Cracking a skill-specific interview, like one for Polymer Compounding, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Polymer Compounding Interview

Q 1. Explain the difference between melt compounding and solid-state compounding.

The key difference between melt compounding and solid-state compounding lies in the physical state of the polymer during the mixing process. In melt compounding, the polymer is processed in its molten state, offering excellent mixing and dispersion of additives. Think of it like making a cake – you mix all the ingredients together while the batter is liquid. This method is effective for achieving homogenous blends, incorporating a wide range of additives, and creating complex formulations. It’s widely used for producing high-performance polymers requiring uniform dispersion.

Solid-state compounding, on the other hand, involves mixing the polymer in its solid form, usually using techniques like dry blending or co-rotating twin-screw extrusion at lower temperatures. This is like carefully layering ingredients in a parfait – ensuring thorough mixing without melting. It’s particularly useful for heat-sensitive polymers or situations where melt processing can degrade the material. The method is less efficient in terms of achieving perfect dispersion, but minimizes thermal degradation. For example, solid-state compounding is often preferred for materials where thermal history affects the final performance such as certain pharmaceuticals or specialty polymers.

Q 2. Describe the role of different additives in polymer compounding (e.g., stabilizers, fillers, plasticizers).

Additives play a crucial role in tailoring the properties of polymer compounds to meet specific application requirements. They act like the secret ingredients in a recipe, transforming the base polymer into a material fit for purpose.

- Stabilizers: These prevent polymer degradation caused by factors like heat, UV light, or oxidation. Think of them as preservatives, extending the shelf life and maintaining the performance of the polymer. Examples include antioxidants (e.g., hindered phenols) and UV stabilizers (e.g., hindered amine light stabilizers or HALS).

- Fillers: These are added to reduce costs, increase stiffness, improve strength, or modify other properties. They are like the ‘filler’ ingredients in a recipe, adding bulk and modifying texture. Examples include talc, calcium carbonate, and glass fibers.

- Plasticizers: These soften the polymer, making it more flexible and easier to process. They’re akin to the oil in a cake recipe, making it moist and pliable. Common examples include phthalates and adipates.

- Other Additives: Many other additives exist, including colorants (pigments and dyes), flame retardants, lubricants, coupling agents (improve interaction between filler and polymer), and anti-static agents.

The specific choice and quantity of additives are crucial in determining the final properties and performance of the polymer compound.

Q 3. How do you determine the optimal processing parameters for a specific polymer compound?

Determining optimal processing parameters for a specific polymer compound requires a systematic approach. It’s not about guesswork; it’s about scientific understanding and controlled experimentation. The process typically involves:

- Understanding the polymer and additives: This includes knowing the melt flow index (MFI), thermal stability, and other key properties of the polymer and the interactions among different additives.

- Experimental design: Employing techniques like Design of Experiments (DOE) to efficiently explore the parameter space (temperature, screw speed, residence time, etc.).

- Process monitoring: Using sensors (e.g., thermocouples, pressure transducers) to monitor and control the processing parameters during compounding.

- Material characterization: Analyzing the resulting compound for its physical and mechanical properties (e.g., tensile strength, elongation at break, impact strength) to evaluate the effect of processing parameters.

- Iteration and optimization: Based on the characterization results, iteratively adjust the processing parameters to reach the desired performance.

Software simulation tools are increasingly employed to predict process behavior and optimize parameter settings before carrying out physical experiments, saving time and resources.

Q 4. What are the common challenges in polymer compounding, and how do you address them?

Polymer compounding presents several challenges, many of which are intertwined:

- Inhomogeneous mixing: Achieving a uniform distribution of additives is crucial. Poor mixing can lead to variations in properties across the final product. Strategies to mitigate this include optimizing mixing equipment and processing parameters, along with using appropriate compatibilizers.

- Thermal degradation: Excessive heat can degrade the polymer, leading to discoloration, reduced mechanical properties, and other problems. Controlling the processing temperature and using appropriate stabilizers are essential. Employing techniques like solid-state compounding is relevant when dealing with heat-sensitive polymers.

- Agglomeration: Fillers or other additives can form agglomerates (clusters), leading to non-uniformity. Pre-treatment of additives (e.g., surface modification) and optimization of mixing conditions can help address this.

- Cost optimization: Balancing the desired properties with cost-effective filler loadings is an ongoing challenge. It requires careful selection of fillers and understanding the cost-performance trade-offs.

Addressing these challenges demands a thorough understanding of polymer science, materials engineering, and process engineering principles. Often, an iterative approach of troubleshooting and optimization is needed to resolve issues.

Q 5. Explain the concept of rheology and its importance in polymer compounding.

Rheology is the study of the flow and deformation of matter. In polymer compounding, it’s absolutely critical because it governs how the polymer melts, mixes, and flows during the processing stages. Understanding a polymer’s rheological behavior is essential for selecting appropriate processing equipment, optimizing processing parameters, and predicting the final product’s properties.

