The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Boilerhouse Operations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Boilerhouse Operations Interview

Q 1. Describe your experience with different types of boilers (e.g., firetube, watertube).

My experience encompasses a wide range of boiler types, primarily firetube and watertube boilers. Firetube boilers, simpler in design, are characterized by hot gases passing through tubes surrounded by water. These are commonly found in smaller applications, like heating smaller buildings. I’ve worked extensively with horizontal return tubular (HRT) and scotch marine firetube boilers. Watertube boilers, on the other hand, have water circulating inside tubes surrounded by hot gases. They are preferred for larger-scale applications due to their higher efficiency and capacity. I have significant experience with various watertube designs, including D-type, O-type, and modular watertube boilers, often found in power generation and industrial settings. In my previous role, I managed the operation and maintenance of a 500,000 lbs/hr watertube boiler used for process steam generation in a large manufacturing plant.

The key difference boils down to scale and efficiency. Think of a firetube boiler as a simpler, more robust kettle—great for smaller tasks. A watertube boiler is like a sophisticated, high-pressure espresso machine—perfect for large-scale, high-efficiency operations. Understanding the nuances of each type is crucial for effective operation and maintenance.

Q 2. Explain the process of boiler water treatment and its importance.

Boiler water treatment is essential for preventing scale buildup, corrosion, and other issues that can significantly reduce boiler efficiency and lifespan. It involves a multi-step process aimed at maintaining optimal water chemistry. This includes:

- Pre-treatment: This often involves softening the feedwater to remove hardness minerals like calcium and magnesium. Methods include ion exchange, lime softening, and reverse osmosis.

- Internal Treatment: Once inside the boiler, chemicals are added to further condition the water. These include oxygen scavengers (to prevent corrosion), pH control agents, and dispersants (to prevent scale formation). The specific chemicals and their dosages depend on the boiler type, operating pressure, and water quality.

- Blowdown: Regularly removing a small portion of boiler water (blowdown) helps to control the concentration of dissolved solids and maintain water purity. The frequency of blowdown depends on factors such as boiler pressure and the concentration of solids.

The importance of proper water treatment can’t be overstated. Neglecting it can lead to costly repairs, reduced efficiency, potential boiler failure, and even safety hazards. Imagine scale buildup restricting water flow, causing overheating and potentially leading to an explosion. Regular testing and analysis of boiler water parameters are critical for proactive adjustments to the treatment regime.

Q 3. How do you monitor boiler water levels and pressure?

Monitoring boiler water levels and pressure is crucial for safe and efficient operation. We use a combination of methods:

- Water Level Gauges: These provide a visual indication of the water level within the boiler. Both high and low water levels are dangerous and need immediate attention. We have both glass and electronic level indicators for redundancy.

- Pressure Gauges: These show the steam pressure generated by the boiler. Maintaining the correct pressure is crucial for efficient operation and safety. High pressure can lead to catastrophic failure. Low pressure might indicate a problem with fuel supply or water level.

- Electronic Monitoring Systems: Modern boilers often incorporate automated systems that provide continuous monitoring and alarms for abnormal water levels or pressure deviations. These systems provide early warning, often sending alerts to mobile devices.

In my experience, regular checks, especially during startup and shutdown, are critical. I always perform manual checks in addition to relying on automated systems, ensuring a layered approach to monitoring and safety.

Q 4. What are the safety procedures for handling boiler chemicals?

Handling boiler chemicals requires strict adherence to safety procedures to prevent accidents and ensure the health of personnel. This includes:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, and protective clothing, when handling chemicals. The specific PPE required will depend on the chemical being handled.

- Material Safety Data Sheets (MSDS): Thoroughly review the MSDS for each chemical before handling it. The MSDS provides detailed information about hazards, safe handling procedures, and emergency response measures.

- Proper Storage: Chemicals should be stored in designated areas, away from incompatible materials. Storage areas should be well-ventilated and clearly labeled.

- Spill Response Plan: Having a well-defined spill response plan is crucial. This plan should outline steps to safely contain and clean up spills, including the use of appropriate neutralizing agents.

- Training: All personnel handling chemicals must receive proper training on safe handling procedures and emergency response protocols.

For example, when adding concentrated chemicals to the boiler, we always ensure the boiler is under pressure and the feed is diluted and slow to avoid shock and damage to the system.

Q 5. Describe your experience with boiler combustion controls and optimization.

My experience with boiler combustion controls and optimization involves fine-tuning the fuel-air mixture to achieve maximum efficiency and minimize emissions. This involves understanding the boiler’s combustion process and utilizing control systems to adjust fuel and air flow rates in response to changing demands. I am proficient in using various control systems, including:

- Proportional-Integral-Derivative (PID) controllers: These controllers continuously adjust fuel and air ratios to maintain the desired steam pressure and temperature.

