Unlock your full potential by mastering the most common Seamstressing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Seamstressing Interview

Q 1. What types of sewing machines are you proficient with?

My proficiency spans a range of sewing machines, from basic mechanical models to advanced computerized machines. I’m experienced with both industrial and domestic machines, including those with specialized features like embroidery capabilities, overlock/serger functionality, and even quilting specific features. For example, I’m highly skilled in using a Singer 4423 for everyday projects and a Juki MO-654DE for professional-grade overlocking. This diverse experience allows me to adapt to any sewing project, regardless of the machine’s capabilities.

- Mechanical Machines: These machines provide a great understanding of the fundamental mechanics of sewing, teaching precision and control.

- Computerized Machines: These machines offer advanced stitch options, programmable functions, and ease of use for complex designs.

- Industrial Machines: These robust machines are crucial for high-volume production and working with heavy-duty fabrics.

Q 2. Describe your experience with different sewing techniques (e.g., hand-sewing, machine sewing, serging).

My sewing technique expertise encompasses both hand-sewing and machine sewing, with a strong focus on precision and efficiency. Hand-sewing is indispensable for intricate details, delicate repairs, or when a machine isn’t practical. I frequently use hand-sewing for appliqué, buttonholes, or fine alterations where machine stitching might damage the fabric. Machine sewing is my primary method for construction, speed, and consistent stitching. Serging, or overlocking, is crucial for finishing seams professionally and prevents fraying—it’s an essential skill in creating durable, high-quality garments. For instance, while constructing a tailored jacket, I would use machine sewing for the main construction, hand-sewing for buttonholes and lining details, and serging to finish all raw edges to prevent fraying.

- Hand-sewing: Used for fine details, alterations, and repairs.

- Machine sewing: Used for construction, speed, and consistent stitching. I’m proficient in various stitch types, including straight stitch, zigzag, satin stitch, and decorative stitches.

- Serging: Used to finish seams professionally, prevent fraying, and enhance the garment’s durability. I can adjust tension and stitch length for varying fabric weights.

Q 3. How familiar are you with various fabric types and their properties?

My familiarity with fabric types is extensive. I understand the properties of various fibers (natural, like cotton, linen, silk, wool; and synthetic, like polyester, nylon, rayon), their drape, weight, texture, and how they react to different sewing techniques. For example, knowing the difference between a tightly woven cotton poplin and a loosely woven linen is crucial for choosing appropriate needle sizes and stitch types to achieve a professional finish. Understanding the characteristics of each fabric type allows me to choose the best interfacing, pattern weight, and sewing techniques for optimal results. I’m experienced working with knits, wovens, silks, and specialty fabrics, each requiring a unique approach.

- Natural Fibers: Cotton, linen, silk, wool – understanding their drape, weight, and care.

- Synthetic Fibers: Polyester, nylon, rayon – understanding their durability, stretch, and potential for pilling.

- Specialty Fabrics: Leather, suede, velvet, lace – understanding their unique characteristics and sewing requirements.

Q 4. Explain your process for reading and interpreting sewing patterns.

Reading and interpreting sewing patterns is a systematic process that ensures accuracy and a successful outcome. I begin by carefully examining the pattern envelope, noting the size, fabric recommendations, and notions required. I then lay out the pattern pieces according to the instructions, checking for any markings or notches. Precisely cutting the fabric according to the pattern pieces is key; I use sharp shears and pay close attention to grainlines and matching notches. Once cut, I follow the instructions, paying close attention to seam allowances, pressing, and finishing details. A good understanding of garment construction principles is critical. For example, understanding how darts shape a garment is fundamental to creating a well-fitting garment.

- Understanding pattern markings: Grainlines, notches, seam allowances.

- Accurate cutting: Using sharp shears and paying attention to details.

- Following instructions meticulously: Paying close attention to assembly instructions and finishing details.

Q 5. What are your methods for troubleshooting common sewing machine problems?

Troubleshooting sewing machine problems is a vital skill. I approach this systematically, starting with the most common issues. A skipped stitch might indicate a bent needle, improper tension, or clogged bobbin case. A machine that jams may have a lint buildup or a problem with the feed dogs. I begin by checking the obvious—the needle, thread, and bobbin—ensuring they’re correctly inserted and in good condition. If the issue persists, I consult the machine’s manual or online resources. For example, if a machine is consistently creating uneven stitching, I systematically check the tension, needle, thread, and bobbin until I identify and resolve the cause.

- Systematic approach: Check needle, thread, bobbin first.