Rheological properties like viscosity, elasticity, and shear thinning behavior influence mixing efficiency, the ability to fill molds, and the final mechanical properties of the compound. For instance, a polymer with high viscosity will be difficult to process, while a shear-thinning polymer will flow more readily under high shear rates.

Rheological measurements, often performed using rheometers, provide essential data for process optimization and quality control. These measurements can be used to predict the processability of a compound, design appropriate mixing protocols and ensure consistent product quality.

Q 6. How do you ensure the quality and consistency of a polymer compound?

Ensuring quality and consistency in polymer compounding involves a multi-faceted approach, encompassing:

- Raw material quality control: Rigorous testing of incoming polymers and additives to ensure they meet specifications.

- Process control: Maintaining strict control over processing parameters throughout the compounding process. This involves using automated systems and real-time monitoring.

- In-process quality control: Regular sampling and testing of the compound during processing to detect and correct deviations from the desired properties.

- Final product quality control: Thorough testing of the final compound for its physical, mechanical, and chemical properties to ensure they meet specifications and quality standards.

- Statistical Process Control (SPC): Implementing SPC methods to monitor process variability and identify potential sources of variation.

Implementing a robust quality management system (QMS), such as ISO 9001, helps maintain consistent quality over time.

Q 7. Describe different techniques for characterizing polymer properties (e.g., tensile strength, melt flow index).

Various techniques are used to characterize polymer properties:

- Tensile strength: Measured using a universal testing machine to determine the material’s ability to withstand tensile forces. This gives an indication of the material’s strength.

- Melt Flow Index (MFI): This measures the ease of flow of the molten polymer under specific temperature and pressure conditions. It’s a crucial indicator of processability.

- Differential Scanning Calorimetry (DSC): Used to determine the glass transition temperature (Tg), melting point (Tm), and crystallization behavior of polymers.

- Thermogravimetric Analysis (TGA): Measures weight changes as a function of temperature, providing information on thermal stability and decomposition behavior.

- Dynamic Mechanical Analysis (DMA): Measures the viscoelastic properties of polymers as a function of temperature and frequency, offering insights into material stiffness and damping characteristics.

- Impact strength: Assesses the material’s resistance to impact forces. Different test methods exist, like Izod and Charpy impact tests.

The choice of characterization technique depends on the specific properties of interest and the application requirements.

Q 8. What are the common types of polymers used in compounding, and what are their unique characteristics?

Polymer compounding utilizes a wide array of polymers, each with unique properties influencing the final product. The choice of polymer is crucial for achieving desired characteristics.

- Polyethylene (PE): Known for its flexibility, toughness, and chemical resistance. Low-density polyethylene (LDPE) is used in films and bags, while high-density polyethylene (HDPE) finds application in bottles and containers. Its versatility makes it a workhorse in compounding.

- Polypropylene (PP): Offers good stiffness, chemical resistance, and is lighter than PE. Common in packaging, automotive parts, and fibers. Its ability to withstand higher temperatures than PE expands its applications.

- Polyvinyl Chloride (PVC): A rigid polymer with excellent weather resistance and durability. Widely used in pipes, window frames, and flooring. However, it requires careful handling due to its potential toxicity during processing.

- Polystyrene (PS): A versatile, easily processed thermoplastic, known for its clarity and low cost. Used in food containers, insulation, and packaging. Its brittleness is often addressed through compounding.

- Polyamide (PA) or Nylon: High strength, excellent abrasion resistance, and good chemical resistance. Used in engineering plastics for parts requiring high durability. Its high melting point necessitates specialized compounding equipment.

- Polycarbonate (PC): High impact resistance, excellent optical clarity, and high heat resistance. Used in safety glasses, lenses, and automotive parts. Its high cost is balanced against its superior performance in certain applications.

Understanding these unique properties is critical in selecting the right polymer base for the desired application and optimizing the compounding process for the best results.

Q 9. How do you troubleshoot processing issues such as degradation or poor dispersion?

Troubleshooting processing issues in polymer compounding requires a systematic approach. Let’s look at degradation and poor dispersion specifically.

Degradation: This often manifests as discoloration, reduced molecular weight (leading to weaker material), or changes in melt viscosity. Troubleshooting steps include:

- Temperature Control: Excessive heat can cause degradation. Reducing processing temperatures or optimizing the residence time in the extruder are common solutions.

- Antioxidant/Stabilizer Addition: Adding antioxidants to the polymer formulation can prevent oxidative degradation. The choice of antioxidant depends on the polymer and processing conditions.

- Material Compatibility: Incompatible additives or fillers can catalyze degradation. Careful selection of additives is crucial.

- Moisture Content: Excessive moisture can lead to hydrolysis and degradation, especially in polymers susceptible to moisture. Drying the materials before processing is often necessary.

