Preparation is the key to success in any interview. In this post, we’ll explore crucial Snow and Ice Management Equipment interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Snow and Ice Management Equipment Interview

Q 1. Describe your experience operating different types of snow plows.

My experience encompasses operating a wide range of snow plows, from smaller, one-ton trucks equipped with straight blades ideal for residential areas and smaller parking lots, to heavy-duty, tandem-axle plow trucks capable of clearing large highways and industrial sites. I’m proficient with both conventional straight blades, which are excellent for pushing large volumes of snow, and V-plows, which offer greater maneuverability and precision in tight spaces. I’ve also operated wing plows, which significantly increase clearing width, improving efficiency on wide roads and runways. Each plow type demands a different operating technique; for instance, the speed and angle of the blade must be adjusted constantly with a V-plow to maximize efficiency and prevent damage. I’ve successfully used all these types in various weather conditions, from light flurries to blizzard conditions.

Q 2. Explain the proper techniques for pre-trip inspections of snow removal equipment.

Pre-trip inspections are critical for safety and operational efficiency. My procedure starts with a visual check of all lights, ensuring they function correctly. Then, I check the fluid levels: engine oil, coolant, transmission fluid, power steering fluid, and hydraulic fluid. Low fluid levels can lead to significant problems. Next, I inspect the plow’s mounting system, ensuring bolts are tight and there’s no damage to the frame. I thoroughly examine the plow blade itself, checking for cracks, bends, or any damage that could impede its performance. I test the plow’s hydraulic system, ensuring the blade raises and lowers smoothly. Finally, I check the tires for adequate tread and proper inflation, as this significantly impacts traction on icy surfaces. Any issues are documented and reported immediately. Think of it like a pilot’s pre-flight checklist—it’s non-negotiable.

Q 3. How do you determine the appropriate type and amount of de-icing materials for various conditions?

Selecting the right de-icing material and amount depends on several factors: the type of precipitation (snow, freezing rain, sleet), the air temperature, the pavement type, and the expected traffic volume. For light snow or freezing rain on bare pavement, a liquid de-icer like brine or calcium magnesium acetate (CMA) is often sufficient. CMA is environmentally friendly and effective at lower temperatures than rock salt. For heavier snowfall or icy conditions, rock salt (sodium chloride) is often necessary, but its effectiveness decreases below 15°F (-9°C). Sand can provide added traction, but it’s primarily used as a supplemental traction aid rather than a primary de-icer. The application rate varies widely—a light dusting of CMA might suffice for a light freezing rain, while several tons of rock salt might be needed for a heavy snowstorm on a major highway. Experience and local conditions guide these decisions.

Q 4. What safety procedures do you follow while operating snow removal equipment?

Safety is paramount. Before starting, I ensure all safety equipment is in place: high-visibility clothing, working lights, and functional warning devices. I always maintain a safe following distance from other vehicles. I’m mindful of pedestrians and other road users, especially in residential areas or crowded spaces. I avoid abrupt maneuvers, and I adjust my speed according to road conditions. I never operate the equipment while fatigued or under the influence of substances. Regular communication with dispatch and other crews is key, particularly in challenging conditions, to ensure everyone’s safety and situational awareness. I also always follow the employer’s safety policies and procedures.

Q 5. How do you handle equipment malfunctions during a snow event?

Equipment malfunctions during a snow event require a calm, systematic approach. My first step is to assess the situation and ensure the safety of myself and others. If it’s a minor issue, such as a minor hydraulic leak, I’ll attempt a temporary fix or work-around if feasible. For more serious problems, like a complete hydraulic failure or engine trouble, I immediately contact dispatch and follow established protocols for reporting equipment malfunctions. I secure the area, turn off the equipment, and wait for qualified maintenance personnel. Safety and preventing further damage are the priorities during any malfunction.

Q 6. Describe your experience with different types of snow removal equipment (e.g., plows, spreaders, blowers).

