Cracking a skill-specific interview, like one for Sludge Management and Dewatering, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Sludge Management and Dewatering Interview

Q 1. Explain the different methods of sludge dewatering.

Sludge dewatering aims to reduce the water content of sludge, making it easier and cheaper to transport and dispose of. Several methods achieve this, each with its strengths and weaknesses. These methods can be broadly categorized into mechanical and thermal dewatering.

- Mechanical Dewatering: This involves using mechanical forces to separate water from solids. Common techniques include:

- Belt Filter Presses: These use belts and filter media to squeeze water out of sludge under pressure.

- Centrifuges: High-speed spinning forces water away from the solids.

- Plate and Frame Filter Presses: These use plates and frames to compress the sludge, forcing water out.

- Vacuum Filters: These use vacuum pressure to draw water through a filter medium.

- Thermal Dewatering: This utilizes heat to evaporate water from the sludge. This is generally more expensive and energy-intensive than mechanical methods and is less common.

The choice of method depends on factors like sludge characteristics (e.g., solids content, viscosity), budget, available space, and regulatory requirements. For instance, a municipality with limited space might opt for a centrifuge due to its compact footprint, while a large industrial facility might choose a belt filter press for its high throughput.

Q 2. What are the advantages and disadvantages of belt filter presses?

Belt filter presses are popular due to their efficiency and relatively low maintenance, but they also have drawbacks.

- Advantages:

- High solids capture: They achieve high dryness (typically 25-35% solids), significantly reducing disposal costs.

- High throughput: They can process large volumes of sludge efficiently.

- Relatively low operating costs: Compared to some other methods, they have lower energy consumption.

- Automated operation: Modern belt filter presses are often automated, reducing labor costs.

- Disadvantages:

- High capital cost: The initial investment is substantial.

- Sensitivity to sludge characteristics: Their performance is affected by sludge viscosity and solids content. Pre-conditioning is often necessary.

- Maintenance requirements: While relatively low, regular maintenance, including belt cleaning and replacement, is crucial.

- Potential for clogging: Clogging can reduce efficiency, requiring frequent cleaning or adjustments.

For example, a wastewater treatment plant upgrading its sludge handling infrastructure might weigh the high initial cost of a belt filter press against the long-term savings from reduced disposal volume and labor.

Q 3. Describe the process of centrifuge dewatering.

Centrifuge dewatering uses centrifugal force to separate solids from liquids. Sludge is fed into a rotating drum or bowl, where the centrifugal force pushes the water outwards, leaving behind a concentrated cake of solids.

The process generally involves these steps:

- Sludge feed: The conditioned sludge is fed into the rotating centrifuge.

- Separation: Centrifugal force pushes the water through the screen or filter in the centrifuge bowl, while the solids are retained.

- Cake discharge: The thickened solids (cake) are discharged from the centrifuge.

- Liquor discharge: The separated water (liquor) is discharged from the centrifuge.

Different types of centrifuges exist, including decanter centrifuges (for higher solids content sludges) and screen bowl centrifuges (for lower solids content sludges). The choice depends on the characteristics of the sludge and desired dryness.

Imagine a salad spinner – it works on a similar principle. The centrifugal force pushes the water out, leaving the salad drier. A centrifuge is just a much larger, more sophisticated version designed for industrial applications.

Q 4. How do you optimize sludge dewatering for cost-effectiveness?

Optimizing sludge dewatering for cost-effectiveness requires a holistic approach considering multiple factors.

- Sludge conditioning: Proper conditioning using polymers is critical to improve dewatering efficiency. Finding the optimal polymer type and dosage can significantly reduce the amount of water remaining in the sludge.

- Dewatering equipment selection: Choosing the right dewatering technology – belt press, centrifuge, etc. – based on the sludge characteristics and budget is essential.

- Process optimization: Regularly monitoring and optimizing the dewatering process parameters (e.g., pressure, speed, polymer dosage) ensures maximal efficiency.

- Energy efficiency: Implementing energy-saving measures, such as using variable frequency drives for equipment, reduces operational costs.

- Waste minimization: Minimizing the volume of sludge through optimized wastewater treatment reduces the overall dewatering costs.

- Disposal costs: Exploring various disposal options and negotiating favorable contracts can reduce the cost of handling the dewatered sludge.

Regular performance monitoring and data analysis are essential to identify areas for improvement and implement adjustments to maintain optimal cost-effectiveness.

Q 5. What are the key factors influencing sludge thickening?