Poor Dispersion: This results in an uneven distribution of fillers, additives, or other components in the polymer matrix. Solutions include:

- Pre-mixing: Thoroughly mixing the components before feeding them into the extruder can improve dispersion.

- Higher Shear Mixing: Using equipment capable of generating higher shear forces (such as twin-screw extruders) enhances the dispersion of fillers and additives.

- Additive Selection: Choosing additives with good compatibility and dispersibility in the polymer is important. Surface treatments of fillers can also improve their dispersion.

- Optimization of Extruder Parameters: Adjusting screw speed, temperature profile, and die geometry can enhance dispersion.

A combination of these approaches, guided by thorough material characterization and process monitoring, usually resolves these issues. Careful record-keeping is vital for future process improvements.

Q 10. Explain the importance of safety procedures in a polymer compounding facility.

Safety is paramount in polymer compounding. The materials and processes involved present several potential hazards, necessitating strict adherence to safety protocols.

- Personal Protective Equipment (PPE): This includes safety glasses, gloves, protective clothing, and respirators, depending on the specific materials and processes involved. Regular PPE training and inspections are critical.

- Machine Guarding: Extruders, mixers, and other processing equipment must have appropriate guarding to prevent accidental contact with moving parts.

- Emergency Shut-off Systems: Easily accessible emergency stop buttons and emergency shut-off systems are crucial to quickly halt operations in case of accidents.

- Fire Prevention and Suppression: Many polymers are flammable, so fire safety measures, including fire extinguishers, sprinkler systems, and emergency evacuation plans, are essential.

- Material Handling: Safe handling procedures for raw materials and finished products must be implemented. This includes proper storage, lifting techniques, and spill response plans.

- Ventilation: Adequate ventilation is needed to control dust and fumes released during the compounding process. Regular air quality monitoring helps ensure a safe working environment.

- Regular Safety Training: Ongoing training programs for all personnel on safe operating procedures, hazard recognition, and emergency response protocols are crucial for maintaining a safe work environment. This includes both theoretical and practical training and refreshing this training regularly.

A proactive safety culture, where safety is the top priority, is essential in preventing accidents and ensuring the well-being of all workers.

Q 11. How do you design experiments to optimize the properties of a polymer compound?

Designing experiments to optimize polymer compound properties often involves a structured approach like Design of Experiments (DOE).

1. Define Objectives: Clearly state the desired properties (e.g., tensile strength, impact resistance, melt flow index) and their target values.

2. Select Variables: Identify the factors that can influence the desired properties (e.g., type and amount of fillers, processing temperature, shear rate).

3. Choose Experimental Design: Select a suitable DOE method (e.g., factorial design, central composite design) based on the number of variables and the desired level of detail.

4. Conduct Experiments: Carry out the experiments according to the chosen design, carefully controlling the variables and recording the results.

5. Analyze Data: Use statistical methods (e.g., ANOVA) to analyze the data and identify the significant factors affecting the properties of interest.

6. Optimize: Based on the analysis, optimize the formulation and processing conditions to achieve the desired properties. This often involves iterative experimentation and refinement.

Example: Suppose we want to optimize the impact resistance of a polypropylene compound by varying the type and amount of rubber toughener. A factorial design could be used to test different combinations of rubber type and concentration, allowing us to determine the optimal combination for maximizing impact resistance.

Effective experimental design ensures efficiency and leads to significant improvements in material properties. This approach reduces the number of experiments needed to achieve the desired outcome.

Q 12. What is the role of statistical analysis in polymer compounding?

Statistical analysis plays a crucial role in polymer compounding, enabling data-driven decision-making and process optimization.

- Process Control: Statistical methods like control charts are used to monitor the consistency of the compounding process and detect deviations from desired specifications. This helps prevent the production of off-spec materials.

- Experiment Design & Analysis: As discussed previously, DOE and ANOVA are essential for analyzing experimental data and identifying significant factors influencing material properties. This allows for targeted improvements in formulation and processing parameters.

- Quality Control: Statistical methods are used to assess the variability and conformance of the final product to specifications. This ensures that the manufactured polymer meets the required quality standards.

- Predictive Modeling: Statistical models can be developed to predict the properties of the polymer compound based on the input variables. This is useful for process optimization and scaling up production.

- Data Analysis: Statistical software is often employed for analyzing large datasets, identifying trends, and generating reports on product quality and process performance.

Statistical analysis provides an objective way to evaluate the effects of various factors, optimize processes, and ensure consistent product quality, ultimately contributing to cost savings and improved product performance. The use of such software and appropriate statistical knowledge is a must in modern polymer compounding facilities.

Q 13. Describe your experience with different types of compounding equipment (e.g., twin-screw extruders, internal mixers).

My experience encompasses a range of compounding equipment, each with its own strengths and limitations.