Beyond plows, I have extensive experience with snow blowers, ideal for clearing walkways, driveways, and smaller areas where plows are impractical or unsafe. I’ve also operated various types of spreaders, from small tailgate spreaders on pickup trucks to larger, self-contained spreaders mounted on dedicated trucks. These spreaders allow for precise application of de-icing materials, reducing waste and environmental impact. My experience extends to the use of specialized equipment like snow removal loaders and front-end loaders with snow buckets. The choice of equipment is always dictated by the task and the conditions, understanding the strengths and limitations of each type of machinery is critical. For example, a snow blower would be inefficient for clearing a major highway while a V-plow wouldn’t be suitable for narrow sidewalks.

Q 7. What are the common maintenance issues associated with snow plows and spreaders?

Snow plows and spreaders are subject to significant wear and tear due to the harsh conditions. Common issues include damage to the plow blade from impact with obstacles, hydraulic system leaks, wear and tear on the spreader’s auger and conveyor belts, issues with electrical systems due to exposure to moisture and salt, and problems with the chassis from the constant stress and vibrations. Regular lubrication is vital, as is inspecting for rust and corrosion. Proper maintenance, including timely repairs and preventative maintenance, is crucial to extend the lifespan and operational efficiency of the equipment.

Q 8. How do you prioritize snow removal routes based on traffic volume and road conditions?

Prioritizing snow removal routes is crucial for ensuring public safety and minimizing disruption. We use a tiered system based on a combination of traffic volume and road conditions. Think of it like triage in a hospital – the most critical areas get addressed first.

Tier 1: These are primary routes with the highest traffic volume, such as major highways, emergency service routes (hospitals, fire stations), and public transportation routes. These are cleared first, even if the snow accumulation isn’t exceptionally high, because the impact of blockage is immense. We often use real-time traffic data feeds to refine this prioritization during active storms.

Tier 2: Secondary roads, major arterial streets, and school bus routes fall under this tier. These routes are prioritized after Tier 1 routes are passable, and the clearing intensity might be adjusted based on snow accumulation and predicted future snowfall. We consider factors like hill gradients and potential for black ice formation to decide clearing intensity here.

Tier 3: Residential streets and less trafficked roads make up the final tier. While these are vital, they are cleared after ensuring the main arteries are safe and accessible. The order within this tier might be further refined based on factors such as road gradient, resident density, and reported issues.

This tiered approach ensures the most critical areas receive immediate attention, maximizing safety and minimizing the impact of the storm on the community. We constantly monitor weather forecasts and adjust the plan dynamically throughout the storm.

Q 9. Explain your experience with GPS tracking and route optimization for snow removal.

GPS tracking and route optimization are indispensable for efficient snow removal. I’ve extensively used GPS-enabled systems to track plow trucks in real-time, monitor their progress, and optimize routes dynamically. It’s like having a bird’s-eye view of the entire operation.

For example, we use software that integrates with GPS trackers on our trucks. This allows us to see the location of each plow, its speed, and its progress along its assigned route. If a truck encounters unexpected delays (a major accident, for instance), the system can reroute it or dispatch a nearby truck to assist, minimizing delays and ensuring complete coverage.

Route optimization goes beyond simple tracking. The software can analyze historical data, real-time conditions (snow depth, traffic), and predicted weather patterns to suggest the most efficient routes. This means fewer trucks idle, reduced fuel consumption, and faster overall snow clearance. In one particularly challenging blizzard, optimized routing saved us nearly three hours of operation time.

The data collected also helps us refine our strategies for future snow events. We can identify areas where our processes were less efficient and implement changes for improvement.

Q 10. How familiar are you with different types of de-icing chemicals and their environmental impact?

I’m very familiar with various de-icing chemicals and their environmental impact. Choosing the right de-icer is a delicate balance between effectiveness and minimizing environmental harm. It’s not a simple case of ‘more is better’.

Sodium Chloride (Rock Salt): This is the most common and cost-effective, but it can harm vegetation, corrode infrastructure, and contribute to water pollution. We use it sparingly and strategically, focusing on areas where other de-icers are less effective.

Calcium Chloride: More effective at lower temperatures than rock salt and less corrosive, but it still has environmental impacts. It’s also more expensive. We consider using this on particularly critical areas or during extremely cold conditions.

Magnesium Chloride: Less corrosive and environmentally damaging than sodium chloride, but it’s also more expensive. We’ve used this in environmentally sensitive areas or where minimizing corrosion is paramount.