- Oxygen analyzers: These instruments measure the amount of oxygen in the flue gases, which helps to determine the efficiency of combustion.

- Combustion efficiency software: This allows us to analyze combustion parameters, identify areas for improvement, and track the boiler’s performance over time.

Optimization involves regularly monitoring key parameters such as excess oxygen levels and flue gas temperature to adjust the combustion process for the optimal fuel-air ratio, thereby minimizing fuel consumption and environmental impact. In one instance, I was able to improve the combustion efficiency by 5% through careful optimization, resulting in significant annual cost savings.

Q 6. How do you troubleshoot common boiler malfunctions (e.g., low water level, high pressure)?

Troubleshooting boiler malfunctions requires a systematic approach. For example:

- Low Water Level: This is a serious issue and requires immediate action. Possible causes include a leak, faulty feedwater pump, or improper blowdown. The immediate response is to secure the boiler and investigate the cause. A visual inspection, checking the feedwater pump, and examining the water level gauges and their associated sensors and systems all play a part. Once the cause is identified, appropriate corrective actions are undertaken.

- High Pressure: This can also be dangerous and requires immediate attention. Possible causes include a malfunctioning pressure relief valve or excessive fuel input. The priority is to reduce the pressure safely, often involving manual intervention to relieve pressure through the relief valve system and investigation into the control systems. Once the pressure is safely under control, the underlying cause must be determined.

My approach to troubleshooting is to follow a structured methodology: gather information (pressure, temperature, water level, alarms), identify potential causes, test hypotheses, implement corrective actions, and document the entire process.

Q 7. Explain the importance of regular boiler inspections and maintenance.

Regular boiler inspections and maintenance are critical for ensuring safe and efficient operation, preventing costly breakdowns, and extending the boiler’s lifespan. This includes:

- Visual Inspections: Regular visual checks of the boiler and its components help to identify potential problems early on. Looking for leaks, corrosion, or damage is critical.

- Pressure Testing: Periodic pressure testing helps to verify the integrity of the boiler and its pressure vessels.

- Cleaning: Regular cleaning of the boiler tubes and other components removes accumulated deposits that can impede efficiency and lead to overheating.

- Component Replacements: Replacing worn-out or damaged parts prevents unexpected failures. This includes things like gaskets, valves, pumps, and sensors.

Think of it like regular car maintenance—small, regular investments prevent major problems down the road. Neglecting maintenance can lead to significant operational disruptions and repair costs. A comprehensive preventative maintenance program is essential and significantly reduces unforeseen costly repairs or, worse, catastrophic failure.

Q 8. What are the different types of boiler fuel sources you’ve worked with?

Throughout my career, I’ve worked extensively with various boiler fuel sources. The choice of fuel often depends on factors like cost-effectiveness, availability, and environmental regulations. My experience encompasses:

- Natural Gas: This is a common and relatively clean-burning fuel, ideal for many boiler systems. I’ve managed natural gas boilers ranging from small commercial units to large industrial ones, focusing on efficient combustion and minimizing emissions.

- Fuel Oil (No. 2, No. 6): I’ve worked extensively with both lighter No. 2 fuel oil (suitable for smaller boilers) and heavier No. 6 fuel oil (used in larger, higher-capacity systems). Managing fuel oil involves meticulous attention to storage, handling, and combustion optimization to ensure efficient operation and minimize particulate matter.

- Biofuels: I have experience with boilers adapted to use biofuels such as biomass pellets or wood chips. These fuels present unique challenges related to consistent fuel quality and ash management. Proper handling and efficient combustion are crucial for optimal performance and reduced emissions.

- Coal (less recent experience): While less prevalent now due to stricter environmental regulations, I have past experience with coal-fired boilers. This involved managing the complexities of coal handling, ash disposal, and stringent environmental compliance measures.

Understanding the characteristics of each fuel source is paramount for safe and efficient boiler operation. This includes knowledge of their heating values, emission profiles, and potential hazards.

Q 9. Describe your experience with boiler safety valves and pressure relief systems.

Boiler safety valves and pressure relief systems are critical for preventing catastrophic failures. My experience encompasses the installation, maintenance, testing, and troubleshooting of various safety devices. I’m proficient in understanding their operation principles and ensuring their proper functioning. This includes:

- Regular Inspections and Testing: I perform routine inspections of safety valves according to established schedules, including pop testing to verify their ability to relieve pressure at the designated setpoint. Any discrepancies or malfunctions are immediately addressed.

- Pressure Relief Valve Sizing and Selection: I have experience in selecting appropriately sized pressure relief valves based on boiler capacity, pressure ratings, and relevant safety codes. Incorrect sizing can lead to inadequate pressure relief or premature valve failure.