Sludge thickening concentrates the sludge by removing excess water before dewatering. This process reduces the volume of sludge needing dewatering, lowering overall costs and improving efficiency. Key factors influencing thickening include:

- Sludge characteristics: The solids content, particle size distribution, and organic content of the sludge significantly affect thickening performance. Higher solids content sludges generally thicken more easily.

- Temperature: Temperature affects the viscosity of the sludge, impacting settling rates.

- pH: Adjusting the pH can influence flocculation and settling.

- Mixing and settling conditions: The design of the thickening tank, including its geometry and mixing system, significantly impacts thickening efficiency. Proper mixing helps to initially disperse the sludge, while minimizing mixing during settling is crucial for optimal performance.

- Polymers: Adding polymers aids in flocculation, improving settling and thickening.

For example, if a plant has a low-solids sludge, they might improve thickening efficiency through the addition of a polymer to enhance flocculation, leading to a more compact and settleable sludge.

Q 6. Explain the role of polymers in sludge conditioning.

Polymers play a vital role in sludge conditioning, a critical step before dewatering. They act as flocculants, binding smaller sludge particles together into larger, more easily settled and dewatered flocs.

The choice of polymer depends on several factors, including the type of sludge, desired dewatering method, and cost considerations. Common polymer types include:

- Anionic polymers: Effective for a wide range of sludges and commonly used in several dewatering techniques.

- Cationic polymers: Often used with more difficult-to-dewater sludges.

- Non-ionic polymers: Used less frequently but can provide synergistic effects when combined with other polymer types.

The polymer dosage is also crucial; too little won’t effectively improve dewatering, while too much can be wasteful and potentially hinder the process. Optimizing the polymer dosage involves careful experimentation to determine the optimal concentration for the specific sludge.

Think of polymers as a sort of ‘glue’ that binds the sludge particles together, making them behave more like a solid mass, and thus easier to separate the water from.

Q 7. What are the environmental regulations concerning sludge disposal?

Environmental regulations governing sludge disposal vary by location but generally aim to protect human health and the environment. Key concerns include:

- Pathogen control: Sludge must undergo treatment to eliminate or significantly reduce pathogens (bacteria, viruses) before disposal or land application.

- Heavy metal content: Regulations often limit the concentration of heavy metals in sludge to prevent contamination of soil and water.

- Organic contaminants: The presence of organic pollutants, like persistent organic pollutants (POPs), is a significant concern, often leading to stringent limitations on disposal options.

- Disposal methods: Land application (for agricultural purposes), landfilling, incineration, and other methods are subject to specific regulations. Land application, for example, typically requires compliance with regulations related to the amount of sludge applied, the type of soil, and the crop grown.

- Monitoring and reporting: Facilities often need to monitor and report on the composition of their sludge and adherence to regulatory limits.

Non-compliance can lead to significant penalties. Staying abreast of current regulations and implementing appropriate sludge management practices is crucial for any facility handling sludge.

Q 8. How do you monitor the effectiveness of sludge dewatering?

Monitoring sludge dewatering effectiveness centers around measuring the cake solids content and the dewatered sludge volume. We aim to achieve the optimal balance between minimizing volume and maximizing solids concentration for efficient disposal or further processing. Think of it like squeezing a sponge – the more water you remove (higher solids content), the smaller the sponge (lower volume) becomes.

We use several methods: Regular sampling and laboratory analysis to determine the percentage of solids in the dewatered sludge using methods like gravimetric analysis. This data is crucial for optimization. Monitoring equipment performance such as belt filter press pressure, centrifuge RPM, and polymer dosage also helps. Changes in these parameters often reflect changes in dewatering efficiency. For instance, a sudden drop in pressure in a belt filter press may indicate a problem that needs immediate attention. Finally, we track the volume of dewatered sludge generated. Consistent monitoring of these factors provides a clear picture of the dewatering process’s health and efficiency.

Q 9. Describe different sludge treatment technologies.

Sludge treatment technologies aim to reduce sludge volume and stabilize the organic matter. These technologies are broadly categorized as:

- Mechanical Dewatering: This involves physically separating water from solids. Common methods include belt filter presses, centrifuges, and vacuum filters. Each has its own strengths and weaknesses depending on the sludge characteristics and desired cake solids content. For example, belt filter presses are ideal for high-volume applications, while centrifuges are better suited for slurries with high solids concentrations.

- Biological Treatment: This method uses microorganisms to break down organic matter in the sludge, reducing its volume and pathogen load. Aerobic digestion (with oxygen) and anaerobic digestion (without oxygen) are two primary approaches. Anaerobic digestion, while slower, produces biogas, a valuable renewable energy source.