Organic De-icers: These are generally more environmentally friendly, but less effective and more expensive. We explore using these in environmentally sensitive areas, but usually supplement them with other methods.

We continually assess the environmental impact of our choices and are exploring using more sustainable practices, such as pre-wetting salt applications to reduce usage, improved brine solutions and alternative methods such as improved snow plowing techniques and anti-icing measures to minimize chemical usage.

Q 11. Describe your experience managing a team during snow removal operations.

Managing a team during snow removal operations requires strong leadership, clear communication, and swift decision-making. It’s a high-pressure environment where efficiency and safety are paramount. Think of it as conducting a well-orchestrated symphony, each instrument (truck and crew) playing its part to create a harmonious result.

My approach focuses on proactive planning, clear task assignments, and constant communication. Before a storm, we hold briefings outlining routes, priorities, and safety protocols. During the storm, I use radio communication and GPS tracking to monitor progress, address any issues, and re-allocate resources as needed. I empower my team, giving them the autonomy to make on-the-spot decisions to deal with unexpected situations.

Providing clear and consistent feedback is crucial, both positive reinforcement and constructive criticism, improving our performance each time we face a snow event. One time, a particularly heavy snowfall disrupted a pre-planned route. By communicating the change effectively and offering support, the team adapted smoothly, preventing delays.

Team building and fostering a positive work environment are also essential for handling stressful situations effectively. A well-coordinated team not only works efficiently but also safely.

Q 12. What is your approach to ensuring the safety of both equipment operators and the public?

Ensuring the safety of equipment operators and the public is my top priority. It’s non-negotiable. We implement a multi-layered approach.

Pre-Storm Preparation: Thorough equipment inspections, driver training on safe operating procedures (especially in adverse conditions), and pre-storm briefings outlining potential hazards are critical. We also communicate any relevant weather warnings and potential road closures to the team and the public.

During Snow Removal: We use high-visibility safety apparel, maintain safe distances between trucks, and equip trucks with appropriate safety lights and signage. Clear communication channels are maintained to prevent accidents. Public safety announcements are frequently issued, alerting the public to road conditions and advising caution.

Post-Storm Assessment: We conduct a thorough review of the operation to identify any areas where safety could have been improved. This often includes analyzing accident reports (if any), reviewing GPS data for potential near misses, and gathering feedback from operators and the public. We use this feedback to improve future operations.

Safety is ingrained in our culture; it’s not just a checklist. We believe a proactive and continuous approach is essential to ensure everyone’s safety.

Q 13. How do you stay up-to-date on industry best practices and technological advancements in snow removal?

Staying current with industry best practices and technological advancements is essential in this ever-evolving field. We actively pursue several strategies to stay ahead of the curve.

Industry Associations: We participate in professional organizations such as the Snow and Ice Management Association (SIMA) or similar groups. This offers access to training, conferences, and networking opportunities with other professionals. We also stay involved with ongoing dialogue and discussions within the industry and share best practices and lessons learned.

Publications and Trade Shows: We regularly read trade publications, attend industry conferences and trade shows, and explore new technologies and equipment showcased there. These provide insights into the latest innovations in de-icing chemicals, equipment, and operational strategies.

Continuous Training: We provide regular training to our operators and staff on new technologies, safety procedures, and best practices. This ensures that our team is equipped with the knowledge and skills to handle any situation effectively.

Data Analysis: We continuously analyze data from our operations to identify areas where we can improve our efficiency, reduce environmental impact, and enhance safety. This data-driven approach allows us to refine our practices and adopt new technologies strategically.

Q 14. What is your experience with snow removal budgeting and cost control?

Snow removal budgeting and cost control are crucial for responsible resource management. We use a multi-faceted approach.

Accurate Forecasting: Detailed weather forecasting is the foundation of our budget. Predicting snowfall intensity, duration, and timing allows us to accurately estimate labor, fuel, and material costs. This forecasting is often refined during the event with real-time updates.

Equipment Maintenance: Preventive maintenance significantly reduces downtime and repair costs, which are major budget items. Proper maintenance scheduling and proactive repairs keep our equipment running efficiently.

Material Procurement: We leverage bulk purchasing agreements to reduce the cost of de-icing materials. Efficient inventory management also prevents waste and minimizes storage costs.