- Safety Valve Maintenance: This includes cleaning, lubricating, and repairing valves as needed, following manufacturer’s recommendations and best practices. It is crucial to maintain detailed records of all inspections, testing and maintenance activities.

- Understanding Pressure Relief System Components: My knowledge extends to other components within a pressure relief system, such as pressure gauges, safety interlocks, and alarm systems. The entire system needs to function cohesively to ensure boiler safety.

A real-world example involves identifying a malfunctioning safety valve during a routine inspection. Immediate action was taken to replace the faulty valve, preventing a potential accident. This underscores the importance of proactive maintenance.

Q 10. How do you ensure compliance with relevant safety regulations and codes?

Compliance with safety regulations and codes is paramount in boilerhouse operations. I ensure compliance by:

- Staying Updated on Regulations: I actively follow changes and updates in relevant codes and standards such as ASME, NFPA, and local regulations. This involves attending training sessions and reviewing updated codes regularly.

- Maintaining Detailed Records: Thorough record-keeping is crucial. This includes logs of boiler operations, maintenance activities, safety inspections, and any incidents or near-misses. These records are crucial for audits and demonstrate compliance.

- Implementing Safe Operating Procedures: I develop and implement clear, concise, and easy-to-understand safe operating procedures (SOPs) for all aspects of boiler operation and maintenance. These SOPs cover startup, shutdown, emergency procedures, and routine tasks.

- Regular Audits and Inspections: I collaborate with regulatory authorities and conduct internal audits to identify and address any non-compliance issues proactively. This proactive approach minimizes risks and ensures continuous improvement.

- Employee Training: All boilerhouse personnel receive thorough training on safety procedures, emergency response, and safe work practices. Regular refresher courses are conducted to ensure everyone is up-to-date.

Non-compliance can lead to severe penalties, operational disruptions, and potential safety hazards, hence it’s crucial to maintain a robust compliance program.

Q 11. Explain the process of starting up and shutting down a boiler.

The process of starting up and shutting down a boiler is critical for safety and efficiency. The exact procedures vary depending on the boiler type and size, but the general principles remain consistent.

Startup:

- Pre-start Checks: Inspect the boiler for any visible damage, check fuel supply, water levels, and ensure all safety devices are functioning correctly.

- Water Filling and Purging: Carefully fill the boiler with treated water and purge any trapped air to prevent overheating and damage.

- Ignition and Flame Establishment: Initiate the ignition sequence according to the manufacturer’s instructions and carefully monitor flame establishment to ensure proper combustion.

- Burner Adjustment and Stabilization: Adjust the burner to achieve optimal combustion efficiency and maintain stable steam pressure.

- Load Increase: Gradually increase the boiler load to meet the required steam demand.

Shutdown:

- Load Reduction: Gradually reduce the boiler load to minimize thermal stress.

- Fuel Shut-off: Safely shut off the fuel supply.

- Cooling Down: Allow the boiler to cool down slowly under controlled conditions to prevent thermal shock.

- Draining: Carefully drain the boiler water according to established procedures.

- Post-Shutdown Inspection: Conduct a final inspection to identify any issues or areas needing attention.

Careful adherence to these procedures minimizes the risk of accidents and extends the boiler’s lifespan.

Q 12. What is your experience with boiler efficiency monitoring and improvement?

Boiler efficiency monitoring and improvement is a continuous process. My experience involves using various techniques and technologies to optimize boiler performance and reduce energy consumption.

- Data Acquisition and Analysis: I utilize various monitoring systems to collect real-time data on key parameters such as fuel consumption, steam production, water temperature, pressure, and flue gas analysis. This data is then analyzed to identify areas for improvement.

- Efficiency Calculation: I’m proficient in calculating boiler efficiency using standard formulas and comparing actual performance against the design specifications.

- Identifying Losses: Through data analysis, I can pinpoint areas of energy loss such as excess air in combustion, heat loss through radiation, and inefficiencies in the steam distribution system.

- Implementing Improvement Measures: Based on the analysis, I implement targeted improvements such as burner adjustments, insulation upgrades, air-preheater optimization, and leak repairs.

- Regular Maintenance: A well-maintained boiler is a key factor in achieving high efficiency. This includes periodic inspections, cleaning, and preventative maintenance.

For example, in a recent project, by analyzing data and adjusting the air-fuel ratio, we achieved a 5% improvement in boiler efficiency, resulting in significant cost savings.

Q 13. How do you interpret boiler performance data and identify areas for improvement?

Interpreting boiler performance data requires a deep understanding of thermodynamics and combustion principles. I use a systematic approach to analyze data and identify areas for improvement.