- Twin-Screw Extruders: I have extensive experience operating and optimizing various twin-screw extruders, from small lab-scale units to large-scale production extruders. Twin-screw extruders excel in high-shear mixing, enabling excellent dispersion of fillers and additives, particularly in demanding applications requiring high quality and uniformity. They are highly versatile and allow precise control of temperature and residence time, reducing degradation risks.

- Internal Mixers (Banbury Mixers): I have worked with internal mixers, particularly for applications requiring high viscosity compounds and/or very high filler loadings. Internal mixers provide intense mixing action and are highly efficient at incorporating high filler loadings, but less control over temperature gradients. They are very energy intensive, producing high heat.

- Single-Screw Extruders: While less versatile for demanding applications, I’m also familiar with single-screw extruders. These are typically used for simpler compounding tasks, requiring less stringent dispersion, or for melt conveying. They are lower in capital cost but are less capable than twin-screw extruders.

My experience includes selecting the appropriate equipment based on the specific application requirements, optimizing process parameters, troubleshooting equipment malfunctions, and ensuring the safe and efficient operation of these machines. This includes preventative maintenance, understanding capabilities and limitations, and making appropriate adjustments to process parameters to obtain the desired properties within acceptable limits.

Q 14. How do you ensure compliance with regulatory requirements for polymer compounds?

Ensuring compliance with regulatory requirements is crucial in polymer compounding. This involves understanding and adhering to various regulations concerning material safety, environmental protection, and product labeling.

- Material Safety Data Sheets (MSDS): We meticulously maintain and utilize MSDS for all raw materials and finished products, ensuring proper handling, storage, and disposal procedures.

- Environmental Regulations: We adhere to all relevant environmental regulations, including waste management practices, air emissions control, and water discharge standards. This often includes working with recycling facilities for material recovery and minimizing waste.

- Product Labeling and Certification: All finished products are labeled accurately according to relevant regulations, including ingredients, safety warnings, and appropriate certifications (e.g., FDA compliance for food contact materials).

- Quality Control and Documentation: Rigorous quality control measures are in place to ensure that all products meet the required specifications and regulatory standards. Detailed documentation of all processes, including raw material traceability, production records, and quality control tests, is maintained to demonstrate compliance.

- Regulatory Updates: We stay current with changes in relevant regulations and adapt our practices accordingly. This includes participating in industry workshops and monitoring governmental agency websites for updates.

Compliance is not just a matter of avoiding penalties; it’s a commitment to producing safe and reliable products that meet the needs of our customers and protect the environment. Proactive compliance strategies, with a focus on prevention, are much more efficient than reacting to violations.

Q 15. Explain the concept of polymer compatibilization.

Polymer compatibilization is the process of improving the miscibility and interfacial adhesion between two or more immiscible polymers. Think of it like trying to mix oil and water – they naturally separate. Compatibilization uses various techniques to make them ‘get along’ better, creating a more homogeneous blend with improved properties.

This is crucial because many polymer blends offer superior properties compared to using a single polymer. For example, combining a strong, stiff polymer with a flexible, impact-resistant one can result in a material that’s both strong and tough. However, without compatibilization, these polymers might separate, leading to poor mechanical strength and other undesirable properties.

Common methods include using:

- Compatibilizers: These are usually block copolymers with segments that are chemically similar to each of the immiscible polymers. They act like ‘bridges’, connecting the two phases and reducing interfacial tension. A common example is the use of styrene-butadiene-styrene (SBS) block copolymers to compatibilize polystyrene (PS) and polybutadiene (PB) blends.

- Reactive Compatibilization: This involves chemically reacting the different polymers to create covalent bonds between them, thus improving interfacial adhesion. This might involve grafting or interpenetrating polymer networks.

- In-situ Polymerization: One polymer is polymerized in the presence of another, leading to better dispersion and adhesion.

The choice of compatibilization method depends on the specific polymers involved, the desired properties of the blend, and cost considerations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of fillers and their impact on polymer properties?

My experience encompasses a wide range of fillers, including:

- Carbon black: Excellent for enhancing electrical conductivity and improving mechanical strength, particularly in rubber compounds. I’ve worked on formulations using high-structure carbon blacks to increase tensile strength in tire applications.

- Calcium carbonate: A cost-effective filler commonly used to reduce the cost and improve stiffness in applications like plastics and coatings. In one project, we optimized the particle size distribution of calcium carbonate to maximize its impact on stiffness without compromising processing.

- Glass fibers: Significantly improve the stiffness, strength, and thermal stability of polymers. I’ve been involved in designing composites using glass fibers for automotive parts, where weight reduction and enhanced strength were key requirements.

- Talc: Improves stiffness, reduces shrinkage, and can lower the cost. I’ve utilized talc in formulations for rigid PVC pipes, improving their dimensional stability.

- Nanofillers (e.g., clays, carbon nanotubes): These offer significant potential to enhance properties at lower loading levels compared to conventional fillers. I’ve explored using nanoclays to enhance the barrier properties of food packaging films.