- Consult manuals and resources: Seek professional help if necessary.

- Cleaning and maintenance: Regular cleaning and lubrication are crucial.

Q 6. How do you ensure accuracy and precision in your sewing work?

Accuracy and precision are paramount in sewing. I employ several methods to ensure these qualities. I use a seam ripper sparingly, preferring careful preparation and precise cutting. I utilize tools like measuring tapes, rulers, and marking pencils to maintain consistent seam allowances and accurate pattern placement. Proper pressing at each stage of construction helps to maintain shape and prevent distortion. A critical aspect is attention to detail and using high-quality materials. My focus is on creating garments that are not only functional but also aesthetically pleasing. For example, when stitching a curved seam, I often use clips or pins to keep the fabric aligned and prevent puckering.

- Precise cutting and marking: Using rulers, measuring tapes, and marking tools.

- Consistent seam allowances: Paying attention to detail and accuracy.

- Proper pressing: Helps to maintain shape and prevent distortion.

Q 7. Describe your experience with pattern making and alterations.

My pattern making and alteration skills are well-developed. I can draft basic patterns from scratch and adapt existing patterns to create custom fits. Alterations are a common part of my work, whether adjusting a sleeve length, altering the waistline, or creating a unique detail. I use draping techniques for complex designs, and I’m proficient in making adjustments using slopers and pattern drafting tools. For instance, I recently altered a store-bought dress pattern to create a custom-fit bodice, modifying the shoulder seams and side seams to fit the client’s specific measurements. This involves understanding body measurements, pattern design principles, and practical adaptation skills.

- Basic pattern drafting: Creating patterns from scratch using measurements and design principles.

- Pattern alteration techniques: Adjusting existing patterns for proper fit and style.

- Draping: Creating patterns directly on fabric using pins and muslin.

Q 8. How do you manage time effectively when working on multiple sewing projects?

Effective time management is crucial when juggling multiple sewing projects. I employ a system that combines detailed planning with flexible adaptation. First, I meticulously list all projects, assigning each a realistic timeline based on complexity and fabric type. This involves breaking down larger projects into smaller, manageable tasks. For example, a complex wedding dress might be divided into stages like pattern making, cutting, assembling the bodice, creating the skirt, and finally, adding embellishments. Each stage gets its own dedicated time slot in my schedule.

Next, I prioritize projects based on deadlines and client needs. Using a project management tool (either digital or a simple planner), I allocate specific time blocks for each task. This helps me avoid feeling overwhelmed and prevents me from getting bogged down in one project at the expense of others. Importantly, I build in buffer time to account for unexpected delays – a vital element in preventing stress and ensuring timely project completion. Finally, I review and adjust my schedule regularly, maintaining a flexible approach that accommodates changes in workload or unforeseen issues. This agile approach ensures I’m consistently on track, delivering high-quality work on time.

Q 9. What safety precautions do you follow when using sewing equipment?

Safety is paramount in my sewing practice. Before starting any project, I ensure my workspace is well-lit and clutter-free to minimize the risk of accidents. I always use sharp, well-maintained sewing machine needles appropriate for the fabric type. Dull needles increase the likelihood of the needle breaking and causing injury. I handle pins and needles with care, and I never leave them scattered on my workspace. When using rotary cutters, I always keep my fingers out of the blade’s path and use a self-healing cutting mat to protect my work surface and prevent accidents. For electrical equipment, I always unplug the sewing machine before changing needles, cleaning, or performing any maintenance. Regular machine inspections for frayed cords or other electrical hazards are vital. Finally, I always use appropriate safety glasses when working with tools that might create flying debris, such as rotary cutters and some specialized sewing machines.

Q 10. How do you maintain your sewing machines and equipment?

Maintaining my sewing machines and equipment is a key aspect of my workflow. Regular cleaning is essential. After each project, I remove lint and fabric scraps from the bobbin area, feed dogs, and presser foot. I use a small brush to clear out the dust and debris from around the needle plate and other hard-to-reach areas. I oil the machine regularly, following the manufacturer’s instructions, to keep moving parts lubricated. This ensures smooth operation and extends the machine’s lifespan. For industrial machines, this process might require more specialized lubricants and attention to specific parts. I also check the tension regularly, making adjustments as needed to ensure consistent stitching. Keeping my scissors sharp is vital. I use sharpening stones periodically to maintain a clean, precise cut. I store all my equipment in a safe, dry environment to protect it from dust, moisture, and damage.

