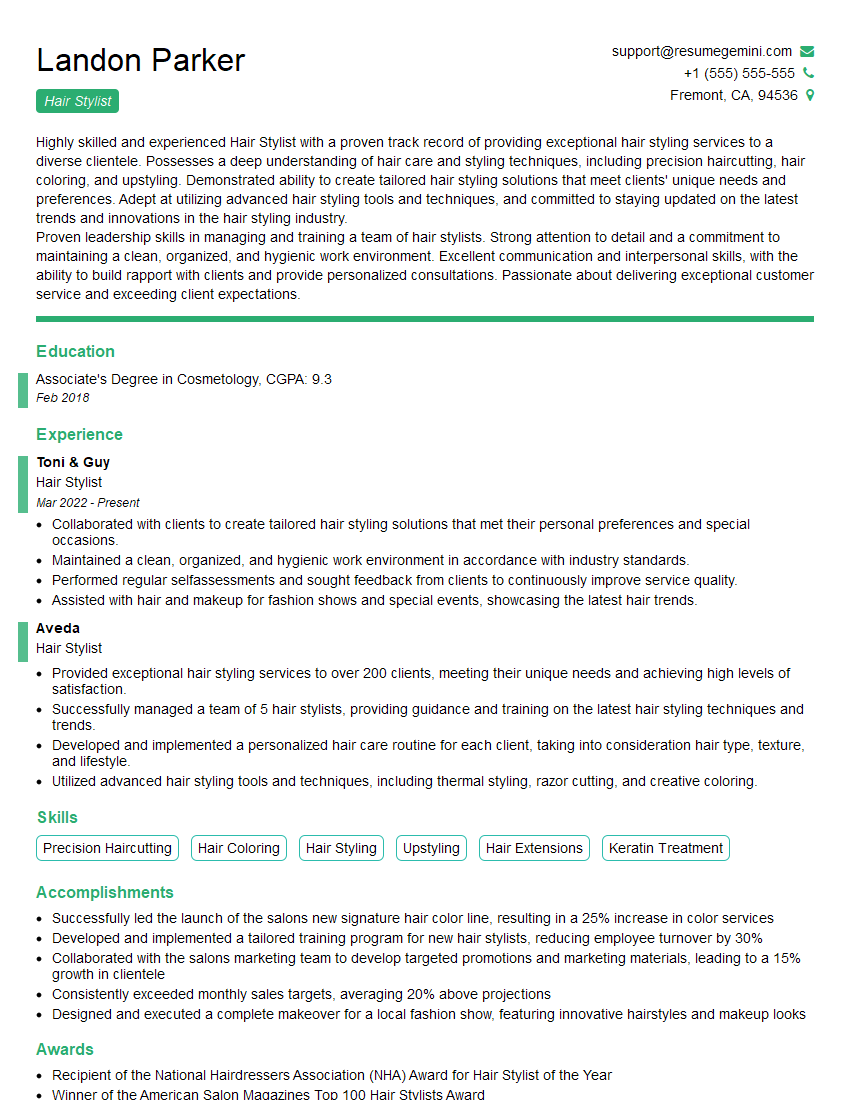

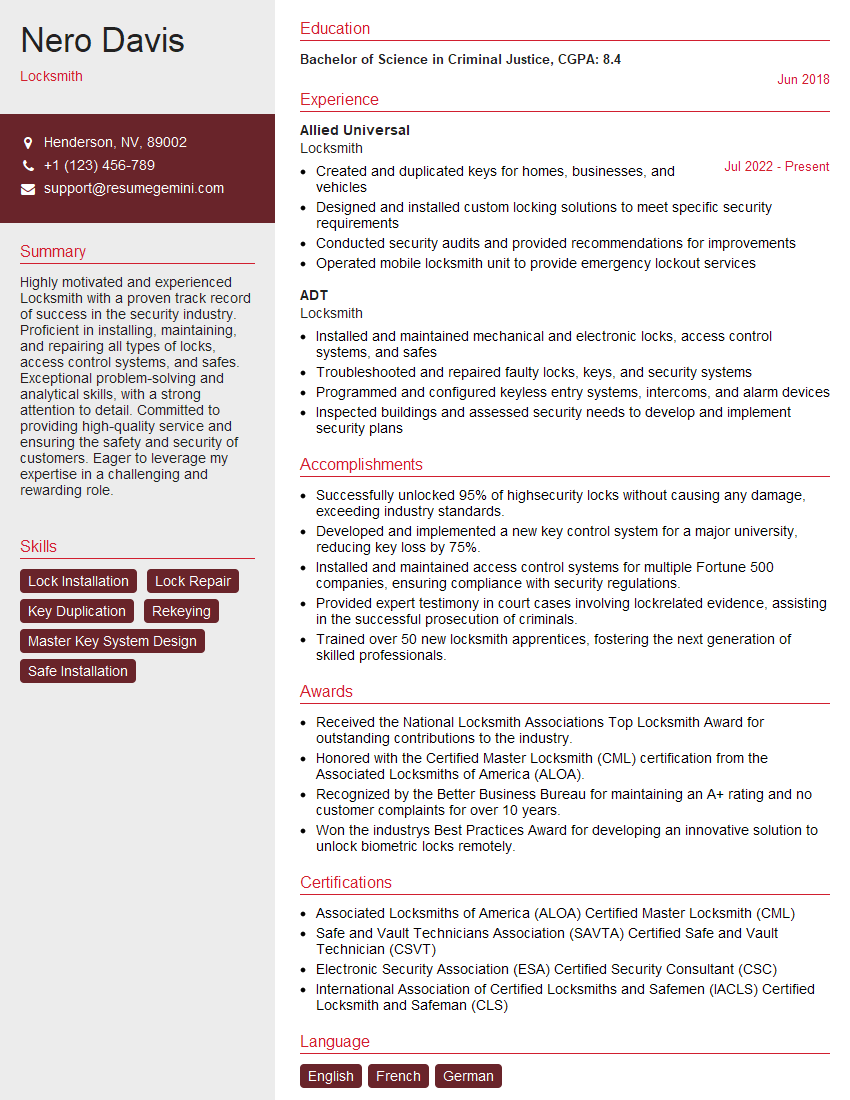

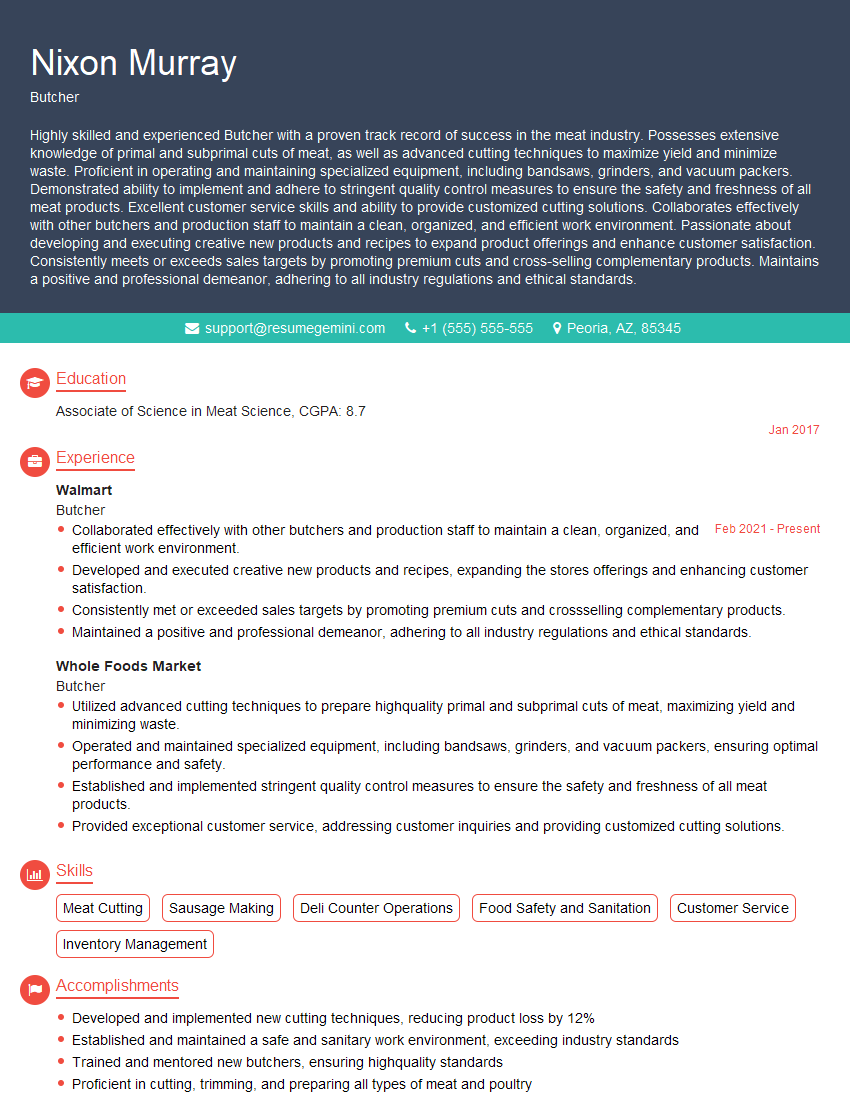

Mastering safe practices in working with sharp objects is crucial for career advancement in many fields, demonstrating your commitment to safety and professionalism. A strong resume highlighting your skills and experience in this area is essential for securing your desired role. To build an ATS-friendly resume that effectively showcases your qualifications, leverage the power of ResumeGemini. ResumeGemini provides tools and resources to create a professional and impactful resume, increasing your chances of getting noticed by potential employers. Examples of resumes tailored to Working with Sharp Objects are available within the ResumeGemini platform to help guide your creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.