The impact of fillers on polymer properties depends heavily on the type and amount of filler used, as well as the interaction between the filler and the polymer matrix. Factors to consider include particle size, shape, surface treatment, and filler loading.

Q 17. How do you select the appropriate processing aids for a given polymer compound?

Selecting appropriate processing aids is critical for efficient and effective polymer compounding. The choice depends on several factors, including the type of polymer, the processing equipment used, and the desired final properties. It’s a bit like choosing the right tools for a specific job.

I consider the following when making a selection:

- Polymer type: The melting point, viscosity, and other rheological properties of the polymer dictate the type of processing aid needed. For example, high-viscosity polymers might require more powerful processing aids to improve flow.

- Processing equipment: The type of extruder or mixer used affects the selection of processing aids. Some aids work better with twin-screw extruders, while others are more suited to single-screw extruders.

- Desired properties: The final application of the polymer compound dictates the properties that need to be optimized. For example, a processing aid might be chosen to improve dispersion of fillers, reduce melt viscosity, or enhance surface finish.

Common processing aids include:

- Lubricants: Reduce friction during processing, improving flow and reducing energy consumption.

- Plasticizers: Increase flexibility and reduce the glass transition temperature of the polymer.

- Coupling agents: Improve the adhesion between the polymer and fillers.

- Antioxidants: Prevent polymer degradation during processing.

I often employ a systematic approach, starting with literature reviews and small-scale experiments to screen different processing aids before scaling up to larger batches.

Q 18. Describe your experience with different methods for analyzing polymer morphology.

Analyzing polymer morphology is essential for understanding the relationship between structure and properties. My experience involves a variety of techniques:

- Optical Microscopy: A simple and effective technique for observing the overall morphology of the sample. Useful for identifying large-scale structures but limited in resolution.

- Scanning Electron Microscopy (SEM): Provides high-resolution images of the surface morphology, allowing for the observation of fine details like filler dispersion, particle size distribution, and the presence of voids. I’ve used SEM extensively to evaluate filler dispersion in polymer nanocomposites.

- Transmission Electron Microscopy (TEM): Offers even higher resolution than SEM, allowing the examination of internal structures. Useful for characterizing the morphology of polymer blends and studying the interfacial region between different phases.

- Atomic Force Microscopy (AFM): Provides three-dimensional images of the surface topography, enabling the measurement of surface roughness and the characterization of nano-scale features. I’ve used AFM to investigate the surface properties of polymer films.

- X-ray Diffraction (XRD): Provides information on the crystallinity and crystal structure of the polymer. Helpful in characterizing the degree of crystallinity in semi-crystalline polymers.

The choice of technique depends on the specific morphological features of interest and the required level of resolution. I frequently employ a combination of techniques for a comprehensive analysis.

Q 19. Explain the concept of crosslinking and its effects on polymer properties.

Crosslinking is a process that creates covalent bonds between polymer chains, forming a three-dimensional network. Think of it like weaving a net from individual strands. This significantly alters the polymer’s properties.

Effects on polymer properties include:

- Increased mechanical strength and stiffness: Crosslinking restricts chain movement, making the polymer more resistant to deformation.

- Improved thermal stability: Crosslinked polymers exhibit higher melting points and are less susceptible to thermal degradation.

- Reduced solubility and swelling: The crosslinked network limits the penetration of solvents into the polymer.

- Enhanced chemical resistance: Crosslinking improves the resistance of the polymer to chemicals and solvents.

- Changes in elasticity and flexibility: Depending on the degree of crosslinking, the polymer can become more rigid or even rubbery (vulcanization of rubber is a prime example).

Crosslinking can be achieved through various methods, including:

- Peroxide curing: Uses organic peroxides as initiators to create free radicals that initiate crosslinking.

- Electron beam irradiation: Generates free radicals that initiate crosslinking.

- Sulfur vulcanization (for rubbers): Involves reacting rubber with sulfur to form crosslinks.

The degree of crosslinking is crucial and affects the final properties of the crosslinked polymer. Too little crosslinking might not provide sufficient improvement, while too much can lead to brittleness.

Q 20. How do you interpret rheological data to optimize processing conditions?

Rheological data, which describes the flow and deformation behavior of materials, is essential for optimizing processing conditions. I use rheometers to measure viscosity, elasticity, and other rheological parameters as a function of temperature, shear rate, and time.

Interpreting rheological data allows me to:

- Determine the melt flow index (MFI): This indicates the ease with which the polymer can be processed.

- Optimize processing temperature: Rheological data helps determine the optimal temperature range to achieve the desired viscosity for efficient processing without degradation.

- Select appropriate processing equipment: The rheological properties influence the choice of extruder or mixer.

- Predict processing stability: Rheological data helps anticipate potential problems like melt fracture or die swell.

- Control the final product properties: By adjusting processing parameters based on rheological data, we can control the final properties of the polymer compound, such as tensile strength, impact resistance, and flexibility.