Route Optimization: As mentioned earlier, GPS tracking and route optimization significantly reduce fuel consumption, labor hours, and overall operational costs.

Post-Event Analysis: Post-event analysis helps in identifying areas where cost savings are possible. This includes reviewing fuel consumption, overtime hours, and material usage to pinpoint areas for improvement in future budgets. Continuous improvement is key to cost-effective snow and ice management.

Q 15. How do you handle unexpected weather events and challenges during snow removal operations?

Handling unexpected weather events during snow removal requires a proactive and adaptable approach. Think of it like being a conductor of an orchestra – each instrument (piece of equipment, crew member) needs to be ready to adjust to the tempo (weather changes).

- Real-time Monitoring: We constantly monitor weather forecasts, not just the day-of, but the lead-up. Changes in snowfall rates, temperature fluctuations (leading to ice formation), and wind speeds significantly impact operations. We use weather apps and services that provide hyperlocal updates.

- Flexible Staffing & Equipment Allocation: Having extra personnel on standby and a variety of equipment ready allows for a rapid response to changing conditions. For example, if heavy snowfall turns to freezing rain, we switch from plows to spreaders and de-icing equipment.

- Communication Protocols: Clear communication between crews, supervisors, and clients is vital. We utilize two-way radios and mobile apps to coordinate efforts and relay critical information regarding road conditions and equipment malfunctions.

- Contingency Planning: This includes having backup routes, alternate equipment, and pre-arranged arrangements with subcontractors in case of emergencies. Imagine a major blizzard – having alternative fuel sources and lodging secured for the crew could be a lifesaver.

For example, during a recent blizzard that started as light snow and transitioned rapidly to a heavy, wet snowfall, we quickly switched from smaller, lighter-duty trucks to larger, more powerful snowplows. Simultaneously, we increased staffing to meet the accelerated snow removal demands.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with preventative maintenance schedules for snow removal equipment.

Preventative maintenance is the cornerstone of efficient and safe snow removal operations. It’s like regular checkups for your car – catching small problems before they turn into major breakdowns. We follow a rigorous schedule encompassing daily, weekly, and seasonal checks.

- Daily Inspections: Before each shift, we perform a walk-around inspection of all equipment, checking fluid levels (oil, coolant, hydraulic fluid), tire pressure, lights, and the overall condition of the plow or spreader.

- Weekly Maintenance: This includes more in-depth checks of belts, hoses, filters, and other critical components. We also document any minor issues or wear and tear observed during daily inspections.

- Seasonal Maintenance: This comprehensive service happens before and after the snow season. It includes a thorough inspection of the entire system, including hydraulic systems, engine tune-ups, and complete lubrication. We replace worn parts proactively.

- Documentation: Meticulous record-keeping is crucial. We maintain detailed logs of all maintenance activities, including dates, services performed, and any parts replaced. This allows for easy tracking of maintenance history and facilitates preventative action.

For instance, we might replace worn blades on snowplows before the start of the season to prevent unexpected breakdowns during a snowstorm. This is far more efficient and cost-effective than dealing with a mid-storm equipment failure.

Q 17. How do you manage fuel efficiency and minimize operational costs for snow removal equipment?

Minimizing fuel consumption is paramount in snow removal, given the intense usage during storms. We employ several strategies focusing on efficiency and minimizing waste.

- Proper Equipment Selection: We choose equipment suited to the job. Using a small truck for a light snowfall is more fuel-efficient than a large plow for the same job. Oversizing equipment for the job is a common mistake leading to higher fuel costs.

- Driver Training: Proper driving techniques are essential. Aggressive driving behaviors, like rapid acceleration and braking, increase fuel consumption significantly. We train drivers to operate equipment smoothly and efficiently.

- Regular Maintenance: Well-maintained engines burn fuel more efficiently. This includes regular tune-ups, filter changes, and proper lubrication. Think of it as keeping your engine ‘in shape’.

- Route Optimization: Efficient routes minimize idling time and unnecessary travel. We use GPS and mapping technology to plan optimal routes based on snowfall intensity and road conditions.

- Alternative Fuels: Exploring options like biodiesel blends can offer fuel efficiency and environmental benefits.