- Chemical Treatment: This involves adding chemicals like polymers to improve sludge dewaterability. Polymers act as flocculants, binding the sludge particles together and making them easier to separate from water. The type of polymer used significantly impacts the effectiveness of the process.

- Thermal Treatment: This method involves high-temperature treatment to reduce sludge volume and potentially create a stable end product suitable for land application or disposal. Incineration is one example, but is more expensive and requires careful management of emissions.

The choice of technology often depends on several factors, including sludge characteristics (e.g., solids content, organic matter content), available space, budget, and environmental regulations.

Q 10. How do you manage sludge storage and handling?

Sludge storage and handling are critical aspects of sludge management, focusing on safety, environmental protection, and efficient processing. Improper handling can lead to odor problems, leachate generation, and potential environmental contamination. The strategy involves careful planning and control of several stages:

- Temporary Storage: Sludge is often stored temporarily in equalization tanks or thickeners before further treatment. These tanks must be appropriately designed to prevent overflow and maintain anaerobic conditions to minimize odor. Regular monitoring of levels and potential leaks is vital.

- Transportation: Sludge transport is carefully controlled, using specialized trucks or pipelines. Regulations on transport routes and spill prevention are crucial. Documentation, including manifests, must be carefully kept.

- Long-term Storage/Disposal: This step often involves landfilling, incineration, or beneficial reuse (e.g., agricultural application of biosolids). Each method has its own regulatory requirements and environmental considerations. Land application, for instance, requires careful monitoring of soil nutrient levels and heavy metals to prevent contamination.

Proper record keeping is crucial throughout the entire process, from the sludge generation to final disposal or reuse. This ensures traceability and allows for prompt identification and resolution of any issues.

Q 11. What are the safety precautions involved in sludge handling?

Sludge handling presents several safety hazards, demanding strict adherence to protocols. These precautions include:

- Personal Protective Equipment (PPE): This is paramount, involving the use of gloves, coveralls, respirators (especially when dealing with odorous or potentially toxic sludges), eye protection, and appropriate footwear. The type of PPE needed varies depending on the specific sludge and handling procedures.

- Confined Space Entry Procedures: If working in confined spaces such as storage tanks, strict confined space entry protocols must be followed. This includes proper ventilation, atmospheric monitoring, and the use of safety harnesses and retrieval systems. A supervisor must always be present.

- Emergency Response Plan: A detailed emergency response plan must be in place, covering scenarios like spills, equipment failure, or worker injury. Training and regular drills are essential. Emergency contacts, including local authorities, should be readily available.

- Lockout/Tagout Procedures: Before any maintenance or repair work on equipment, lockout/tagout procedures must be strictly followed to prevent accidental startup and injury.

- Proper Training and Supervision: All personnel involved in sludge handling must receive adequate training on safe work practices, hazard identification, and emergency procedures. Experienced supervisors should always oversee operations.

Ignoring these precautions can result in serious injuries or environmental damage. A proactive safety culture is essential for successful and safe sludge management.

Q 12. Explain the concept of sludge digestion.

Sludge digestion is a biological process that uses microorganisms to stabilize sludge. It aims to reduce the volume of sludge and break down organic matter, making the resulting material safer and easier to handle. Think of it as a natural composting process, but on a much larger scale.

Two main types exist:

- Aerobic Digestion: This process requires oxygen and involves the breakdown of organic matter by aerobic bacteria. It’s relatively fast but requires energy for aeration. The resulting sludge is relatively stable and easier to dewater.

- Anaerobic Digestion: This process doesn’t require oxygen and relies on anaerobic bacteria. It’s slower but produces biogas (a mixture of methane and carbon dioxide), which can be captured and used as a renewable energy source. This method generates a smaller volume of stabilized sludge, but it is often more viscous and requires specialized dewatering technologies.

The choice between aerobic and anaerobic digestion depends on factors such as energy availability, sludge characteristics, and environmental regulations. The end product of both processes – digested sludge or biosolids – is significantly reduced in volume and has a lower pathogen content compared to raw sludge.

Q 13. What are the different types of sludge produced in wastewater treatment?

Wastewater treatment plants produce several types of sludge, each with unique characteristics:

- Primary Sludge: This is the sludge that settles out in the primary clarifier. It contains a significant amount of organic matter and grit.

- Secondary Sludge: This sludge is produced in the secondary treatment process (e.g., activated sludge process). It contains a higher concentration of microorganisms and is often more difficult to dewater than primary sludge.