For example, a low viscosity polymer might require a higher processing temperature or a different type of extruder than a high-viscosity polymer. By analyzing the shear thinning behavior of the polymer melt, I can determine the optimal shear rate for efficient processing.

Q 21. What is your experience with designing and conducting scale-up experiments?

Scale-up experiments are critical in translating laboratory-scale findings to industrial production. My experience encompasses a systematic approach involving:

- Careful planning: I start by thoroughly understanding the process at the lab scale, meticulously documenting all parameters, and identifying potential scaling challenges.

- Material characterization: Ensuring consistent material properties across scales is crucial. We conduct rigorous material characterization at both scales to address any variations.

- Geometric similarity: Maintaining geometric similarity between the lab-scale and industrial-scale equipment is important to minimize scale-up issues. This often involves using scale-up factors derived from dimensionless numbers.

- Process parameter optimization: I use design of experiments (DOE) techniques to efficiently explore the parameter space and optimize processing conditions for the industrial scale. This minimizes the number of experiments required while maximizing information gained.

- Process monitoring and control: Implementing effective process monitoring and control systems is critical to maintain consistent product quality throughout the scale-up process. This often involves online sensors and advanced control algorithms.

- Validation: Rigorous testing of the scaled-up product is vital to ensure that it meets the required specifications and quality standards.

I’ve successfully scaled up numerous polymer compounding processes, from small pilot plants to large-scale industrial production lines. A memorable project involved scaling up a novel polymer composite for use in high-performance automotive parts. The scale-up process required careful attention to mixing uniformity, avoiding degradation during processing, and ensuring consistent product quality at the larger scale.

Q 22. Explain the difference between batch and continuous compounding processes.

Batch and continuous compounding are two fundamentally different approaches to mixing and processing polymers. Think of it like baking: batch is like making a single cake in a bowl, while continuous is like having a cake-making machine that constantly produces cakes.

In batch compounding, all ingredients are added to a mixing vessel (like a large blender) at once, mixed for a specified time, and then discharged. This is suitable for smaller production volumes and for custom formulations, allowing for greater flexibility in recipe adjustments. However, it’s less efficient for large-scale production due to the downtime between batches.

Continuous compounding, on the other hand, involves a continuous flow of materials through a series of mixing and processing units. This provides consistent product quality and higher production rates, making it ideal for mass production. However, changing formulations requires significant adjustments to the entire system. A common example is twin-screw extrusion, where the polymer and additives are fed continuously into a heated extruder, mixed, and formed into pellets.

- Batch: Higher flexibility, lower capital investment, lower production rate, higher labor costs.

- Continuous: Higher production rate, consistent quality, higher capital investment, lower labor costs (per unit).

Q 23. How do you manage and interpret data from quality control testing?

Quality control data interpretation in polymer compounding is crucial for maintaining product consistency and meeting customer specifications. It’s not just about numbers; it’s about understanding what those numbers mean in terms of the final product’s performance.

We typically analyze data from various tests, including melt flow index (MFI), tensile strength, elongation at break, color, and particle size distribution. I use statistical process control (SPC) methods to track these parameters over time and identify trends. Control charts help visualize the process variation and highlight any outliers or shifts that might indicate a problem. For instance, a sudden increase in MFI could signal a problem with the molecular weight of the polymer, which will impact the mechanical properties of the final product.

If data falls outside the acceptable range, we investigate the root cause. This may involve checking the raw material quality, reviewing the compounding process parameters (temperature, mixing time, screw speed), or inspecting the equipment for wear and tear. Effective data management involves detailed record-keeping, including batch numbers, ingredient specifications, and processing conditions. This allows for traceability and helps in identifying and resolving quality issues quickly and effectively.

Q 24. What is your experience with different types of polymer degradation mechanisms?

Polymer degradation is a significant concern in compounding, as it directly impacts the final product’s properties. Understanding the various mechanisms is critical for controlling and mitigating this phenomenon.

I’m familiar with several degradation mechanisms, including:

- Thermal degradation: High processing temperatures can break down the polymer chains, leading to changes in molecular weight and properties. This is particularly relevant during extrusion compounding.

- Oxidative degradation: Exposure to oxygen and heat can cause chain scission and crosslinking, affecting the polymer’s color, strength, and flexibility. Antioxidants are added to counteract this.

- Hydrolytic degradation: Moisture can cause chain cleavage in certain polymers, especially those sensitive to water. This is common in materials exposed to high humidity or used in outdoor applications.

- Mechanical degradation: High shear forces during processing can cause chain breakage, particularly in high-viscosity melts. This can be minimized by optimizing processing parameters.

- Photodegradation: Ultraviolet (UV) radiation can cause chain scission and discoloration. UV stabilizers are used in applications where exposure to sunlight is expected.