- Data Review: I start by reviewing historical data trends, looking for patterns and anomalies in fuel consumption, steam production, and emissions. Any deviation from established norms warrants further investigation.

- Performance Indicators: I focus on key performance indicators (KPIs) such as boiler efficiency, fuel consumption rate, and excess air levels. These KPIs provide a quantifiable assessment of boiler performance.

- Identifying Trends: I look for trends over time to identify gradual degradation or recurring issues. This helps in proactive maintenance and preventing potential problems before they escalate.

- Correlation Analysis: I correlate different data points to understand the relationships between various parameters. For instance, analyzing the correlation between excess air and fuel consumption can pinpoint inefficiencies in combustion.

- Root Cause Analysis: When problems are identified, root cause analysis techniques are employed to determine the underlying cause and implement appropriate corrective actions.

For instance, by noticing a gradual increase in fuel consumption over time, coupled with higher than normal flue gas temperatures, I was able to identify a problem with the boiler’s insulation, leading to a timely repair and preventing further energy losses.

Q 14. Describe your experience with boiler automation and control systems.

My experience with boiler automation and control systems is extensive, ranging from simple pneumatic systems to advanced digital controls. I’m comfortable working with various technologies and programming languages involved in these systems.

- PLC Programming: I’m proficient in programming Programmable Logic Controllers (PLCs) to automate boiler operations, optimize combustion, and implement safety interlocks. I’ve used various PLC platforms and programming languages.

- SCADA Systems: I’m experienced in working with Supervisory Control and Data Acquisition (SCADA) systems to monitor and control multiple boilers from a central location. This provides real-time visibility into boiler performance and enables remote diagnostics.

- Control Strategies: I understand and can implement various control strategies such as PID (Proportional-Integral-Derivative) control to maintain stable steam pressure and temperature. I have hands-on experience tuning controllers to optimize performance.

- Data Logging and Reporting: Modern control systems provide extensive data logging capabilities. I use this data for performance analysis, reporting, and regulatory compliance.

- Troubleshooting and Maintenance: I’m proficient in troubleshooting automated systems, diagnosing malfunctions, and performing necessary maintenance to ensure reliable operation.

For example, I implemented a new SCADA system for a multi-boiler plant, resulting in improved operational efficiency, reduced downtime, and enhanced data visualization for better decision-making.

Q 15. What is your experience with boiler blowdown procedures?

Boiler blowdown is a crucial process for removing impurities and dissolved solids accumulated in the boiler water. These impurities can cause scaling, corrosion, and ultimately, boiler tube failure. My experience encompasses both continuous and intermittent blowdown procedures, tailored to the specific boiler type and operating parameters. Continuous blowdown involves a small, continuous discharge of water to maintain a steady concentration of solids. Intermittent blowdown involves periodically opening a valve to quickly discharge a larger volume of water.

For example, in a previous role managing a high-pressure boiler system, I implemented a precise continuous blowdown schedule based on regular water quality testing (using conductivity meters and chemical analysis). This ensured optimal solids concentration while minimizing water waste. For intermittent blowdown, we followed a strict log, recording the duration and frequency of each blowdown to ensure consistent boiler water purity. This systematic approach prevented costly repairs and downtime.

Safety is paramount in blowdown. I always ensure that proper safety procedures are followed, including verifying pressure and temperature levels before initiating blowdown, and utilizing proper personal protective equipment (PPE) such as heat-resistant gloves and eye protection. The blowdown lines are regularly inspected for leaks and corrosion.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle emergency situations in the boilerhouse?

Emergency situations in a boilerhouse require swift, decisive action. My approach is based on a structured framework: Assess, Act, Alert.

- Assess: Quickly identify the nature and severity of the emergency. Is it a pressure surge, a leak, a fire, or a power failure? This assessment dictates the immediate response.

- Act: Implement the appropriate emergency procedures. This could involve shutting down the boiler, isolating affected equipment, activating fire suppression systems, or evacuating personnel. My experience includes handling situations ranging from minor leaks to major equipment malfunctions, always prioritizing the safety of personnel.

- Alert: Immediately notify relevant personnel, such as maintenance staff, management, and emergency services, depending on the situation’s severity. Clear and concise communication is critical during an emergency.

For instance, during a sudden pressure surge incident at my previous plant, I immediately initiated an emergency shutdown sequence, followed established protocols to isolate the affected section of the boiler system, and immediately notified the maintenance team while simultaneously contacting the plant’s emergency response team. We successfully contained the issue and prevented a more serious incident.

Q 17. Describe your experience with different types of boiler feedwater pumps.

My experience encompasses various boiler feedwater pump types, including centrifugal pumps, positive displacement pumps (like piston or diaphragm pumps), and even multi-stage pumps for higher pressure applications. Each type has its strengths and weaknesses.