For example, by implementing driver training programs focused on fuel efficiency, we’ve seen a 15% reduction in fuel consumption over the past two years.

Q 18. What are your troubleshooting skills regarding hydraulic systems in snow removal equipment?

Hydraulic systems are crucial in snow removal equipment, powering plows, spreaders, and other functions. Troubleshooting involves systematic diagnosis and methodical repairs.

- Visual Inspection: We begin with a careful visual inspection, checking for leaks, loose connections, or damaged hoses. This is like checking the pipes in your house for any leaks before tackling a plumbing issue.

- Pressure Testing: Using pressure gauges, we check the pressure in different parts of the hydraulic system to identify pressure drops or blockages. It’s like checking the water pressure in your system.

- Fluid Analysis: Analyzing hydraulic fluid for contamination or degradation can pinpoint internal issues. Think of it as getting your blood tested for medical purposes.

- Component Testing: Individual components, such as pumps, valves, and cylinders, can be tested to isolate faulty parts. It’s like testing a specific part in a car’s engine.

- Diagnostic Tools: Modern equipment often incorporates advanced diagnostic tools that provide specific codes indicating system issues.

For example, if a plow fails to lift, we’d check the hydraulic fluid level, inspect the hoses for leaks, and then use a pressure gauge to isolate the problem to a faulty pump or valve. Depending on the findings, we would then replace the faulty component or repair the leak.

Q 19. How proficient are you in using diagnostic tools for snow removal equipment?

Proficiency with diagnostic tools is essential for quick and accurate troubleshooting. Modern snow removal equipment employs advanced onboard computer systems that provide diagnostic trouble codes (DTCs).

- OBD-II Scanners: Similar to scanners used in automobiles, these tools connect to the equipment’s computer system and read DTCs. These codes pinpoint specific problems within the system.

- Manufacturer-Specific Software: Many manufacturers provide specialized software for accessing more detailed diagnostic information and performing advanced troubleshooting.

- Data Logging: Some tools allow for data logging, recording various parameters such as engine RPM, hydraulic pressure, and temperature. This helps identify patterns and trends related to malfunctions.

I’m highly proficient in using a variety of diagnostic tools, including OBD-II scanners and manufacturer-specific software for multiple brands of snow removal equipment. I can accurately interpret DTCs, use data logging to identify intermittent problems, and effectively troubleshoot based on the gathered data.

Q 20. What are the key performance indicators you use to measure the effectiveness of snow removal operations?

Key performance indicators (KPIs) for snow removal operations ensure efficiency and effectiveness. They’re like the scorecard for the operation, showing where we excel and where we can improve.

- Time to Clear: The time taken to clear a specific area or route is crucial, especially during severe weather events. This is a direct measure of operational efficiency.

- Miles Covered: This measures the overall distance covered by our equipment, providing insight into operational reach and effectiveness.

- Salt/De-icer Usage: Monitoring salt and de-icer consumption helps in cost control and resource management. It also helps to refine de-icing strategies.

- Equipment Downtime: Minimizing downtime through preventative maintenance improves overall efficiency. This KPI reflects maintenance effectiveness.

- Safety Incidents: A critical KPI reflecting the safety measures in place. Zero incidents should always be the target.

- Client Satisfaction: Feedback from clients provides invaluable insights into operational performance and areas for improvement. It is a direct reflection of our service quality.

For example, by tracking time-to-clear data over different seasons, we identify areas where routes can be optimized or more equipment deployed to improve speed and efficiency.

Q 21. Describe your experience with salt spreader calibration and maintenance.

Salt spreader calibration and maintenance are critical for effective and efficient de-icing operations. Inaccurate calibration leads to wasted salt and potentially unsafe road conditions.

- Calibration Procedures: Calibration involves accurately setting the spreader to dispense the correct amount of salt based on the desired application rate. This often involves using a calibrated scale and following manufacturer instructions.

- Regular Inspection: Regular inspections check the auger, spinner, and the entire spreading mechanism for wear and tear, blockages, or damage. This includes checking the motor, belts, and chute.

- Maintenance: Regular maintenance includes lubrication of moving parts, replacement of worn components, and cleaning of the spreader to prevent corrosion and blockages. This extends the lifespan of the equipment and ensures consistent performance.