For example, I once worked on a project where polyethylene pipes were exhibiting premature cracking. After thorough investigation, it was identified that oxidative degradation during the compounding process was the root cause, due to insufficient antioxidant addition. We adjusted the formulation by increasing the antioxidant concentration which resolved the problem.

Q 25. How do you troubleshoot problems related to color matching and pigment dispersion?

Color matching and pigment dispersion are critical for the aesthetics and performance of many polymer products. Troubleshooting problems in these areas often requires a systematic approach.

Color matching involves achieving a precise color by carefully selecting and blending pigments. Discrepancies can arise from variations in pigment batches, differences in equipment, or errors in weighing. I use spectrophotometers to measure color and compare it against target values. Adjustments in pigment concentration and selection are made iteratively until the desired color is reached.

Pigment dispersion refers to the even distribution of pigments within the polymer matrix. Poor dispersion can lead to uneven color, reduced gloss, and reduced mechanical properties. Troubleshooting poor dispersion involves checking several factors:

- Pigment properties: Particle size, surface treatment, and type influence dispersibility.

- Mixing equipment: Adequate mixing is crucial. I would inspect the equipment for proper operation and consider alternatives if necessary.

- Processing conditions: Temperature, shear rate, and mixing time affect dispersion.

- Additives: Dispersion aids can improve the distribution of pigments.

For instance, I once encountered a problem with uneven color distribution in a polypropylene product. By optimizing the mixing temperature and adding a dispersing agent, we achieved uniform pigment dispersion and solved the issue.

Q 26. What is your familiarity with different types of polymer recycling methods?

Polymer recycling is a growing area of importance in the industry, both from an environmental and economic perspective. My familiarity extends to several methods.

Common methods include:

- Mechanical recycling: This involves physically processing scrap polymer to recover and reuse it. Processes include washing, shredding, and melting before reforming into pellets.

- Chemical recycling: This involves breaking down the polymer into its monomeric constituents through chemical processes like pyrolysis or depolymerization. This allows for higher-quality material recovery compared to mechanical recycling but can be more energy-intensive.

- Energy recovery: This involves using scrap polymer as a fuel source for energy generation. While this isn’t material recycling, it prevents landfill disposal and can provide energy.

The choice of recycling method depends on the type of polymer, its contamination level, and the desired quality of the recycled material. Each method has its advantages and limitations in terms of cost, energy consumption, and the quality of the recycled product. For instance, PET (polyethylene terephthalate) is often mechanically recycled for fiber production, while PVC (polyvinyl chloride) may require chemical recycling due to its chlorine content.

Q 27. Describe your experience with developing and implementing new compounding processes.

Developing and implementing new compounding processes requires a systematic approach that blends scientific understanding with practical experience. I’ve been involved in several projects, including the development of a novel flame-retardant compound for electrical applications and a high-strength, lightweight compound for automotive parts.

The process typically involves:

- Defining requirements: Determining the desired properties of the final product, such as mechanical strength, thermal stability, and chemical resistance.

- Material selection: Choosing the base polymer and additives based on performance requirements, cost, and regulatory compliance.

- Process optimization: Experimentation to determine the optimal processing parameters, such as temperature, shear rate, and mixing time.

- Scale-up: Transitioning the process from a lab scale to a production scale. This involves careful attention to equipment selection and process control.

- Testing and validation: Thorough testing of the final product to verify that it meets the specified requirements.

For example, in developing the flame-retardant compound, we faced challenges with maintaining the mechanical properties while achieving the required fire-retardant rating. By using a combination of different flame retardants and optimizing the compounding parameters, we successfully developed a material that met all the required specifications.

Q 28. How do you stay current with advancements in polymer compounding technology?

Staying current with advancements in polymer compounding technology is essential for maintaining professional competence and competitiveness. I employ several strategies to accomplish this.

These include:

- Reading trade publications and journals: I regularly follow industry publications such as Polymer Engineering & Science and Plastics Engineering to stay abreast of the latest research and developments.

- Attending conferences and workshops: Participating in industry events allows for networking and learning about new technologies from leading experts.

- Online courses and webinars: Many online platforms offer courses and webinars on various aspects of polymer science and engineering.

- Collaboration and networking: Engaging with colleagues and peers through professional organizations and online forums facilitates the exchange of information and best practices.

- Vendor engagement: Directly interacting with material and equipment suppliers keeps me updated on their latest offerings and technological improvements.

This continuous learning ensures I can apply the most effective and efficient techniques in my work and contribute to the advancement of polymer compounding.

Key Topics to Learn for Your Polymer Compounding Interview

Landing your dream Polymer Compounding role requires a strong understanding of both the theoretical foundations and practical applications. This section outlines key areas to focus your preparation.

- Polymer Chemistry Fundamentals: Master the concepts of polymerization mechanisms (addition, condensation), molecular weight distribution, and the relationship between polymer structure and properties. Consider exploring different types of polymers (thermoplastics, thermosets, elastomers) and their respective characteristics.