- Centrifugal Pumps: These are the most common type, ideal for high flow rates but less efficient at very high pressures. I’ve extensively used these in large boiler systems where a continuous and high volume feedwater supply is essential.

- Positive Displacement Pumps: These pumps deliver a precise and consistent volume of water, making them suitable for applications requiring accurate flow control, but they are generally less efficient at higher flow rates. I’ve used these in situations where precise dosage of chemicals into the feedwater system was needed.

- Multi-stage Pumps: These pumps are used for high-pressure boiler systems. I’ve worked with these in power generation facilities requiring significantly higher pressure to efficiently deliver feedwater to the boiler.

Selecting the appropriate pump type depends on factors such as the boiler’s pressure, required flow rate, and the characteristics of the feedwater. Regular maintenance, including lubrication and monitoring for vibration and noise, is crucial for ensuring pump longevity and efficiency.

Q 18. What are the common causes of boiler tube failure?

Boiler tube failure can have several causes, all stemming from either internal or external factors. Internal factors relate primarily to the water quality inside the boiler, while external factors often involve issues with the boiler’s physical condition or operating procedures.

- Internal Factors: These include scaling and deposits (which restrict flow and overheat the tubes), corrosion (caused by low pH or oxygen in the water), and caustic gouging (due to highly alkaline water).

- External Factors: These involve overheating due to insufficient water flow, flame impingement (direct flame contact with the tube), and external corrosion (caused by exposure to oxygen and moisture).

For example, in one case, we diagnosed frequent tube failures to be due to improper water treatment, leading to significant scaling. Implementing a robust water treatment program, including regular chemical testing and adjustments to the boiler’s chemical dosing, immediately reduced the failure rate. Another time, a tube failure was traced to flame impingement due to burner misalignment. This highlights the importance of regular inspections and maintenance.

Q 19. How do you prevent boiler scale and corrosion?

Preventing boiler scale and corrosion is paramount for maintaining boiler efficiency and extending its lifespan. This involves a multi-pronged approach focusing on water treatment, regular maintenance, and operational practices.

- Water Treatment: This is crucial. It includes softening the water to remove hardness minerals (calcium and magnesium), using chemical treatments like oxygen scavengers to remove dissolved oxygen, and maintaining the correct pH level to prevent corrosion. Regular water analysis is essential to adjust the treatment accordingly.

- Regular Maintenance: This includes regular inspections of the boiler interior to identify and remove any existing scale or corrosion. Cleaning the boiler periodically is necessary. Blowdown procedures, as discussed earlier, play a key role.

- Operational Practices: Maintaining proper water levels, avoiding sudden temperature changes, and ensuring proper airflow around the boiler helps prevent overheating and localized corrosion. Accurate operation and monitoring of all boiler equipment are also important.

In my experience, a combination of these strategies has consistently proven effective in minimizing scale and corrosion. This involved a combination of regular water testing, consistent chemical treatment adjustments, and scheduled boiler inspections and cleanings. The result was consistently cleaner boiler tubes, less downtime, and an extended boiler lifespan.

Q 20. What is your experience with boiler stack emissions monitoring?

Boiler stack emissions monitoring is crucial for environmental compliance and operational efficiency. My experience includes monitoring various emissions, including NOx (nitrogen oxides), SOx (sulfur oxides), CO (carbon monoxide), and particulate matter, using a variety of methods. This monitoring is typically done using continuous emission monitoring systems (CEMS) which provide real-time data on emissions levels.

These systems usually comprise various sensors (e.g., infrared or ultraviolet sensors for gas detection, opacity meters for particulate matter) and data acquisition systems. Data is logged and analyzed to ensure compliance with emission standards and identify potential operational problems. For example, elevated NOx levels might indicate a problem with the combustion process, requiring adjustments to the burner settings or fuel mix. I am also familiar with the use of extractive sampling methods for more detailed analysis of emissions.

Furthermore, I’m experienced in interpreting the data generated by these systems, identifying trends and anomalies, and using this information to optimize boiler operation for both environmental compliance and improved efficiency. Regular calibration and maintenance of the CEMS are critical to ensure data accuracy.

Q 21. Describe your experience with boiler fuel storage and handling.

Safe and efficient boiler fuel storage and handling are critical aspects of boilerhouse operations. My experience involves managing various fuel types, including natural gas, fuel oil, and coal (though coal is less common now). Each fuel type requires specific handling procedures to ensure safe storage and prevent spills, leaks, and environmental hazards.