- Material Handling: Proper material handling is vital to prevent clumping or bridging of salt, which can affect calibration. Using a material flow aid can prevent bridging within the hopper.

For example, before each snowfall, we calibrate our spreaders using a calibrated scale to ensure that the correct amount of salt is dispensed based on road conditions and traffic volume. Regular maintenance ensures the spreaders remain accurate and efficient throughout the season.

Q 22. What are the legal and regulatory compliance requirements related to snow removal operations in your area?

Legal and regulatory compliance in snow removal is crucial for safety and liability reasons. It varies significantly by location, so I always thoroughly research local ordinances. For example, in many municipalities, there are specific deadlines for clearing sidewalks and roadways after a snowfall, often dependent on the amount of accumulated snow. There might be regulations concerning the use of salt or other de-icing agents, particularly regarding their environmental impact, requiring specific application methods or restrictions near waterways. Further, regulations might mandate the use of specific safety equipment for operators and proper signage to alert pedestrians and drivers of ongoing operations. I always maintain up-to-date records of permits, insurance, and compliance certifications, ensuring our operations are fully compliant with all applicable laws and regulations. Failure to comply can result in significant fines or legal action.

For instance, in one municipality I worked in, we had to submit a detailed snow removal plan each winter, outlining our equipment, staffing, and response times. This plan was reviewed and approved by the city’s public works department. Regular inspections were also conducted to ensure we adhered to their safety and environmental guidelines.

Q 23. How do you manage the storage and inventory of snow removal equipment and materials?

Efficient storage and inventory management is essential for a smooth snow removal operation. We utilize a dedicated, well-organized storage facility designed to protect equipment from the elements. This typically includes a secure, enclosed space for smaller equipment like snow blowers and spreaders, and a larger, paved area for larger vehicles like plow trucks. Equipment is strategically placed for easy access and to minimize downtime. A detailed inventory management system tracks each piece of equipment, noting its condition, maintenance history, and location. This ensures prompt identification of equipment needing repair or replacement. We maintain sufficient stock of essential materials such as rock salt, sand, and de-icing chemicals, carefully monitoring usage and ordering replacements proactively to avoid shortages during critical times. Regular inventory checks and condition assessments are integrated into our operational schedule, allowing for early detection and resolution of any potential problems.

Think of it like a well-stocked kitchen: You wouldn’t want to start a large meal and realize you’re missing key ingredients. Similarly, we plan ahead to avoid unexpected interruptions during a snowstorm.

Q 24. Describe your experience with different types of snow removal contracts and agreements.

My experience encompasses various snow removal contracts, from simple, per-event agreements to comprehensive, multi-year contracts. Simple contracts often specify a per-hour or per-event rate, suitable for smaller properties or one-off snowfalls. More complex contracts for larger clients like shopping malls or municipalities usually detail specific service areas, response times, and acceptable snow accumulation levels before removal begins. They often include clauses defining liability, insurance requirements, and payment schedules. Some contracts incorporate performance-based incentives, rewarding faster or more efficient snow removal. Others might stipulate the type and quantity of de-icing materials to be used. Before signing any contract, a thorough review and understanding of all terms and conditions are paramount. Negotiations often focus on balancing the client’s needs with the realities of operational capabilities and potential weather challenges. Understanding the nuances of each contract type is critical for successful project management and profit margins.

For example, a large commercial property might require a contract outlining different service levels based on snowfall intensity. A light snowfall could have a shorter response time than a major blizzard, and the contract reflects this tiered approach to service.

Q 25. Explain your experience with snow removal equipment training and safety programs.

Safety is paramount in snow removal operations. Our training programs cover both theoretical and practical aspects. New employees undergo comprehensive safety orientation, covering topics like operating equipment safely, identifying hazards, emergency procedures, and personal protective equipment (PPE) use. Regular refresher training keeps our team updated on best practices and safety regulations. Practical training includes hands-on experience with different types of snow removal equipment, emphasizing proper operation and maintenance. We conduct regular safety inspections of equipment and work sites, enforcing strict adherence to safety protocols. We also utilize simulations and role-playing scenarios to prepare our team for various emergency situations, such as equipment malfunctions or unexpected weather changes. All employees are required to have proper certifications for operating the specific heavy machinery they use. Moreover, we maintain detailed records of all training activities and safety incidents, allowing us to identify areas for improvement and refine our safety protocols over time.