- Compounding Techniques and Equipment: Familiarize yourself with various mixing techniques (internal, external), the role of different types of mixing equipment (e.g., Banbury mixers, twin-screw extruders), and the impact of processing parameters on final product quality.

- Rheology and Material Characterization: Understand how rheological properties (viscosity, elasticity) influence processing and final product performance. Learn about common characterization techniques used to assess polymer properties (e.g., tensile testing, DSC, DMA).

- Additive Selection and Functionality: Gain a solid understanding of the role of various additives (fillers, plasticizers, stabilizers, colorants) in modifying polymer properties. Be prepared to discuss how the selection of additives impacts the final product’s performance and cost-effectiveness.

- Quality Control and Process Optimization: Explore methods for ensuring consistent product quality throughout the compounding process. This includes understanding statistical process control (SPC) techniques and troubleshooting common processing challenges.

- Problem-Solving and Troubleshooting: Practice analyzing and resolving common issues encountered during polymer compounding, such as poor mixing, degradation, or inconsistent product properties. Develop your ability to approach problems systematically and utilize data-driven solutions.

Next Steps: Position Yourself for Success

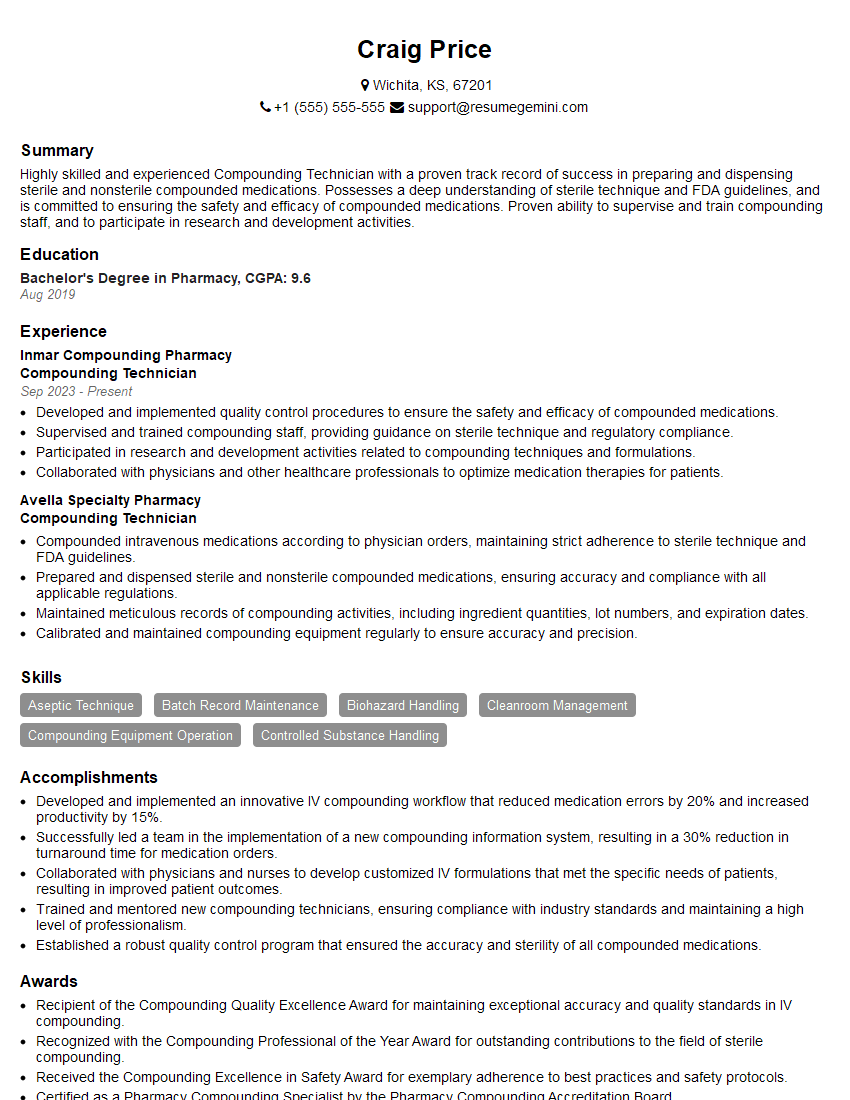

Mastering Polymer Compounding opens doors to exciting career opportunities in a dynamic industry. To maximize your chances of landing your ideal role, it’s crucial to present your skills and experience effectively. Creating a strong, ATS-friendly resume is the first step. This ensures your application gets noticed by recruiters and hiring managers.

We recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to help you craft a resume that highlights your qualifications and experience in Polymer Compounding. Examples of resumes tailored to this field are available to guide you. Take the next step towards your dream career – build your best resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

This was kind of a unique content I found around the specialized skills. Very helpful questions and good detailed answers.

Very Helpful blog, thank you Interviewgemini team.