For instance, with fuel oil, maintaining proper tank levels, regular inspections for leaks and corrosion, and ensuring adequate ventilation are all crucial. With natural gas, regular leak checks on pipelines and valves are necessary, and safety systems should be in place to detect gas leaks. In previous roles, we had comprehensive safety plans that included emergency procedures for fuel spills and leaks, with clearly defined responsibilities and emergency response teams.

Proper documentation, including fuel deliveries, consumption rates, and inventory levels, is essential for efficient management. This helps in predicting fuel needs, optimizing procurement, and minimizing storage costs. Regular inspection and maintenance of fuel handling equipment (pumps, filters, etc.) are also essential for safety and efficient operation.

Q 22. What are the different types of boiler instrumentation and controls you’re familiar with?

Boiler instrumentation and controls are crucial for safe and efficient operation. They monitor key parameters and allow for adjustments to maintain optimal performance. I’m familiar with a wide range, including:

- Level Indicators and Transmitters: These measure water level within the boiler drum, preventing both low-water conditions (which can damage the boiler) and high-water conditions (which can lead to water hammer).

- Pressure Gauges and Transmitters: Essential for monitoring steam pressure and boiler pressure. Variations from setpoints indicate potential issues.

- Temperature Sensors (Thermocouples, RTDs): Used to measure various temperatures throughout the system, including feedwater, steam, flue gas, and burner flame. These are critical for combustion efficiency and safety.

- Flow Meters: Measure the flow rate of feedwater, fuel, and air, ensuring proper combustion and preventing overheating or equipment damage.

- Safety Valves: Act as a last resort to prevent overpressure, releasing steam to maintain safe operating conditions.

- Control Systems (PLC/DCS): Programmable Logic Controllers (PLCs) or Distributed Control Systems (DCSs) automate many aspects of boiler operation, including fuel/air ratio control, water level control, and safety interlocks.

- Combustion Analyzers: Measure the levels of oxygen, carbon monoxide, and other gases in the flue gas. They’re used to optimize combustion efficiency and minimize emissions.

For example, in one plant, I implemented a new DCS system that significantly improved efficiency by providing more precise control over the fuel/air ratio, resulting in a reduction in fuel consumption and emissions.

Q 23. Explain the importance of maintaining accurate boiler logs and records.

Accurate boiler logs and records are paramount for several reasons. They are the backbone of effective maintenance, regulatory compliance, and operational optimization. Think of them as a boiler’s medical history.

- Predictive Maintenance: Analyzing trends in data—pressure, temperature, fuel consumption—allows for predictive maintenance, preventing unexpected failures and costly downtime. For example, a gradual increase in fuel consumption could indicate scaling within the boiler, allowing for scheduled cleaning before a major problem arises.

- Regulatory Compliance: Many jurisdictions have strict regulations regarding boiler operation and safety. Maintaining detailed logs demonstrates compliance with these regulations and prevents potential fines or legal issues.

- Troubleshooting: When a problem occurs, accurate logs provide a historical context to quickly identify the root cause. A sudden drop in steam pressure, for instance, can be tracked back to specific events or conditions.

- Performance Optimization: By tracking key performance indicators (KPIs) like efficiency and fuel consumption, we can identify areas for improvement and implement changes to reduce operational costs. For example, analyzing fuel consumption data over time might reveal inefficiencies related to burner operation.

In short, well-maintained logs are not just a record-keeping exercise; they are an essential tool for managing risks, optimizing performance, and ensuring safe and compliant operation.

Q 24. How do you ensure the safety of personnel working in the boilerhouse?

Boilerhouse safety is my top priority. A multi-layered approach is crucial, encompassing both procedures and equipment.

- Lockout/Tagout Procedures: Strict adherence to lockout/tagout (LOTO) procedures is vital before any maintenance or repair work. This ensures that all power sources are isolated to prevent accidental starts and injuries.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, including heat-resistant gloves, safety glasses, and hearing protection, is essential for minimizing risks of burns, eye injuries, and hearing damage.

- Regular Inspections: Frequent inspections of equipment and safety systems, like pressure relief valves and emergency shutdowns, are vital to proactively identify and address potential hazards.

- Training and Competency: All personnel working in the boilerhouse must receive comprehensive training on safe operating procedures, emergency response protocols, and the use of relevant equipment. Regular competency assessments ensure that their skills are up-to-date.

- Emergency Response Plan: A clearly defined and regularly practiced emergency response plan is crucial to handle incidents quickly and effectively, minimizing the potential for injuries and damage.

For example, we conduct regular fire drills and emergency shutdown drills to ensure that everyone is prepared to react appropriately in case of an emergency.

Q 25. Describe your experience with troubleshooting boiler control system malfunctions.

Troubleshooting boiler control system malfunctions requires a systematic approach. I typically follow these steps:

- Identify the Problem: Precisely define the malfunction. Is there an alarm? What parameter is out of range? Use the boiler’s monitoring system to gather data.