- Digested Sludge: This is the sludge resulting from the anaerobic or aerobic digestion process. It has a reduced volume and a lower pathogen content.

- Waste Activated Sludge (WAS): This is the excess sludge removed from the activated sludge process to maintain a healthy microbial population in the aeration tank.

The characteristics of these sludges (e.g., solids content, volatile solids content, pH) significantly impact the selection of appropriate dewatering and disposal methods.

Q 14. How do you determine the optimal cake solids content?

Determining the optimal cake solids content is crucial for efficient sludge dewatering. It’s a balance between maximizing solids removal and minimizing energy and chemical consumption. A higher solids content means less volume to handle, transport and dispose of, leading to cost savings. However, achieving extremely high solids content often requires substantial increases in energy and chemical inputs. It’s a point of diminishing returns.

We determine the optimum through a combination of:

- Pilot Testing: Small-scale testing with different dewatering technologies and chemical dosages helps to identify the optimal solids content achievable under various conditions. This allows for optimization before investing in full-scale equipment.

- Process Monitoring and Data Analysis: Continuous monitoring of key parameters such as polymer dosage, pressure, and cake solids content allows us to identify trends and optimize the process for maximum efficiency and cost-effectiveness.

- Economic Analysis: This involves balancing the cost of energy, chemicals, and disposal with the value of reduced sludge volume. The optimum solids content will be the point where the marginal cost of achieving higher solids content exceeds the marginal benefit of reduced volume.

- Regulatory Considerations: Environmental regulations on sludge disposal may dictate minimum or maximum allowable solids content. The plant must operate within these limits.

The optimal cake solids content is not a fixed value but rather an operating range that is determined by carefully considering these various factors.

Q 15. How do you troubleshoot common problems in sludge dewatering equipment?

Troubleshooting sludge dewatering equipment involves a systematic approach. Think of it like diagnosing a car problem – you need to identify the symptom, pinpoint the cause, and then implement the solution. First, we observe the problem: is the cake too wet? Is the filtrate cloudy? Is the equipment making unusual noises? Once the symptom is identified, we can investigate potential causes.

- Low solids content in the cake: This could indicate issues with the polymer dosage, flocculation process, or the filter media itself. We might adjust the polymer type, concentration, or addition point. A clogged filter cloth would need cleaning or replacement.

- High filtrate turbidity: This suggests incomplete solids separation. Possible causes include insufficient flocculation, high influent flow rate, or damaged filter media. Solutions might include adjusting the flocculant, reducing the flow rate, or replacing the filter cloth.

- Equipment malfunction: Unusual noises or reduced performance could point to mechanical issues like belt slippage (in belt filter presses), pump failure, or motor problems. Regular maintenance checks and prompt repairs are crucial here.

A well-maintained logbook tracking operational parameters and maintenance activities is invaluable for effective troubleshooting. By systematically analyzing the data and following a logical process, we can quickly identify and resolve most dewatering equipment problems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of dewatering equipment.

My experience encompasses a wide range of dewatering technologies. I’ve worked extensively with:

- Belt filter presses: These are highly efficient for a variety of sludge types, offering excellent cake dryness. I’ve overseen installations and optimized performance in several wastewater treatment plants, focusing on belt tension, polymer application, and cake discharge mechanisms.

- Centrifuges: I’ve used both decanter centrifuges and solid bowl centrifuges for applications requiring high throughput and rapid dewatering. Understanding the interplay between feed rate, bowl speed, and polymer dosage is crucial for optimal performance. For instance, I once troubleshot a centrifuge experiencing low solids capture by adjusting the polymer type and optimizing the feed slurry concentration.

- Vacuum filters: These are suitable for handling larger volumes of sludge with lower solids content. My expertise includes optimizing drum speed, vacuum level, and filter cloth selection to maximize dewatering efficiency. One project involved improving the filter cloth life by implementing a more effective cleaning cycle.

- Plate and frame filter presses: Although more labor-intensive, these are useful for small-scale operations or sludges with specific properties. I have experience in managing their operation and optimizing the filter cycle.

Each technology presents unique operational challenges and requires a tailored approach to achieve optimal performance. My experience allows me to select the most appropriate technology for any specific sludge characteristic and project requirement.

Q 17. What are the key performance indicators (KPIs) for sludge dewatering?

Key Performance Indicators (KPIs) for sludge dewatering are crucial for monitoring efficiency and optimizing the process. Think of them as the vital signs of your dewatering operation.

- Cake solids content (%): This indicates the dryness of the dewatered sludge. Higher percentage means more efficient water removal.