Q 11. How do you handle difficult or challenging fabrics?

Sewing with challenging fabrics requires adapting techniques and choosing the right tools. For instance, working with silks and other delicate fabrics necessitates using fine needles and delicate stitches to prevent tearing. I may also use a walking foot on my sewing machine to feed the fabric evenly and prevent slippage. Conversely, thick or heavy fabrics like denim or canvas may require heavier needles, stronger threads, and possibly a different stitch length or pattern to ensure durability and a professional finish. Stretchy fabrics, such as knits, often demand using a special needle and a stitch that allows for give and stretch to prevent the seam from breaking or puckering. I adjust my sewing machine settings such as stitch length and width to match the fabric’s characteristics. Experimenting with different needle types, stitch patterns and presser feet on a scrap piece of the fabric is key before starting on the main project.

Q 12. What is your experience with different types of seams and finishes?

My experience with seams and finishes is extensive. I’m proficient in a wide range of seam types, including French seams (ideal for sheer or delicate fabrics), flat-felled seams (durable and used often in men’s wear), and bound seams (for a clean, professional look). I also utilize various finishes like serging (overlocking) to prevent fraying, and Hong Kong finishing for a neat and professional look inside garments. The selection of seam and finish depends heavily on the fabric type, garment style, and the desired level of durability and aesthetic appeal. For example, a French seam would be inappropriate for a heavy-duty work garment but would be excellent for a silk blouse. Understanding the properties of different fabrics and tailoring my approach accordingly is crucial to achieving consistent high-quality results.

Q 13. Describe your experience with industrial sewing machines.

I have significant experience operating industrial sewing machines, including high-speed models and specialized machines for specific tasks, like button-sewing machines or overlockers. These machines are powerful and designed for high-volume production and often require a different technique and understanding than domestic machines. They demand a greater understanding of machine maintenance, including lubrication and regular cleaning. I’m familiar with various industrial stitch types and their appropriate applications, and I can adjust machine settings rapidly for different fabrics and stitch requirements. I can operate a variety of industrial sewing machines and understand how to adjust settings for optimal performance with different materials and project requirements.

Q 14. How do you ensure quality control in your sewing work?

Quality control is an integral part of my process. It begins with careful pattern cutting and fabric selection, checking for any imperfections before starting. Throughout the construction process, I perform regular checks to ensure seams are straight, even, and well-finished. I pay close attention to detail and use tools to measure precision where necessary. I use a variety of quality control checks at each stage of the project, from the initial measurements to the final press. After the garment is completed, I carefully inspect the garment for any flaws or imperfections, paying close attention to the stitching, finishing, and overall fit. I often use a pressing cloth to prevent shine and maintain the shape and integrity of the fabric throughout the process. This multi-layered approach ensures that every project meets my exacting standards before delivery.

Q 15. How familiar are you with different types of embroidery?

I’m very familiar with a wide range of embroidery techniques, from the most basic to highly specialized styles. My expertise encompasses both hand embroidery and machine embroidery. In hand embroidery, I’m proficient in techniques like:

- Cross-stitch: A classic technique creating distinct ‘X’ shaped stitches, perfect for detailed designs and counted work.

- Satin stitch: Used to create smooth, solid fills of color, ideal for creating flowers or leaves.

- French knots: Small, decorative knots often used to add texture and dimension, like to depict centers of flowers.

- Chain stitch: A simple, continuous stitch that can be used to create outlines or flowing lines, especially in floral designs.

My machine embroidery skills include working with various types of embroidery machines, using different types of stabilizers and thread to achieve precise and intricate designs. I’m also experienced in digitizing embroidery patterns for custom creations. For instance, I recently created a custom monogram design for a client’s wedding invitations using machine embroidery, perfectly coordinating it with their chosen font and color scheme. This demonstrates my ability to adapt techniques to meet specific project demands.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your preferred methods for finishing seams?

Choosing the right seam finish depends entirely on the fabric’s weight, type, and the garment’s intended use. My preferred methods are versatile and ensure durability and a clean, professional finish. These include:

- Serging/Overlocking: This is my go-to for most projects. It creates a neat, finished edge that prevents fraying, particularly important for lightweight and knit fabrics. It’s fast and efficient, which is essential for larger projects.

- Zigzag stitch: A simple and effective method for preventing fraying on woven fabrics, especially those less prone to unraveling. It’s useful when a serger is unavailable.

- French seams: Ideal for fine fabrics where a clean, invisible seam is crucial. It encases the raw edges for an exceptionally neat, durable finish. This is a higher level of detail usually found in high-end garments.