- Review Historical Data: Check logs and historical data to identify any patterns or trends leading up to the malfunction. This can help pinpoint the root cause.

- Inspect the System: Physically inspect the control system components, checking for loose connections, damaged wires, or other visible issues.

- Test Components: Use appropriate testing equipment (multimeters, etc.) to test individual components and verify their functionality.

- Utilize Diagnostics: Many modern control systems have built-in diagnostic tools that can identify specific faults. Use these tools to their full extent.

- Consult Documentation: Refer to the system’s manuals and schematics to better understand the system’s design and functionality.

- Implement Corrective Action: Once the fault is identified, implement the necessary repairs or replacements, making sure to follow safety procedures.

- Verify Repair: After making repairs, verify the system’s functionality and ensure that the problem is resolved.

For example, I once diagnosed a malfunction in a steam pressure control system by tracing a faulty signal back to a corroded sensor. Replacing the sensor immediately restored normal operation.

Q 26. What is your familiarity with predictive maintenance techniques for boilers?

Predictive maintenance is a cornerstone of efficient and reliable boiler operation. It focuses on preventing problems rather than reacting to them. My experience includes using various techniques such as:

- Vibration Analysis: Using vibration sensors to detect abnormal vibrations that indicate potential bearing failure or other mechanical issues. Early detection allows for proactive maintenance, preventing catastrophic failures.

- Oil Analysis: Regularly analyzing boiler lubricating oil samples can reveal wear and tear in critical components, such as pumps and turbines. This allows for timely replacement of parts.

- Thermal Imaging: Infrared cameras can detect overheating in boiler components, providing early warnings of potential problems. This is particularly useful for identifying insulation issues or blocked passages.

- Data Analysis: Using historical data on parameters like fuel consumption, pressure, and temperature to identify trends and predict potential failures. Statistical analysis and machine learning algorithms can help automate this process.

For instance, we implemented a predictive maintenance program that used vibration analysis to predict a potential bearing failure in a boiler feed pump weeks in advance. This allowed us to schedule the replacement during a planned shutdown, avoiding costly emergency repairs and downtime.

Q 27. How do you manage boilerhouse energy consumption and costs?

Managing boilerhouse energy consumption and costs involves a multi-pronged strategy focusing on efficiency and optimization.

- Regular Tuning and Cleaning: Regularly tuning burners and cleaning boiler surfaces (removing scale and deposits) improves combustion efficiency and reduces fuel consumption.

- Optimized Combustion Control: Implementing advanced combustion control systems ensures the optimal fuel-air ratio, minimizing energy waste and emissions.

- Insulation and Sealing: Proper insulation and sealing of pipes, valves, and equipment reduces heat loss, leading to significant energy savings.

- Water Treatment: Effective water treatment programs prevent scale buildup, which reduces boiler efficiency and extends the lifespan of the boiler.

- Energy Monitoring and Tracking: Implementing a robust energy monitoring system allows for accurate tracking of energy consumption and identification of areas for improvement. This includes analyzing energy usage patterns and isolating inefficient equipment or processes.

For example, by implementing a more efficient water treatment program, we reduced scale buildup in the boilers, leading to a 5% reduction in fuel consumption and a significant decrease in maintenance costs.

Q 28. Describe a time you had to solve a complex boilerhouse problem.

One challenging situation involved a sudden and unexplained drop in steam pressure during peak demand. Initial investigations revealed no obvious mechanical problems. The system’s logs indicated a correlation between the pressure drop and the operation of a specific feedwater pump.

After examining the data, it became apparent that a subtle, intermittent fault in the pump’s control circuitry caused the feedwater flow to fluctuate erratically. This fluctuation, though small, was significant enough to upset the delicate balance of the steam generation process, causing the pressure drop. The standard diagnostic tools weren’t highlighting this specific issue.

To solve the problem, I delved into the control system’s programming and electrical schematics. I discovered that a loose connection within a specific relay, not directly indicated by the system’s fault codes, was the root cause. After securely reconnecting the relay and implementing software changes to improve system stability, the problem was permanently resolved.

This experience underscored the importance of a thorough investigation that goes beyond superficial diagnostics and highlights the need for a deep understanding of the intricate interactions within a boiler control system.

Key Topics to Learn for Boilerhouse Operations Interview

- Boiler Systems & Components: Understanding various boiler types (e.g., firetube, watertube), their components (burners, pumps, controls), and operating principles.

- Water Treatment & Chemistry: Practical application of water treatment techniques to prevent scaling, corrosion, and maintain optimal boiler efficiency. Understanding water chemistry parameters and their impact on boiler performance.