- Filtrate turbidity (NTU): Measures the clarity of the liquid separated from the sludge. Lower turbidity shows better solids separation.

- Specific resistance (ohm.cm): This indicates the sludge’s resistance to dewatering. Lower values represent easier dewatering.

- Sludge volume reduction (%): Measures the percentage reduction in sludge volume after dewatering. This is a key indicator of space savings and disposal cost reduction.

- Polymer dosage (kg/tonne of dry solids): Monitors the amount of polymer used. Optimization can lead to cost savings without sacrificing performance.

- Dewatering efficiency (%): This combines several factors to represent the overall effectiveness of the process.

- Downtime (%): Measures the percentage of time the equipment is not operational due to maintenance or repairs. Reducing downtime is a key goal.

By regularly monitoring these KPIs, we can identify areas for improvement and ensure the dewatering process operates efficiently and cost-effectively.

Q 18. How do you calculate sludge volume reduction?

Calculating sludge volume reduction is straightforward. It involves comparing the initial sludge volume to the final volume after dewatering. Imagine you start with a bucket of sludge, and after dewatering, it’s significantly smaller. That’s volume reduction.

The formula is:

Sludge Volume Reduction (%) = [(Initial Volume - Final Volume) / Initial Volume] x 100For example:

Initial sludge volume = 1000 liters

Final sludge volume after dewatering = 200 liters

Sludge Volume Reduction (%) = [(1000 – 200) / 1000] x 100 = 80%

This means the dewatering process reduced the sludge volume by 80%. This calculation is critical for assessing the effectiveness of the dewatering process and planning for sludge disposal or storage.

Q 19. How do you manage and dispose of sludge dewatering residuals?

Managing and disposing of sludge dewatering residuals depends heavily on local regulations and the characteristics of the dewatered sludge. The approach should always be environmentally sound and compliant with all applicable laws.

- Landfill disposal: This is a common method, but regulations are becoming increasingly stringent due to environmental concerns. Dewatered sludge often requires special handling and may be subject to landfill tipping fees.

- Incineration: This method reduces sludge volume significantly and can recover energy. However, it requires careful consideration of air emissions and ash disposal.

- Land application (beneficial reuse): If the dewatered sludge meets specific quality criteria, it can be used as a soil amendment in agriculture or for land reclamation. This is an environmentally friendly option, reducing landfill burden and providing valuable nutrients to the soil. For instance, I’ve worked on projects where dewatered sludge was successfully used as a soil conditioner in landscaping projects.

- Composting: Under certain conditions, sludge can be composted along with other organic materials, creating a valuable soil amendment. This requires careful monitoring of the composting process to ensure pathogen reduction and stability.

Careful characterization of the dewatered sludge is crucial to determine the most appropriate disposal or reuse method. Regulations often dictate permissible limits for contaminants such as heavy metals and pathogens.

Q 20. Explain the importance of sludge characterization.

Sludge characterization is fundamentally important because it dictates the entire sludge management strategy. Think of it as the blueprint for successful sludge handling. Without it, you’re working blindly.

Characterizing sludge involves determining its:

- Solids content (%): This is the percentage of solids in the sludge, a crucial factor influencing dewatering efficiency.

- Specific resistance (ohm.cm): This measures how readily the sludge dewaters. High resistance necessitates more intense dewatering methods.

- pH: Affects the effectiveness of certain dewatering aids (chemicals) and can influence the choice of disposal method.

- Organic and inorganic content: Determines the suitability for land application or composting. High concentrations of heavy metals, for example, may rule out land application.

- Particle size distribution: Influences the choice of dewatering equipment and the optimal polymer dosage.

- Pathogen levels: Essential for determining safe disposal or reuse options.

Thorough characterization allows for the selection of the most appropriate dewatering technology, optimization of the dewatering process, and determination of the safest and most cost-effective disposal or reuse pathway.

Q 21. What are the common challenges faced in sludge management?

Sludge management presents several significant challenges:

- High operational costs: Dewatering and disposal are expensive processes, requiring significant capital investment and ongoing operational expenses. Optimizing the process and exploring cost-effective disposal options are critical.

- Stringent environmental regulations: Regulations concerning sludge disposal and land application are becoming increasingly stricter, necessitating careful planning and compliance measures.

- Sludge variability: The characteristics of sludge can vary significantly depending on the source and operational conditions. This variability necessitates flexible and adaptable management strategies. For example, changes in the influent wastewater composition can directly impact sludge properties.

- Limited disposal options: Landfill space is becoming increasingly scarce and expensive, pushing the need for alternative disposal methods.