- Hong Kong finish: A luxurious binding technique used for more prestigious projects. Bias binding neatly encloses the raw seam allowance, resulting in a beautifully finished, durable seam that’s perfect for visible seams or curved edges.

The decision of which method to use is a nuanced one, requiring an understanding of the properties of each fabric and the overall design goals. For example, I would use a French seam for a luxurious silk blouse but opt for serging for a durable children’s play dress.

Q 17. Explain your experience working with different types of zippers and closures.

My experience spans a wide range of zippers and closures. I’m comfortable installing various zipper types, including:

- Invisible zippers: These require precision and attention to detail for a seamless integration into the garment.

- Metal zippers: Durable and commonly used in outerwear and bags.

- Plastic zippers: Lighter weight and often used in apparel for children or more casual wear.

- Separating zippers: Used where complete opening and closing is necessary.

- Coil zippers: A smoother, quieter alternative to metal zippers, typically for higher-end clothing.

Beyond zippers, I have experience with various closures, such as buttons (including hand-sewing and machine-sewing options), hooks and eyes, snaps, and even more intricate closures like antique-style hooks and eyes. For example, while crafting a vintage-inspired dress recently, I used hand-sewn antique-style hooks and eyes to achieve a truly authentic look and finish. My ability to select and apply the appropriate closure type enhances the overall quality and feel of the garment, reflecting the desired aesthetic and functional requirements.

Q 18. How do you handle client feedback and requests for alterations?

Client feedback is invaluable. I approach it as an opportunity for improvement and collaboration. My process involves:

- Active Listening: Carefully listening to the client’s concerns, asking clarifying questions, and summarizing their feedback to ensure complete understanding.

- Open Communication: Clearly explaining my approach to addressing the feedback, outlining potential solutions, and setting realistic expectations regarding timelines and costs for alterations.

- Collaborative Problem-Solving: Working with the client to find mutually agreeable solutions that meet both their needs and maintain the integrity of the garment. Sometimes, a minor alteration can resolve the issue. Other times, a more extensive redesign or rework might be required.

- Documentation: Maintaining detailed records of feedback and alterations to ensure transparency and prevent future misunderstandings. This also helps in identifying any recurring issues or patterns in feedback that may indicate improvements to my processes.

A recent example involved a client who felt the neckline on a custom-made blouse was slightly too high. After discussing their preferences, we agreed on a simple adjustment that lowered the neckline by about an inch. This small change resulted in a significantly more comfortable and aesthetically pleasing fit for the client.

Q 19. How do you stay up-to-date with current trends and techniques in sewing?

Staying current is crucial in this dynamic field. I employ several strategies:

- Professional Development: I regularly attend workshops and seminars on new sewing techniques, fabric types, and industry trends. Recently, I participated in a workshop on sustainable sewing practices, expanding my knowledge in eco-friendly fabrics and construction methods.

- Industry Publications and Blogs: I subscribe to sewing magazines and follow relevant blogs and online communities to stay informed about the latest innovations and designs.

- Networking: I actively engage with other sewists and designers, attending local events and online forums to exchange ideas and learn from others’ experiences.

- Experimentation: I actively experiment with new techniques and materials in my own projects. This practical application of new knowledge helps solidify my understanding and build confidence.

For example, I recently learned about a new technique for creating pleats using laser cutting, which I’m keen to incorporate into my next project. Keeping abreast of these innovations ensures I remain competitive and deliver high-quality, contemporary work.

Q 20. Describe your experience working with different sewing notions (e.g., buttons, thread, zippers).

My experience with sewing notions is extensive. I’m highly selective in my choice of materials, understanding that quality notions significantly impact the final product. My selection considers:

- Thread: I use high-quality threads from reputable brands, selecting the appropriate type based on fabric weight and project needs (e.g., polyester for strength, silk for fine fabrics). For example, I always use a high-quality all-purpose thread for general construction and a heavier-duty thread for things like seams that will experience a lot of stress.

- Buttons: My collection includes various types, sizes, and materials, allowing me to perfectly complement the chosen fabric and garment style. I prioritize buttons known for durability and consistent sizing.

- Zippers: As mentioned earlier, I select zippers according to the garment’s style and intended use, considering material, color, and finish.

- Interfacing: The proper choice of interfacing is crucial for creating structure and support. I use a variety of fusible and sew-in interfacings, selecting each one based on the fabric’s weight and the desired level of stiffness.