Think of it like pilot training – continuous learning and practice are crucial for maintaining the highest levels of safety and proficiency.

Q 26. How familiar are you with the different types of blades used on snow plows and their applications?

Different snow plow blades are designed for various snow conditions and applications. The most common types include straight blades, V-plows, and wing plows. Straight blades are versatile, ideal for moderate snowfalls and general clearing. They offer a simple, effective way to move snow. V-plows excel at pushing large volumes of snow efficiently, especially during heavy snowfalls. Their angled design allows for better snow flow and less material buildup. Wing plows are excellent for wider clearing paths, particularly effective in large parking lots or wide roadways. They extend the plow’s reach significantly. Specialized blades include box blades, ideal for transporting and stockpiling snow, and curved blades which minimize snow accumulation. The choice of blade depends heavily on the type of terrain, the amount of snow, and the clearing requirements. Experience helps in choosing the most suitable blade for each situation to maximize efficiency and minimize damage to surfaces.

Imagine a chef choosing the right knife for the task – a paring knife for detail work, a chef’s knife for general chopping. Similarly, we choose the correct blade to optimize our snow removal efforts.

Q 27. How would you handle a situation where a piece of snow removal equipment breaks down during a major snowstorm?

Equipment breakdown during a major snowstorm is a critical situation requiring immediate action. Our first response involves assessing the severity of the malfunction and its impact on operations. We have a dedicated emergency response plan outlining procedures for such events. This includes contacting our maintenance team or a qualified mechanic immediately to arrange for repairs or replacements. In the meantime, we implement contingency plans, which might involve rerouting operations to ensure continuous service, using backup equipment if available, or contracting with another snow removal company for temporary assistance. Depending on the breakdown’s severity and location, we might need to deploy additional crew members to manage traffic flow and ensure public safety. Clear and consistent communication with clients and relevant authorities is crucial during these situations to keep them informed about any service interruptions or delays. Thorough documentation of the breakdown, repair, and any resulting delays are essential for liability and insurance purposes. Regular preventative maintenance significantly reduces the likelihood of such breakdowns.

Think of it like a fire drill – having a pre-planned procedure in place significantly improves our ability to respond effectively.

Q 28. Describe your experience with using weather forecasts and predictions to plan for snow removal operations.

Weather forecasting is integral to efficient snow removal operations. We utilize a variety of sources, including national weather services, specialized weather forecasting companies, and local news reports, to obtain accurate and timely snow predictions. This information allows us to preemptively plan for staffing levels, equipment deployment, and material requirements, minimizing delays and maximizing effectiveness. We closely monitor weather patterns, paying attention to storm intensity, snowfall accumulation, wind speed, and temperature. This data is used to develop detailed operational plans specific to the expected conditions. For instance, a heavy snowfall necessitates a larger crew and multiple pieces of equipment, while a light dusting might require only minimal intervention. Real-time updates allow for dynamic adjustments to our plans as conditions change, ensuring a responsive and effective approach. This proactive approach minimizes downtime and increases efficiency.

Just like a captain charts a course using navigation tools, we use weather forecasts to navigate the complexities of a snowstorm and deploy our resources optimally.

Key Topics to Learn for Snow and Ice Management Equipment Interview

- Equipment Types and Functionality: Understand the differences between snow plows, snow blowers, ice melting equipment (chemical and mechanical), de-icing agents, and spreader types. Be prepared to discuss their strengths, weaknesses, and appropriate applications.

- Safety Procedures and Regulations: Discuss safe operating procedures, maintenance protocols, and relevant industry safety regulations. Highlight your understanding of risk assessment and mitigation strategies in snow and ice management operations.

- Maintenance and Repair: Demonstrate knowledge of preventative maintenance, troubleshooting common equipment malfunctions, and basic repair procedures. Discuss your experience with diagnostic tools and techniques.

- Logistics and Planning: Explain your understanding of route planning, resource allocation, and effective deployment of equipment and personnel during snow and ice events. Discuss strategies for optimizing efficiency and minimizing downtime.