- Public perception: Negative public perceptions of sludge disposal can create obstacles to implementation of even environmentally sound practices.

- Technological advancements: The field of sludge management is continuously evolving, and staying abreast of the latest technologies is crucial for efficient and sustainable management.

Addressing these challenges effectively requires a multi-faceted approach involving technological innovation, cost optimization, strict regulatory compliance, and public education.

Q 22. How do you ensure compliance with environmental regulations regarding sludge?

Ensuring compliance with environmental regulations for sludge management is paramount. It involves a multi-faceted approach, starting with a thorough understanding of all applicable local, regional, and national regulations. This includes permits, discharge limits for pollutants (like heavy metals, pathogens, and organic matter), and reporting requirements.

We begin by conducting regular monitoring of sludge characteristics, including analyses for key parameters such as solids content, pH, volatile solids, and pollutants. This data is meticulously documented and used to inform our operational strategies and ensure we remain within the permitted discharge limits. We also maintain detailed records of all sludge handling processes, including transportation, treatment, and disposal methods, to provide transparent traceability. Regular audits and inspections are conducted to verify our compliance procedures and identify areas for improvement. Furthermore, we actively engage with regulatory agencies and environmental consultants to remain updated on any changes in regulations and best practices.

For example, in one project, we implemented a robust sampling and analysis program that identified a slight increase in heavy metal concentration in our dewatered sludge. By adjusting our chemical conditioning process and optimizing our treatment strategies, we quickly brought the concentration back within the permitted limits, preventing any potential environmental violations.

Q 23. Describe your experience with different sludge conditioning agents.

My experience encompasses a wide range of sludge conditioning agents, each with its specific strengths and weaknesses. The choice of agent depends heavily on the sludge characteristics (e.g., type of sludge, solids content, and chemical composition), the desired dewatering performance, and cost considerations.

- Polymeric coagulants: These are widely used due to their effectiveness in reducing sludge viscosity and improving dewaterability. Anionic polymers are frequently employed for primary and secondary sludge, while cationic polymers are more effective for digested sludge. I have extensive experience optimizing polymer dosage to achieve optimal dewatering results while minimizing costs.

- Inorganic coagulants: Ferric chloride and lime are common inorganic coagulants. These are generally less expensive than polymers but may not be as effective in all sludge types. I’ve worked with these agents, particularly in projects where cost was a primary constraint.

- Organic conditioners: These include materials such as activated carbon and zeolites, often used for enhancing dewatering and reducing the concentration of undesirable substances in the sludge. The use of these agents typically requires careful optimization of dosage and operational parameters.

In a recent project, we successfully transitioned from using a more expensive polymeric coagulant to a combination of ferric chloride and a lower dosage of polymer, resulting in significant cost savings without compromising dewatering efficiency.

Q 24. How do you optimize energy consumption in sludge dewatering?

Optimizing energy consumption in sludge dewatering is crucial for both economic and environmental sustainability. This involves a holistic approach that considers all aspects of the process.

- Process Optimization: Careful optimization of sludge conditioning parameters, such as polymer dosage, mixing intensity, and solids concentration, significantly impacts energy consumption. For example, precise control of polymer addition ensures efficient flocculation, reducing the energy needed for subsequent dewatering steps.

- Equipment Selection: Choosing energy-efficient dewatering equipment is paramount. This includes selecting high-speed centrifuges with optimized bowl designs and efficient drive systems, or employing belt filter presses with improved press cycles and reduced energy consumption per cycle.

- Waste Heat Recovery: In some cases, it’s possible to recover waste heat generated during the dewatering process and utilize it to preheat the sludge or for other operational needs. This can substantially reduce overall energy consumption.

- Automation and Control Systems: Implementing advanced control systems to optimize the dewatering process in real-time can significantly reduce energy usage by minimizing idle time and preventing inefficient operation.

A practical example involved implementing a real-time monitoring system for a centrifuge operation. The system allowed us to continuously monitor key parameters and dynamically adjust operational settings to minimize energy consumption while maintaining the desired dewatering performance.

Q 25. What are the latest technological advancements in sludge dewatering?

The field of sludge dewatering is constantly evolving, driven by the need for improved efficiency, reduced energy consumption, and enhanced environmental protection.

- Advanced Automation and Control: The use of advanced sensors, artificial intelligence (AI), and machine learning (ML) algorithms is improving process optimization and predictive maintenance, leading to improved efficiency and reduced downtime.