My expertise in selecting appropriate notions is just as important as my sewing proficiency. The right materials enhance the garment’s quality, durability, and overall appearance. For instance, using high-quality interfacing on a collar will significantly improve its shape and drape compared to using a lower-quality alternative.

Q 21. What is your experience with various pressing techniques and equipment?

Pressing is an integral part of quality sewing. It shapes, smooths, and sets seams, contributing significantly to a garment’s professional finish. My experience includes proficiency with various pressing techniques and equipment such as:

- Ironing: I use a professional-grade iron, capable of controlling temperature and steam for various fabrics. I always test the iron’s temperature on a scrap of fabric first before applying it to the project.

- Pressing cloths: These protect the fabric from scorching, especially delicate materials. I use different types of pressing cloths depending on the material I am working with (e.g., a cotton cloth for most materials, a silk cloth for very delicate fabrics).

- Tailor’s ham and sleeve board: These specialized tools help shape curves and maintain the three-dimensional shape of the garment while pressing.

- Steam pressing: For delicate fabrics or to relax and reduce wrinkles, steam pressing is the optimal method. I carefully control the amount of steam to avoid damaging the fabric.

Effective pressing is not simply about removing wrinkles; it’s about shaping and setting the garment properly. For example, pressing seams open on woven fabrics creates a flat, smooth surface, while pressing seams to one side creates a more structured look, often essential for more tailored garments. My understanding of these techniques ensures the professional and polished finish of each garment I create.

Q 22. How do you calculate fabric yardage requirements for a project?

Calculating fabric yardage accurately is crucial for avoiding costly mistakes and ensuring project completion. It’s not just about adding up measurements; it involves understanding fabric width, grainlines, and the project’s complexity.

The process generally involves these steps:

- Obtain Pattern Measurements: Each pattern piece will list its required length and width. Note that these are often given *on the grain* which impacts cutting and layout.

- Account for Pattern Layout: Consider how efficiently the pattern pieces can be arranged on the fabric’s width. This is where waste is minimized. Consider the grain direction (straight or cross grain) required for each piece, it can impact placement dramatically.

- Fabric Width: Most fabrics come in standard widths, commonly 45 inches (115 cm) or 60 inches (150 cm). Knowing this width is critical for calculating how many pattern pieces can fit on one length.

- Add Seam Allowances: Remember to add seam allowances (usually ½ inch or 1.5cm) to each pattern piece’s measurements *before* layout.

- Add Extra for Matching Patterns or Directional Prints: If your fabric has a distinct pattern, like stripes or florals, that need to be matched, add extra fabric to account for pattern alignment.

- Calculate Total Yardage: Based on your layout and the total length of fabric needed, calculate the final yardage required. It’s always a good idea to add at least an extra half-yard for errors or adjustments.

Example: Let’s say you need two pattern pieces, each measuring 24 inches long and 18 inches wide, with a 1/2 inch seam allowance. A 45-inch wide fabric is used. You’ll need 24 + 1/2 + 1/2 = 25 inches of length per piece, giving you a minimum length of 25 inches. On the 45-inch width, you can fit two of these, requiring only one yard (36 inches). It is always safer to purchase an extra half-yard to manage the cutting process and minimize waste.

Q 23. Describe your experience with draping techniques.

Draping is a crucial technique for creating unique and custom-fit garments. It allows for three-dimensional shaping and precise adjustments directly on the model, providing a superior fit compared to solely using flat pattern-making.

My experience with draping encompasses various fabrics, from lightweight silks to heavier wools. I’m proficient in creating basic bodice blocks and more complex skirt and sleeve draping. I’m comfortable using both muslin for initial prototyping and the final chosen fabric. I understand the importance of appropriate fabric manipulation and the interplay between drape, weight, and the desired aesthetic.

For instance, I recently draped a bespoke evening gown using a silk charmeuse. The drape technique was crucial in achieving the desired fluid movement and elegant silhouette. This project involved multiple fittings and adjustments to achieve the perfect fit and drape.

I also have experience with draping on both dress forms and live models, adapting my technique based on the model’s unique body shape and the desired garment style.

Q 24. How do you handle rush orders or tight deadlines?

Handling rush orders requires meticulous planning and efficient execution. My approach is systematic and involves clearly communicating expectations, prioritizing tasks effectively, and optimizing workflow.

Firstly, I’ll thoroughly review the project requirements to understand the complexity and scope. Then, I’ll assess the feasibility of meeting the deadline, openly discussing any potential constraints with the client. If necessary, I might suggest prioritizing certain aspects of the design to ensure a timely delivery of a high-quality product.