- Environmental Considerations: Showcase your awareness of the environmental impact of de-icing chemicals and sustainable snow and ice management practices. Be prepared to discuss environmentally friendly alternatives and best practices.

- Technological Advancements: Discuss your knowledge of modern technologies used in snow and ice management, such as GPS tracking, automated spreading systems, and weather forecasting tools. Highlight your ability to adapt to new technologies and integrate them into operations.

- Budgeting and Cost Management: Demonstrate understanding of cost-effective strategies for equipment selection, maintenance, and operation. Discuss your experience in managing budgets and controlling expenses related to snow and ice removal.

Next Steps

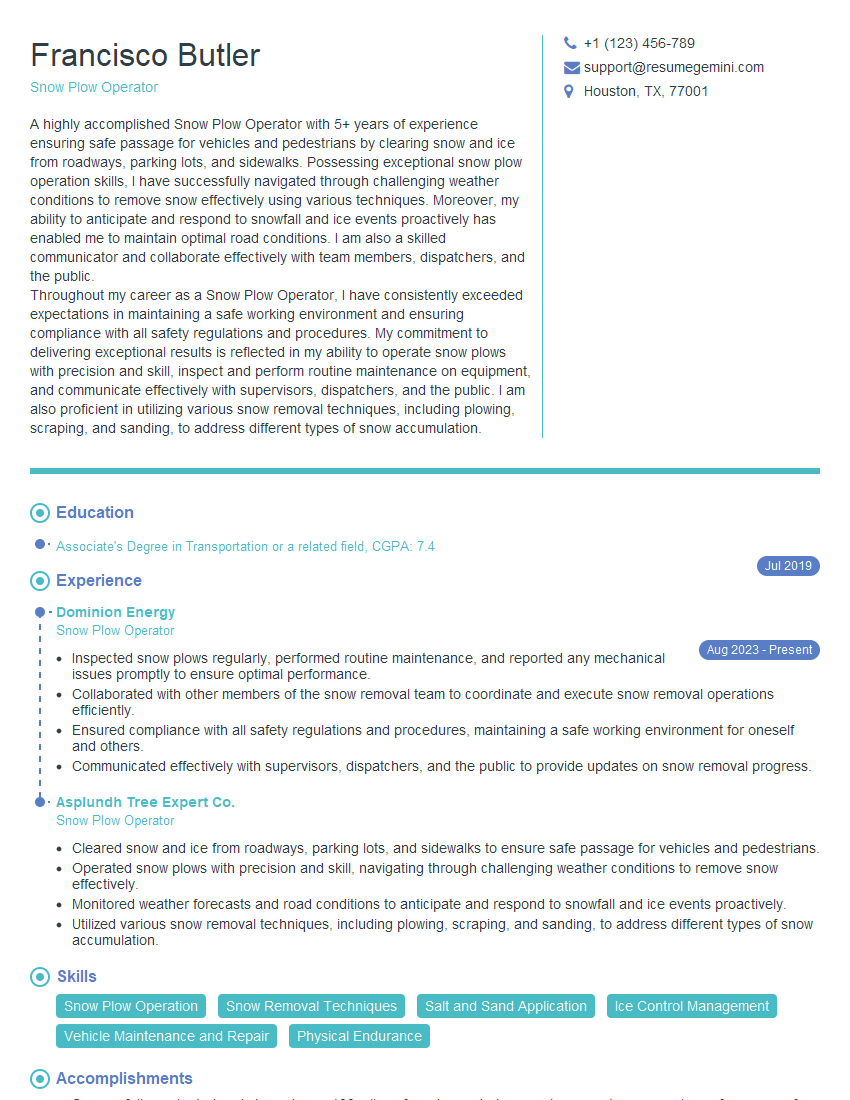

Mastering the intricacies of snow and ice management equipment opens doors to rewarding and challenging career opportunities in a vital industry. A strong understanding of these topics demonstrates your commitment to safety, efficiency, and environmental responsibility – highly valued attributes in this field. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional, impactful resume. Take advantage of their tools and resources, including examples of resumes tailored specifically to the Snow and Ice Management Equipment industry, to present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

To the interviewgemini.com Webmaster.

Very helpful and content specific questions to help prepare me for my interview!

Thank you

To the interviewgemini.com Webmaster.

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.