- Membrane Technology: Membrane filtration technologies, such as ultrafiltration and microfiltration, are becoming increasingly popular for sludge dewatering. These offer the potential for higher solids concentrations and superior dewatering performance compared to conventional methods.

- Improved Centrifuge Designs: Centrifuge manufacturers continuously refine their designs, focusing on improved energy efficiency, higher solids capture, and reduced maintenance requirements. This includes innovations in bowl design, drive systems, and control systems.

- Thermal Hydrolysis: Thermal hydrolysis pretreatment of sludge enhances its dewaterability, allowing for reduced polymer usage and improved efficiency in subsequent dewatering steps.

For instance, the adoption of AI-powered process optimization in one project resulted in a 15% reduction in energy consumption and a 10% increase in dewatering efficiency within a centrifuge operation.

Q 26. Describe your experience with anaerobic digestion of sludge.

Anaerobic digestion is a crucial process in sludge management, offering significant environmental and economic advantages. It’s a biological process where microorganisms break down organic matter in the absence of oxygen, producing biogas (primarily methane and carbon dioxide) and digestate.

My experience includes designing, operating, and optimizing anaerobic digesters for various sludge types. This involves careful consideration of factors such as sludge characteristics, digester design (e.g., CSTR, UASB), operating parameters (temperature, pH, retention time), and process control. Effective monitoring of biogas production, digester performance, and digestate quality is crucial for optimization.

The biogas produced can be used to generate energy, reducing reliance on fossil fuels and lowering operating costs. The digestate, the remaining material after digestion, has a reduced volume and is easier to dewater and dispose of or even potentially used as a soil amendment, minimizing landfill space needs. In one project, we successfully implemented an anaerobic digestion system which reduced the sludge volume by 50% and generated sufficient biogas to power a significant portion of the wastewater treatment plant.

Q 27. How do you address odor control issues associated with sludge handling?

Odor control is a significant concern in sludge handling, as various volatile organic compounds (VOCs) can be released, creating unpleasant smells and potentially causing health issues. A multi-pronged approach is necessary for effective odor control.

- Process Optimization: Optimizing sludge treatment processes to minimize the production of odorous compounds is crucial. For example, ensuring proper aeration in aerobic treatment processes or controlling the pH in anaerobic digestion can reduce odor formation.

- Enclosure and Ventilation: Enclosing sludge handling areas and implementing effective ventilation systems helps contain and remove odorous gases. This often includes the use of scrubbers or biofilters to remove or neutralize odors.

- Chemical Treatment: Odor control agents, such as oxidizing agents or masking agents, can be added to sludge or air streams to neutralize or mask odorous compounds. However, careful selection and dosage are essential to avoid unintended environmental consequences.

- Biofiltration: Biofiltration systems utilize microorganisms to break down odorous compounds, offering a sustainable and effective method of odor control.

In a recent project, the implementation of a combination of process optimization and a biofilter system significantly reduced odor complaints from nearby residents, demonstrating the effectiveness of a comprehensive approach.

Q 28. How do you maintain and troubleshoot centrifuge equipment?

Centrifuge maintenance and troubleshooting are essential for ensuring efficient and reliable dewatering operations. A preventative maintenance program is crucial to minimize downtime and maximize equipment lifespan.

- Regular Inspections: Regular visual inspections of the centrifuge components, including the bowl, feed system, and drive mechanism, help identify potential problems early on. This includes checking for wear and tear, leaks, and any signs of damage.

- Lubrication and Cleaning: Regular lubrication of bearings and other moving parts is crucial to prevent wear and tear. Cleaning the centrifuge, particularly the bowl and discharge system, is necessary to remove accumulated solids and prevent blockages.

- Performance Monitoring: Continuous monitoring of key operational parameters, such as solids concentration in the cake and filtrate, helps identify performance deviations and potential problems. Any significant changes should trigger further investigation.

- Troubleshooting: When problems arise, a systematic approach is necessary for troubleshooting. This often involves checking basic parameters like feed flow rate, polymer dosage, and rotation speed before proceeding to more complex diagnoses.

For example, in one instance, a reduction in centrifuge cake solids content indicated a potential issue with the polymer dosing system. A thorough investigation identified a malfunctioning pump, which was quickly repaired, restoring the centrifuge’s optimal performance.

Key Topics to Learn for Sludge Management and Dewatering Interview

- Sludge Characteristics: Understanding sludge properties (e.g., solids concentration, viscosity, pH) and their impact on treatment processes.

- Sludge Thickening Technologies: Familiarize yourself with various thickening methods (gravity, flotation, centrifugation) and their practical applications in different wastewater treatment plants.