I utilize time-management techniques, like breaking down the project into smaller, manageable tasks, and setting realistic deadlines for each. I’ll also prioritize tasks based on their importance and dependency and often work longer hours, or even weekends, to meet tight deadlines. Efficient fabric cutting and sewing techniques are also crucial in these situations. Transparency and clear communication with the client throughout the entire process are vital to build trust and manage expectations effectively. For example, I’ve successfully completed several rush orders for bridal parties, utilizing efficient pattern cutting and effective stitching methods to meet stringent deadlines.

Q 25. What are your strengths and weaknesses as a seamstress?

My strengths lie in my attention to detail, precision in execution, and creativity in design. I’m highly proficient in various sewing techniques and adept at problem-solving. I’m also a quick learner and always eager to expand my skill set.

For instance, I’m known for my impeccable finishing, creating garments that are not only aesthetically pleasing but also durable and well-constructed. I enjoy experimenting with new fabrics and techniques and always welcome challenging projects which allow me to grow.

A weakness I’m working on is delegating tasks. I sometimes find it difficult to let go of aspects of a project and trust others to contribute effectively. However, I am actively seeking opportunities to improve this area through team projects and mentoring.

Q 26. What are your salary expectations?

My salary expectations are in line with the industry standard for a seamstress with my experience and skill set. I am open to discussing a specific range based on the comprehensive details of the position and the responsibilities involved. I am confident that my contribution would significantly benefit your organization and my compensation should reflect that value.

Q 27. Why are you interested in this position?

I am very interested in this position because it presents an opportunity to contribute my skills and experience to a company with a reputation for [Mention company’s reputation or specific projects that excite you]. I’m particularly drawn to [Mention specific aspects of the job description that appeal to you, e.g., working with a specific type of fabric, collaborative environment]. I believe my dedication to craftsmanship and client satisfaction perfectly aligns with your company’s values.

Q 28. Where do you see yourself in five years?

In five years, I envision myself as a highly skilled and respected member of your team, potentially taking on greater responsibility in [mention specific area like design, mentorship, or project management]. I’m committed to continuous professional development and I plan to expand my expertise in [mention specific techniques or areas of interest]. Ultimately, my goal is to contribute significantly to the success of your organization and enhance my creative skills continuously.

Key Topics to Learn for Your Seamstressing Interview

- Fabric Knowledge: Understanding different fabric types (cotton, silk, linen, etc.), their properties, drape, and suitability for various garments. Consider how you’d choose a fabric for a specific project and explain your reasoning.

- Pattern Making & Draping: Discuss your experience with creating patterns from scratch, adapting existing patterns, and using draping techniques to achieve a desired fit. Be prepared to describe your process.

- Sewing Techniques: Mastery of various stitches (e.g., straight stitch, zigzag stitch, blind hem stitch), seam finishes (e.g., French seams, serging), and construction methods (e.g., setting in sleeves, attaching collars).

- Machine Operation & Maintenance: Demonstrate your understanding of different sewing machines, their functionalities, and basic maintenance procedures. Be ready to discuss troubleshooting common machine issues.

- Garment Construction: Discuss your experience constructing various garments (e.g., dresses, skirts, pants, blouses). Highlight your ability to follow instructions, adapt to challenges, and achieve a high-quality finish.

- Fitting & Alterations: Explain your approach to fitting garments on a model or client and making necessary alterations. Discuss your problem-solving skills in addressing fit issues.

- Design & Aesthetics: Discuss your understanding of design principles, color theory, and how these concepts inform your garment construction choices. Show your understanding of current fashion trends.

- Industry Standards & Safety: Demonstrate awareness of industry best practices and safety regulations related to sewing machine operation and workplace safety.