- Safety Procedures & Regulations: Knowledge of relevant safety regulations, emergency procedures, lockout/tagout protocols, and hazard identification within a boilerhouse environment.

- Energy Efficiency & Optimization: Applying strategies to improve boiler efficiency, reduce fuel consumption, and minimize environmental impact. Understanding performance indicators and optimization techniques.

- Troubleshooting & Maintenance: Practical experience in identifying and resolving common boiler issues, performing preventative maintenance, and utilizing diagnostic tools.

- Instrumentation & Controls: Familiarity with boiler control systems, instrumentation (pressure gauges, temperature sensors, flow meters), and data logging systems. Understanding how these systems maintain optimal boiler operation.

- Environmental Compliance: Understanding emission control regulations and the impact of boiler operations on the environment. Knowledge of relevant permits and reporting requirements.

- Record Keeping & Reporting: Maintaining accurate logs, documenting maintenance activities, and generating reports on boiler performance and efficiency.

Next Steps

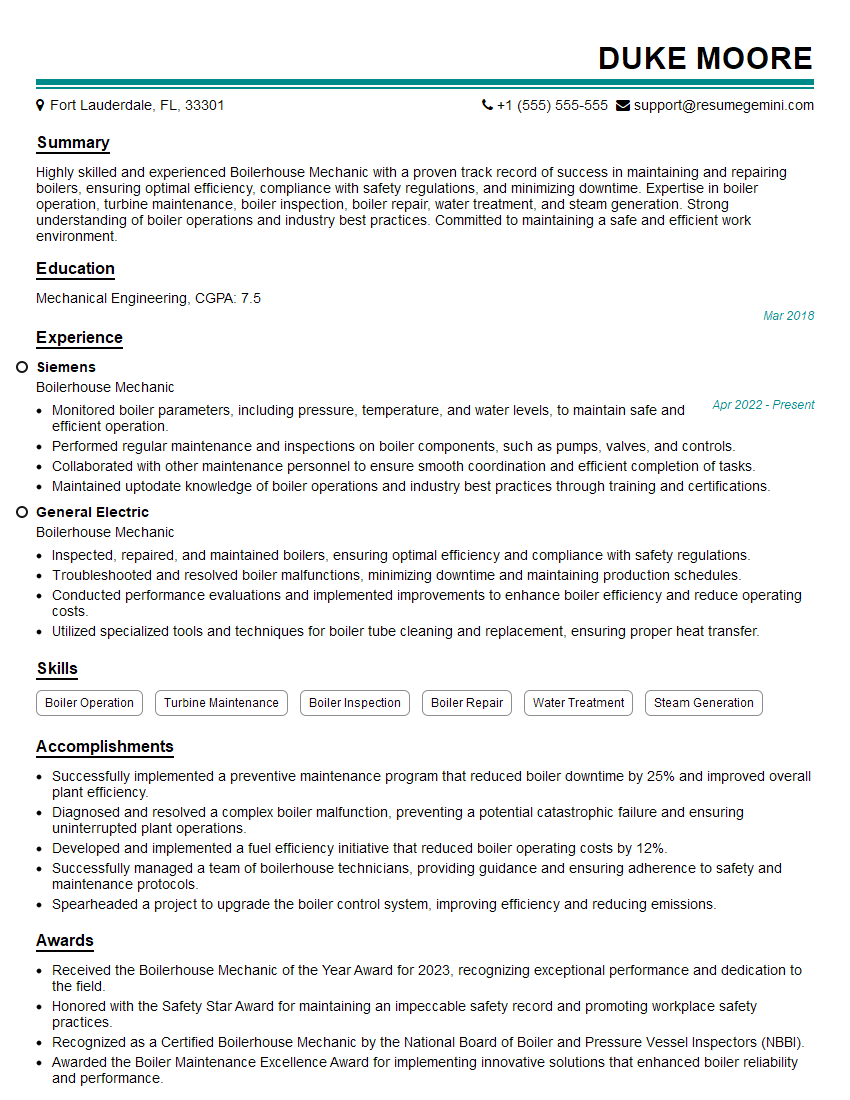

Mastering Boilerhouse Operations opens doors to rewarding careers with excellent growth potential, offering opportunities for specialization and increased responsibility within the energy sector. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to create a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini offers valuable tools and resources, including examples of resumes tailored to Boilerhouse Operations, to help you present yourself in the best possible light. Take advantage of these resources to build a compelling resume that showcases your expertise and helps you land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I have something for you and recorded a quick Loom video to show the kind of value I can bring to you.

Even if we don’t work together, I’m confident you’ll take away something valuable and learn a few new ideas.

Here’s the link: https://bit.ly/loom-video-daniel

Would love your thoughts after watching!

– Daniel

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.