- Dewatering Technologies: Master the principles and applications of different dewatering technologies, including belt filter presses, centrifuges, and vacuum filters. Be prepared to discuss their advantages and disadvantages.

- Sludge Digestion Processes: Understand anaerobic and aerobic digestion, their respective benefits, and the role of microorganisms in sludge stabilization.

- Sludge Handling and Disposal: Explore various disposal options (landfilling, incineration, land application) and the associated environmental regulations and best practices.

- Process Optimization and Control: Discuss strategies for optimizing sludge management processes to minimize costs, maximize efficiency, and ensure environmental compliance. Consider the role of process monitoring and data analysis.

- Safety and Regulatory Compliance: Demonstrate your understanding of relevant safety protocols and environmental regulations related to sludge handling and disposal.

- Troubleshooting and Problem Solving: Be ready to discuss common challenges encountered in sludge management and dewatering, and how you would approach troubleshooting these issues.

- Sustainability and Emerging Technologies: Show awareness of advancements in sludge management and dewatering, such as biosolids utilization and resource recovery.

Next Steps

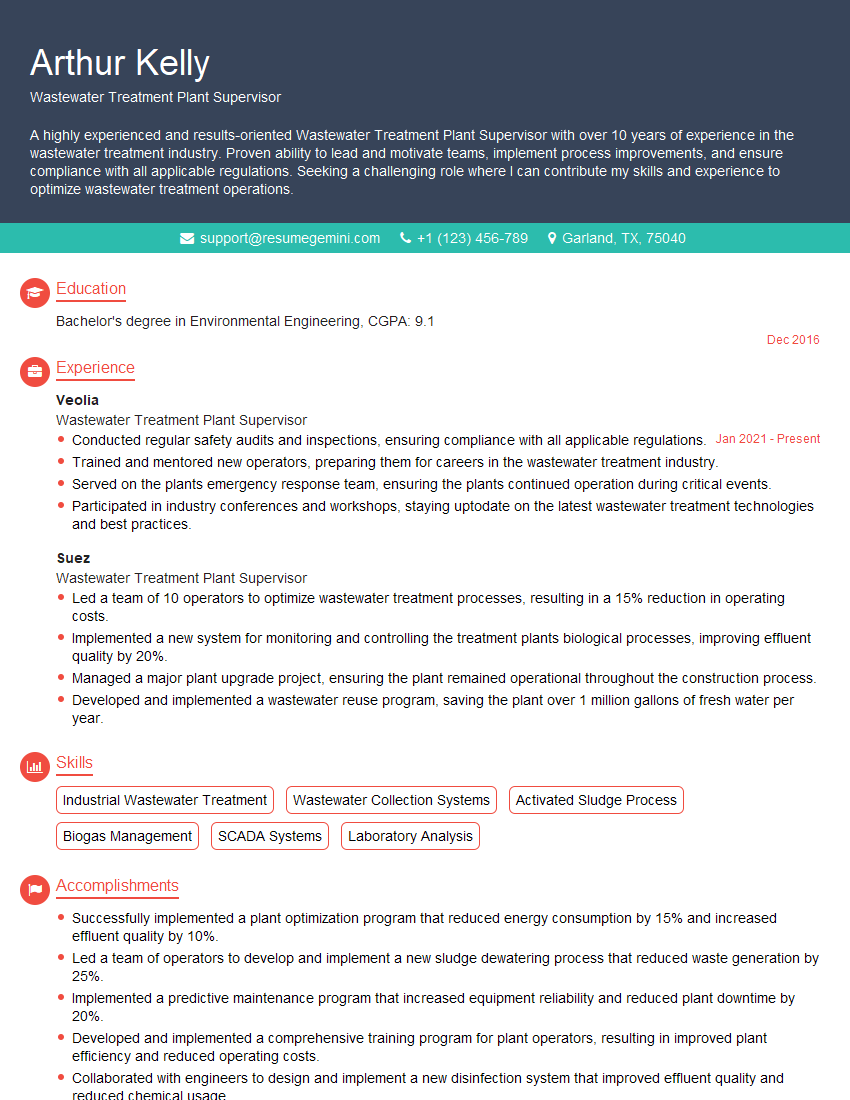

Mastering sludge management and dewatering opens doors to exciting career opportunities in environmental engineering and wastewater treatment. These skills are highly sought after, offering excellent prospects for professional growth and advancement. To maximize your job search success, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. We provide examples of resumes tailored specifically to the Sludge Management and Dewatering field to help you craft a compelling application. Invest in your future – take the next step and create a resume that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.