Next Steps

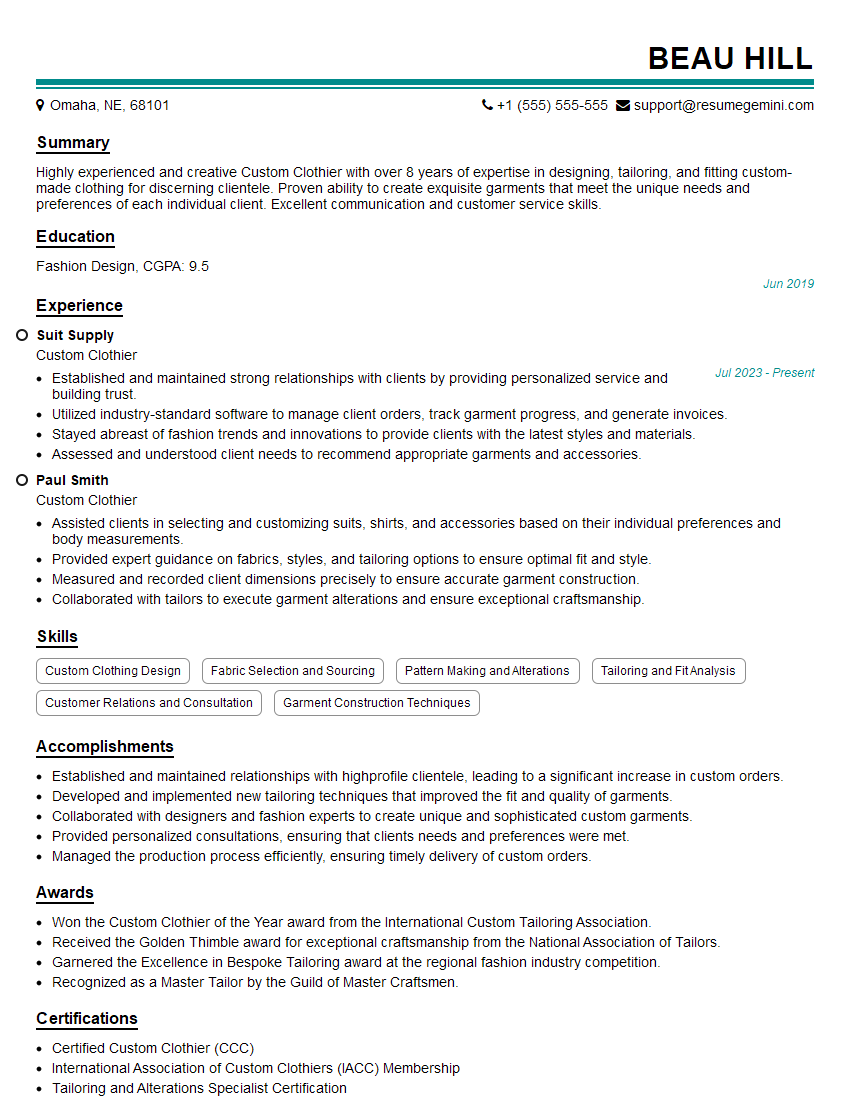

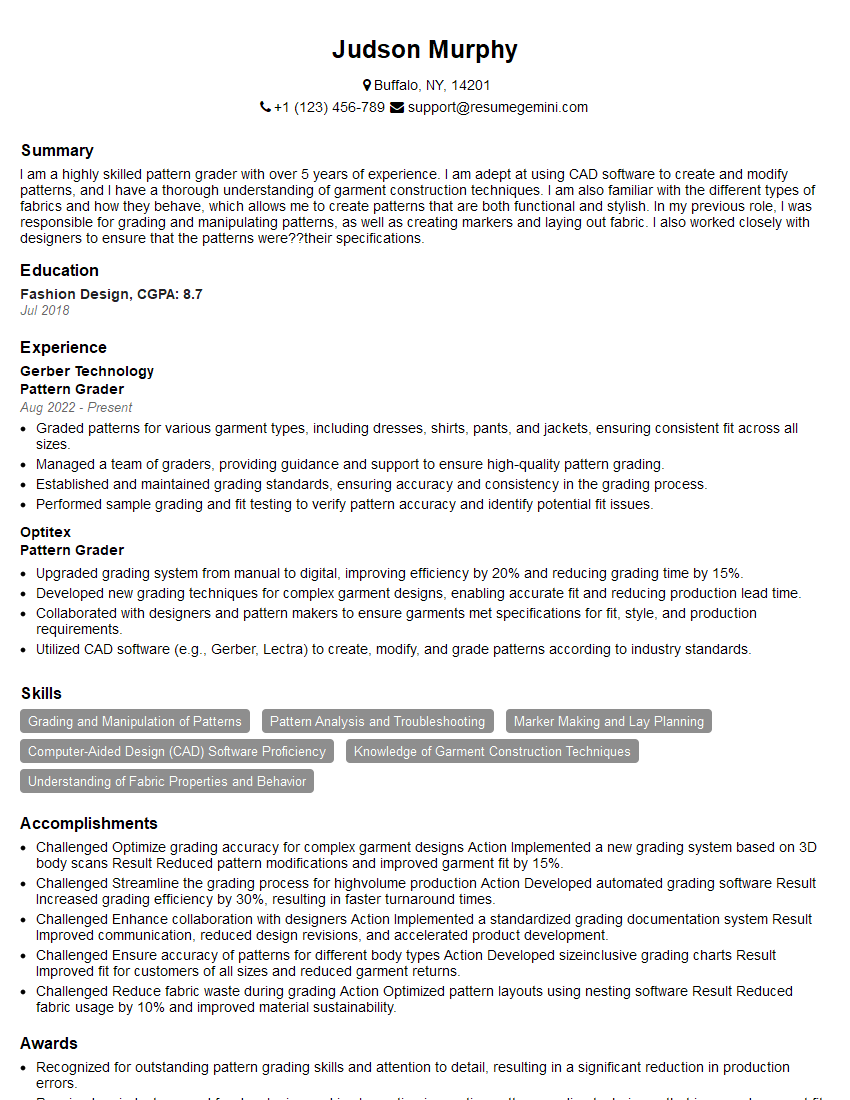

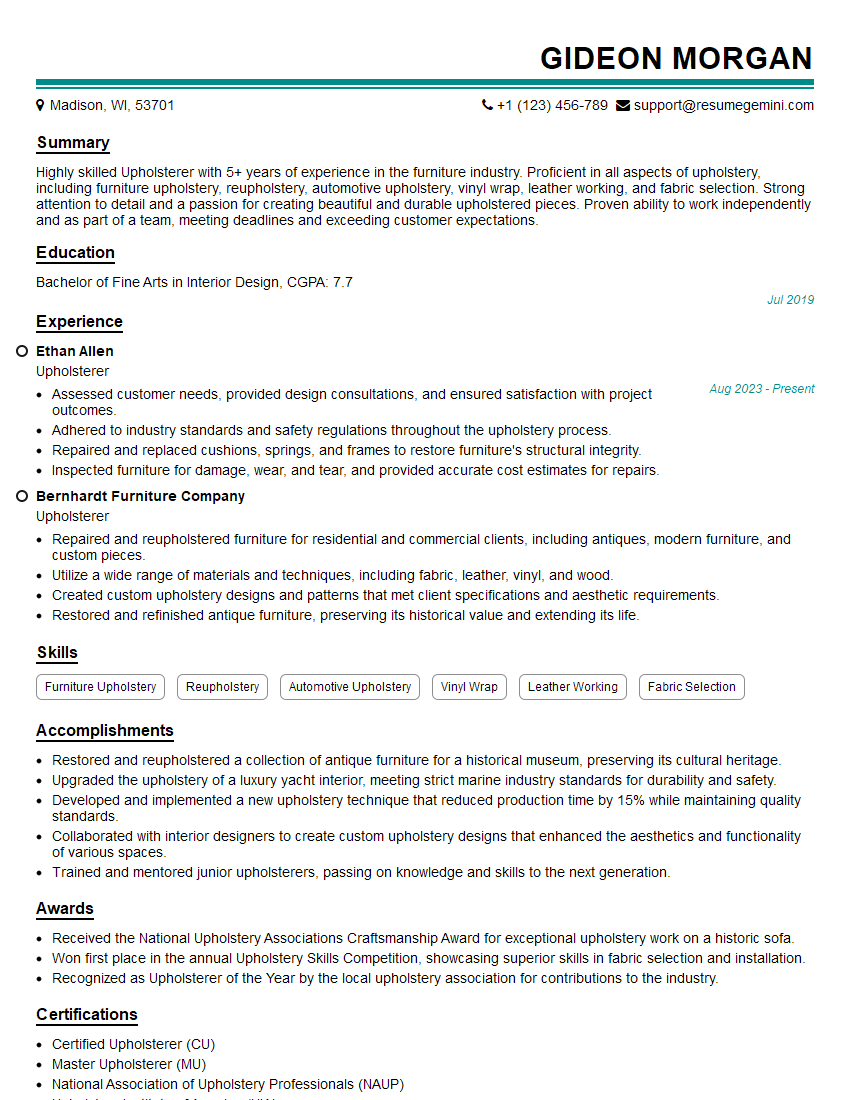

Mastering seamstressing opens doors to exciting career opportunities in fashion, design, and alterations. To stand out, a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to the seamstressing industry, ensuring yours is optimized for success. Take the next step and create a resume that showcases your talent and secures your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.